Flexible unit and flexible wrist

A flexible and limiting technology, applied in the field of mechanical wrists, can solve the problems of limited flexible center position, damage, tearing of the rubber layer, etc., and achieve the effect of improving stability and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

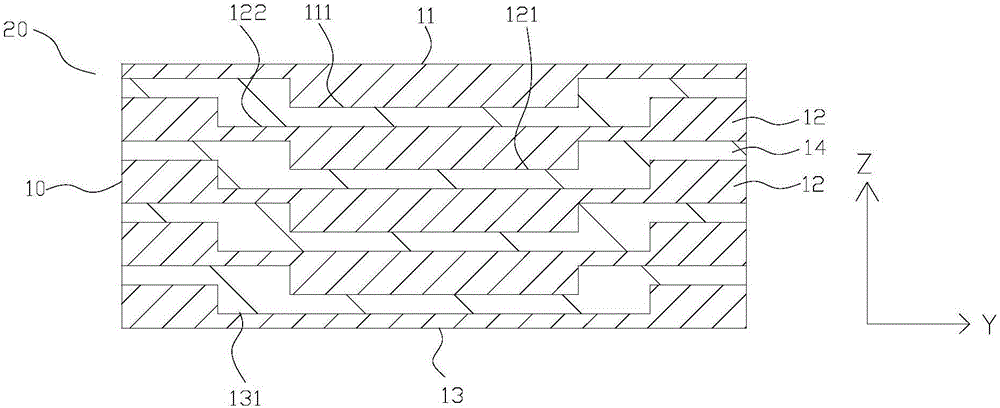

[0034] Such as figure 1 The shown flexible unit 20 includes a strip-shaped flexible body 10. The flexible body 10 has a head stopper 11 and a plurality of middle stoppers 12 stacked at intervals along the length direction of the flexible body 10 and all have rigidity. and a tail limiter 13, the head limiter 11 and the tail limiter 13 are separately arranged at both ends of the flexible body 10; the side of the middle limiter 12 close to the head limiter 11 is recessed to form a first blind hole 122 , the first limiting portion 121 formed on the other side of the middle limiting member 12 near the tail limiting member 13; the first limiting portion 121 of one of the two adjacent middle limiting members 12 The bit portion 121 extends into the first blind hole 122 of the other middle stopper 12, and is used to abut against the wall of the first blind hole 122; the side part of the head stopper 11 close to the middle stopper 12 The protrusion forms a second stopper 111, and the s...

Embodiment 2

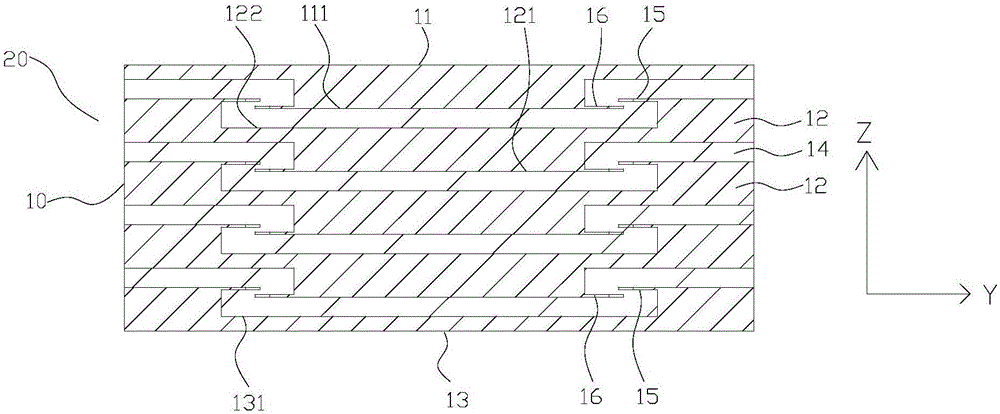

[0039] Such as figure 2 As shown, the difference between the second embodiment and the first embodiment is that the top ends of the walls of the first blind hole 122 and the second blind hole 131 in this embodiment are provided with an annular flange 15, and each first limiting portion 121 The ring mouth of the annular flange 15 extends into the first blind hole 122 and the second blind hole 131 respectively, and the outer walls of the ends of the first limiting parts 121 extend into the first blind hole 122 and the second blind hole 131 Both are provided with an annular clamping portion 16; the second limiting portion 111 extends into the first blind hole 122 from the ring mouth of the annular flange 15, and the second limiting portion 111 extends into the end outer wall of the first blind hole 122. There is an annular clamping part 16; since the annular clamping part 16 of the first limiting part 121 can abut and fit with the side wall of the annular flange 15 facing the bl...

Embodiment 3

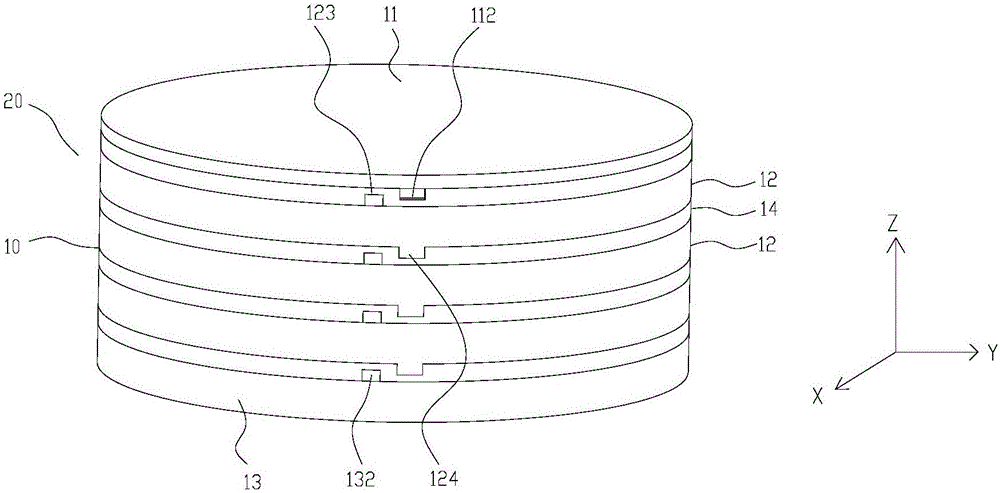

[0041] Such as image 3 As shown, the difference between the third embodiment and the second embodiment is that the two sides of the middle limiting member 12 in this embodiment are respectively provided with a first convex portion 123 and a second convex portion 124, which are close to the middle limiting member 12 The side portions of the head limiter 11 and the tail limiter 13 are respectively provided with a third protrusion 112 and a fourth protrusion 132, therefore, when the flexible body 10 rotates along its axial direction, two adjacent middle limiters The first convex portion 123 of one of the middle limiting pieces 12 in the pieces 12 can abut against the second convex portion 124 of the other middle limiting piece 12, and the middle limiting piece adjacent to the head limiting piece 11 The first protrusion 123 of 12 can be abutted with the third protrusion 112 of the head limiter 11, and the second protrusion 124 of the middle limiter 12 adjacent to the tail limiter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com