Detection method for familial defects of power equipment of power supply plant

A technology of electric power equipment and detection method, which is applied in the field of detection of familial defects of electric power equipment in power supply plants, can solve the problems of inability to find interrelatedness and mutual correlation, inability to find out a large number of defects and frequent occurrence of defects, and achieve the effect of reducing the occurrence rate of maintenance accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Exemplary embodiments, features, and aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

[0042] In the following, each functional module of the system will be described in detail.

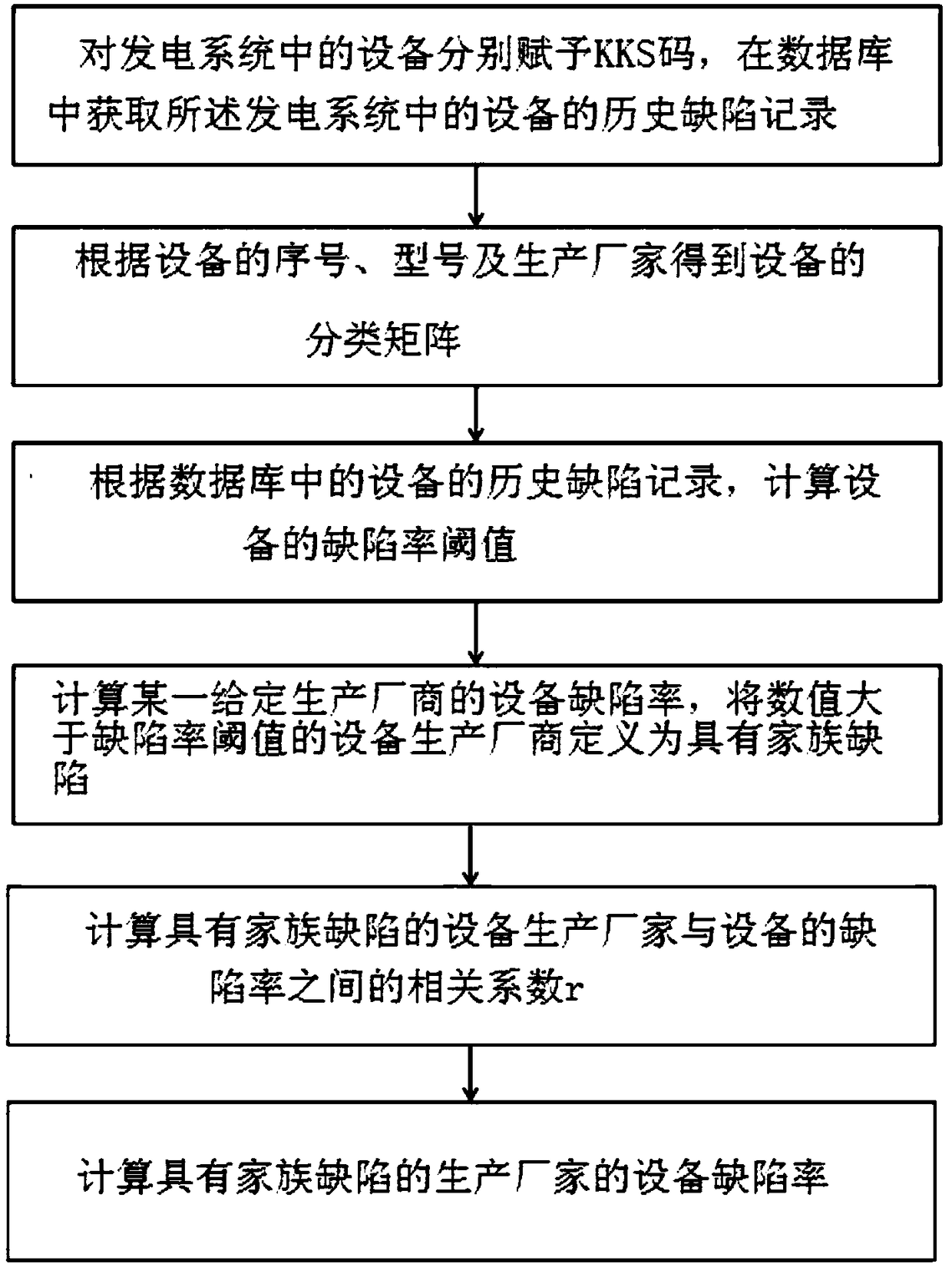

[0043] The present invention provides a detection method for familial defects ("familial defects" also referred to as "family defects") of electric equipment, such as figure 1 As shown, it includes the following steps:

[0044] S1. Use the pre-designed KKS code set to assign KKS codes to the equipment in the power generation system, obtain the historical defect records of the equipment in the power generation system in the database, and establish a corresponding relationship between the historical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com