Machining method for cutting inner hole of grinding wheel

A processing method and technology for cutting grinding wheels, which are applied in the field of mechanical processing, can solve the problems of inability to accurately control the precision of the inner hole of the grinding wheel blank, affect the precision of the inner hole of the grinding wheel blank, and low EDM efficiency, and achieve small deformation, small stress concentration, and Effect of low surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

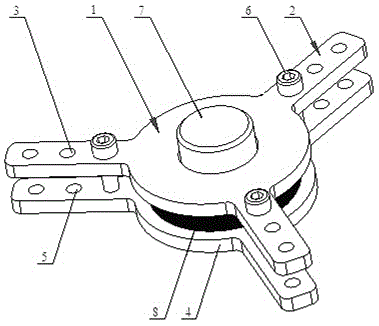

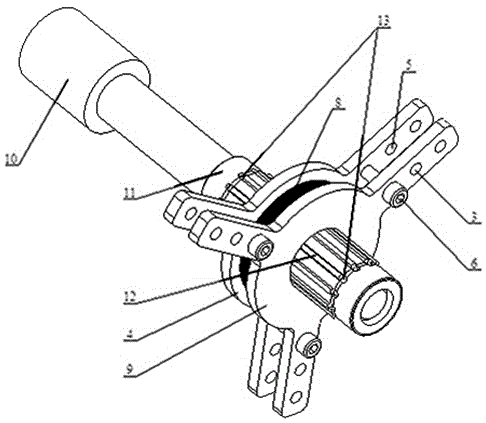

[0022] A method for machining an inner hole of a cutting wheel, comprising the following steps:

[0023] (1) Put 12 metal-bonded diamond stones into the honing head with a specification of D60mm in sequence, and fix the two ends of the stones with rubber rings, and fasten the honing head with the stones installed on the main shaft of the honing machine;

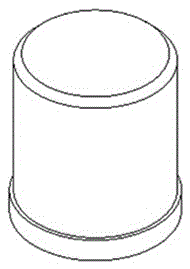

[0024] (2) Fix the grinding wheel blank with an inner hole diameter of 59.90 mm on the honing fixture, set the honing fixture with the fixed grinding wheel blank on the honing head, and lock the honing fixture on the honing machine to keep it still; among them, the grinding wheel blank The depth of the superimposed inner hole is 12mm;

[0025] (3) Adjust the rotation speed of the honing head around the axial centerline of the honing head to 550 rpm, and the reciprocating times of the honing head along the axial direction of the inner hole of the grinding wheel blank to 55 times / min;

[0026] (4) The inner hole of the grindin...

Embodiment 2

[0032] A method for machining an inner hole of a cutting wheel, comprising the following steps:

[0033] (1) Put 8 metal-bonded cubic boron nitride whetstones into the honing head with a specification of D50mm in turn, fix the two ends of the whetstone with rubber rings, and fasten the honing head with the whetstone installed on the main shaft of the honing machine;

[0034](2) Fix the grinding wheel blank with an inner hole diameter of 49.88 mm on the honing fixture, set the honing fixture with the fixed grinding wheel blank on the honing head, and lock the honing fixture on the honing machine to keep it still; among them, the grinding wheel blank The superimposed inner hole depth range is 18mm;

[0035] (3) Adjust the speed of the honing head to 700 rpm, and the number of reciprocations of the honing head to 60 times / min;

[0036] (4) The inner hole of the grinding wheel honed in step (3) is tested for dimensional accuracy with a cylindrical plug gauge, then the grinding wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com