Method for preparing graphene by solution phase

A graphene and solution phase technology, applied in the field of solution phase preparation of graphene, can solve the problems of difficult large-scale preparation, harsh process conditions, complex process, etc., and achieve easy industrial production, low energy consumption of the preparation process, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 100mg of graphite powder to 150mL of freshly dried tetrahydrofuran solution, ultrasonically disperse for 3min under nitrogen protection, then add 0.36g of metal lithium and 4.9g of naphthalene to the dispersion, and keep stirring for 35min. 12.5 g of 1-bromododecane was gradually added to the above mixture, and the reaction was continued for 12 h under nitrogen protection.

[0028] Add ethanol to the above reaction product to remove unreacted metal lithium. The resulting solid product was washed successively with ethanol, toluene, water and ethanol, and dried under vacuum at 60°C to obtain graphene powder.

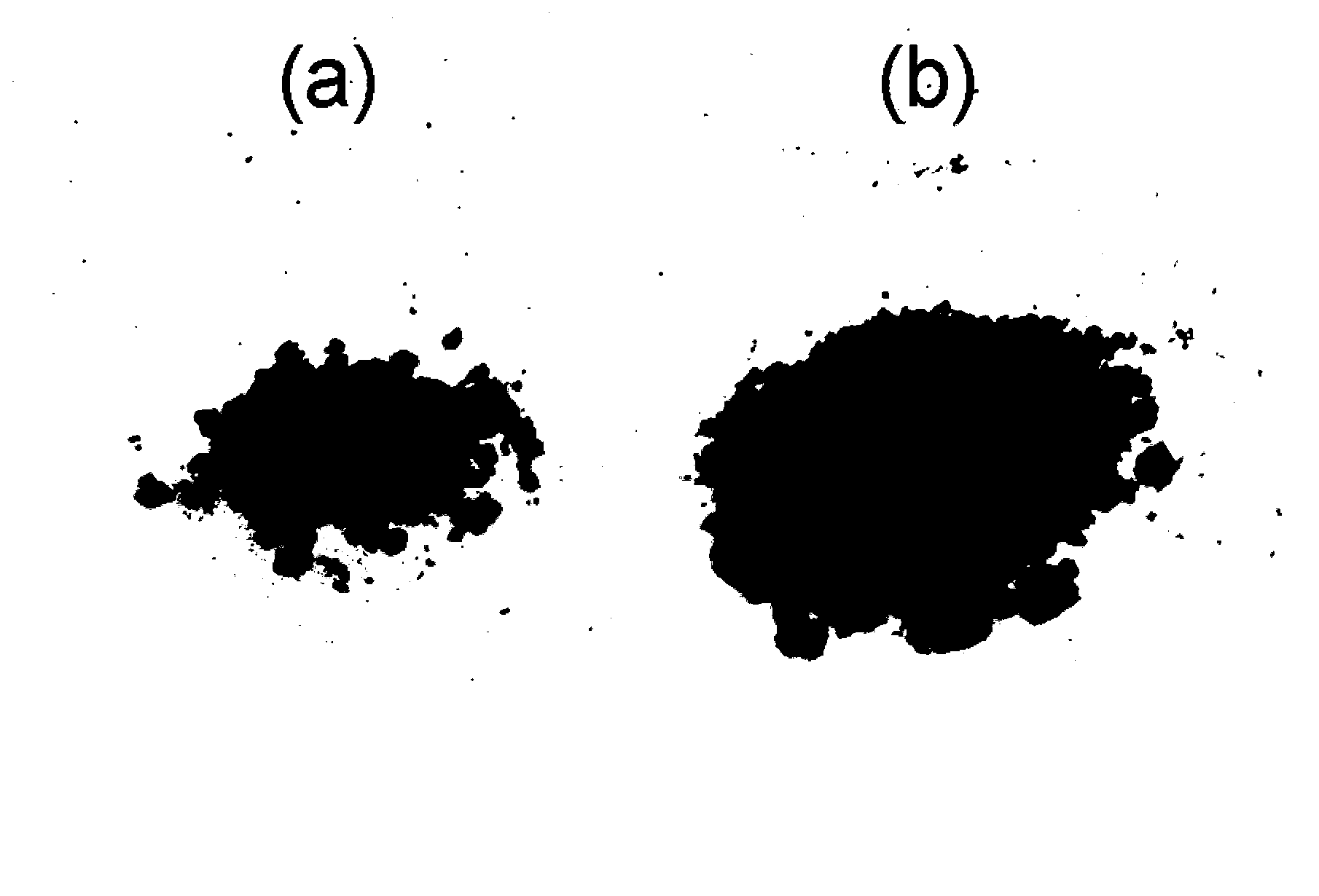

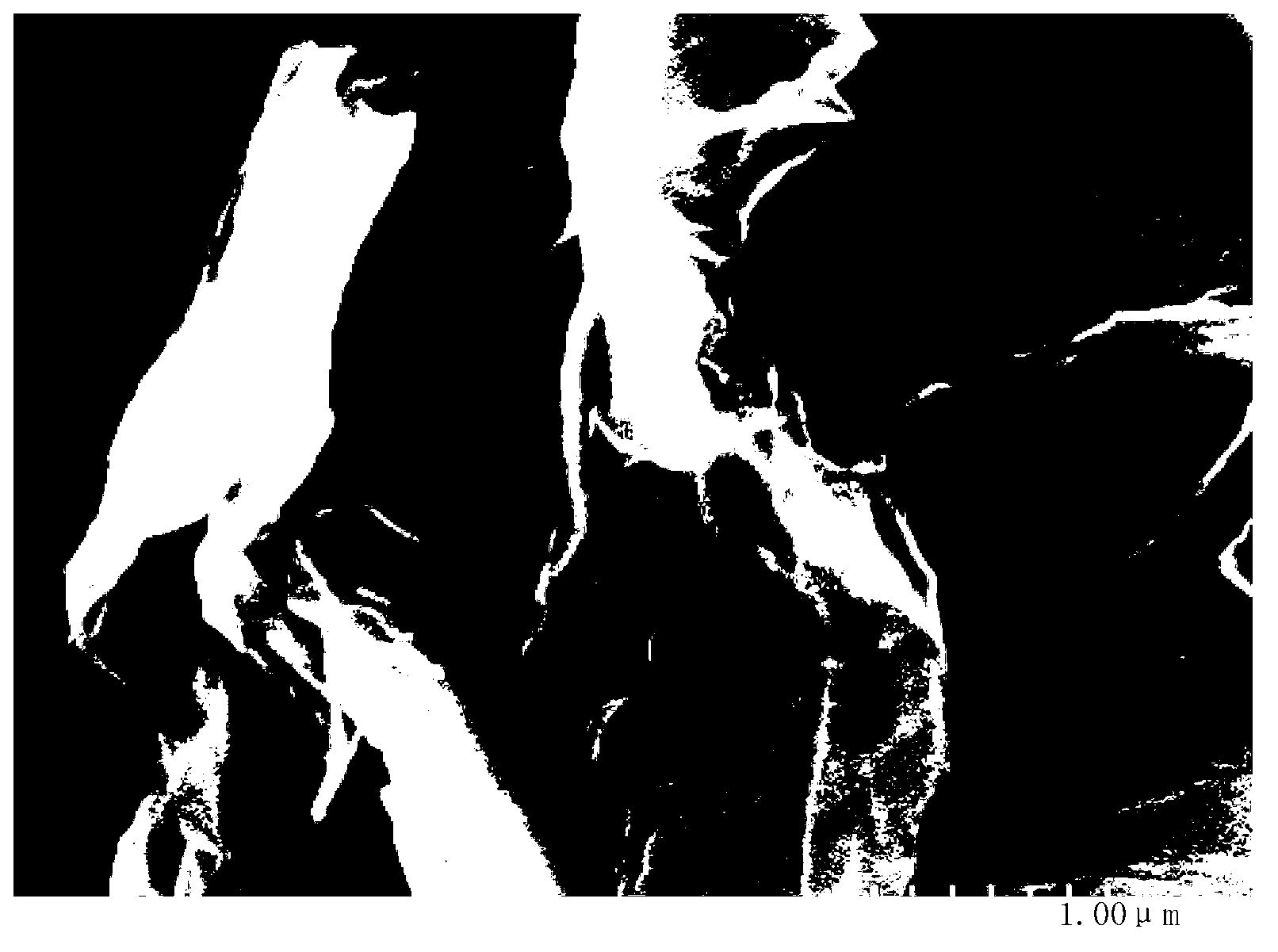

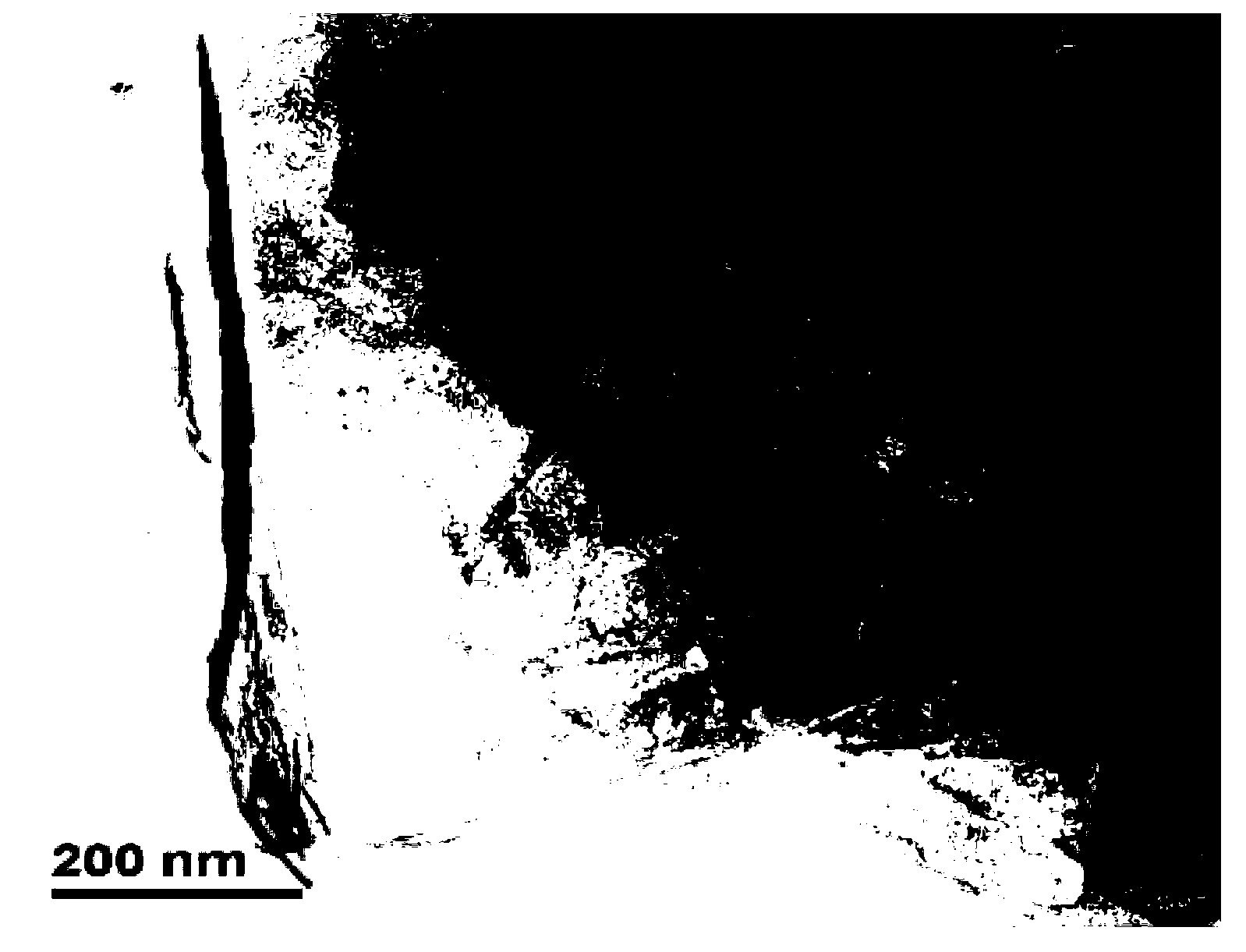

[0029] figure 1 B is the macroscopic morphology figure of the graphene powder obtained in the present invention, and figure 1 Compared with the commercially available graphite powder of a, it is obviously fluffy. Graphene gained in the present invention is observed with a scanning electron microscope and a transmission electron microscope, and the obtained re...

Embodiment 2

[0031] Add 100mg of graphite powder to the freshly dried tetrahydrofuran solution, ultrasonically disperse for 3min under nitrogen protection, then add 0.36g of metal lithium and 4.9g of naphthalene to the mixture, and keep stirring for 35min. Gradually added 9.7g of 6-bromohexanoic acid to the above mixture, and reacted for 12h under nitrogen protection.

[0032] Add ethanol to the above reaction product to remove unreacted metal lithium. The resulting solid product was washed successively with ethanol, toluene, water and ethanol, and dried under vacuum at 60°C to obtain graphene powder. The obtained graphene powder can be dispersed in ethanol or aqueous solution by ultrasonic treatment.

Embodiment 3

[0034]Add 100mg of graphite powder to the freshly dried tetrahydrofuran solution, ultrasonically disperse for 3min under nitrogen protection, then add 0.36g of metal lithium and 4.9g of naphthalene to the mixed solution, and keep stirring for 35min. 11.6 g of methyl 6-bromohexanoate was gradually added to the above mixture, and reacted for 12 h under nitrogen protection.

[0035] Add ethanol to the above reaction product to remove unreacted lithium metal. The resulting solid product was washed successively with ethanol, toluene, water, and ethanol, and dried under vacuum at 60°C to obtain graphene powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com