Self-limited universal honing rod

A honing and self-limiting technology, which is applied in the direction of honing machine tools, metal processing equipment, manufacturing tools, etc., can solve the problems of not too large floating amount, high equipment cost, complicated guiding system, etc., and achieve simple manufacturing, low processing cost, saving The effect of the de-guiding system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below in conjunction with the accompanying drawings.

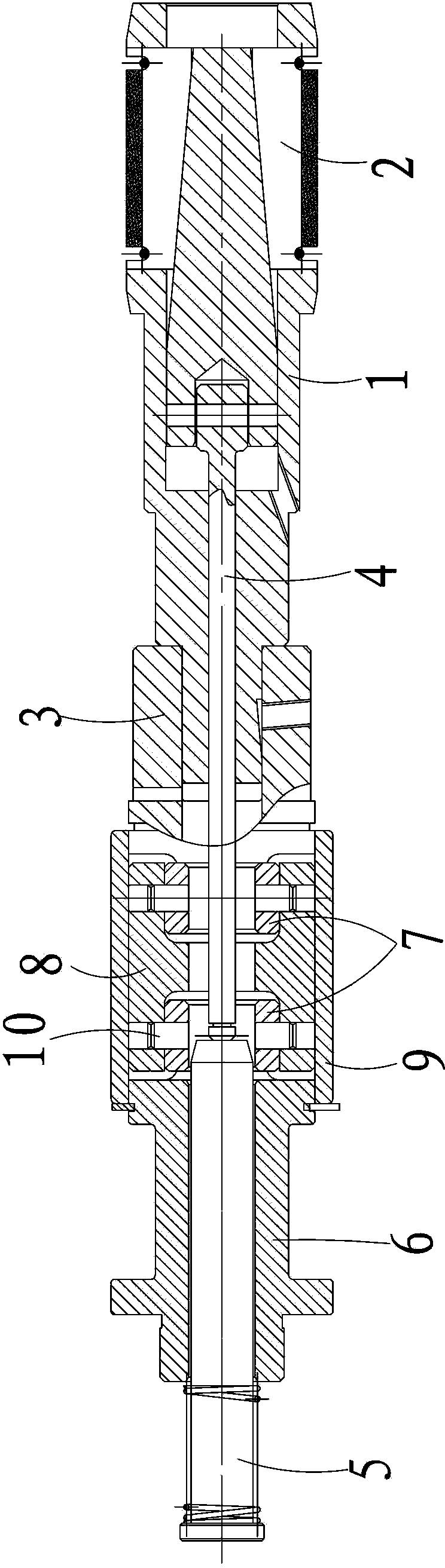

[0017] as attached figure 1 As shown, a self-limiting universal honing rod includes an outer tube 1, a honing head 2 connected to one end of the outer tube 1, a lower joint 3 fixedly connected to the other end of the outer tube 1, and a The push rod 4 inside the pipe 1, the push rod 5 connected with the push rod 4, the upper joint 6 sleeved on the push rod 5, and the honing rod also includes one or more cross blocks 7 sleeved on the push rod 4 , a connecting pipe 8 fixedly sleeved outside one or more cross blocks 7, a limiting sleeve 9 sleeved outside the connecting pipe 8, and the honing rod also includes a plurality of cylindrical pins 10 for fixing the connecting pipe 8 and the cross block 7 .

[0018] Both ends of the limiting sleeve 9 are respectively connected with the upper joint 6 and the lower joint 3 . Cross block 7 has two or three. Two to three cross b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com