Method for preparing aramid nanofibers

A nanofiber, para-aramid fiber technology, applied in fiber raw material processing, textiles and papermaking, etc., can solve the problems of long reaction period, low reaction concentration, shortened reaction period, etc., to achieve easy operation, excellent rigidity, increased The effect of proton exchange rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

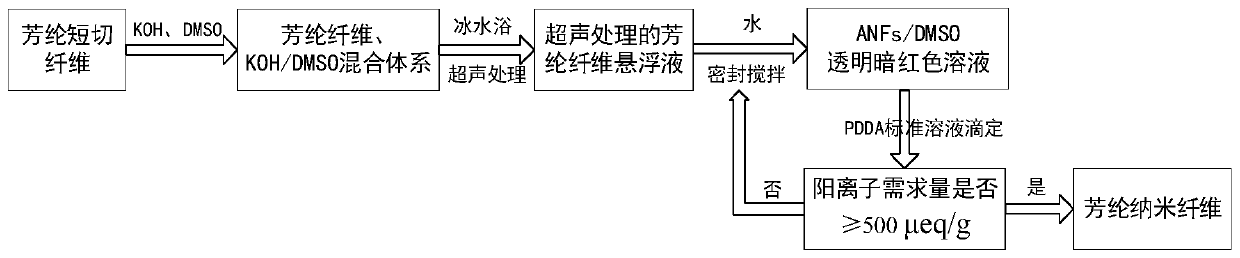

Method used

Image

Examples

Embodiment 1

[0033] (1) Add 1g of para-aramid fiber with an average length of 4mm and 1.5g KOH into 500ml DMSO solution, and place in a 1000ml beaker;

[0034] (2) Place the beaker containing the para-aramid fiber, KOH and DMSO mixed system obtained in step (1) in a water bath, and perform ultrasonic treatment with an ultrasonic cell crusher to obtain ultrasonic-treated para-aramid fiber Suspension A; The processing conditions are: ultrasonic power is 300W, ultrasonic treatment time is 150min, ultrasonic working time: 4s, ultrasonic gap: 2s; further, ice cubes are continuously added to ensure that the temperature of the water bath is maintained below 40°C.

[0035] (3) Add water to the ultrasonically treated para-aramid fiber suspension A obtained in step (2), and the ratio of the volume of the added water to the absolute dry mass of the para-aramid fiber is 2.5:1 ml / g, to obtain Para-aramid fiber suspension B.

[0036] (4) The para-aramid fiber suspension B obtained in step (3) is sealed and pl...

Embodiment 2

[0039] (1) Add 1g of para-aramid fiber with an average length of 5mm and 1.5g of KOH to 500ml of DMSO solution and place it in a 1000ml beaker;

[0040] (2) Place the beaker containing the para-aramid fiber, KOH and DMSO mixed system obtained in step (1) in a water bath, and perform ultrasonic treatment with an ultrasonic cell crusher to obtain ultrasonic-treated para-aramid fiber Suspension A; the treatment conditions are: ultrasonic power is 400W, ultrasonic treatment time is 120min, ultrasonic working time: 4s, ultrasonic gap: 2s; further, ice cubes are added continuously to ensure that the temperature of the water bath is maintained below 40°C.

[0041] (3) Add water to the ultrasonically treated para-aramid fiber suspension A obtained in step (2), and the ratio of the volume of the added water to the absolute dry mass of the para-aramid fiber is 5:1 ml / g, to obtain Para-aramid fiber suspension B.

[0042] (4) The para-aramid fiber suspension B obtained in step (3) was sealed an...

Embodiment 3

[0045] (1) Add 1g of para-aramid fiber with an average length of 6mm and 1.5g of KOH into 500ml DMSO solution and place it in a 1000ml beaker;

[0046] (2) Place the beaker containing the para-aramid fiber, KOH and DMSO mixed system obtained in step (1) in a water bath, and perform ultrasonic treatment with an ultrasonic cell crusher to obtain ultrasonic-treated para-aramid fiber Suspension A; the treatment conditions are: ultrasonic power is 500W, ultrasonic treatment time is 90min, ultrasonic working time: 4s, ultrasonic gap: 2s; further, ice cubes are continuously added to ensure that the temperature of the water bath is maintained below 40°C.

[0047] (3) Add water to the ultrasonically treated para-aramid fiber suspension A obtained in step (2), and the ratio of the volume of the added water to the absolute dry mass of the para-aramid fiber is 8:1 ml / g, to obtain Para-aramid fiber suspension B.

[0048] (4) The para-aramid fiber suspension B obtained in step (3) is sealed and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com