Ultraviolet-curable coating for spraying furniture and preparation method of ultraviolet-curable coating

A technology for curing coatings and ultraviolet light, applied in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor adhesion of interlayer paint films, and achieve low cost, simple process, and enhanced adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

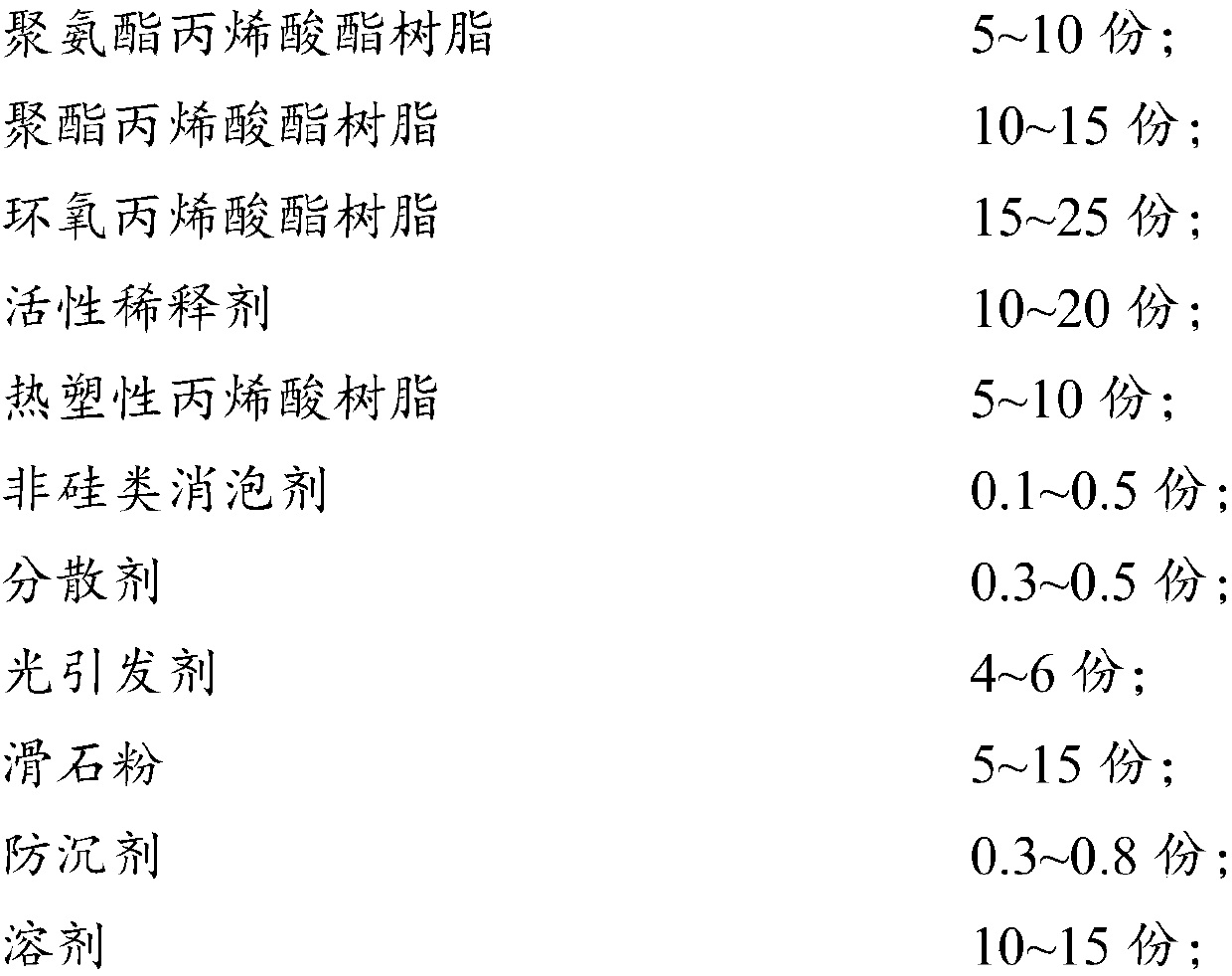

Method used

Image

Examples

preparation example Construction

[0039] On the other hand, the embodiment of the present invention also provides a preparation method of an ultraviolet light curing primer for wood surface, comprising:

[0040] S01, weigh each component according to the formula of the above-mentioned UV-curable coating;

[0041] S02, performing a first mixing treatment on the thermoplastic acrylic resin, the reactive diluent and the solvent to obtain a first mixture;

[0042] S03, adding the urethane acrylate resin, the polyester acrylate resin, the epoxy acrylate resin and the photoinitiator into the first mixture, and performing the second mixing treatment to obtain the second mixture;

[0043] S04. Add the non-silicon defoamer and the dispersant into the second mixture, and perform a third mixture treatment to obtain a third mixture;

[0044] S05. Add the talcum powder and the anti-settling agent into the third mixture, and perform a fourth mixture treatment to obtain the UV-curable coating.

[0045] Specifically, in th...

Embodiment 1

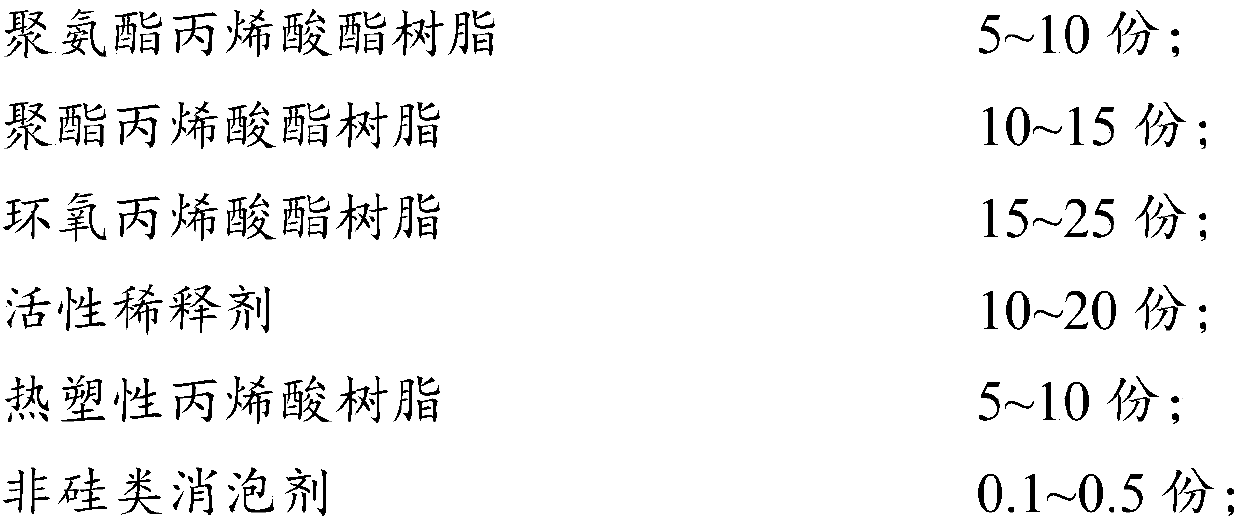

[0053] The content of each component by weight of the UV-curable coating provided in this embodiment is shown in Table 1:

[0054] Table 1

[0055] components

parts by weight

Polyurethane Acrylate Resin

5

Polyester acrylate resin

15

epoxy acrylate resin

25

Active diluent

15

thermoplastic acrylic resin

10

0.3

Dispersant

0.5

5

talcum powder

10

Anti-settling agent

0.5

10

5

[0056] In the above table 1, the polyurethane acrylate resin is selected from the resin produced by Zhanchen New Materials Group Co., Ltd., and the model is S5312; the polyester acrylate resin is selected from the resin produced by Zhanchen New Materials Group Co., Ltd., and the model is S5313; The acrylic resin is selected from the resin produced by Zhanchen New Materials Group Co., Ltd., the model is...

Embodiment 2

[0066] The content of each component of the UV-curable coating provided in this embodiment is shown in Table 2 (in parts by weight).

[0067] Table 2

[0068] components

parts by weight

Polyurethane Acrylate Resin

10

Polyester acrylate resin

10

epoxy acrylate resin

20

Active diluent

15

thermoplastic acrylic resin

10

Non-silicon defoamer

0.5

Dispersant

0.5

5

talcum powder

15

Anti-settling agent

0.8

5

10

[0069] In the above table 2, the reactive diluents are TMPTA and DPGDA produced by Taiwan Changxing Chemical Co., Ltd., wherein, TMPTA 5 parts, DPGDA 10 parts.

[0070] The rest of the place and its preparation process are basically the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com