Honing feeding mechanism and vertical honing machine with same

A feeding mechanism and honing technology, which is applied in honing machine tools, parts of grinding machine tools, manufacturing tools, etc., can solve the problems of poor honing processing adaptability, single feeding mode of honing feeding mechanism, and poor honing quality, etc. Honing efficiency, improving honing accuracy, and improving the effect of honing surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

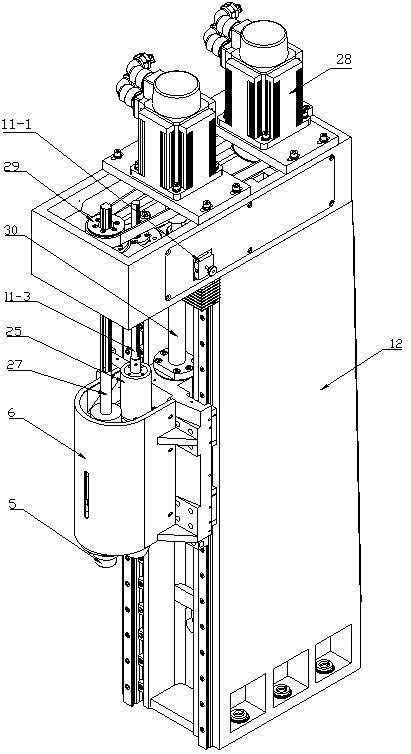

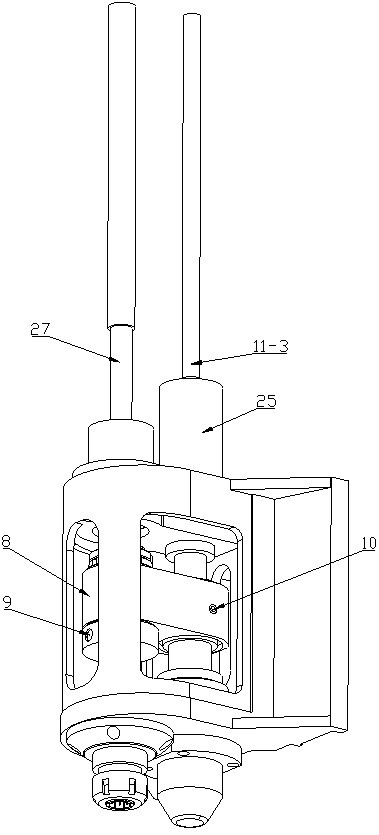

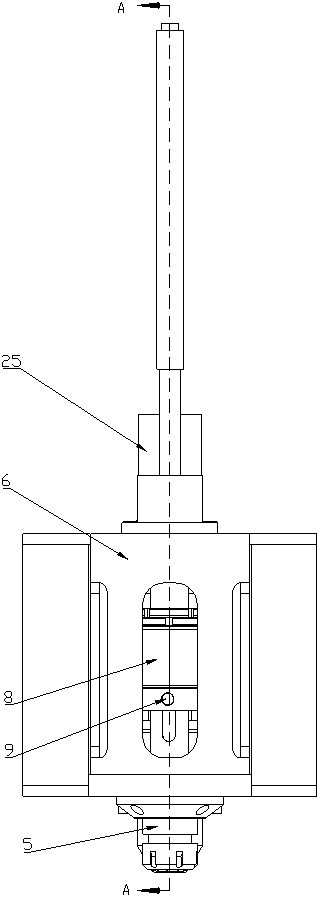

[0031] Example 1, such as figure 1 , 2 , 3, 4 and 5, a honing feed mechanism, including a feed rod 1, a linkage mechanism, a feed drive mechanism, a feed hollow shaft 2, a central inner shaft 3 and a feed elastic member 4, the feed rod 1 It is axially slidably arranged in the main shaft 5 of the honing machine, and the central inner shaft 3 is axially slidably threaded in the feed hollow shaft 2, and the feed drive mechanism acts on the central inner shaft 3 for driving the center The inner shaft 3 is pushed and pulled in the feed hollow shaft 2, and the feed elastic member 4 is placed between the feed hollow shaft 2 and the central inner shaft 3 to pass the push-pull feed force of the central inner shaft 3 through the feed The elastic force of the elastic member 4 is transmitted to the hollow feed shaft 2, and the hollow feed shaft 2 drives the feed rod 1 to push and pull the feed synchronously through the linkage mechanism.

[0032] The hollow feed shaft 2 is axially slida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com