Method for preparing graphene by pulling jelly

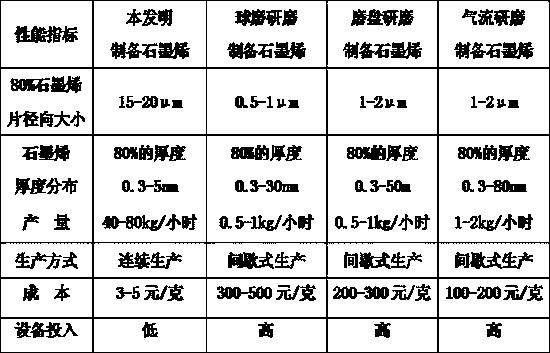

A technology of graphene and jelly, which is applied in the field of drawing and preparing graphene from jelly, which can solve the problems of graphene lattice damage, environmental hazards, etc., and achieve uniform layer distribution, no environmental pollution, and fewer layers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Utilize the method for preparing graphene by jelly drawing:

[0039] (1) Knead flake graphite with a radial size greater than 50 microns and adhesive glucose at a mass ratio of 1:50 in a kneader for 15 minutes, and add an appropriate amount of glycerin to prepare a gel with a viscosity of 3000 cp;

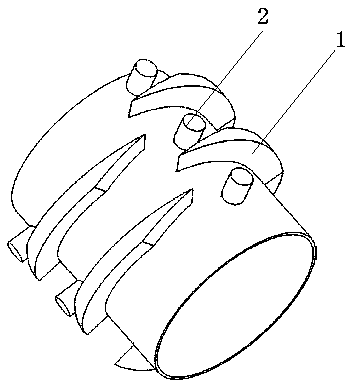

[0040] (2) Send the colloid obtained in step (1) into a reciprocating single-screw extruder with an aspect ratio of 48 / 1 and a screw diameter of 20mm through forced extrusion, set the screw speed to 100rpm, and the screw jacket to circulate and cool Water controls the screw temperature below 80°C. The reciprocating single-screw extruder reciprocates axially while rotating and shearing. The graphite dispersed in the adhesive is sheared by the continuously rotating screw and pulled back and forth in the axial direction. So that the graphite is continuously pulled and peeled off in the adhesive;

[0041](3) Submerge the drawn material obtained in step (2) in distilled water fo...

Embodiment 2

[0043] The method for preparing graphene by jelly drawing:

[0044] (1) Knead expanded graphite with a radial dimension greater than 50 microns and the adhesive arabinose at a mass ratio of 1:80 in a kneader for 20 minutes, and add an appropriate amount of glycerin to prepare a gel with a viscosity of 4500 cp;

[0045] (2) Send the jelly obtained in step (1) into a reciprocating single-screw extruder through forced extrusion, set the screw speed at 150rpm, and control the temperature of the screw with circulating cooling water in the jacket of the screw barrel to be lower than 80°C. The single-screw extruder reciprocates axially while rotating and shearing. The graphite dispersed in the adhesive is sheared by the continuously rotating screw and pulled back and forth in the axial direction, so that the graphite is continuously drawn in the adhesive. peel off;

[0046] (3) Submerge the drawn material obtained in step (2) in distilled water for more than 24 hours, wash with dist...

Embodiment 3

[0048] Utilize the method for preparing graphene by jelly drawing:

[0049] (1) Knead pyrolytic graphite powder with a radial size greater than 50 microns and adhesive mannose at a mass ratio of 1:100 in a kneader for 35 minutes, and add an appropriate amount of glycerin to prepare a gel with a viscosity of 5000 cp;

[0050] (2) Send the colloid obtained in step (1) into a reciprocating single-screw extruder with an aspect ratio of 25 / 1 and a screw diameter of 45mm through forced extrusion, set the screw speed at 120rpm, and the screw jacket for cooling Water controls the screw temperature below 80°C. The reciprocating single-screw extruder reciprocates axially while rotating and shearing. The graphite dispersed in the adhesive is sheared by the continuously rotating screw and pulled back and forth in the axial direction. So that the graphite is continuously pulled and peeled off in the adhesive;

[0051] (3) Submerge the drawn material obtained in step (2) in distilled water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com