Epoxy-modified two-component pavement antiskid coating and preparation method thereof

A technology of anti-slip and epoxy modification on road surfaces, which is applied in the direction of epoxy resin coatings and coatings, which can solve the problems of easy pulverization, high brittleness, non-slip resistance and wear resistance, and prevent hollowing and delamination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The embodiment of the present invention also relates to the preparation method of this two-component road surface anti-skid coating, comprising the following steps:

[0041] (1) Preparation of component A: Mix fumed silica, organic boron clay, inorganic iron oxide pigment, talc powder, silica fume powder and quartz sand to obtain an inorganic mixture, and then add standard bisphenol Mix A epoxy resin evenly, then add epoxy-based toughener, AGE reactive diluent, defoamer, leveling agent and wetting agent and mix evenly to obtain component A;

[0042] (2) Preparation of component B: Mix the modified alicyclic amine curing agent, silane coupling agent and polyamide curing agent evenly to obtain component B;

[0043] (3) Mix components A and B evenly to obtain a two-component road surface anti-skid coating.

[0044] In actual use, use spraying equipment to spray the two-component road surface anti-skid coating prepared above onto the construction road surface, use a roller...

Embodiment

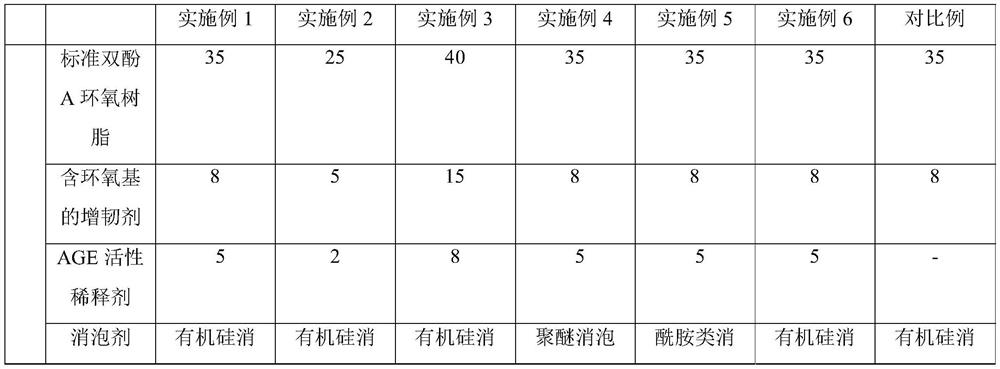

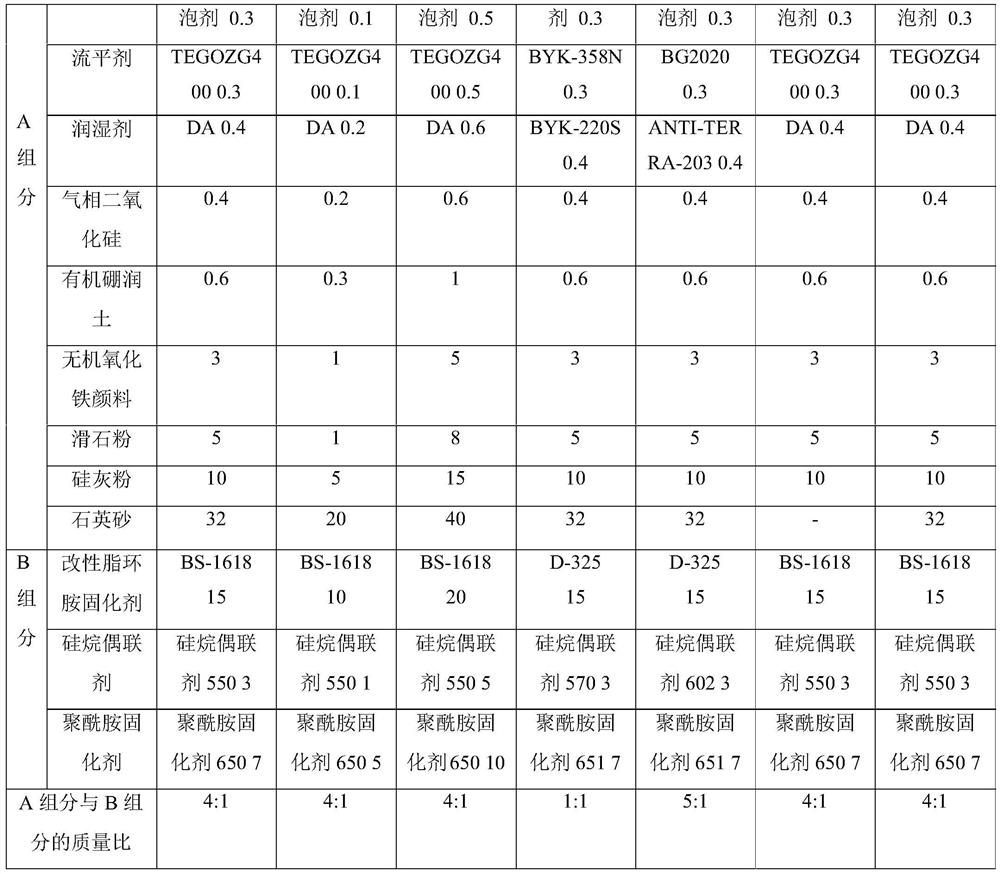

[0046] An epoxy-modified two-component road surface anti-skid coating, including A component and B component, the preparation method is the same as that described in the specific embodiment. The specific substances and contents of A and B components in Examples 1-6 and Comparative Examples are shown in Table 1.

[0047] Among them, the toughening agent containing epoxy group was purchased from Juncai Material Technology Co., Ltd., the brand is BI7770. The silicone defoamer was purchased from Hebei Zhengqian Chemical Products Co., Ltd., the polyether defoamer was purchased from Hebei Leyi Energy Saving Technology Co., Ltd., and the amide defoamer was purchased from Shanghai Guangbai New Material Co., Ltd.

[0048] Table 1

[0049]

[0050]

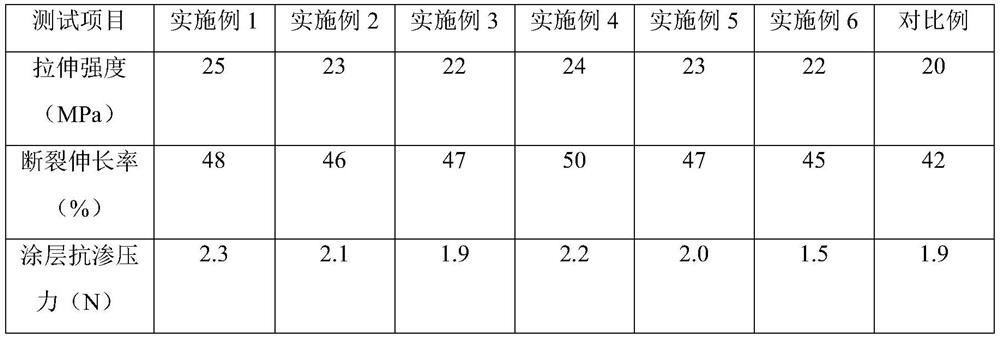

[0051] Mix component A and component B of the above examples and comparative examples uniformly according to the above proportions, let stand for 20 minutes until the air bubbles are eliminated, and then apply the coating evenly on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com