Method for preparing large-sized graphene by highly-efficiently exfoliating graphite powder

A technology for exfoliating graphite and graphene, applied in the field of graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Prepare polyoxyethylene-b-polyoxypropylene-b-polyoxyethylene and deionized water into a 200 mg / mL intercalant solution;

[0037]2) Homogeneously disperse 4000 meshes of pyrolytic graphite in the intercalation agent solution obtained in step 1), mechanically stir for 1.5h, and the stirring speed is 1000r / min, to obtain a graphite powder suspension with a mass concentration of 15%;

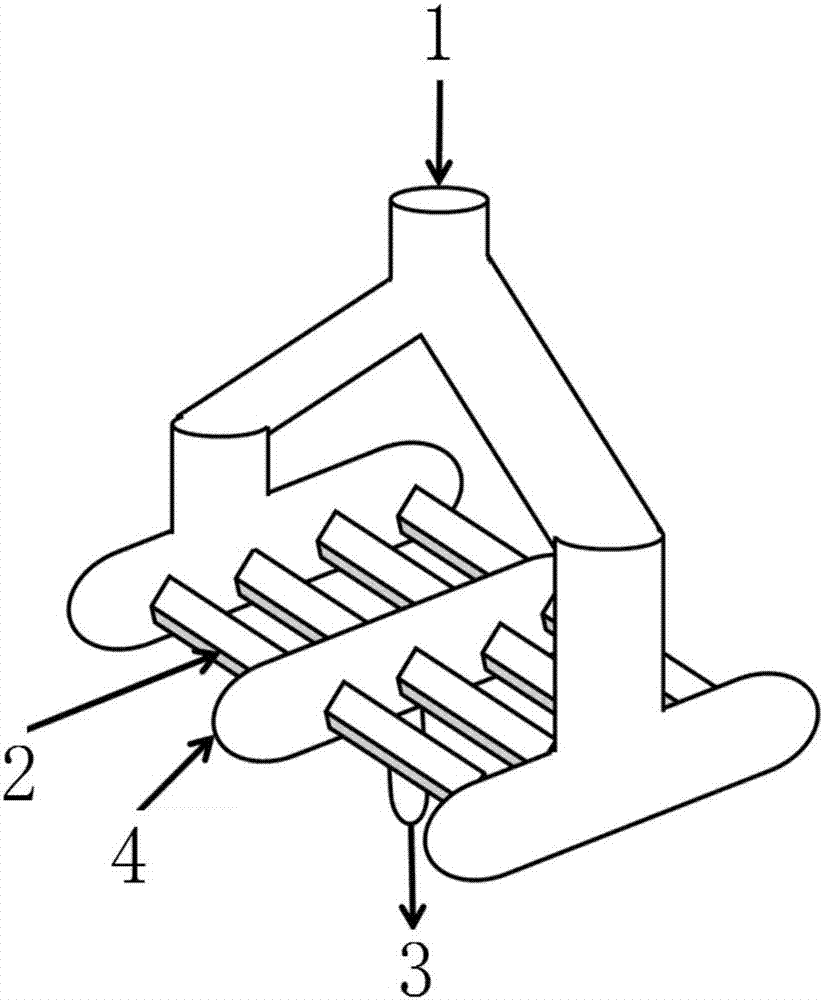

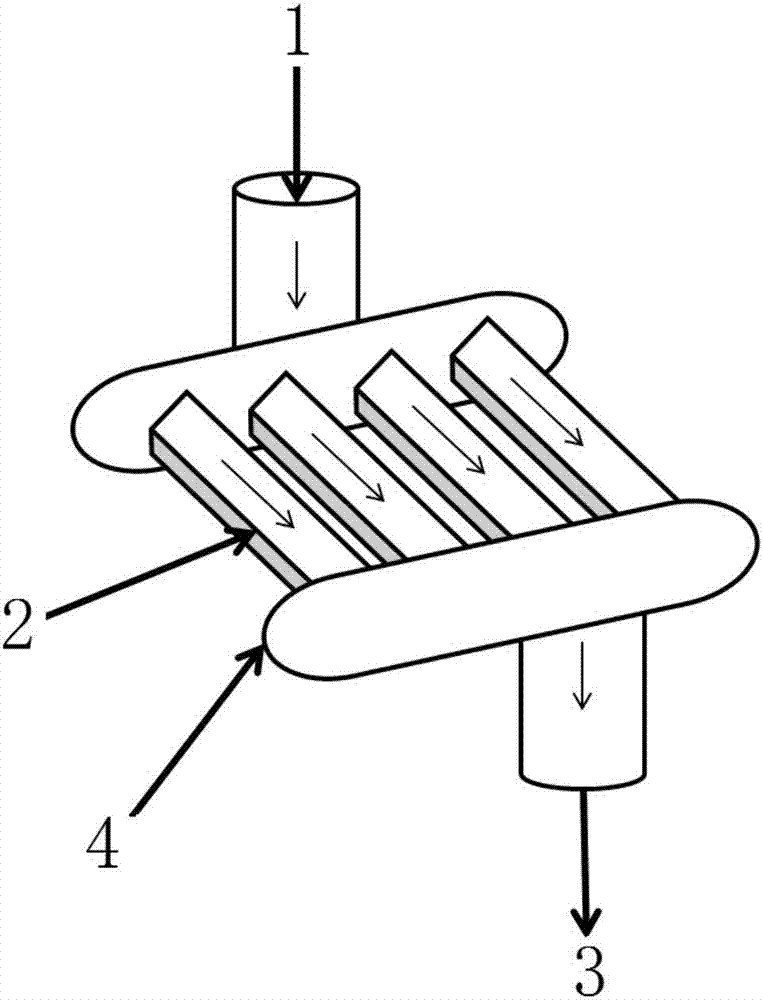

[0038] 3) Inhale the graphite suspension obtained in step 2) through a high-pressure pump, add it into the micro-fluidizer (Y-shaped cavity), and the slit width is 10mm, and the graphite powder suspension enters the pump cavity at a speed of 300mL / min. Collect the graphite suspension; utilize the micro-fluidizer again to carry out 19 cycles of treatment on the graphite suspension to obtain the suspension I;

[0039] 4) The suspension I was centrifuged at 10000rpm for 30min, filtered, washed 3 times with deionized water, then centrifuged at 10000rpm for 30min, filtered, and vacuum-dried to ...

Embodiment 2

[0042] 1) Polyoxypropylene-b-polyoxyethylene copolymer and deionized water are prepared into a 400 mg / mL intercalant solution;

[0043] 2) Disperse the 800-mesh flake graphite powder homogeneously in the intercalation agent solution obtained in step 1), mechanically stir for 1 h, and the stirring speed is 1000 r / min, to obtain a graphite powder suspension with a mass concentration of 10%;

[0044] 3) the graphite suspension obtained in step 2) is inhaled by a high-pressure pump, added in the micro-jet machine (Y-shaped cavity), the slit width is 14mm, and the graphite powder suspension enters the pump cavity at a speed of 450mL / min. Collect graphite suspension; Utilize this micro-jet machine again to carry out 25 times circulation processing to this graphite suspension, obtain suspension I;

[0045] 4) The suspension I was centrifuged at 10,000 rpm for 30 min, filtered, washed 3 times with deionized water, then centrifuged, and vacuum-dried to obtain powdered graphene.

[004...

Embodiment 3

[0048] 1) Polyvinylpyrrolidone and deionized water are prepared into a 50 mg / mL intercalant solution;

[0049] 2) Homogeneously disperse the 300-mesh expanded graphite powder in the intercalation agent solution obtained in step 1), mechanically stir for 2 hours, and the stirring speed is 800r / min, to obtain a graphite powder suspension with a mass concentration of 15%;

[0050] 3) the graphite suspension obtained in step 2) is inhaled by a high-pressure pump, added in the micro-fluidizer (Z-shaped cavity), the slit width is 12mm, and the graphite powder suspension enters the pump cavity at a speed of 100mL / min. Collect graphite suspension; Utilize this microjet machine again to carry out 49 cycles to this graphite suspension, obtain suspension I;

[0051] 4) The suspension I was centrifuged at 10000rpm for 30min, filtered, washed twice with deionized water, then centrifuged at 10000rpm for 30min, filtered to obtain a graphene wet cake.

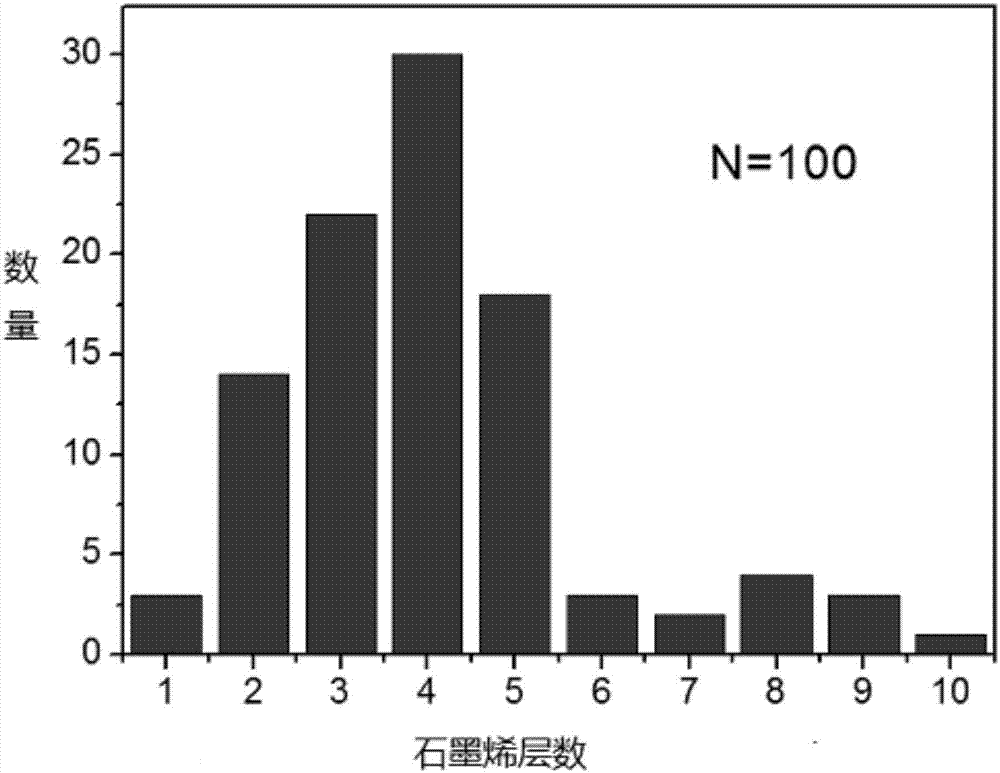

[0052] Show through shape analysis and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com