Preparation method of porous graphene active carbon material as well as product and application thereof

A technology of graphene and activated carbon, which is applied in the field of materials, can solve problems such as the difficulty of electrolyte entering the pores, the difficulty of destroying the interlayer force of carbon materials, and the easy hardening of carbon materials, so as to improve hydrophilicity and enhance energy storage Performance, the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

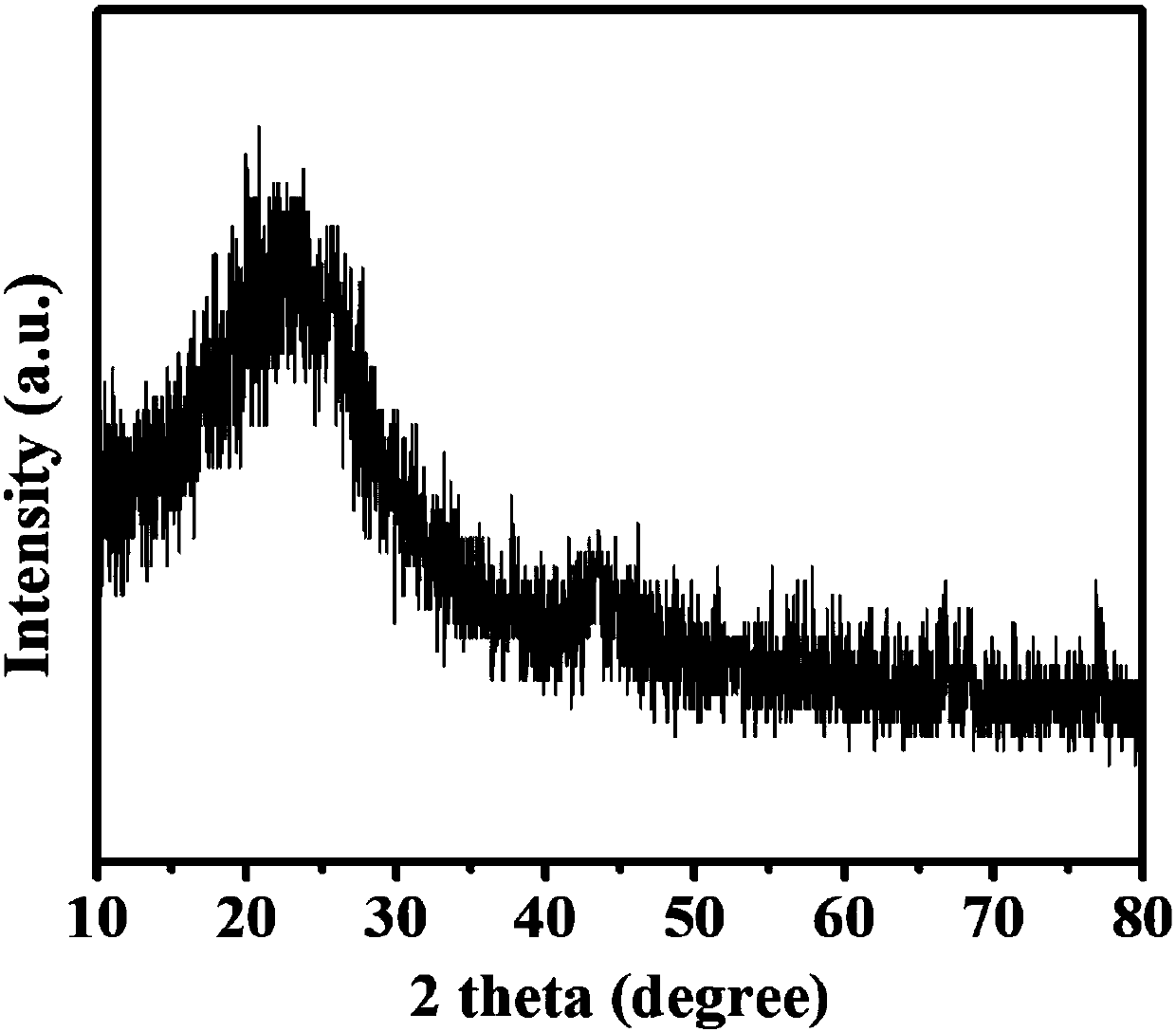

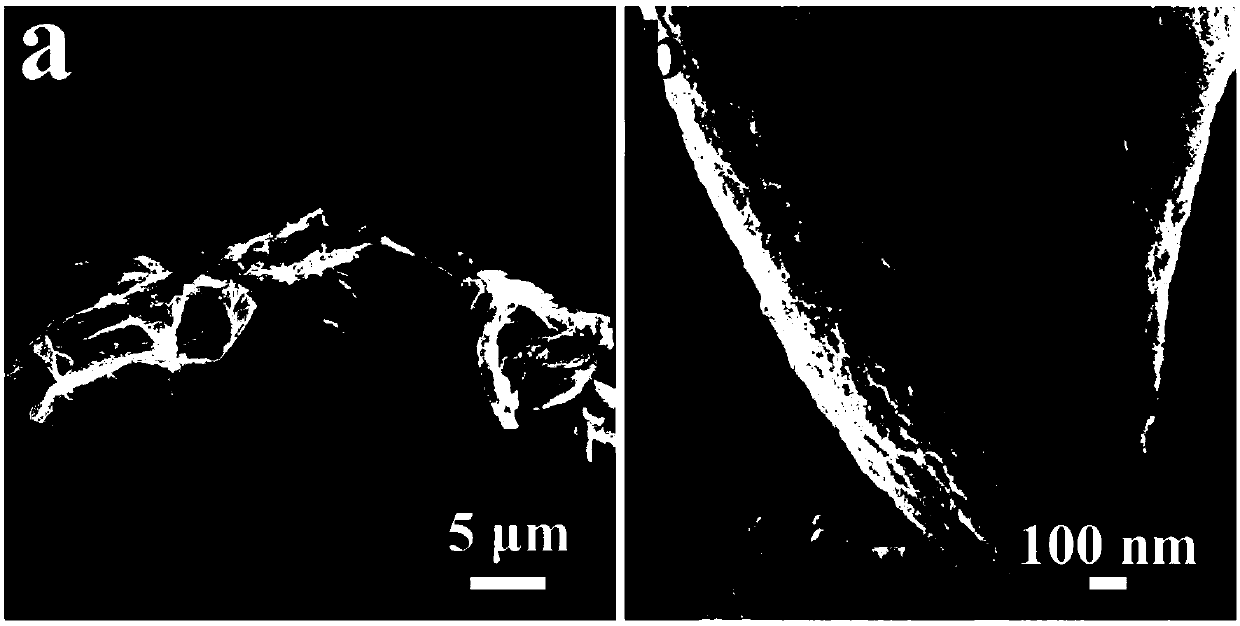

[0037] Preparation of porous graphene-like activated carbon materials

[0038] (1) Hydrogen peroxide and acetic acid are added to deionized water together with the lotus powder, wherein the consumption of hydrogen peroxide is 3.5wt% of the lotus powder, the consumption of acetic acid is 15wt% of the lotus powder, ultrasonically obtains the suspension, and the After the suspension was transferred to the high-temperature reaction kettle, it was reacted at 120°C for 2 hours in a blast drying oven. After the reaction kettle was naturally cooled, the reaction product in the reaction kettle was taken out, and the reaction product was washed with secondary water and absolute ethanol in turn. Dry in a vacuum oven to obtain an intermediate product.

[0039] (2) The intermediate product obtained in step (1) was reacted at 700° C. for 3 hours at a heating rate of 2° C. / min under the protection of argon to prepare a porous graphene-like activated carbon material.

Embodiment 2

[0041] Preparation of porous graphene-like activated carbon materials

[0042] (1) Sodium perchlorate and hypochlorous acid are added to deionized water together with the straw powder, wherein the consumption of sodium perchlorate is 6wt% of the lotus powder, and the consumption of hypochlorous acid is 10wt% of the straw, and the suspension is obtained by ultrasonic , transfer the suspension to a high-temperature reaction kettle and react in a blast drying oven at 100°C for 6 hours. After the reaction kettle is naturally cooled, take out the reaction product in the reaction kettle, and wash the reaction product with secondary water and absolute ethanol in sequence. The reaction product was then dried in a vacuum oven to obtain an intermediate product.

[0043](2) The intermediate product obtained in step (1) was reacted at 800° C. for 5 h at a heating rate of 0.5° C. / min under nitrogen protection to prepare a porous graphene-like activated carbon material.

Embodiment 3

[0045] Preparation of porous graphene-like activated carbon materials

[0046] (1) Chlorine water and carbonic acid are added to deionized water together with peanut shells, wherein the consumption of chlorine water is 1.5wt% of peanut shells, the consumption of carbonic acid is 30wt% of peanut shells, ultrasonically obtains a suspension, and the suspension is After transferring to the high-temperature reaction kettle, react in a blast drying oven at 90°C for 0.5h. After the reaction kettle is naturally cooled, take out the reaction product in the reaction kettle, wash the reaction product with secondary water and absolute ethanol in turn, and place it in a vacuum Dry in a drying oven to obtain an intermediate product.

[0047] (2) The intermediate product obtained in step (1) was reacted at 1000° C. for 2 hours at a heating rate of 5° C. / min under the protection of argon to prepare a porous graphene-like activated carbon material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com