Anticorrosive coating damage distinguishing system and assessment method thereof

A kind of anti-corrosion coating and coating technology, applied in the direction of image data processing, instruments, optical testing flaws/defects, etc., can solve the problems of manual measurement data workload, time-consuming and labor-intensive, accidents, complicated operations, etc., to achieve The evaluation results are stable and reliable, reducing labor and ensuring the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

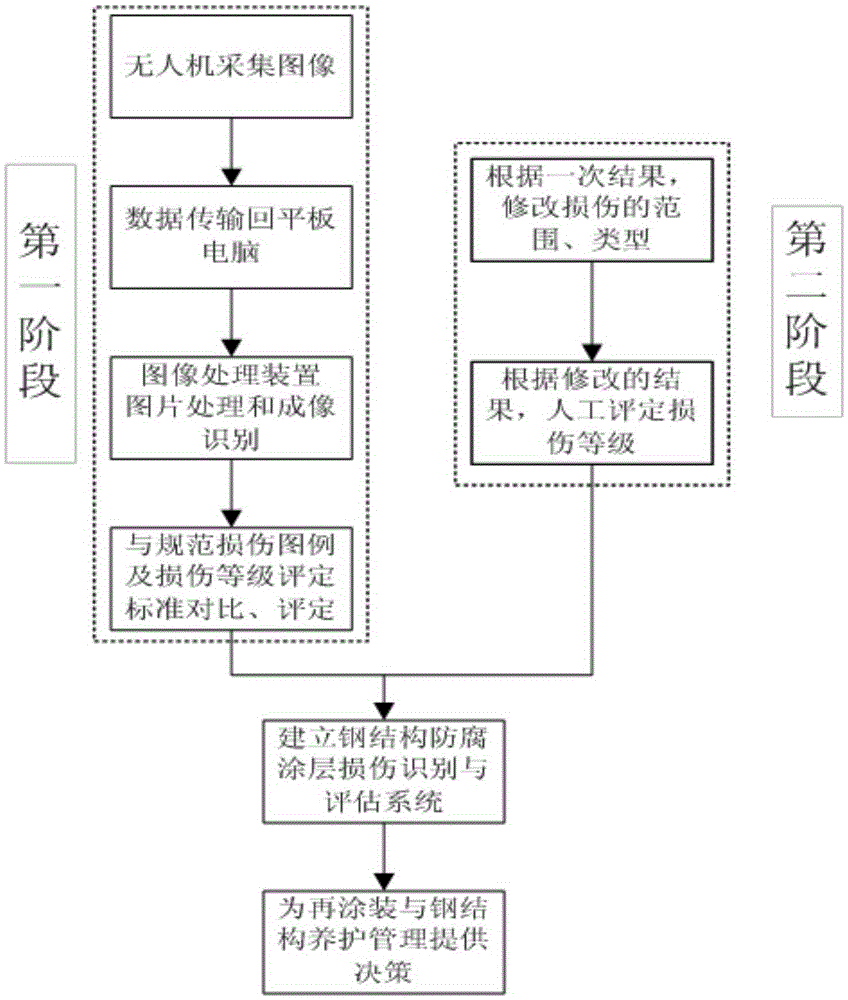

Method used

Image

Examples

Embodiment

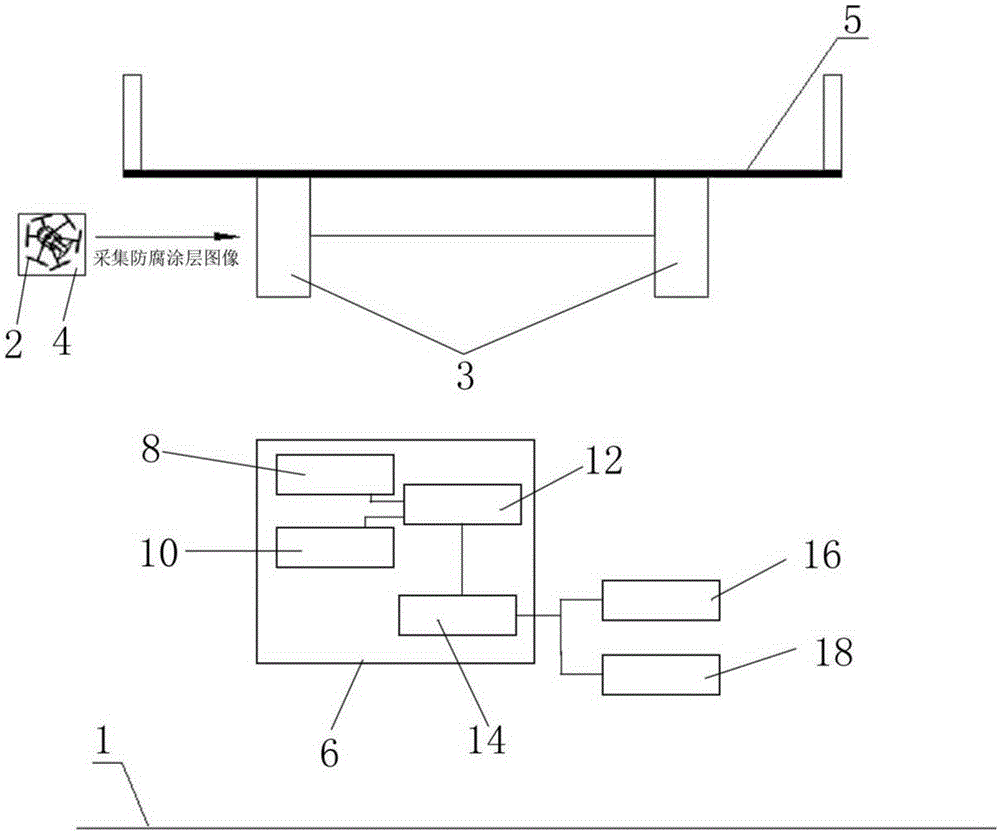

[0024] Such as figure 2 As shown, a kind of anticorrosion coating damage identification system is disclosed in this embodiment, including a camera device 2 for taking images of the surface layer of the anticorrosion coating, a drone 4 and a server terminal 6, and the camera device 2 is installed and fixed on an On the man-machine 4, the server terminal 6 is provided with a coating damage category memory 8, a damage level division standard memory 10, an image processor 12 connected to the output end of the camera 2, and the coating damage category memory 8. The data stored in the damage level division standard memory 10 is based on the image comparison recognizer 14 that compares and recognizes the output results of the image processor 12 . The preferred server terminal of the present invention is a tablet computer, which is easy to carry and is suitable for use in outdoor environments. The pulverization of the layer, the rust of the coating, the cracking of the coating, etc....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com