Honing machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

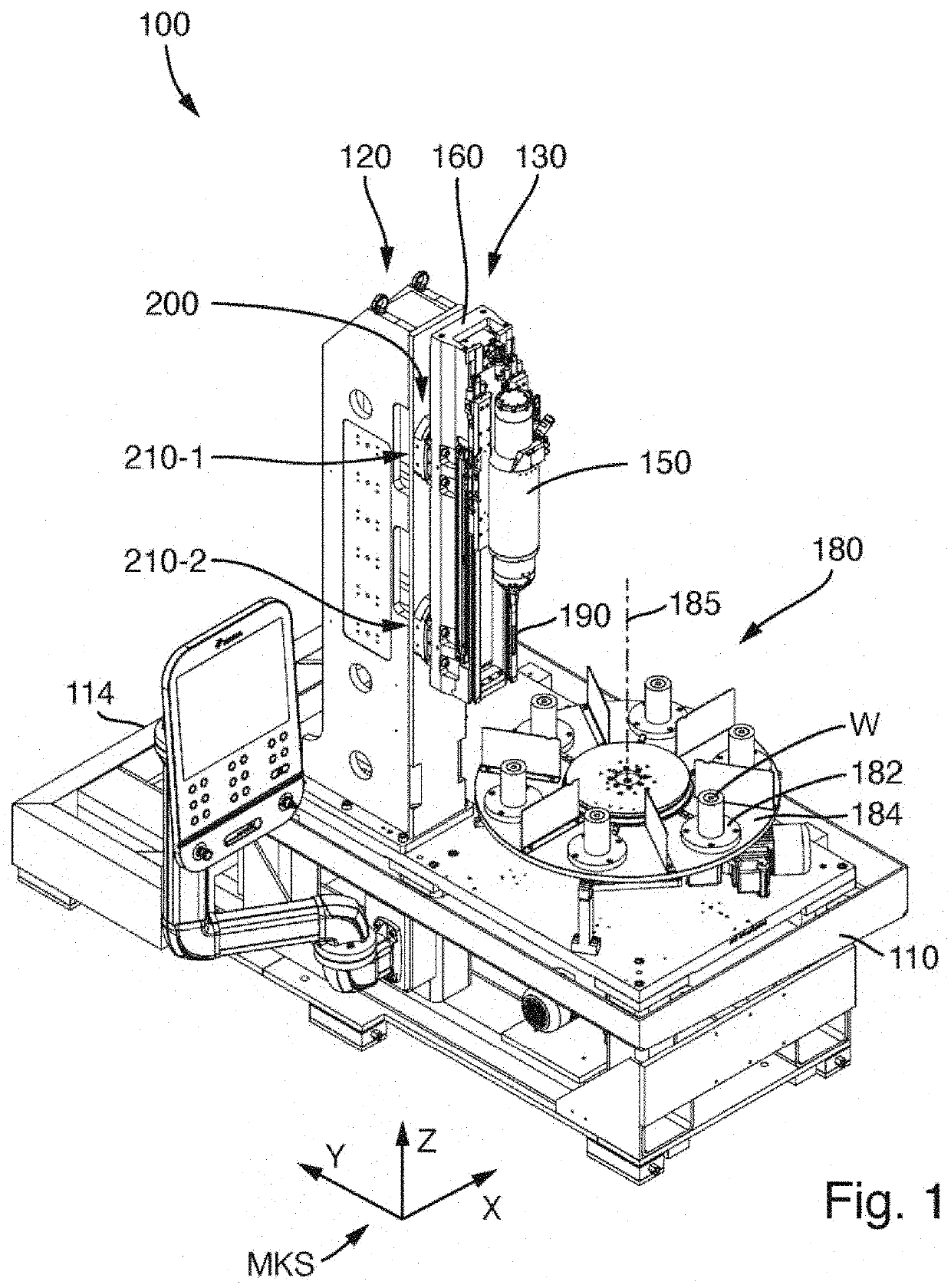

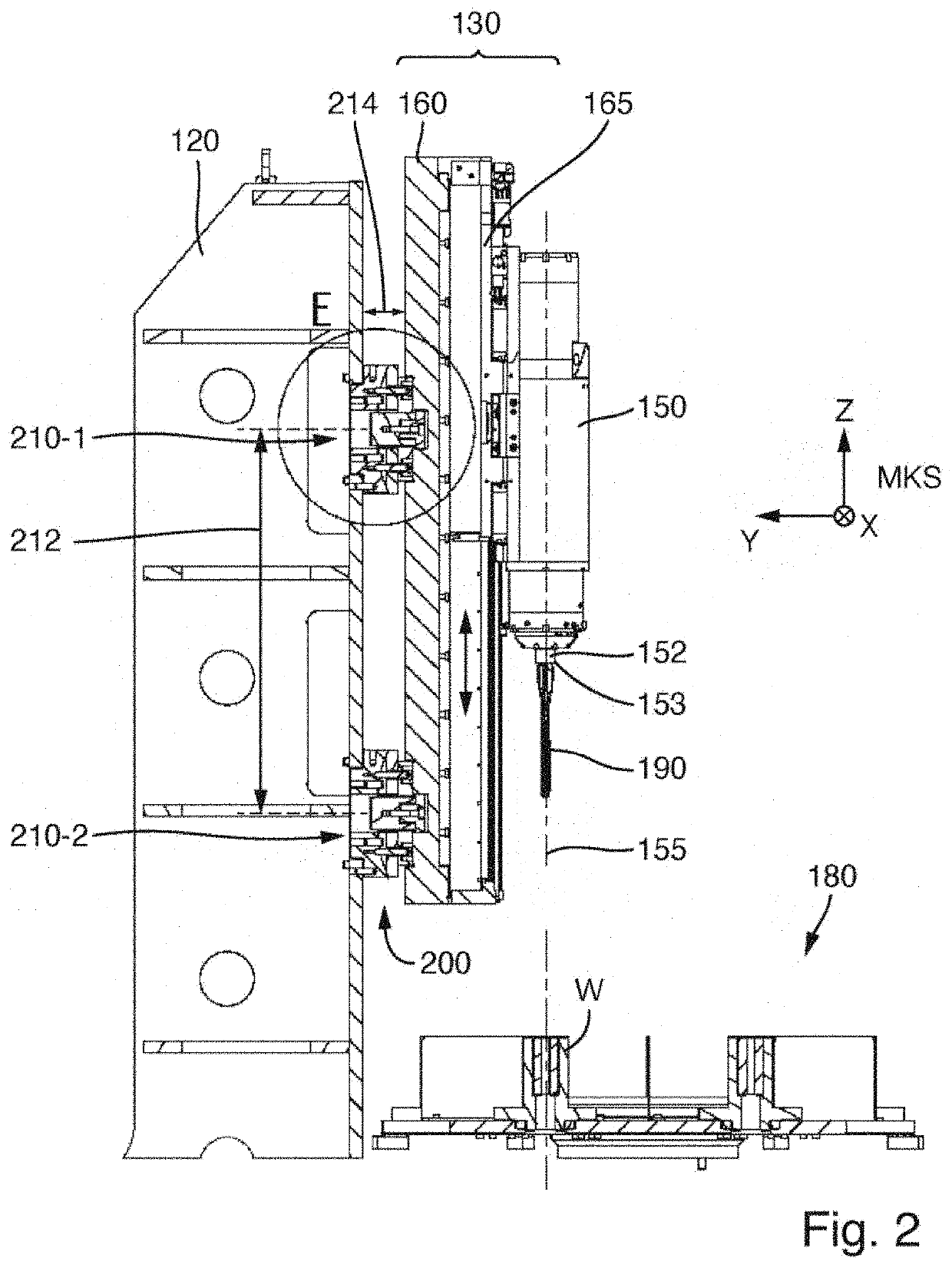

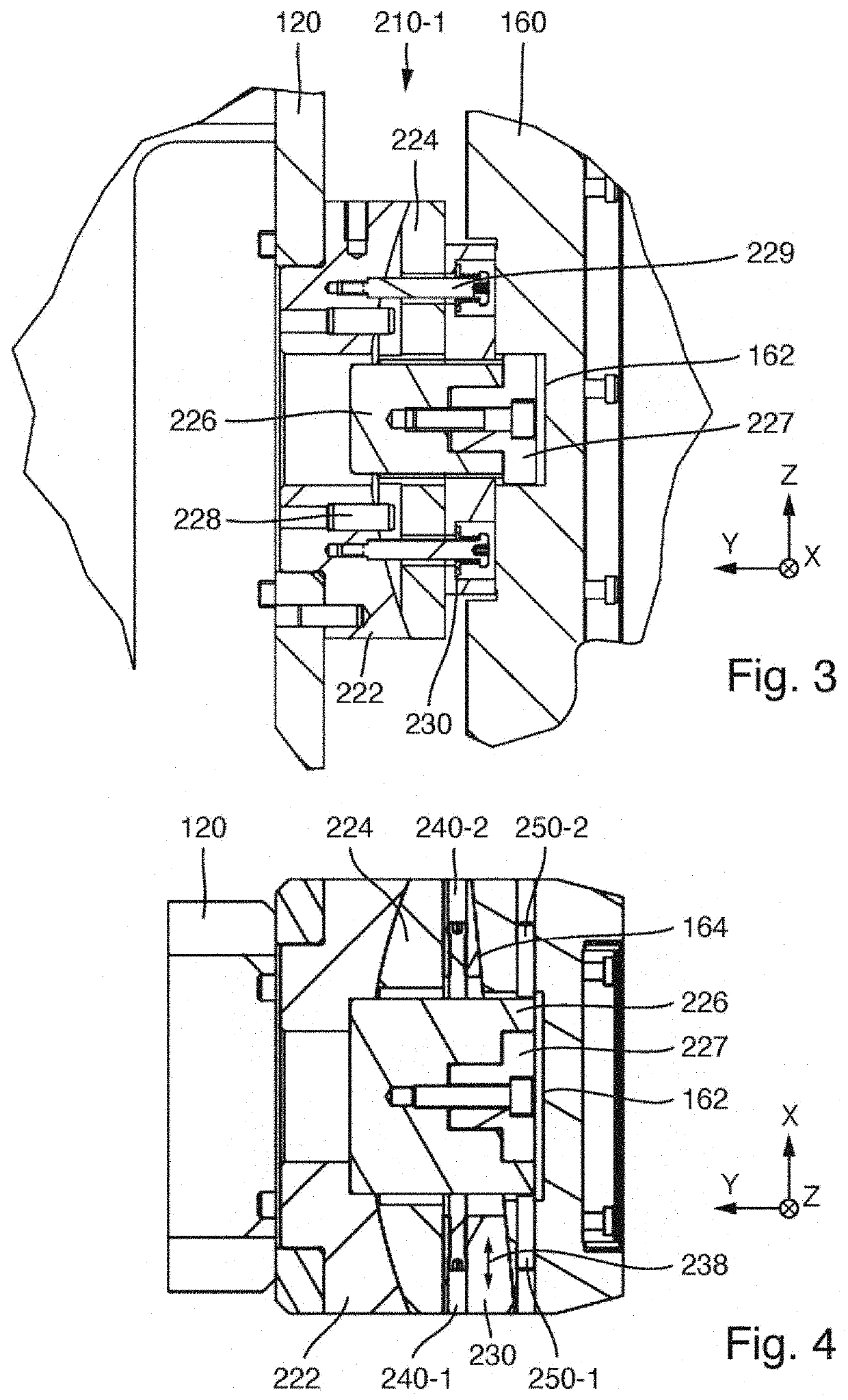

[0037]FIG. 1 shows an oblique perspective view of a honing machine 100 according to an exemplary embodiment. FIG. 2 shows a vertical section through a honing unit arranged on the support structure of the honing machine and components of a rotary table transport system. In the configuration shown, the honing machine has only a single honing unit. A second support structure with a second honing unit for machining the same workpieces may be provided.

[0038]The honing machine 100 has a substantially rectangular machine base 110 with a frame and a base plate which is or should be oriented horizontally in the case of a fully set-up honing machine. The rectangular base plate is somewhat longer in the first direction (longitudinal direction) running parallel to the y axis of the machine coordinate system MKS than in the second direction (transverse direction) which is perpendicular thereto and which runs parallel to the x axis of the machine coordinate system. Close to the rear side 114 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com