Water-based acrylic acid primer-topcoat coating applicable to rusty steel structure and to renovation coating of steel structure as well as preparation method and application method of water-based acrylic acid primer-topcoat coating

A water-based acrylic and steel structure technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of difficult processing and high construction conditions, and achieve the effects of excellent coating performance, super elimination ability, and rust elimination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

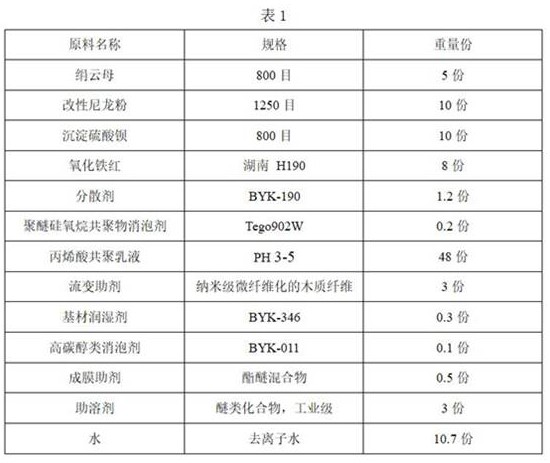

[0034] Table 1 shows the raw material composition of a water-based acrylic primer (iron red) that is suitable for rusty steel structure and steel structure renovation coating.

[0035]

[0036] The preparation method of the present embodiment comprises the following steps:

[0037] A. First, take 10% deionized water of the formula amount and put it into the dispersing basin, and disperse at a speed of 700 r / min. At the same time, add the polyether siloxane copolymer defoamer, sericite, modified Nylon powder, precipitated barium sulfate, pigments, rheological additives, and then adjust the dispersion speed to 1500 r / min, and disperse for 20 minutes to obtain a dispersion mixture for later use;

[0038] B. Pour the dispersion mixture obtained in step A into a sand mill for grinding, control its fineness ≤ 35 μm, and temperature ≤ 50 ° C to obtain a grinding slurry, and then pour out the qualified grinding slurry from the sand mill ,spare;

[0039] C. Take the weakly acidic ...

Embodiment 2

[0041] Table 2 shows the raw material composition of a water-based acrylic primer (dark gray) that is suitable for rusty steel structure and steel structure renovation coating.

[0042]

[0043] The preparation method of the present embodiment comprises the following steps:

[0044] A. First, take 8% deionized water of the formula and put it into the dispersion basin, and disperse at a speed of 500 r / min. At the same time, add the polyether siloxane copolymer defoamer, sericite, modified Nylon powder, precipitated barium sulfate, pigments, rheological additives, and then adjust the dispersion speed to 1200 r / min, disperse for 30 minutes, and obtain a dispersion mixture for later use;

[0045] B. Pour the dispersion mixture obtained in step A into a sand mill for grinding, control its fineness ≤ 35 μm, and temperature ≤ 50 ° C to obtain a grinding slurry, and then pour out the qualified grinding slurry from the sand mill ,spare;

[0046] C. Take the weakly acidic acrylic c...

Embodiment 3

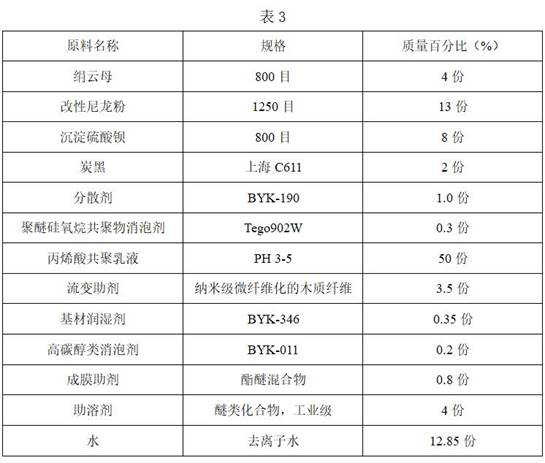

[0048] The raw material composition of a water-based acrylic primer (black) suitable for rusty steel structure and steel structure renovation coating is shown in Table 3.

[0049]

[0050] The preparation method of the present embodiment comprises the following steps:

[0051] A. First take 12% deionized water and put it into the dispersion basin, and disperse at a speed of 600 r / min. At the same time, add the formula amount of polyether siloxane copolymer defoamer, sericite, and modified nylon powder in sequence. , Precipitate barium sulfate, pigments, rheological additives, then adjust the dispersion speed to 1400 r / min, and disperse for 15 minutes to obtain a dispersion mixture for later use;

[0052] B. Pour the dispersion mixture obtained in step A into a sand mill for grinding, control its fineness ≤ 35 μm, and temperature ≤ 50 ° C to obtain a grinding slurry, and then pour out the qualified grinding slurry from the sand mill ,spare;

[0053] C. Take the weakly acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com