Waterborne epoxy acrylic acid modified two-component pavement antiskid coating and preparation method thereof

A technology of epoxy acrylic and water-based acrylic, which is applied in the direction of epoxy resin coatings and coatings, and can solve problems such as high brittleness, easy powdering, and easy yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The embodiment of the present invention also relates to the preparation method of this two-component road surface anti-skid coating, comprising the following steps:

[0038] (1) Preparation of component A: Mix fumed silica, organoboronite, inorganic iron oxide pigments, talc powder, silica fume powder and colored ceramic particles to obtain an inorganic mixture, and then add water-based ring to the inorganic mixture Mix oxygen resin and water-based acrylic resin evenly, then add water-based anti-settling agent, water-based defoamer, water-based dispersant and wetting agent and mix evenly to obtain component A;

[0039] (2) Preparation of component B: Mix the water-based epoxy curing agent and deionized water evenly to obtain component B;

[0040] (3) Mix components A and B evenly to obtain a two-component road surface anti-skid coating.

[0041] In actual use, use spraying equipment to spray the two-component road surface anti-skid coating prepared above onto the const...

Embodiment

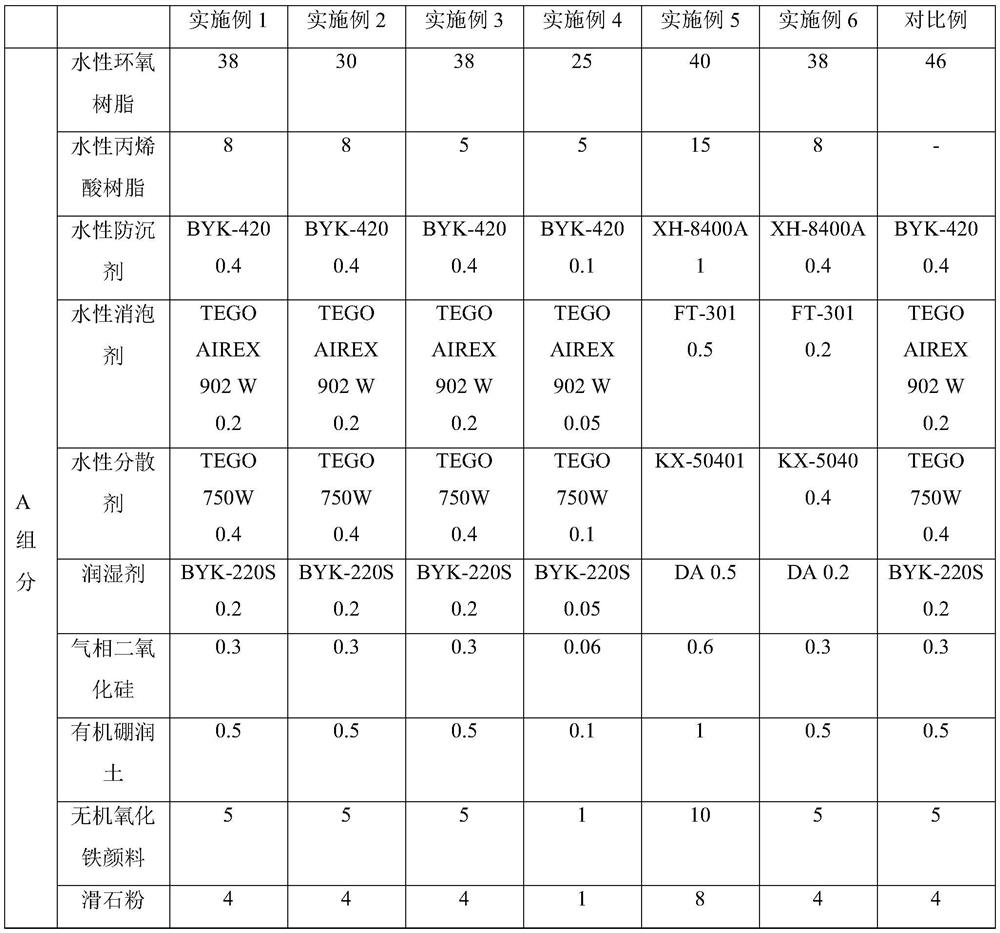

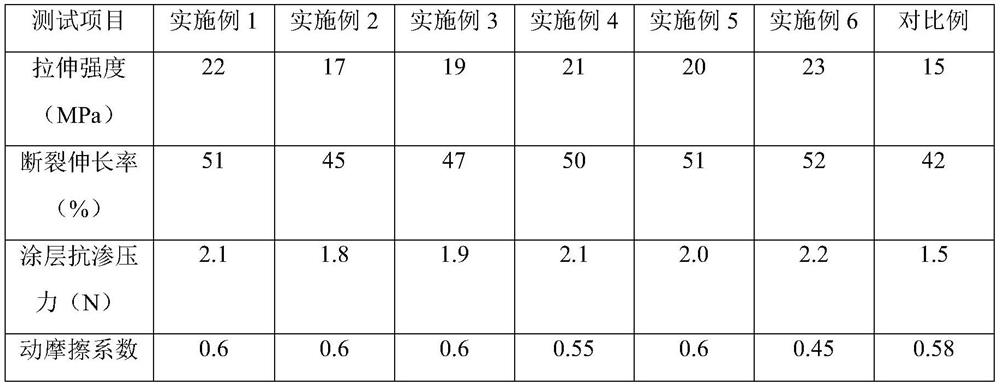

[0043] A water-based epoxy acrylic modified two-component anti-skid coating for road surfaces, including A component and B component, the preparation method is the same as that described in the specific embodiment. The specific substances and contents of A and B components in Examples 1-6 and Comparative Examples are shown in Table 1.

[0044] Table 1

[0045]

[0046]

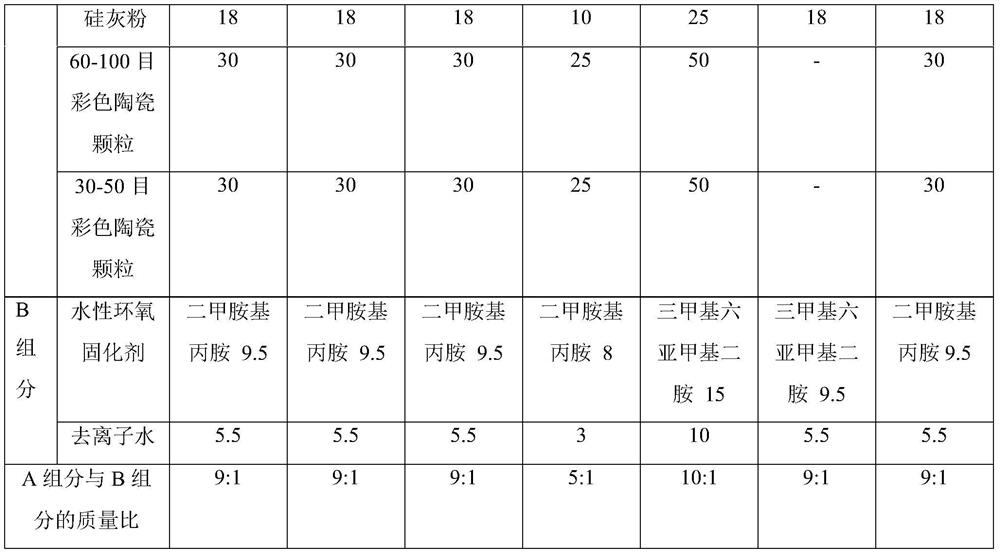

[0047] Mix component A and component B of the above examples and comparative examples uniformly according to the above proportions, let stand for 20 minutes until the air bubbles are eliminated, and then apply the coating evenly on the surface of the concrete sample, and form a coating with a thickness of 1 to 2 mm after curing. Floor. The mechanical properties of the coating were tested and the results are shown in Table 2.

[0048] Table 2

[0049]

[0050]Comparing Examples 2 and 3 with Example 1, it can be seen that when the mass ratio of water-based epoxy resin to water-based acrylic resin is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com