Multilayer recoating high-transparence fast-drying easy-polishing sanding nitrocellulose primer

A high-transparency, transparent primer technology, applied in coatings, anti-corrosion coatings, polyester coatings, etc., can solve rare problems and achieve fast drying, easy sanding, and cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

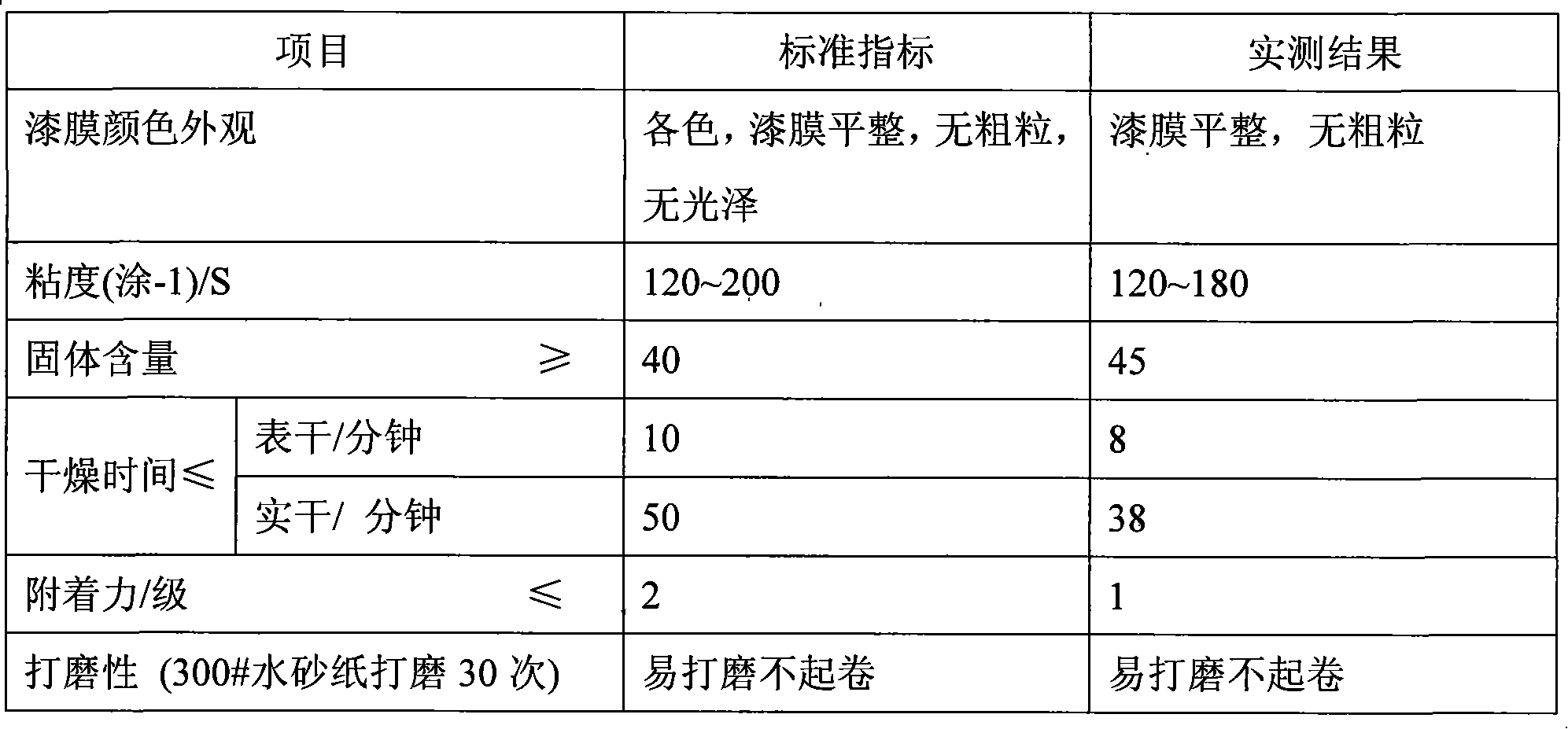

[0019] Add 36 kg of ester solvent without stirring, and then add 23 kg of nitrocellulose. After the nitrocellulose is completely submerged, disperse at a speed of 600-1000 rpm for 15-20 minutes until the nitrocellulose is completely dissolved. Then add 10 kg of maleic acid modified rosin resin, and disperse for 15 to 20 minutes at a rotating speed of 800 to 1000 rpm until the rosin resin is completely dissolved. Add 21 kg of modified saturated polyester resin and 2 kg of dioctyl phthalate at a rotating speed of 300-500 rpm and stir evenly at a rotating speed of 800-1000 rpm. Then add 6 kg of zinc stearate and 2 kg of talcum powder at a speed of 300-500 rpm, gradually increase the speed to 800-1200 rpm, and disperse at a high speed for about 20-30 minutes until the fineness is 40-50 microns , adjust the paint viscosity to 100 ~ 135KU / 30 ℃ (STM viscometer) to get the finished product. The physical and chemical test results are shown in Table 1.

Embodiment 2

[0021] Add 38.3 kg of ester solvent without stirring, and then add 22.5 kg of nitrocellulose. After the nitrocellulose is completely submerged, disperse at a speed of 600-1000 rpm for 15-20 minutes until the nitrocellulose is completely dissolved. Then add 9.5 kg of maleic acid modified rosin resin, and disperse for 15 to 20 minutes at a rotating speed of 800 to 1000 rpm until the rosin resin is completely dissolved. Add 20.5 kg of modified saturated polyester resin and 1.8 kg of dioctyl phthalate at a rotating speed of 300-500 rpm and stir evenly at a rotating speed of 800-1000 rpm. Then add 5.5 kg of zinc stearate and 1.9 kg of talcum powder at a speed of 300-500 rpm, gradually increase the speed to 800-1200 rpm, and disperse at a high speed for about 20-30 minutes until the fineness is 40-50 microns , adjust the paint viscosity to 100 ~ 135KU / 30 ℃ (STM viscometer) to get the finished product. The physical and chemical test results are shown in Table 1.

Embodiment 3

[0023] Add 40.5 kg of ester solvent without stirring, and then add 22 kg of nitrocellulose. After the nitrocellulose is completely submerged, disperse at a speed of 600-1000 rpm for 15-20 minutes until the nitrocellulose is completely dissolved. Then add 9 kg of maleic acid modified rosin resin, and disperse for 15 to 20 minutes at a rotating speed of 800 to 1000 rpm until the rosin resin is completely dissolved. Add 20 kg of modified saturated polyester resin and 1.7 kg of dioctyl phthalate at a rotating speed of 300-500 rpm and stir evenly at a rotating speed of 800-1000 rpm. Then add 5 kg of zinc stearate and 1.8 kg of talcum powder at a speed of 300-500 rpm, gradually increase the speed to 800-1200 rpm, and disperse at a high speed for about 20-30 minutes until the fineness is 40-50 microns , adjust the paint viscosity to 100 ~ 135KU / 30 ℃ (STM viscometer) to get the finished product. The physical and chemical test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com