Epoxy coating on-site recoating method for steel pipeline

A technology of epoxy coating and epoxy coating, applied in epoxy coating, coating, device for coating liquid on the surface, etc., can solve the problem of epoxy coating peeling off and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

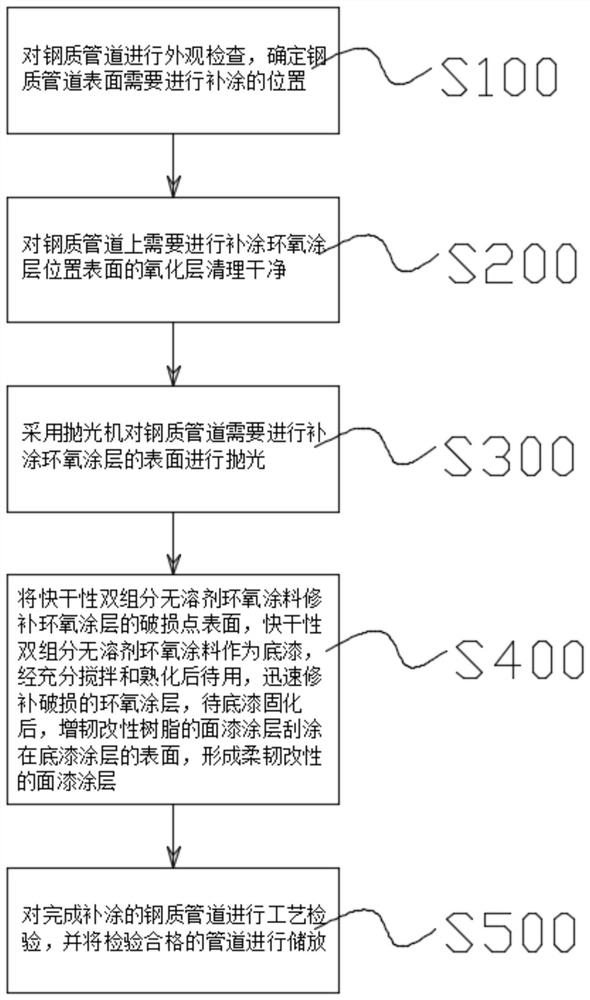

[0025] see figure 1 , in an embodiment provided by the present invention, a method for on-site repairing of epoxy coatings for steel pipelines, comprising the following specific steps: S100: Carry out visual inspection of the steel pipelines, and determine that the surface of the steel pipelines needs to be repaired position; S200: Clean up the oxide layer on the surface of the steel pipeline that needs to be recoated with epoxy coating; S300: Use a polishing machine to polish the surface of the steel pipeline that needs to be recoated with epoxy coating; S400: Put Quick-drying two-component solvent-free epoxy paint repairs the damaged surface of the epoxy coating. The quick-drying two-component solvent-free epoxy paint is used as a primer. After being fully stirred and matured, the damaged ring can be quickly repaired Oxygen coating, after the primer is cured, the topcoat coating of toughened modified resin is scraped on the surface of the primer coating to form a flexible mo...

Embodiment 2

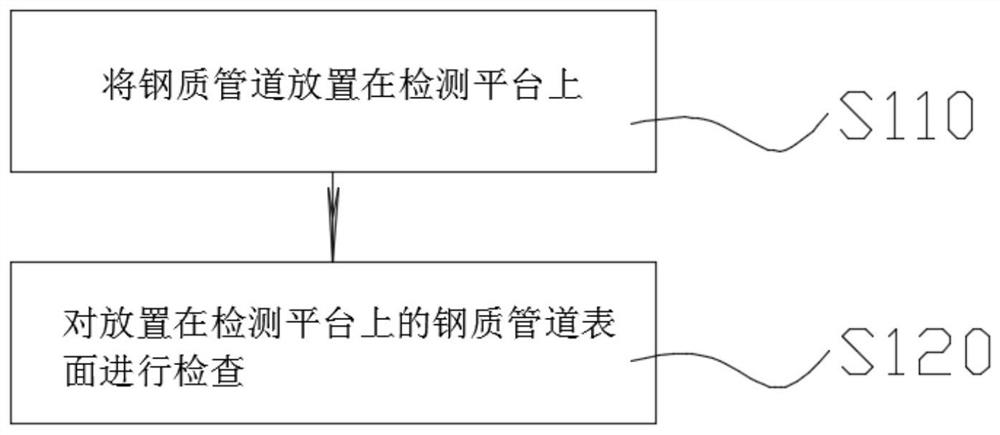

[0027] see Figure 1-2 , in an embodiment provided by the present invention, a method for on-site repairing of epoxy coatings for steel pipelines, comprising the following specific steps: S100: Carry out visual inspection of the steel pipelines, and determine that the surface of the steel pipelines needs to be repaired position; S200: Clean up the oxide layer on the surface of the steel pipeline that needs to be recoated with epoxy coating; S300: Use a polishing machine to polish the surface of the steel pipeline that needs to be recoated with epoxy coating; S400: Put Quick-drying two-component solvent-free epoxy paint repairs the damaged surface of the epoxy coating. The quick-drying two-component solvent-free epoxy paint is used as a primer. After being fully stirred and matured, the damaged ring can be quickly repaired Oxygen coating, after the primer is cured, the topcoat coating of toughened modified resin is scraped on the surface of the primer coating to form a flexible...

Embodiment 3

[0032] see Figure 1-2 , in an embodiment provided by the present invention, a method for on-site repairing of epoxy coatings for steel pipelines, comprising the following specific steps: S100: Carry out visual inspection of the steel pipelines, and determine that the surface of the steel pipelines needs to be repaired position; S200: Clean up the oxide layer on the surface of the steel pipeline that needs to be recoated with epoxy coating; S300: Use a polishing machine to polish the surface of the steel pipeline that needs to be recoated with epoxy coating; S400: Put Quick-drying two-component solvent-free epoxy paint repairs the damaged surface of the epoxy coating. The quick-drying two-component solvent-free epoxy paint is used as a primer. After being fully stirred and matured, the damaged ring can be quickly repaired Oxygen coating, after the primer is cured, the topcoat coating of toughened modified resin is scraped on the surface of the primer coating to form a flexible...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com