Chip peeling device

A technology for stripping devices and chips, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc. It can solve the problems of thimble height changes, wear, and inability to be picked up, and achieve the effect of ensuring repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

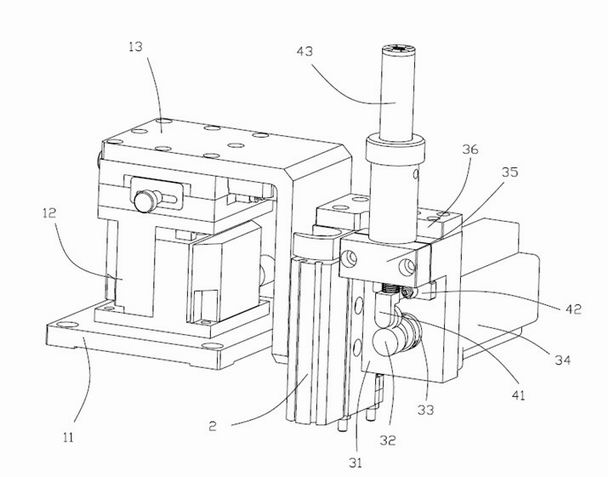

[0013] The chip peeling device of the present invention mainly includes thimble clamping and moving parts and a rotating drive part, and as an optimization, it also includes a lifting mechanism and a three-degree-of-freedom alignment platform. figure 1 It is a schematic diagram of the overall structure of a specific embodiment of the present invention, combined below Figure 1~3 Describe it in detail.

[0014] Such as figure 1 As shown, the supporting components of the device include a connection base plate 11 , a three-degree-of-freedom alignment platform 12 and an L-shaped plate 13 . The connecting bottom plate 11 is connected to the substrate by screws; the three-degree-of-freedom alignment platform 12 is the core part of the support component, which is composed of a Z-direction adjustment platform and an XY-direction adjustment platform, and the Z-direction adjustment platform is located below the XY-direction adjustment platform. The three-degree-of-freedom alignment pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com