Steel sheet continuous recoating and printing process

A printing process and steel plate technology, applied in printing, decorative arts, printing devices, etc., can solve the problems of inappropriate decoration, low cost, falling off, etc., and achieve the effects of considerable market prospects, long service life and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

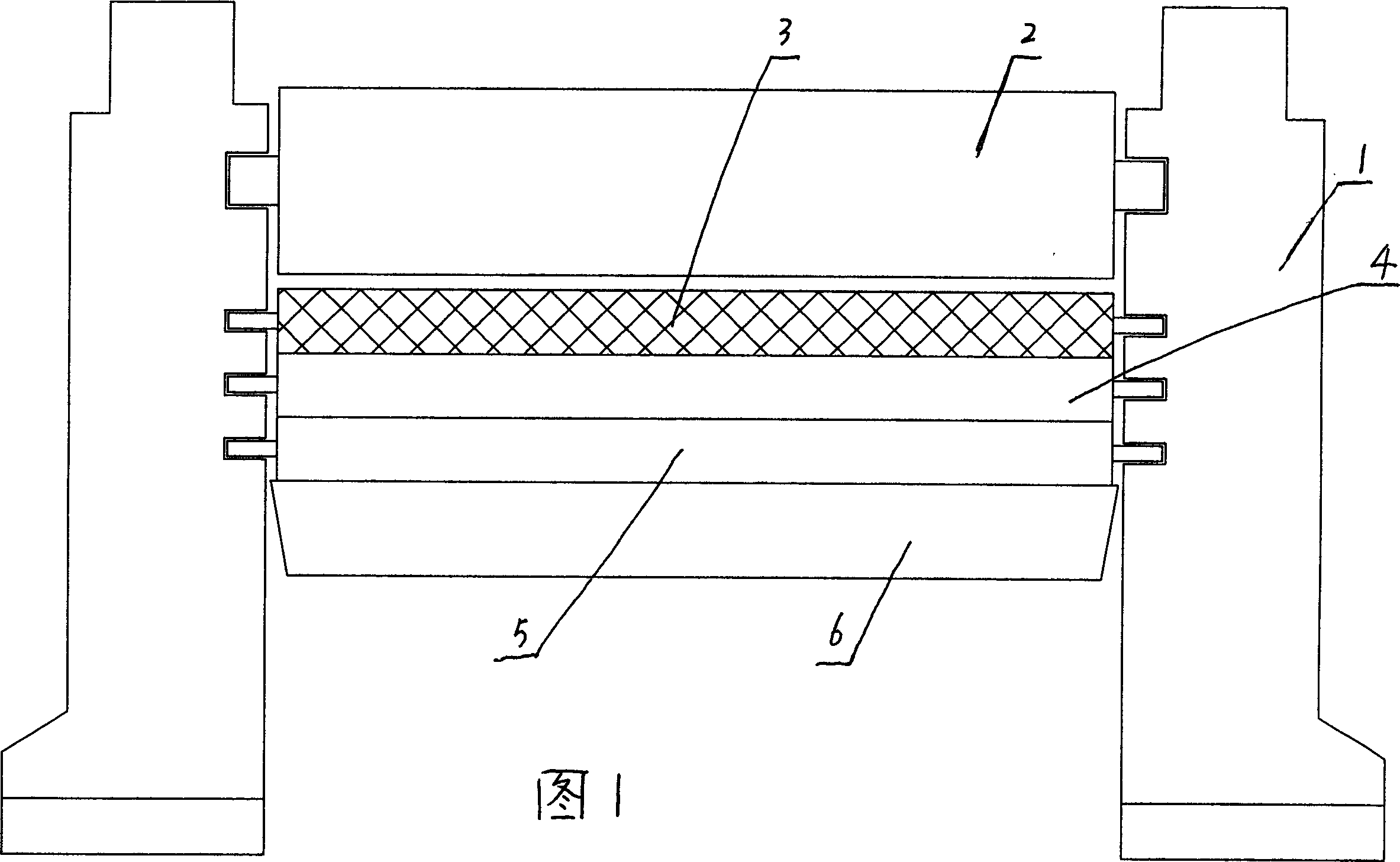

[0009] A continuous overcoating printing process for steel plates, the process flow is: raw material coil → connection → edge straightening → steel strip storage → degreasing → water washing → water mist cooling → hot air drying → chemical treatment → indirect cold water → bottom coating → bottom Dyeing and burning → hot air drying → surface dyeing and back dyeing → primary coating → intermediate coating → third coating → drying → surface inspection → steel strip storage → hot air drying → water mist cooling → drying → fine coating → product separation → product packaging Or cut to size → finished product.

[0010] The present invention is based on the existing steel plate color coating production line, replacing 1-3 special-shaped coating rollers and equalizing rollers with patterns, adding 1-2 three-roller coaters, and implementing the remaining steps The process is the same as the traditional one, so I won't repeat it here.

[0011] The present invention mainly changes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com