Method for finely processing a cylindrical inner surface

a technology of inner surface and processing method, which is applied in the direction of grinding machine, grinding/polishing apparatus, manufacturing tools, etc., can solve the problems of loss of abrasive action, difficult precision machining, and restricted prior art knowledge to the precision machining of a surface. achieve the effect of reducing nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

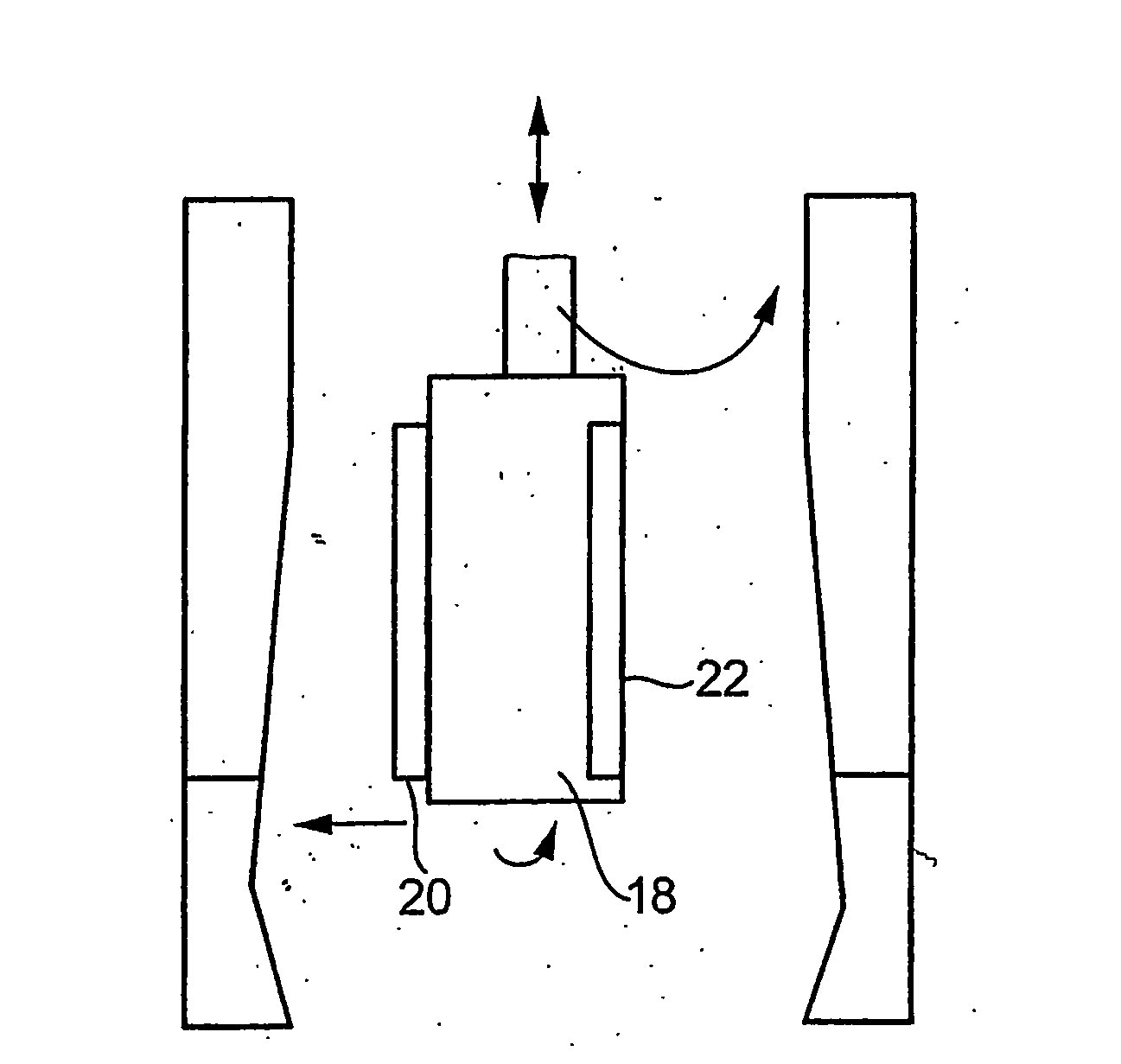

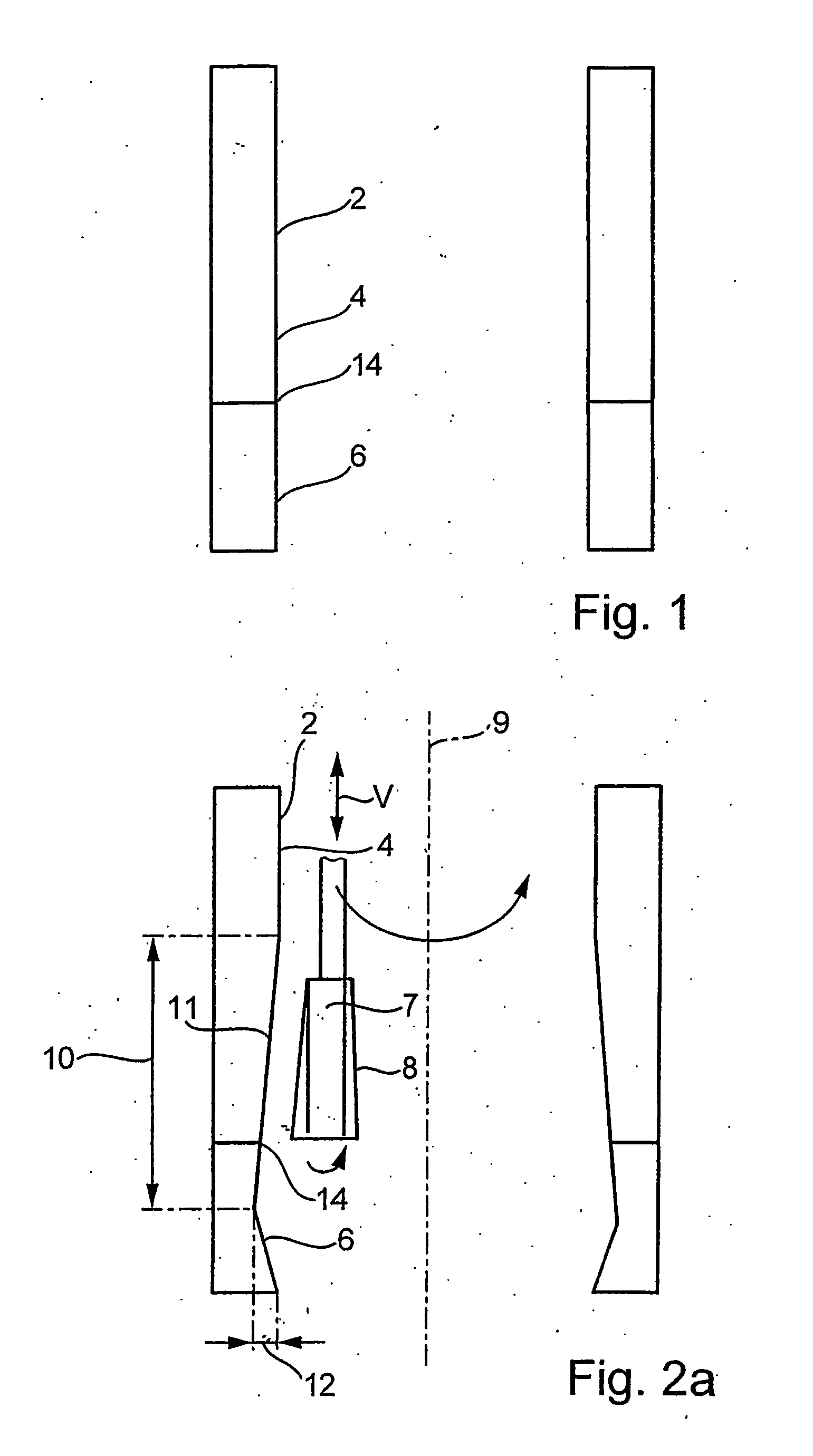

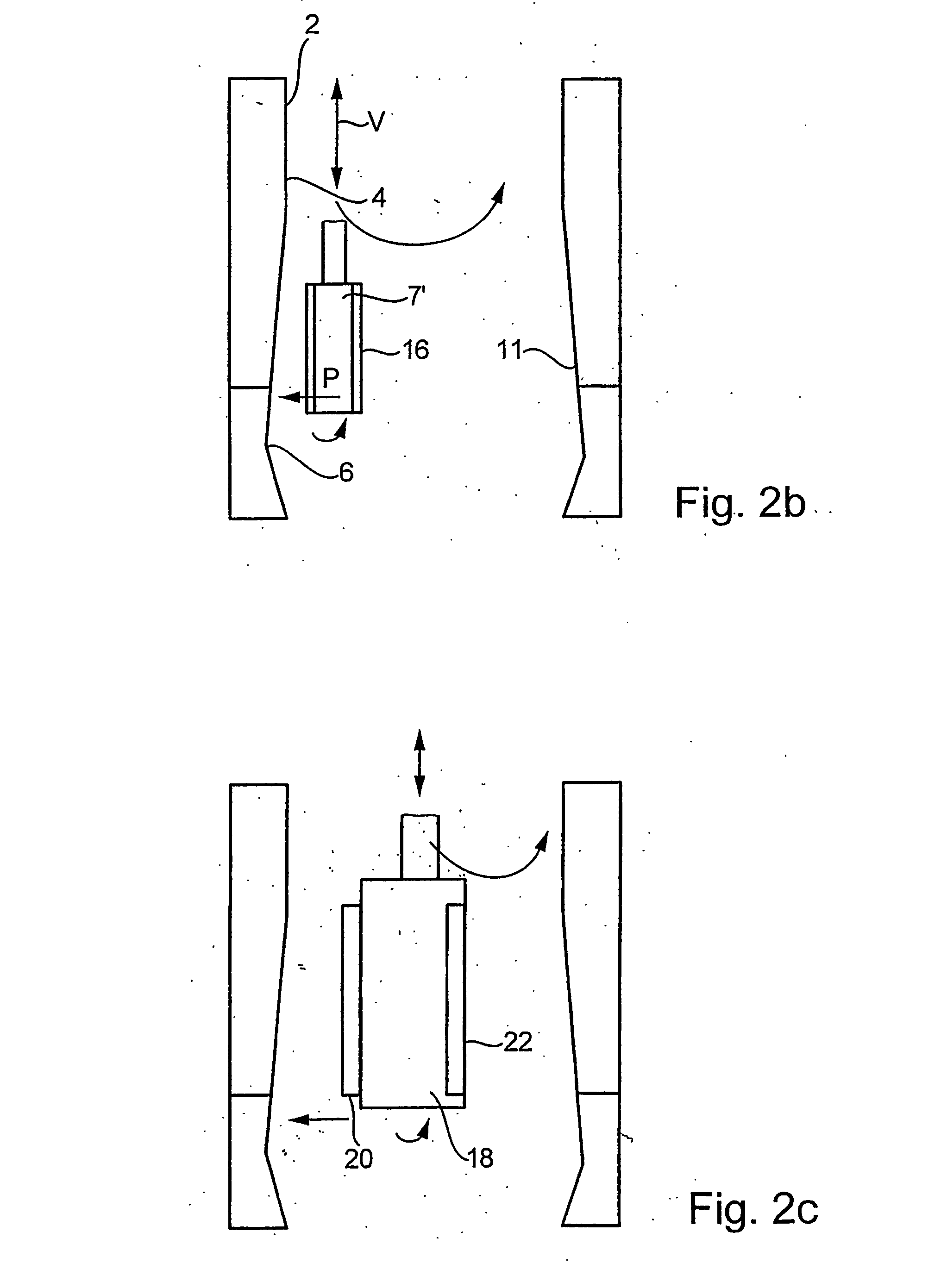

[0026] FIGS. 1 to 3 illustrate the process according to the invention in simplified form, with FIGS. 2a-c showing alternative configurations for the introduction of a cone 11.

[0027]FIG. 1 illustrates an unmachined cylinder bearing surface 2 in cross section. The cylinder bearing surface 2 is divided into a harder region 4 and a softer region 6. The transition 14 between the regions is discrete in this embodiment, but a gradual transition is also conceivable.

[0028] The harder region 4 of the cylinder bearing surface 2 is usually formed by a cylinder liner, which consists, for example, of a hypereutectic aluminum-silicon alloy. In the present example, the alloy has a silicon content of approx. 25%. The high silicon content leads to a high hardness for aluminum alloys. In the present example, the softer region 6 consists of a conventional die-cast aluminum alloy.

[0029] If appropriate, the cylinder liner is machined by preliminary turning (not shown in the figures), so that relativel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com