Aqueous elastic exterior-wall coating and preparation method thereof

An elastic exterior wall and coating technology, applied in the direction of coating, etc., can solve the problems of affecting the use function of buildings, affecting the internal steel bars of the structure, and the corrosion of concrete steel bars, achieving rich expressiveness, strong three-dimensional effect, and easy maintenance and repainting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

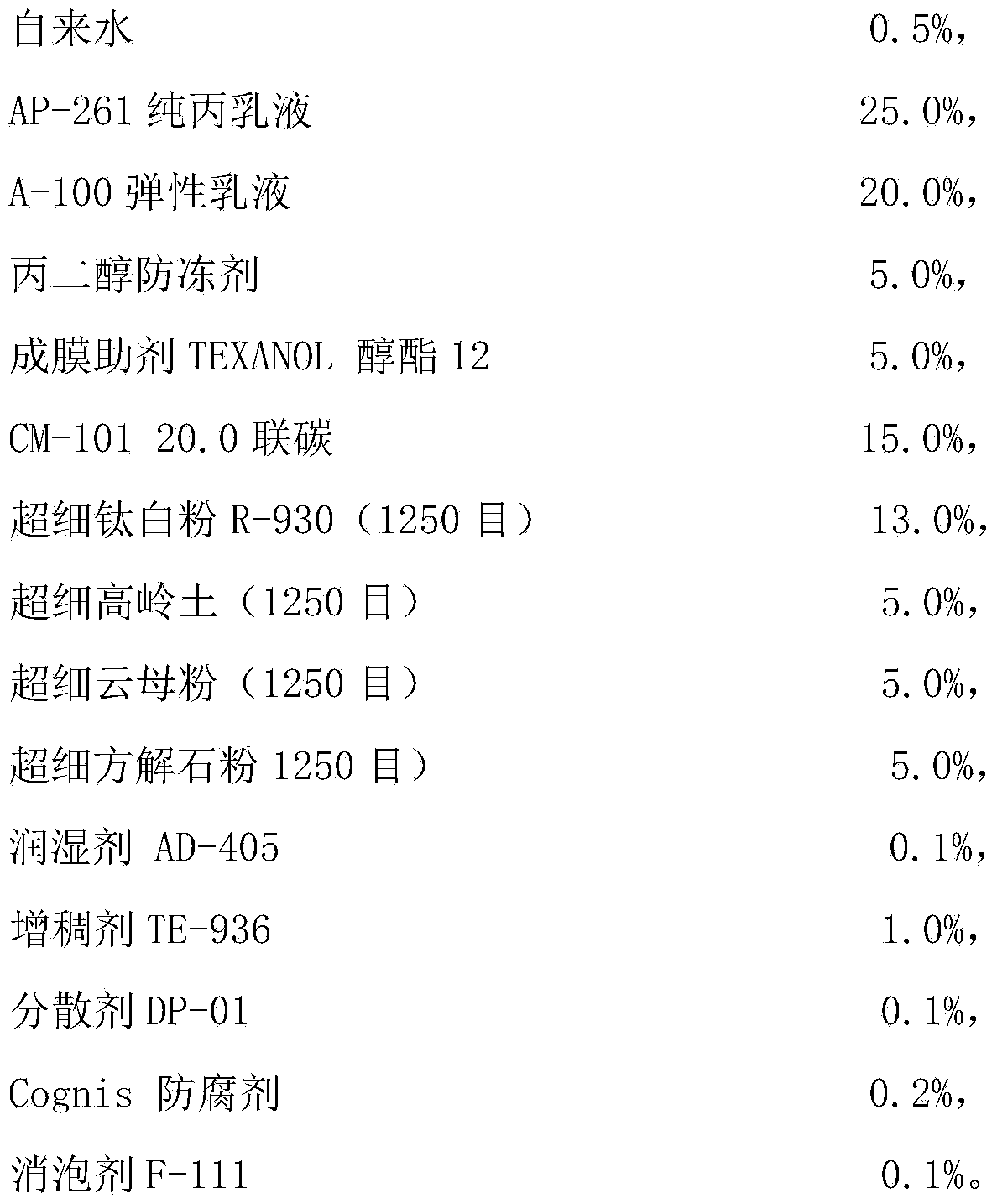

[0021] One, formula according to mass percentage

[0022]

[0023] 2. Preparation method

[0024] 1. According to the mass percentage formula, first add the water in the components, AP-261 pure acrylic emulsion, A-100 elastic emulsion, propylene glycol antifreeze, film forming aids TEXANOL alcohol ester 12, CM-10120.0 bicarbon separately In the mixing tank, stir for 20-25 minutes at 800-900r / min;

[0025] 2. Add ultra-fine titanium dioxide R-930, ultra-fine kaolin, ultra-fine mica powder, and ultra-fine calcite powder into the mixing tank according to the formula dosage, and continue stirring for 30-35 minutes at a speed of 2500-3000r / min; Add wetting agent AD-405, thickener TE-936, dispersant DP-01, antiseptic, and defoamer F-111, respectively, and continue stirring for 20-25 minutes to obtain water-based elastic exterior wall paint.

[0026] 3. Beneficial effects

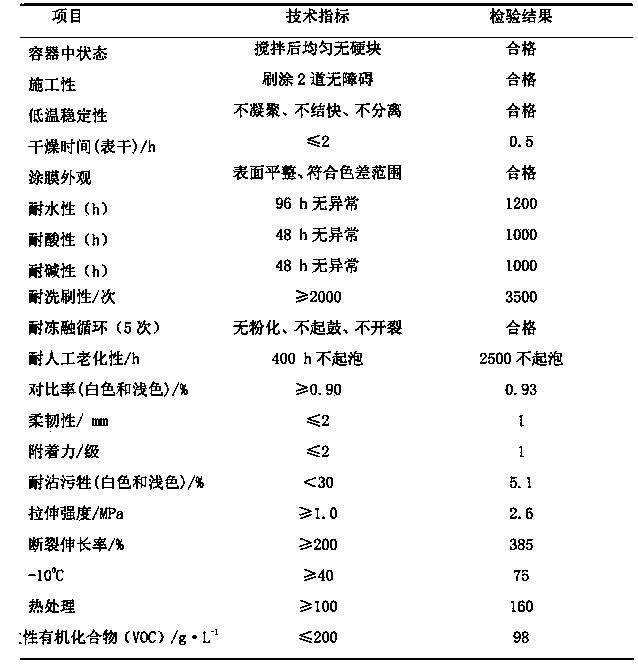

[0027] Table 1 shows the performance test results of a water-based elastic exterior wall coating of Example 1

[0028] ...

Embodiment 2

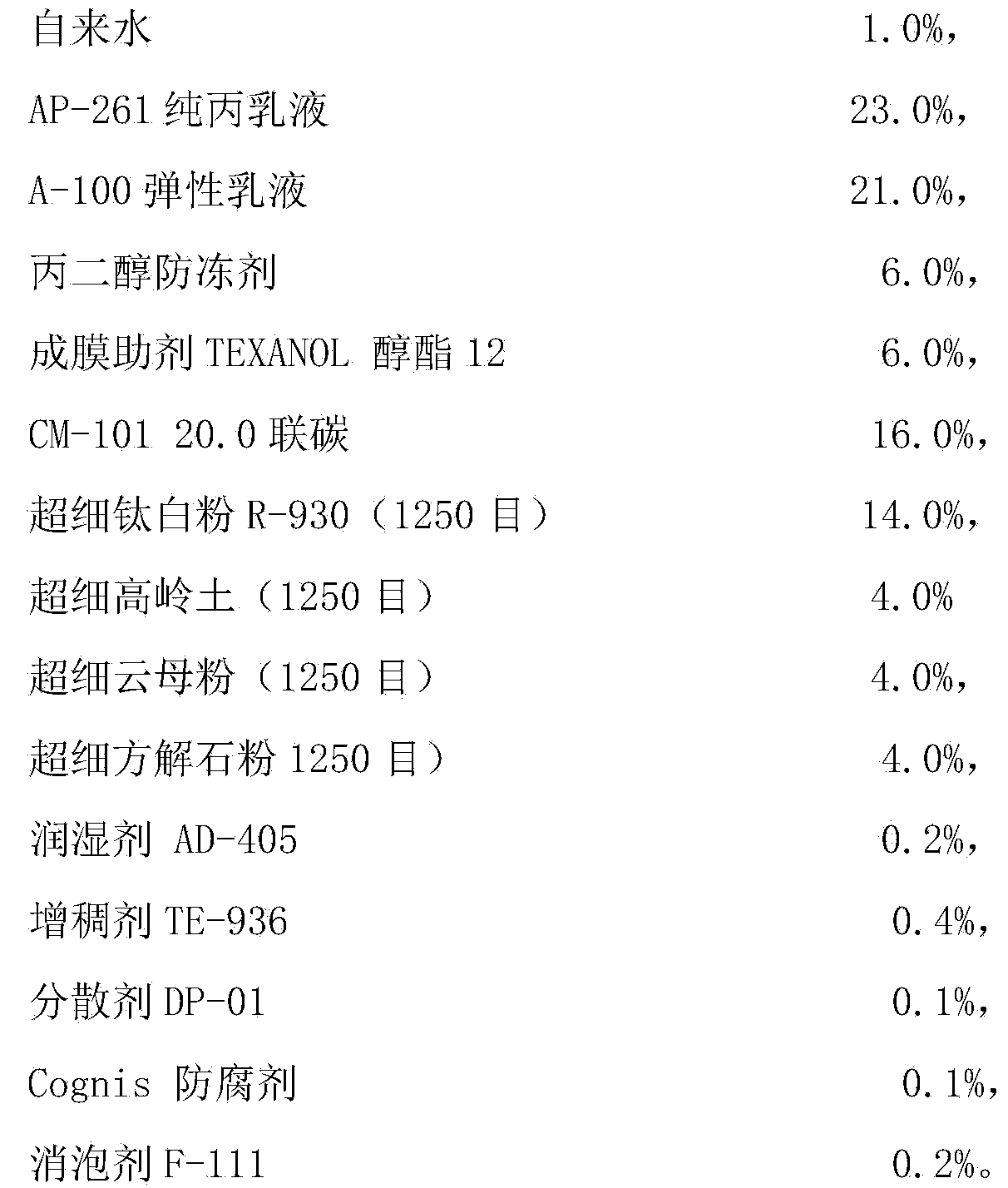

[0030] One, formula according to mass percentage

[0031]

[0032] 2. The preparation method is the same as in Example 1

[0033] 3. Beneficial effects

[0034] Table 2 shows the performance test results of a water-based elastic exterior wall coating in Example 2

[0035]

[0036]

Embodiment 3

[0038] One, formula according to mass percentage

[0039]

[0040] 2. The preparation method is the same as in Example 1

[0041] 3. Beneficial effects

[0042] Table 3 shows the performance test results of a water-based elastic exterior wall coating in Example 3.

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com