Base plate structure, adhering method and peeling method of flexible base plate thereof

A flexible substrate and substrate technology, which is applied in chemical instruments and methods, nonlinear optics, and other household appliances, etc., can solve the problems that the flexible substrate is not easy to remove or has glue residue, the flexible substrate is difficult to fix, and the cost is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation manners of the substrate structure provided in the embodiments of the present invention and the method for attaching and peeling off the flexible substrate thereof will be described in detail below with reference to the accompanying drawings.

[0049] Wherein, the thickness and shape of each film layer in the drawings do not reflect the real scale of the substrate structure, and the purpose is only to illustrate the content of the present invention.

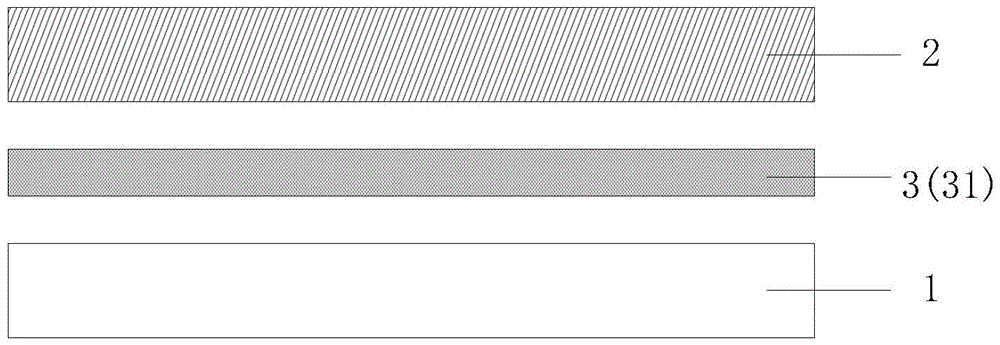

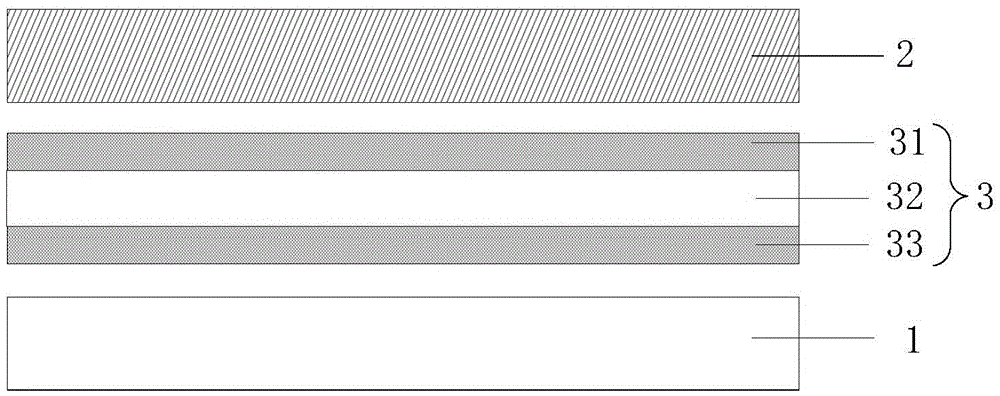

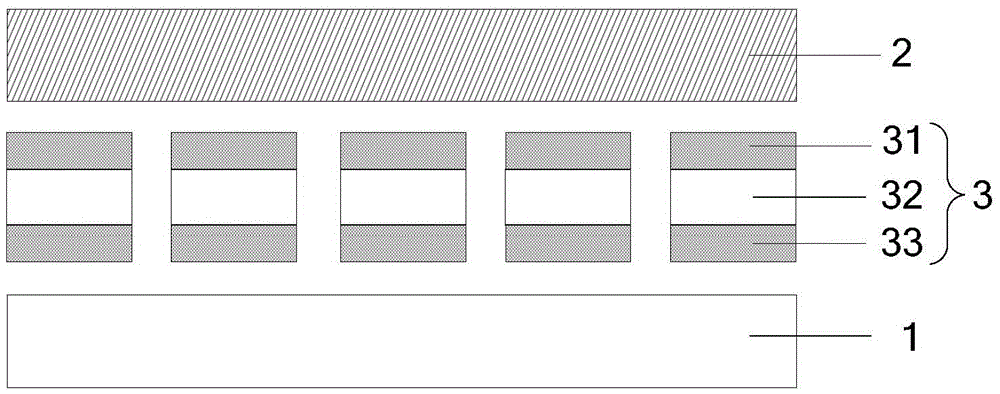

[0050] Embodiments of the present invention provide a substrate structure, such as Figure 1 to Figure 3 As shown, it includes: a carrier substrate 1, a flexible substrate 2 arranged on the carrier substrate 1, wherein the carrier substrate can be a rigid glass substrate, and also includes:

[0051] one or more side-by-side adhesive layers 3 sandwiched between the carrier substrate 1 and the flexible substrate 2;

[0052] The adhesive layer 3 includes a magnetic adhesive layer 31 whose adhesive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com