High-weatherability fluorocarbon ship hull paint with good application properties

A construction and hull technology, applied in the field of high weather resistance fluorocarbon hull paint, can solve the problems of paint film foaming, difficult control of process parameters, shrinkage cavity, etc., to achieve improved construction, significant economic and social benefits, The effect of improving density

Inactive Publication Date: 2010-02-03

XIAMEN SUNRUI SHIP COATING

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, after the fluorocarbon coating is applied, the paint film will easily cause blistering and shrinkage, especially when the airless spraying method is used, the process parameters are difficult to control

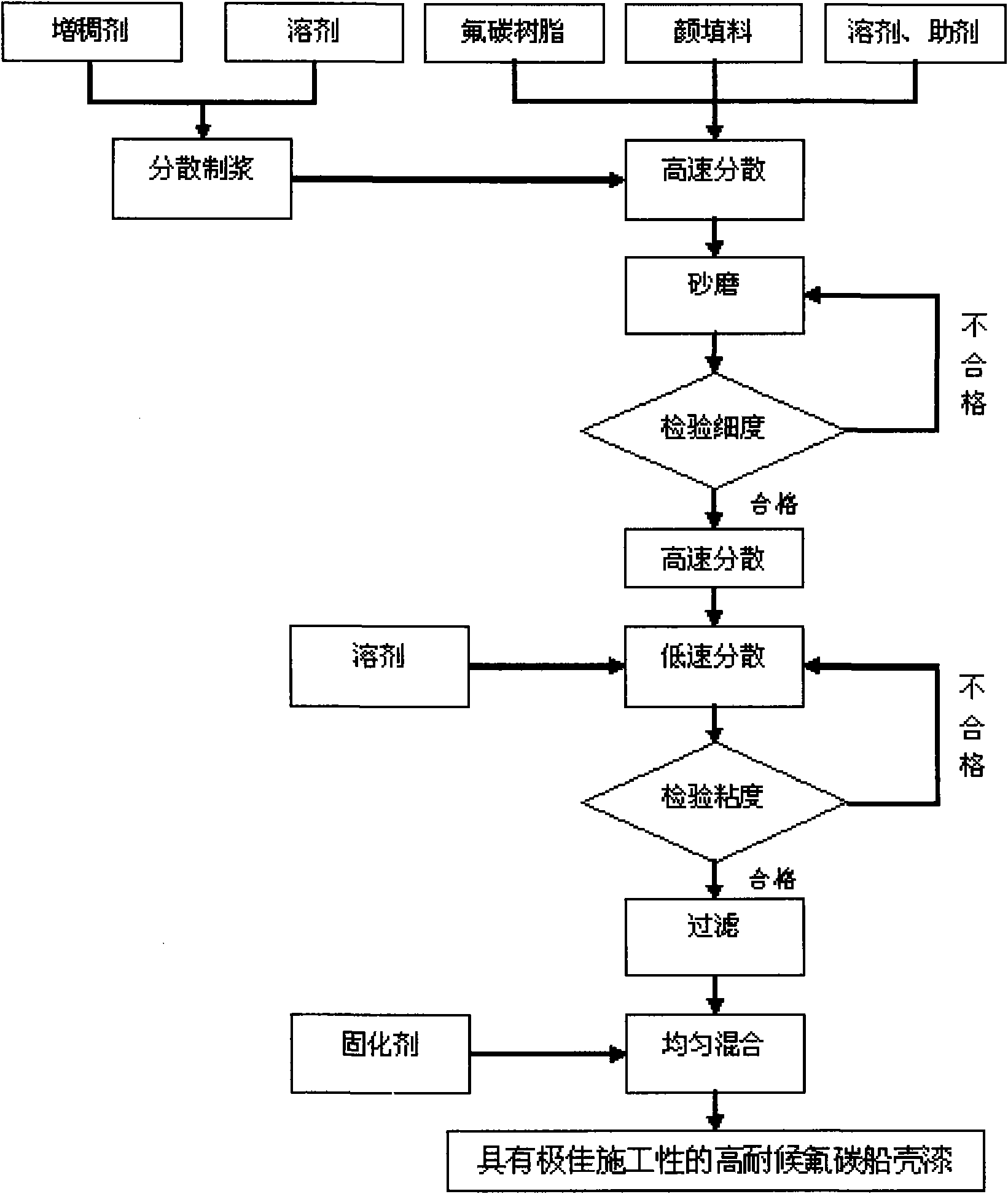

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

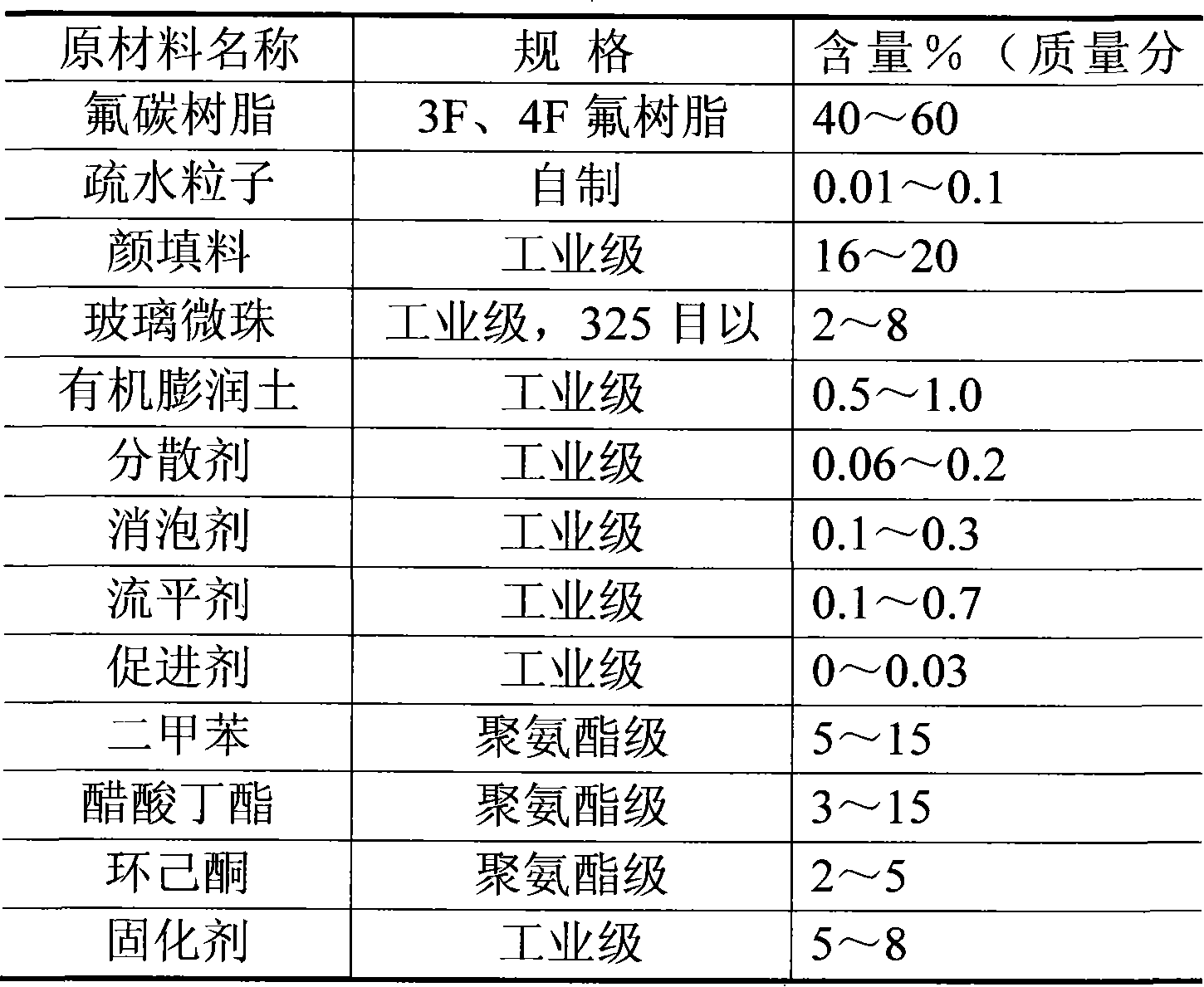

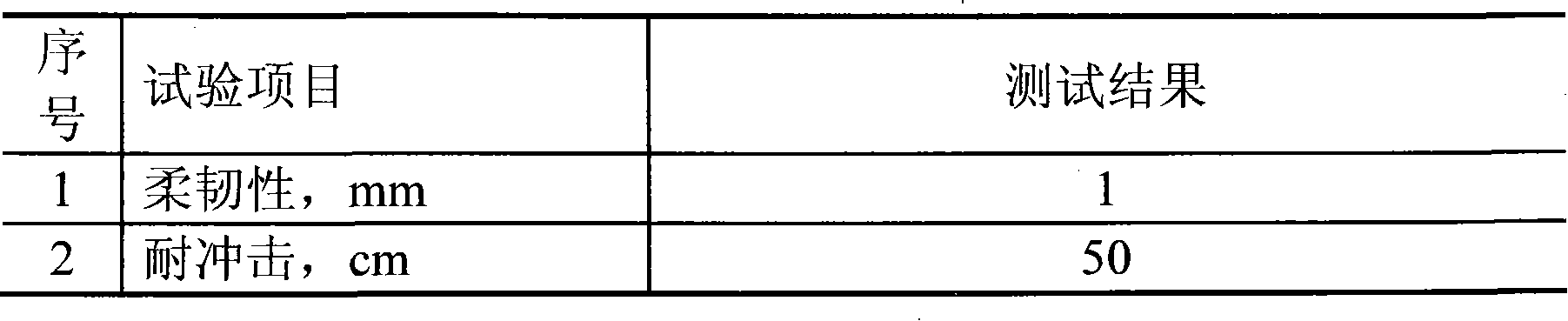

[0030] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention includes but not limited to the examples. Embodiment sees table 3:

[0031] Table 3 has the example of high weather resistance fluorocarbon hull paint with excellent workability

[0032]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a high-weatherability fluorocarbon ship hull paint with good application properties. The fluorocarbon ship hull paint uses a fluorocarbon resin as a main base material, improves the application properties of a fluorocarbon coating system by adjusting a solvent system and adding hydrophobic particles and glass microballoons, and adopts a compound solvent system compounded with butyl acetate, dimethyl benzene and cyclohexanone. The developed fluorocarbon coating can be used through brushing, roller coating, air spraying and airless spraying, and has simple construction control and excellent application properties; by adding the hydrophobic particles and the glass microballoons, the compactness of a fluorocarbon paint film is improved so that the fluorocarbon coating has excellent weatherability and corrosion resistance; and the high-weatherability fluorocarbon ship hull paint provides long acting coating layer protection for a steel structure, reduces the workloads for surface protection and maintenance and recoating, can be mainly applied to ship hulls to play a role of high weathering, heavy corrosion protection and high decoration, and can also be applied in the fields of bridges, offshore facilities and the like.

Description

technical field [0001] The invention relates to a coating, in particular to a highly weather-resistant fluorocarbon hull paint with good workability. Background technique [0002] The coating in the hull area is mainly eroded by seawater, fog, sea breeze, affected by temperature changes and sunlight, which accelerates the loss of light, pulverization, and even cracking and falling off of the paint film, and is often subject to mechanical damage. It must not only have excellent decorative and anti-corrosion properties, but also have high weather resistance and wear resistance. Therefore, the hull paint is developed in a functional direction such as good forward protection performance, convenient construction, and daily maintenance. Hull weather-resistant topcoats include alkyd, chlorinated rubber, acrylic, silicone-modified alkyd, acrylic-modified chlorinated rubber, epoxy polyurethane, acrylic-modified polyurethane, etc. High-grade hull weather-resistant topcoat Polyurethan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D127/12C09D7/12C09D5/16

Inventor 黄志军叶章基林志坚

Owner XIAMEN SUNRUI SHIP COATING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com