Preparation method and application of MXene nano-sheet with Mo vacancy

A nanosheet, vacancy technology, applied in nanotechnology, chemical instruments and methods, tungsten/molybdenum carbides, etc., can solve the problems of complex steps, less than ideal electrocatalytic activity of MXene, and low yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

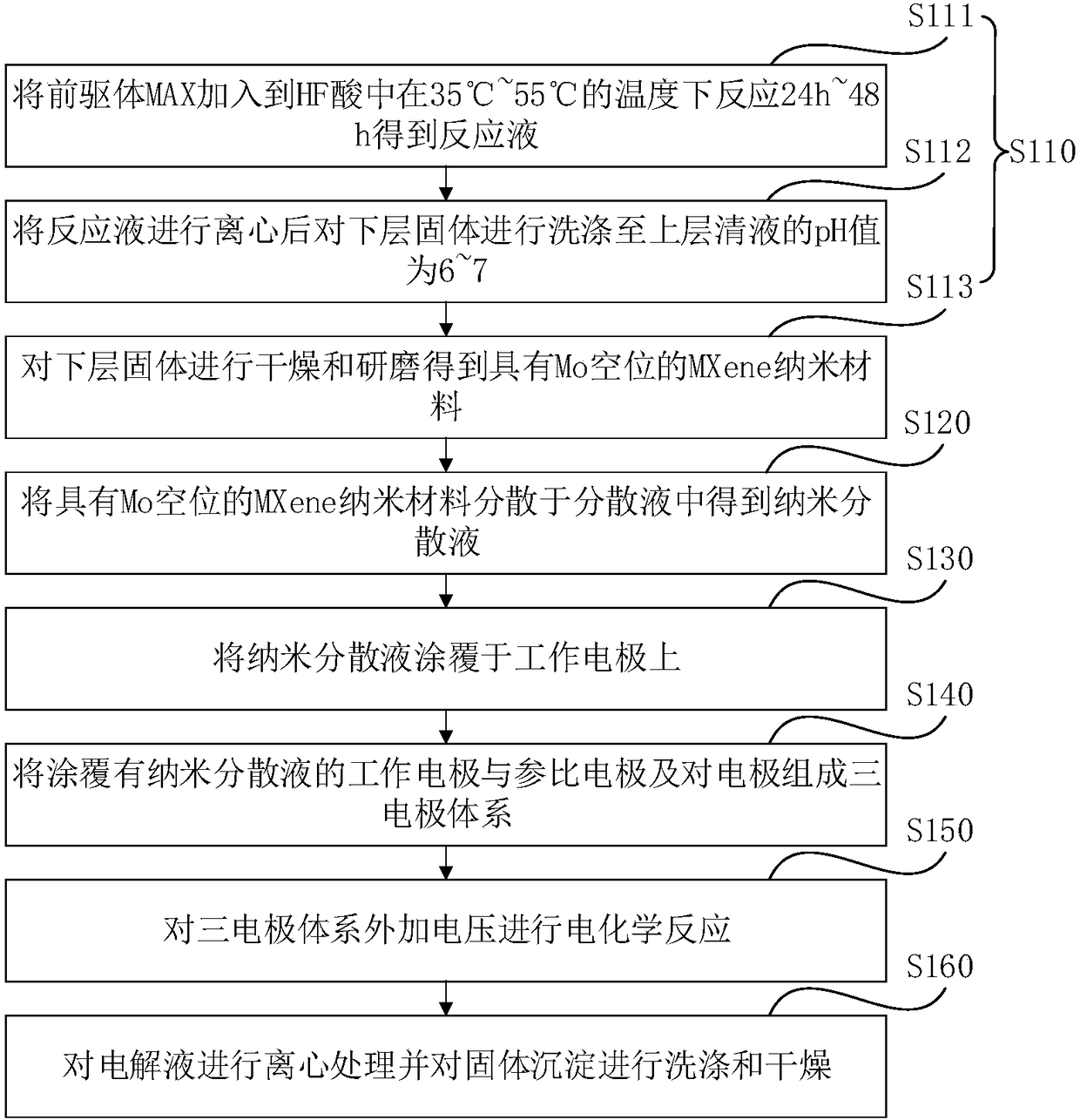

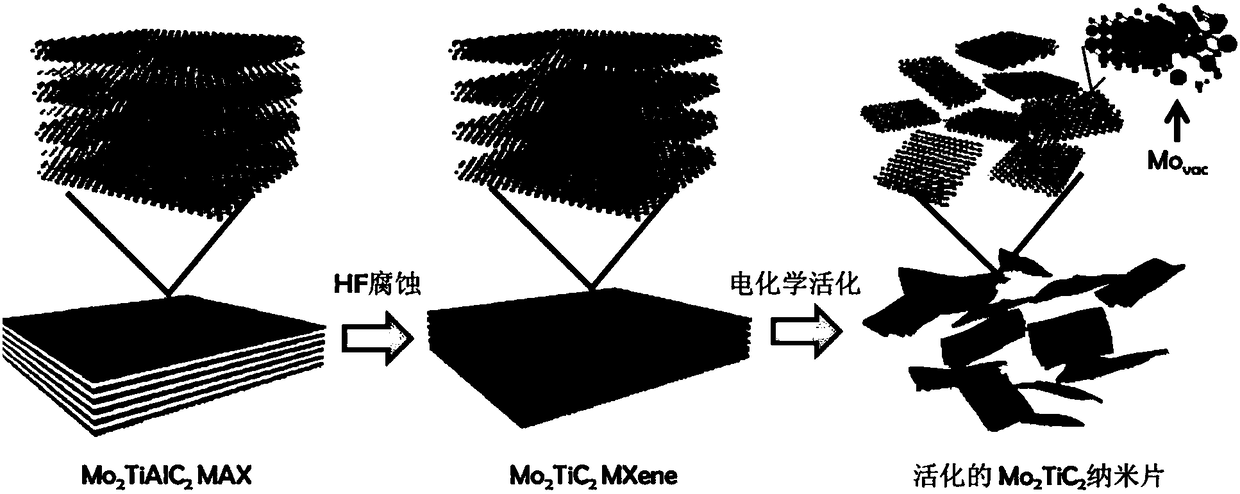

[0030] see figure 1 , the preparation method of the MXene nanosheet with Mo vacancy of one embodiment comprises the following steps:

[0031] S110, preparing a Mo-containing MXene nanomaterial.

[0032] The preparation of MXene nanomaterials generally uses precursor MAX and hydrofluoric acid (HF) as raw materials, and the structural formula of the precursor MAX is generally M n+1 AX n , where M, A and X represent transition metals, main elements of group IIIA or IVA, carbon or nitrogen, respectively. The exposed faces of the upper and lower layers in the MAX structure are typically transition metals. The process of preparing MXene from MAX generally requires relatively harsh synthesis conditions, and the commonly used method is to use HF to its precursor M n+1 AX n MAX is processed, and the Al element in the MAX structure is etched away to obtain the corresponding MXene. During the corrosion process, the transition metal surface of MXene will be replaced by -O, -OH or -...

Embodiment 1

[0067] (1) 0.5g Mo 2 TiAlC 2 It was added to 10 mL of HF acid solution with a mass concentration of 50%, heated to 35°C and reacted for 48 hours to obtain a reaction solution. After centrifuging the reaction solution, the lower layer solid was washed until the pH value of the supernatant was 6. Freeze drying to obtain Mo 2 TiC 2 nanomaterials.

[0068] (2) Take 4 mg of Mo 2 TiC 2 The nanomaterial is dispersed in 1 mL of dispersion liquid to obtain a nanodispersion liquid, wherein the dispersion liquid is a mixed liquid of water and isopropanol with a volume ratio of 1:1.

[0069] (3) Coating the nano-dispersion on the glassy carbon electrode, the coating amount of the nano-dispersion on the glassy carbon electrode is 0.04mg / cm 2 .

[0070] (4) above-mentioned glassy carbon electrode, mercurous sulfate electrode and carbon rod electrode are constituted three-electrode system, and the electrolyte of three-electrode system is that the molar concentration is the H of 0.5M ...

Embodiment 2

[0074] (1) 0.5g Mo 2 TiAlC 2 It was added to 30 mL of HF acid solution with a mass concentration of 35%, heated to 55° C. and reacted for 24 h to obtain a reaction solution. After centrifuging the reaction solution, the lower layer solid was washed until the pH value of the supernatant was 7. drying and grinding to obtain Mo 2 TiC 2 nanomaterials.

[0075](2) Take 10 mg of Mo 2 TiC 2 The nanomaterials were dispersed in 10 mL of dispersion liquid to obtain a nanodispersion liquid, wherein the dispersion liquid was a mixed liquid of water and ethanol with a volume ratio of 1:4.

[0076] (3) The nano-dispersion liquid is coated on the glassy carbon electrode, and the coating amount of the nano-dispersion liquid on the glassy carbon electrode is 0.08 mg / cm 2 .

[0077] (4) above-mentioned glassy carbon electrode, mercurous sulfate electrode and carbon rod electrode are constituted three-electrode system, and the electrolyte of three-electrode system is that the molar concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com