Processing technique of polish-free recoating-available high-light white paint

A production process and white topcoat technology, applied in coatings, polyester coatings, etc., can solve problems affecting fullness, cost manpower and man-hours, and reduce construction efficiency, so as to improve fullness, increase production efficiency, and simplify construction technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

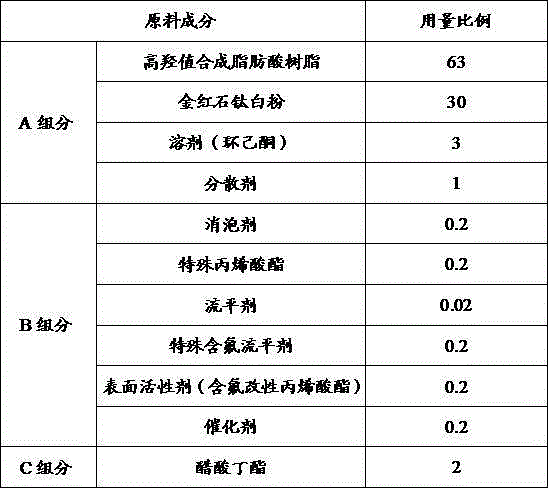

[0019] The ratio of each raw material consumption is as follows:

[0020]

[0021] The process steps are as follows:

[0022] (1) Put component A into the dispersion cylinder, adjust the speed to 1280r / min, and disperse at high speed for 30 minutes;

[0023] (2) Check the fineness. When the fineness is ≦15μm, adjust the speed to 800r / min, put in component B, and stir for 10 minutes;

[0024] (3) Adjust the rotation speed to 350r / min, then add component C, and stir at low speed for 5 minutes.

Embodiment 2

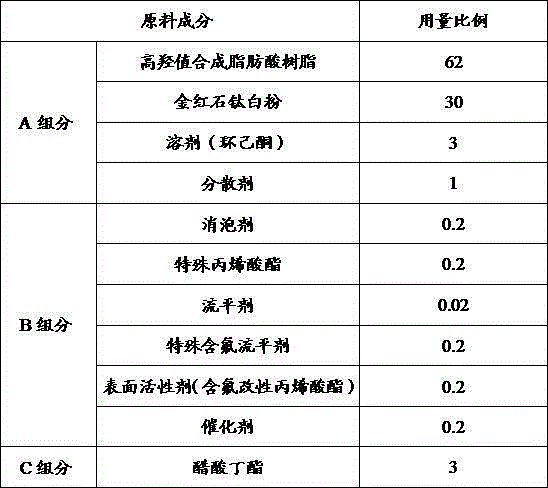

[0026] The ratio of each raw material consumption is as follows:

[0027]

[0028] The process steps are as follows:

[0029] (1) Put component A into the dispersion cylinder, adjust the speed to 1450r / min, and disperse at high speed for 30 minutes;

[0030] (2) Check the fineness. When the fineness is ≦15μm, adjust the speed to 800r / min, put in component B, and stir for 10 minutes;

[0031] (3) Adjust the rotation speed to 380r / min, then add component C, and stir at low speed for 5 minutes.

[0032] The relevant characteristic index of the white finish paint obtained in the above-mentioned embodiment is as follows:

[0033] Index item specific indicators Gloss 100-101 hardness HB-H Fullness excellent Recoatability (no sanding) excellent mirror effect excellent Adhesion between layers Level 0-1

[0034] It can be seen from the above examples that the advantages of the present invention are: (1) the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com