Patents

Literature

106 results about "Work clamp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

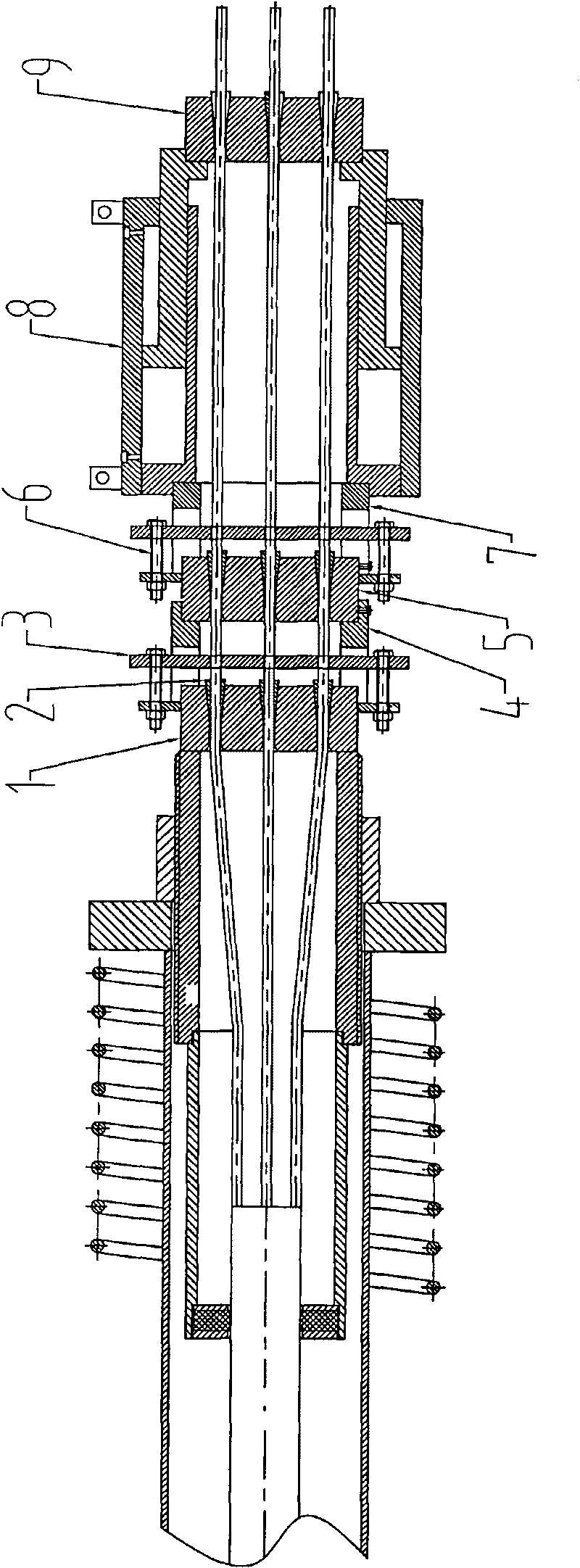

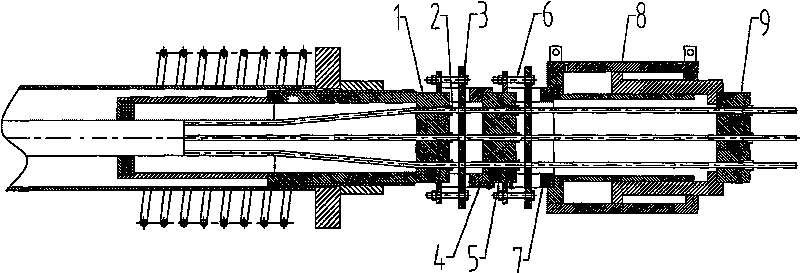

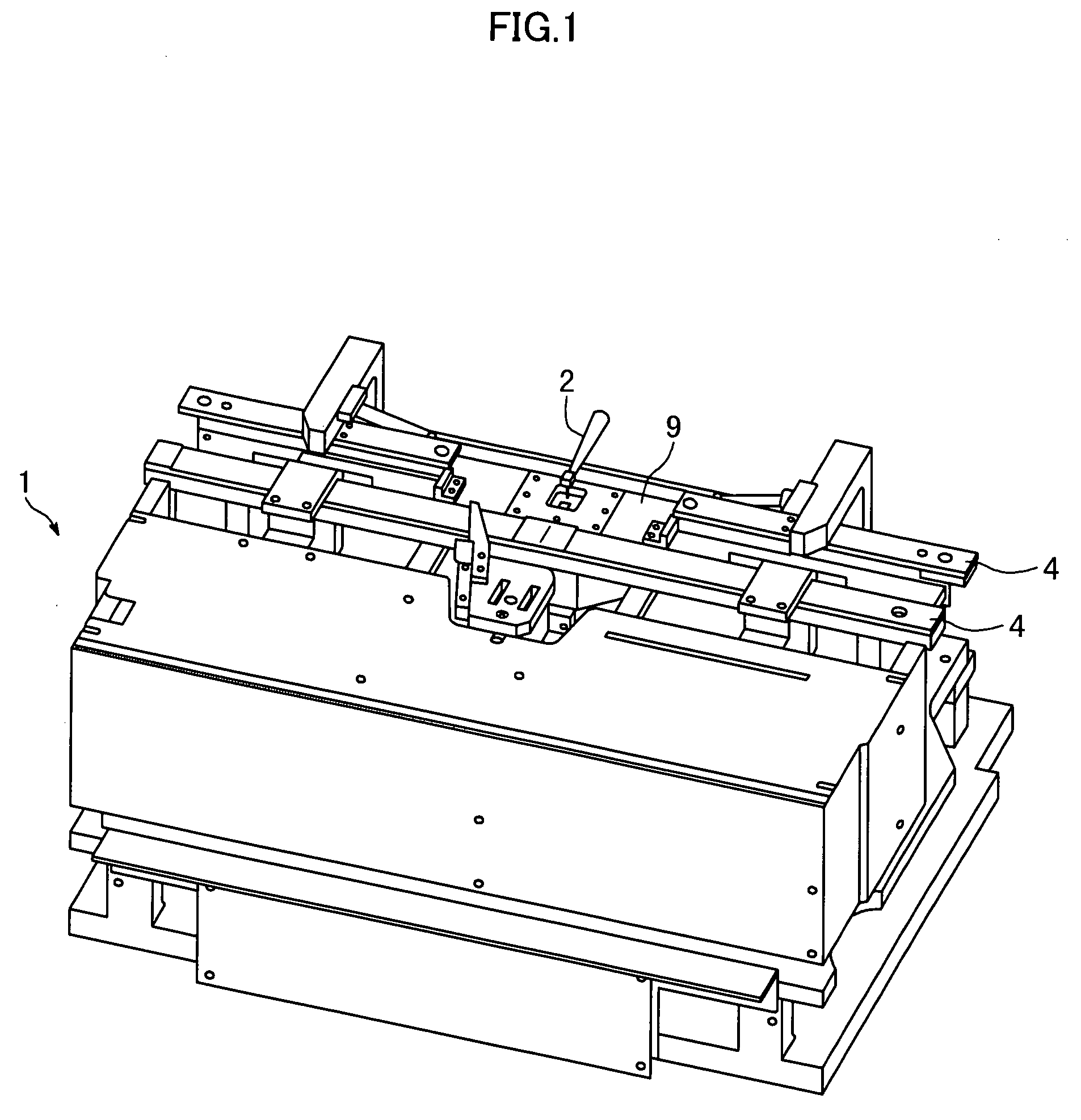

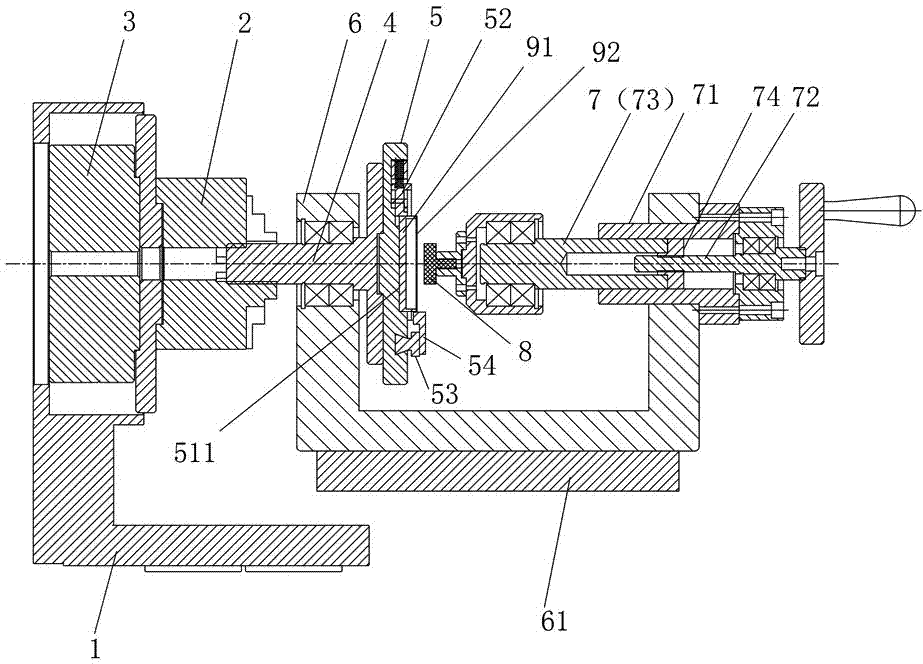

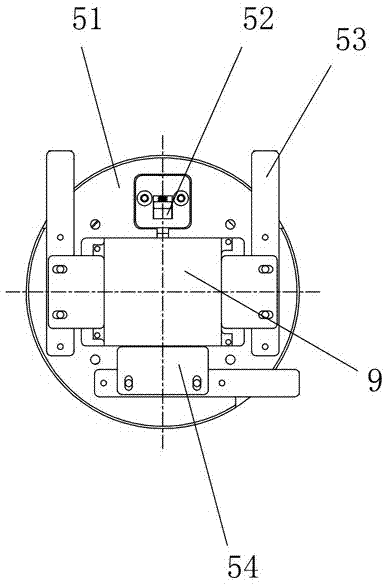

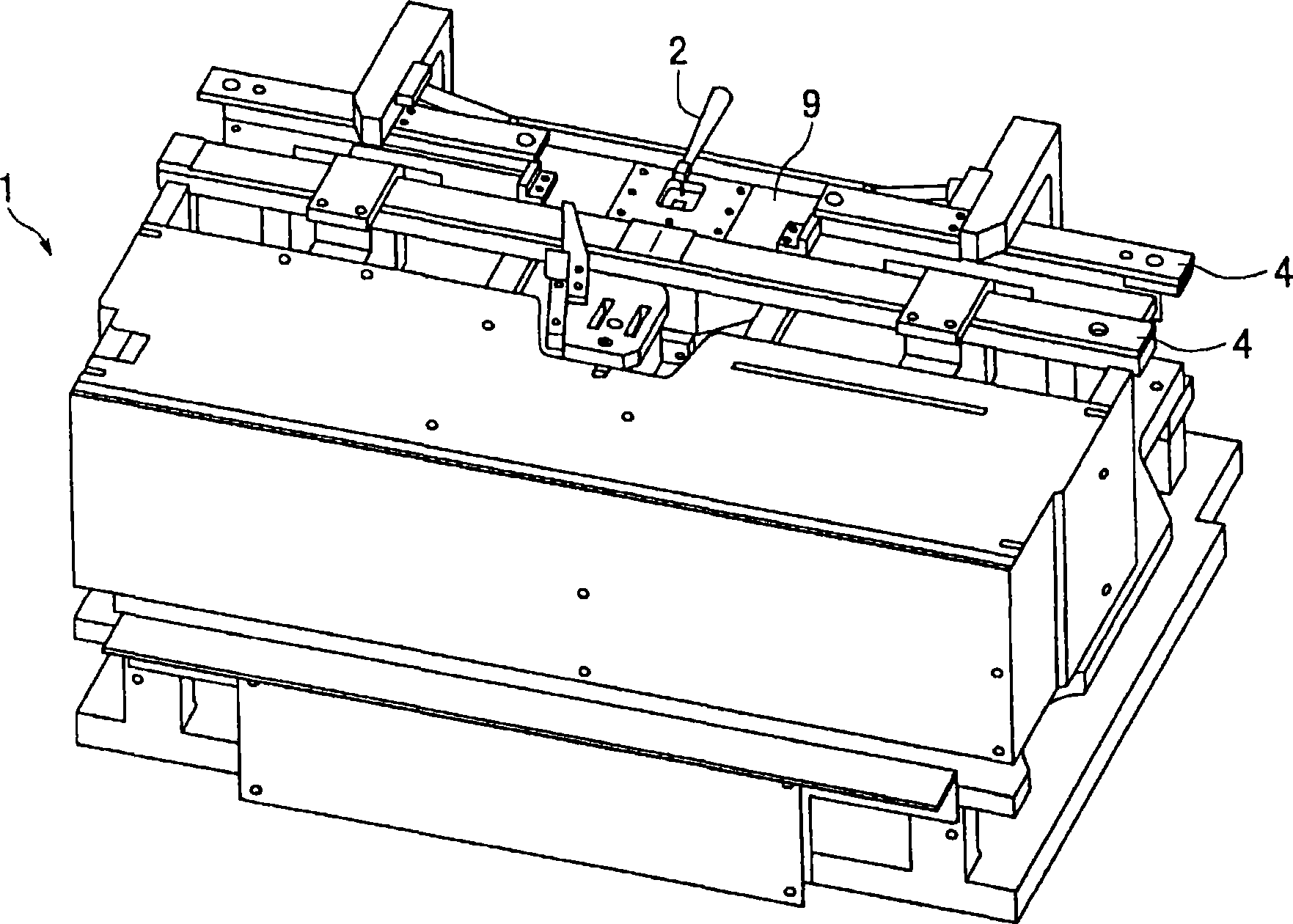

Releasing mechanism and leveling apparatus

ActiveUS20080098786A1Improve responseReduce noiseMetal-working feeding devicesWork manipulationWork rollWork clamp

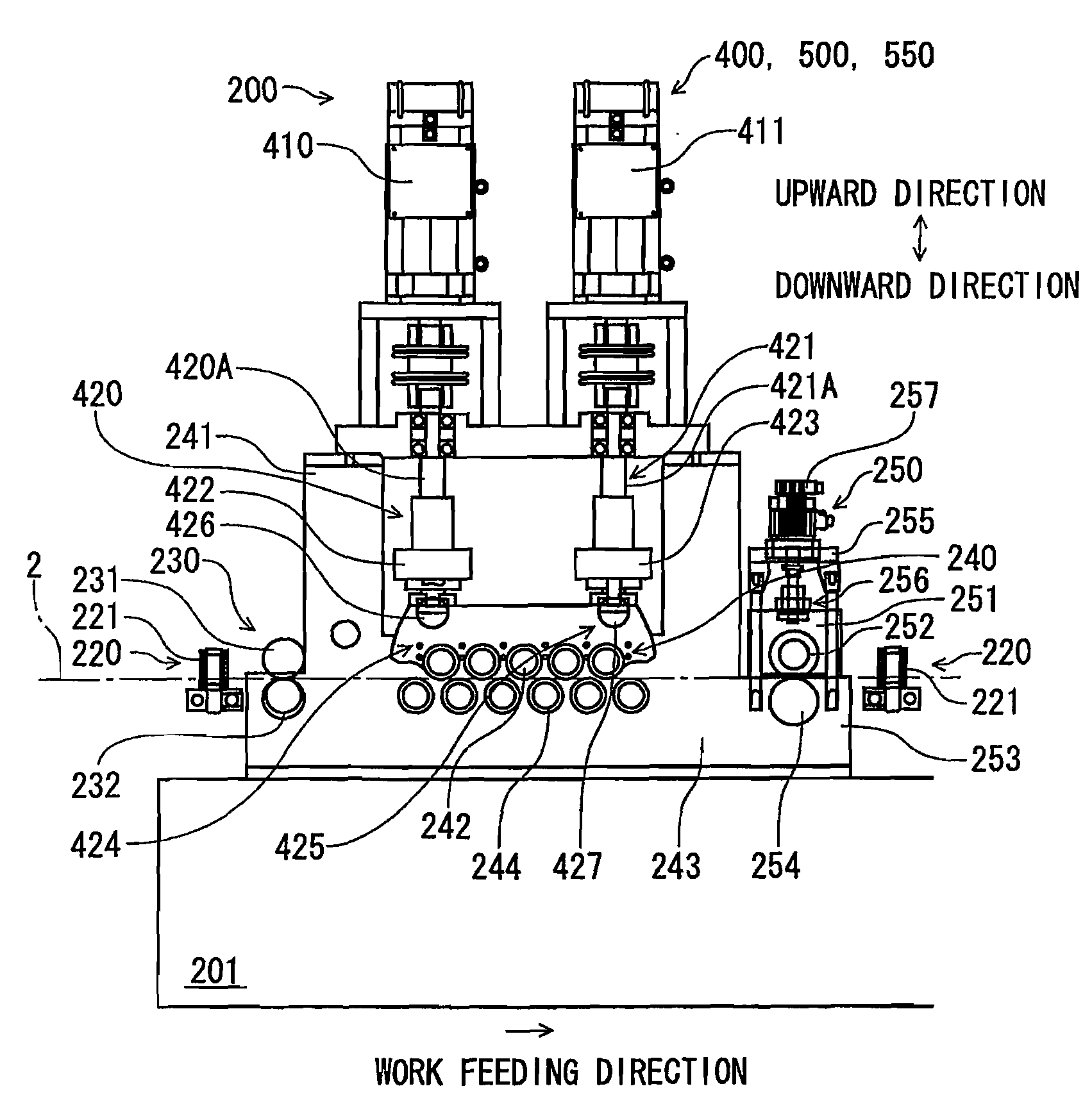

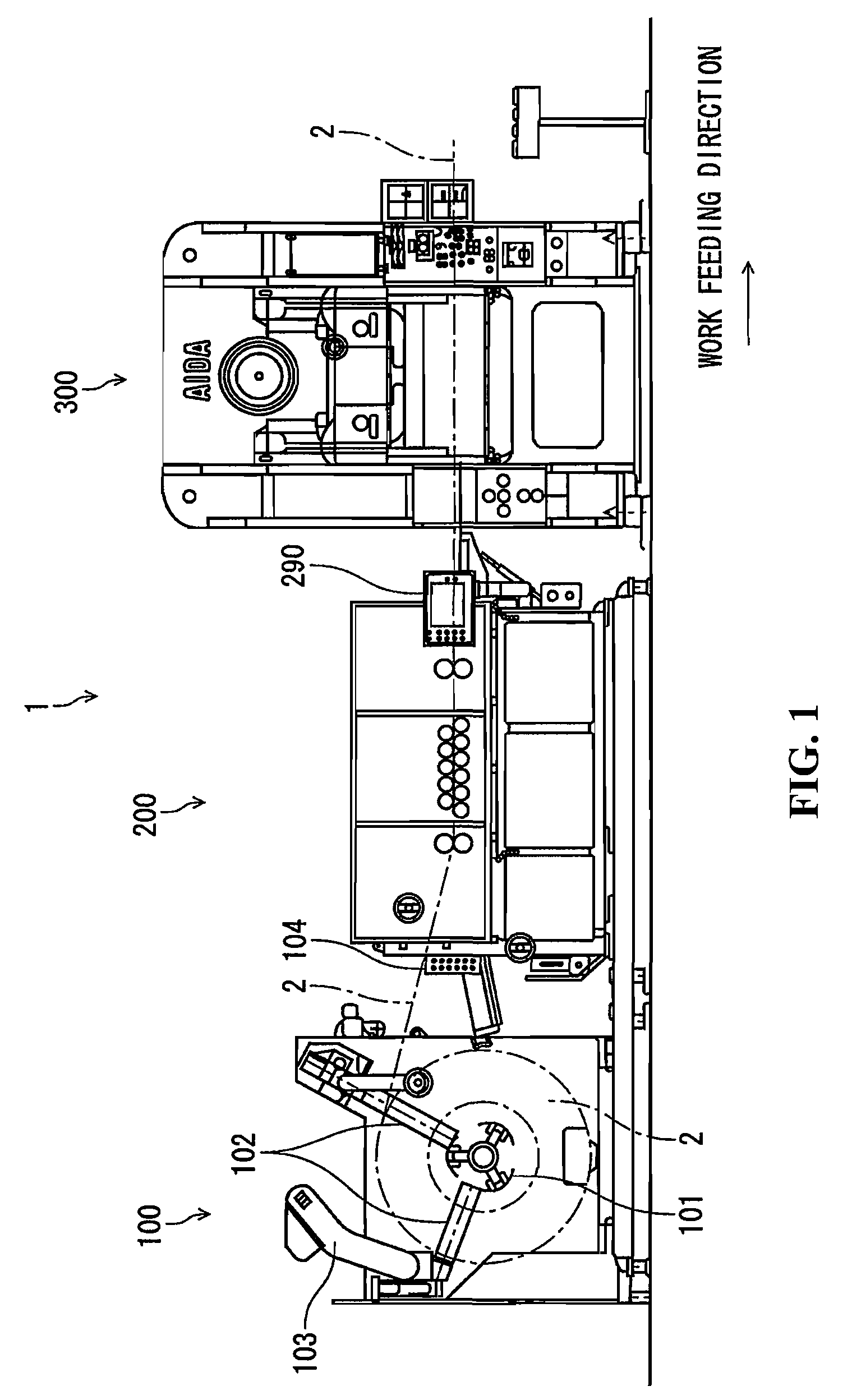

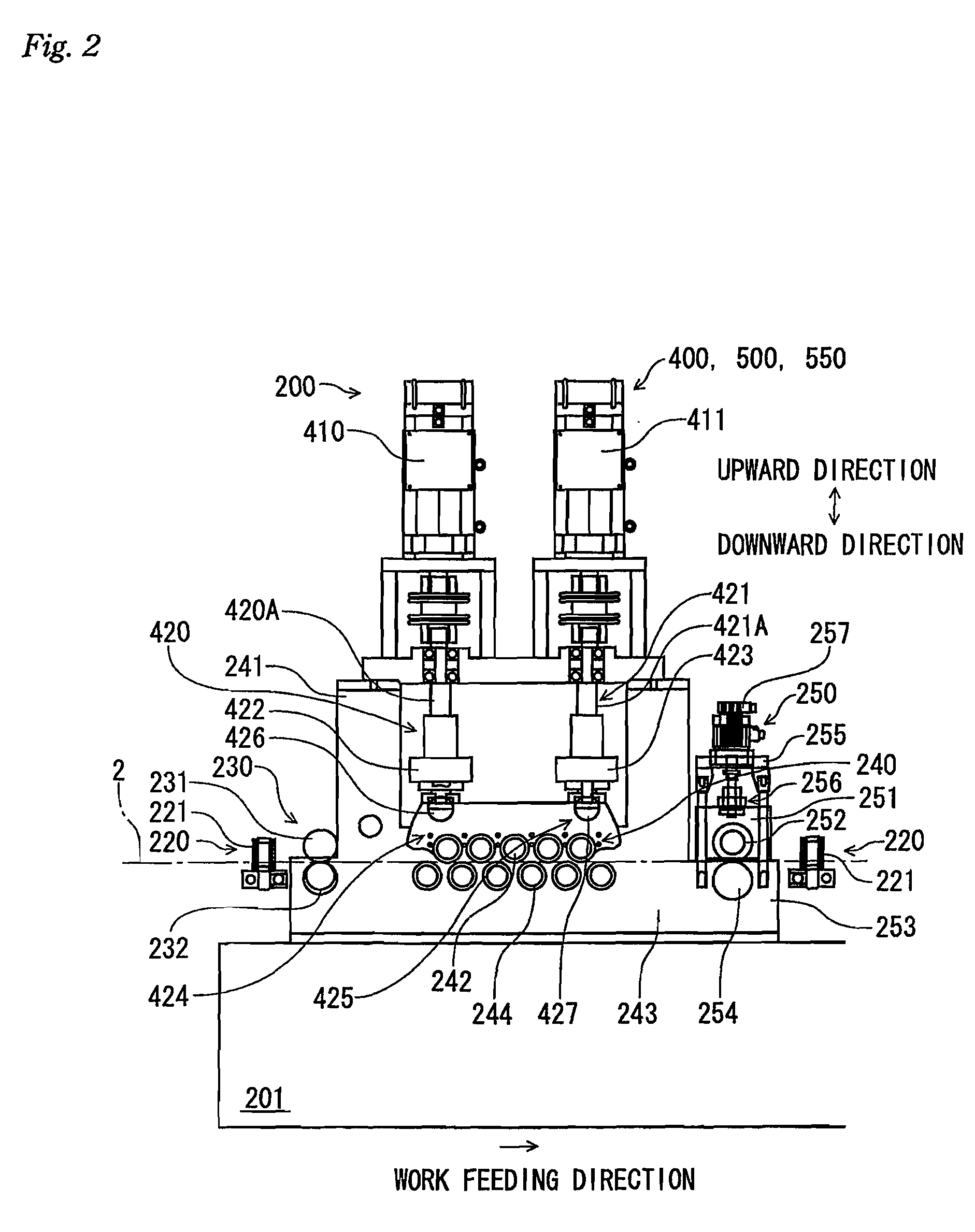

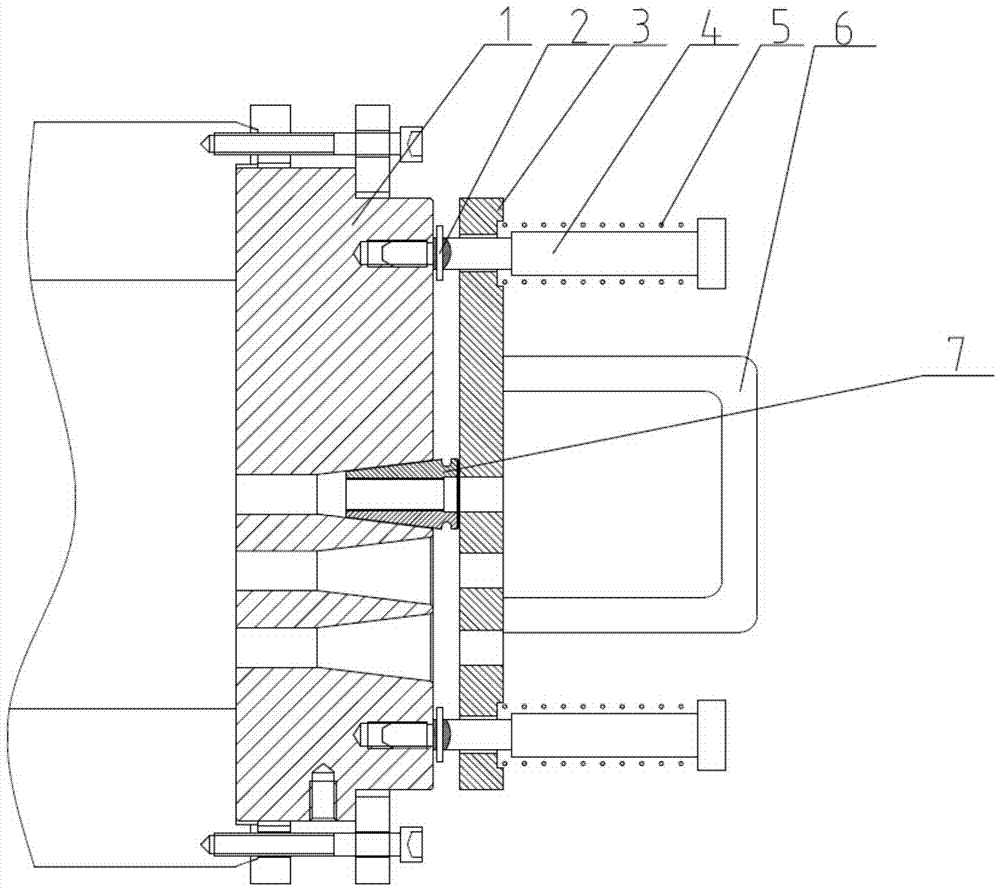

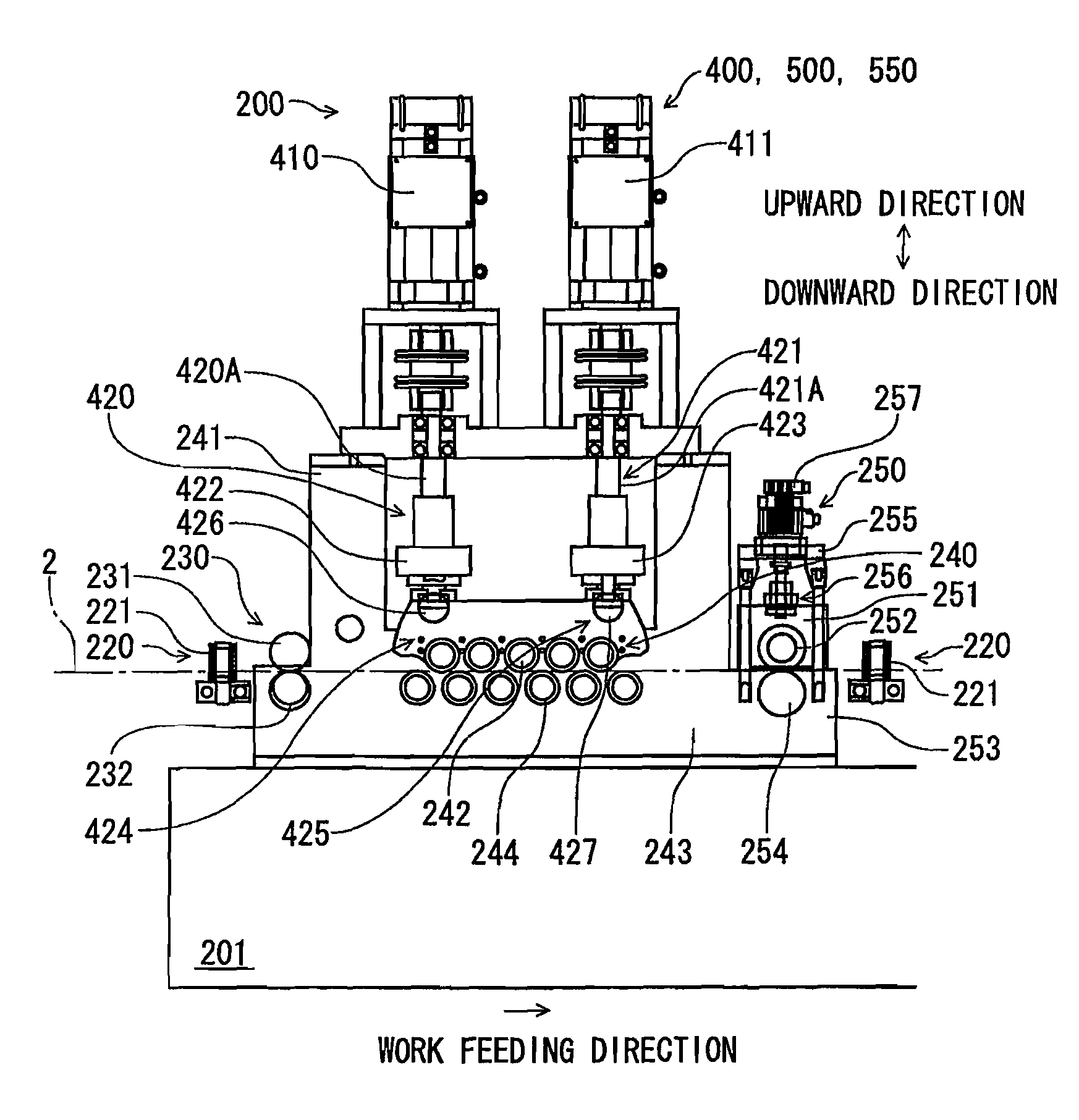

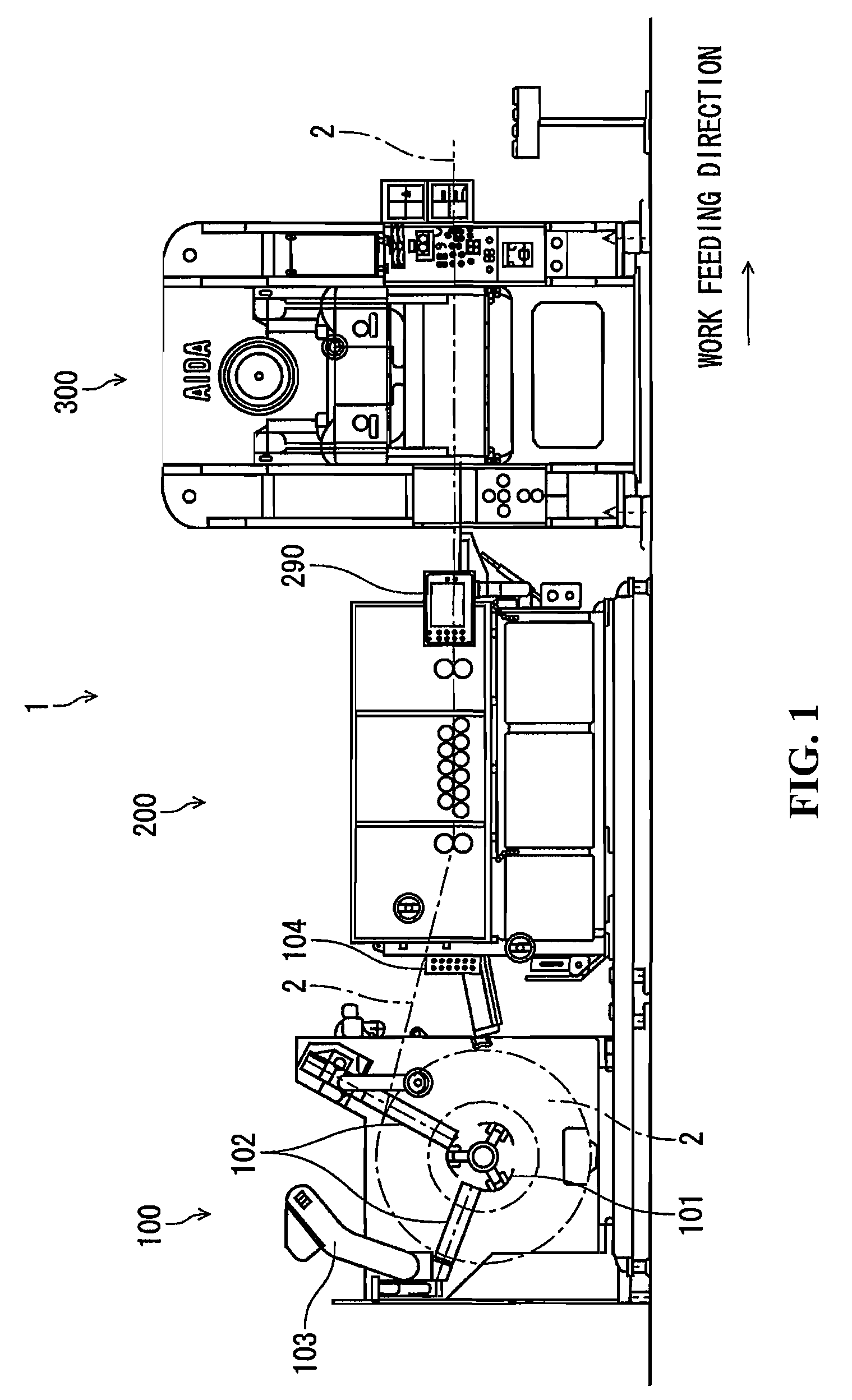

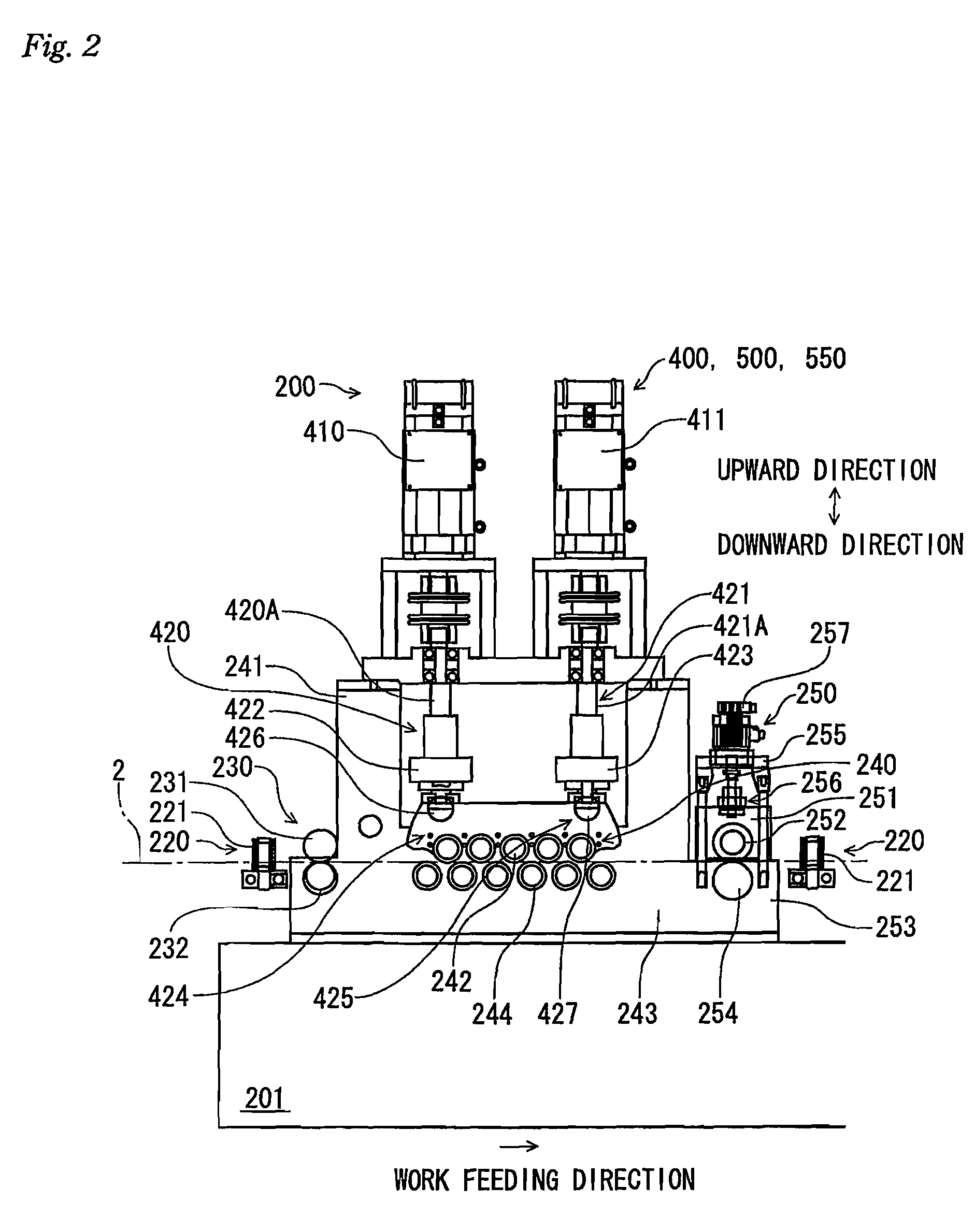

A release mechanism for use in a leveling apparatus that performs a leveling process on a work object that has been wound in a coil configuration as a result of the work object being passed between a front side work roll in contact with the front side surface of the work object and a back side work roll that is in contact with the back side surface of the work, wherein the releasing mechanism switches between a work clamp state that allows performance of the leveling process and a release state that releases the work object from the clamp state by displacing a work roll support member that supports one of the work rolls relative to the another support member to change a distance between the work rolls by utilizing rotational movement of an electric motor.

Owner:AIDA ENG LTD

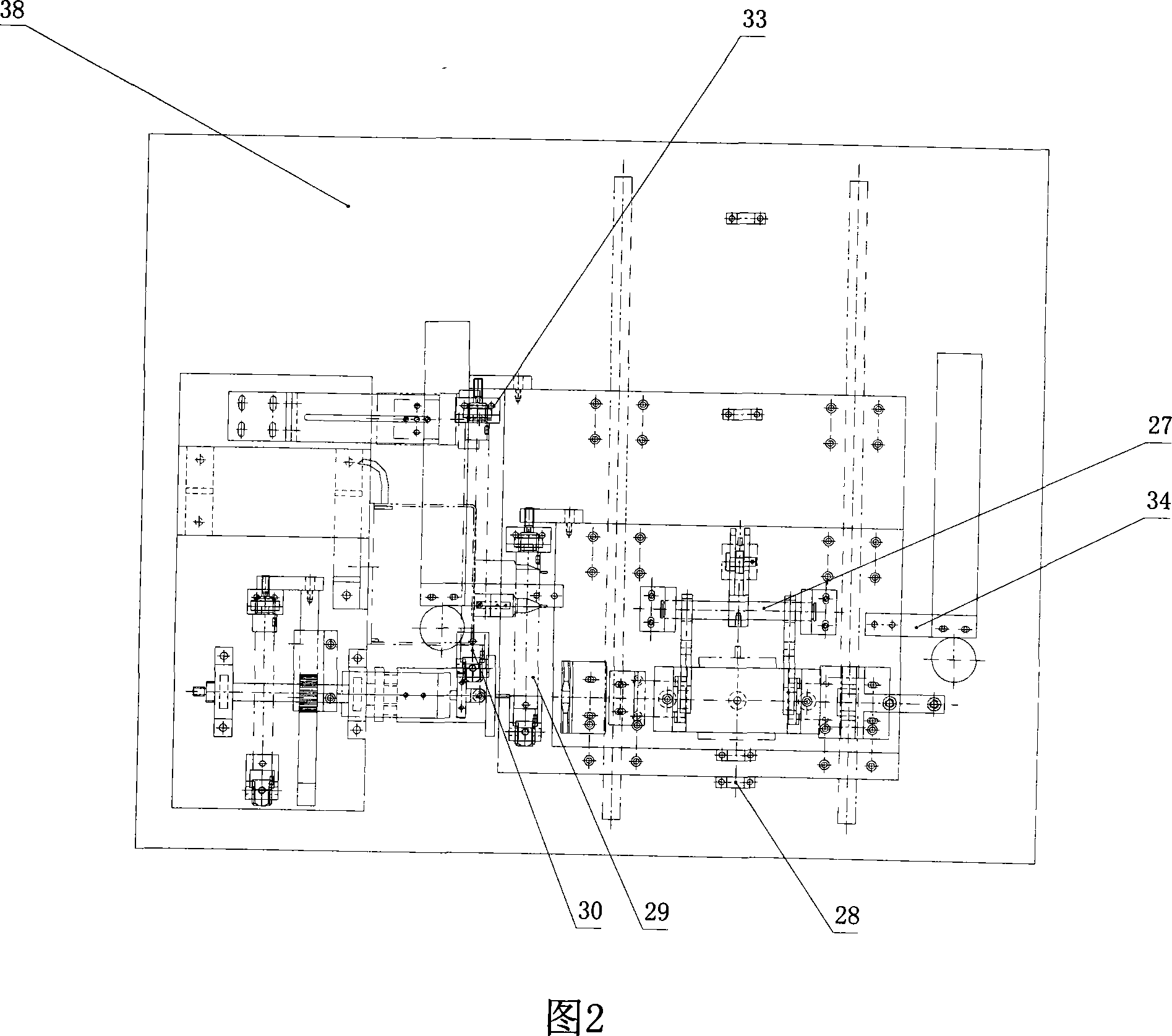

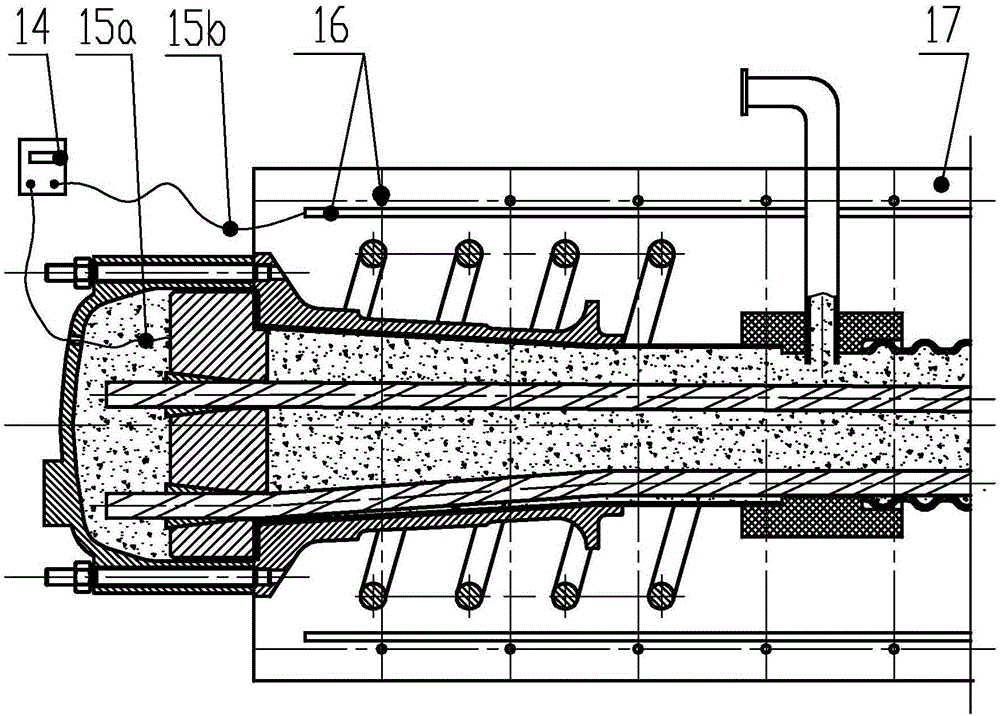

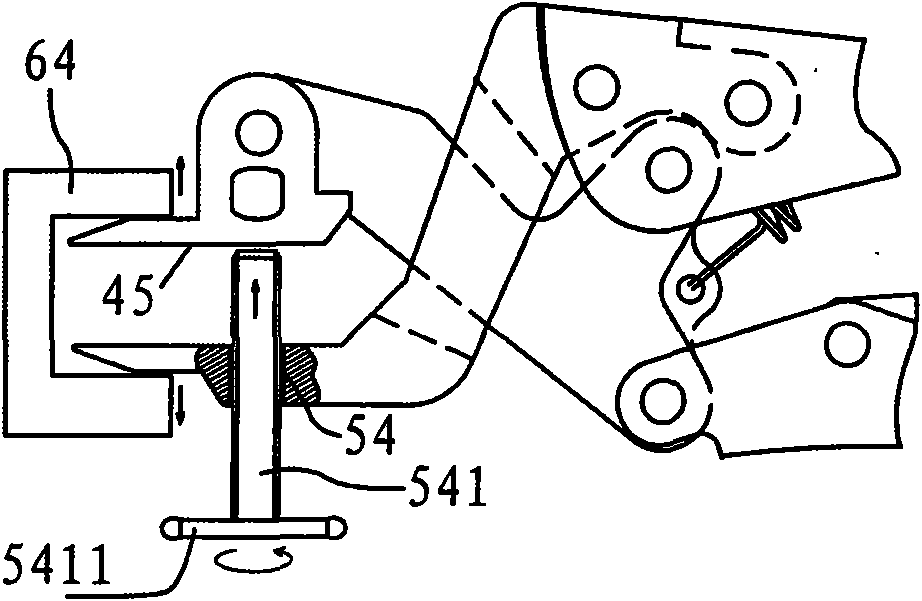

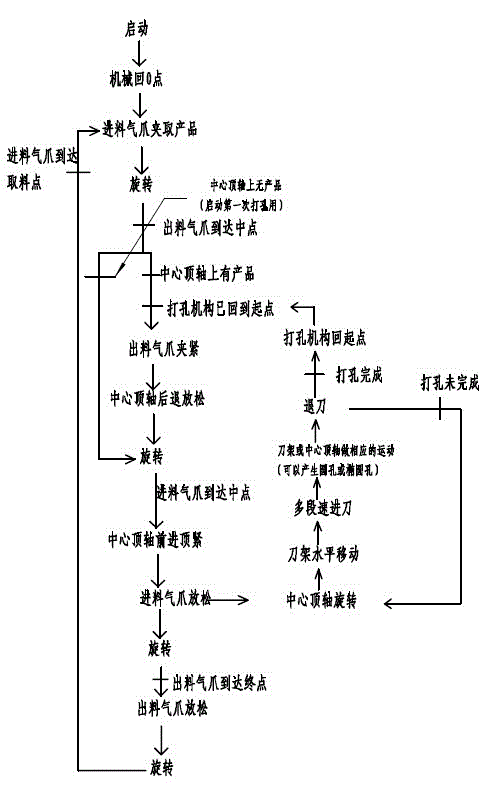

Camshaft fixture cramp and its automatically printing method

InactiveCN101209627AEasy to useA variety ofTypewritersOther printing apparatusProduction lineEngineering

The invention relates to the automobile camshaft printer technique field, in particular to a camshaft clamp and an automatic printing method used for a camshaft product line of a power plant of the automobile field. The device mainly comprises a camshaft marking system and other hardware parts, comprising a work clamp, a gas supply device and a PANEL box, etc. The method is the automatic printing method used for the camshaft work clamp and mainly aims to solve the hardware part and to solve how to improve the work clamp. And a software part mainly solves the relevant technical problems about how to control a PLC, etc. The invention has the beneficial effects that the invention can carry out an anti-error, marking and scanning treatment for different camshafts. And corresponding positions between two process holes at end faces of the camshaft and the cam are random. When the cam for positioning is adopted, the positions of two holes at the printing end face are not fixed. The invention has the advantages that the use is convenient and the variety is various, etc.

Owner:上海亚太计算机信息系统有限公司

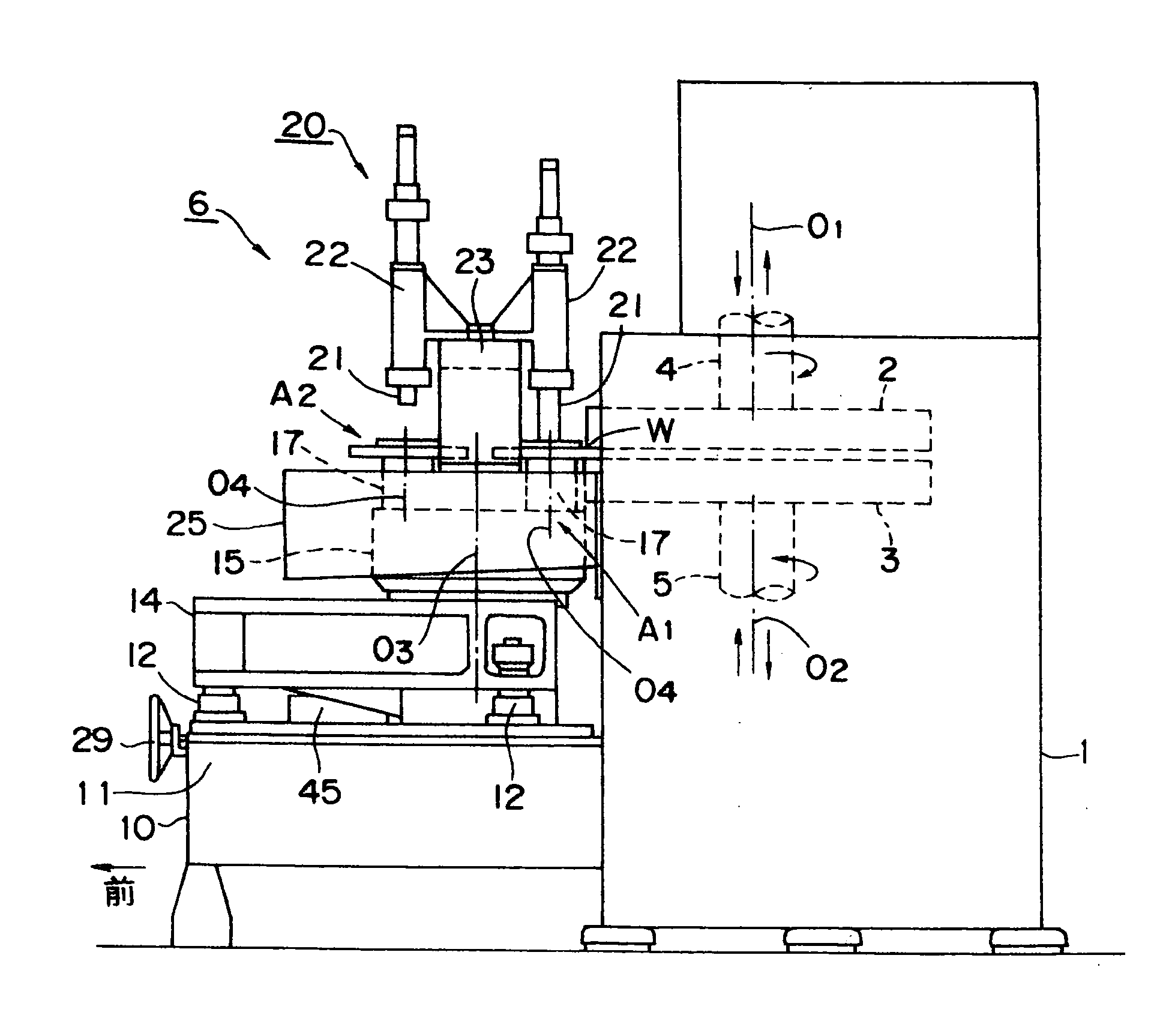

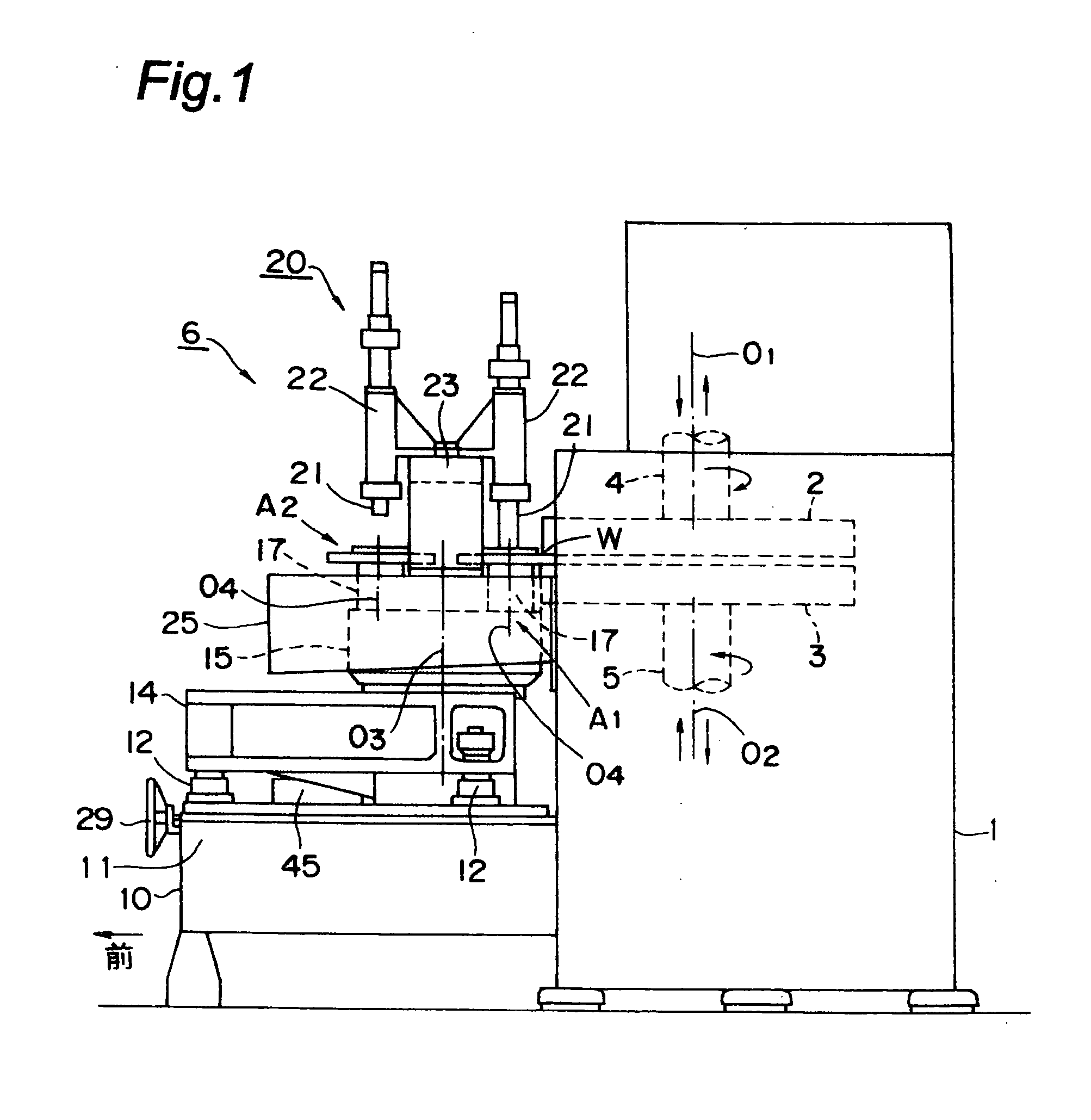

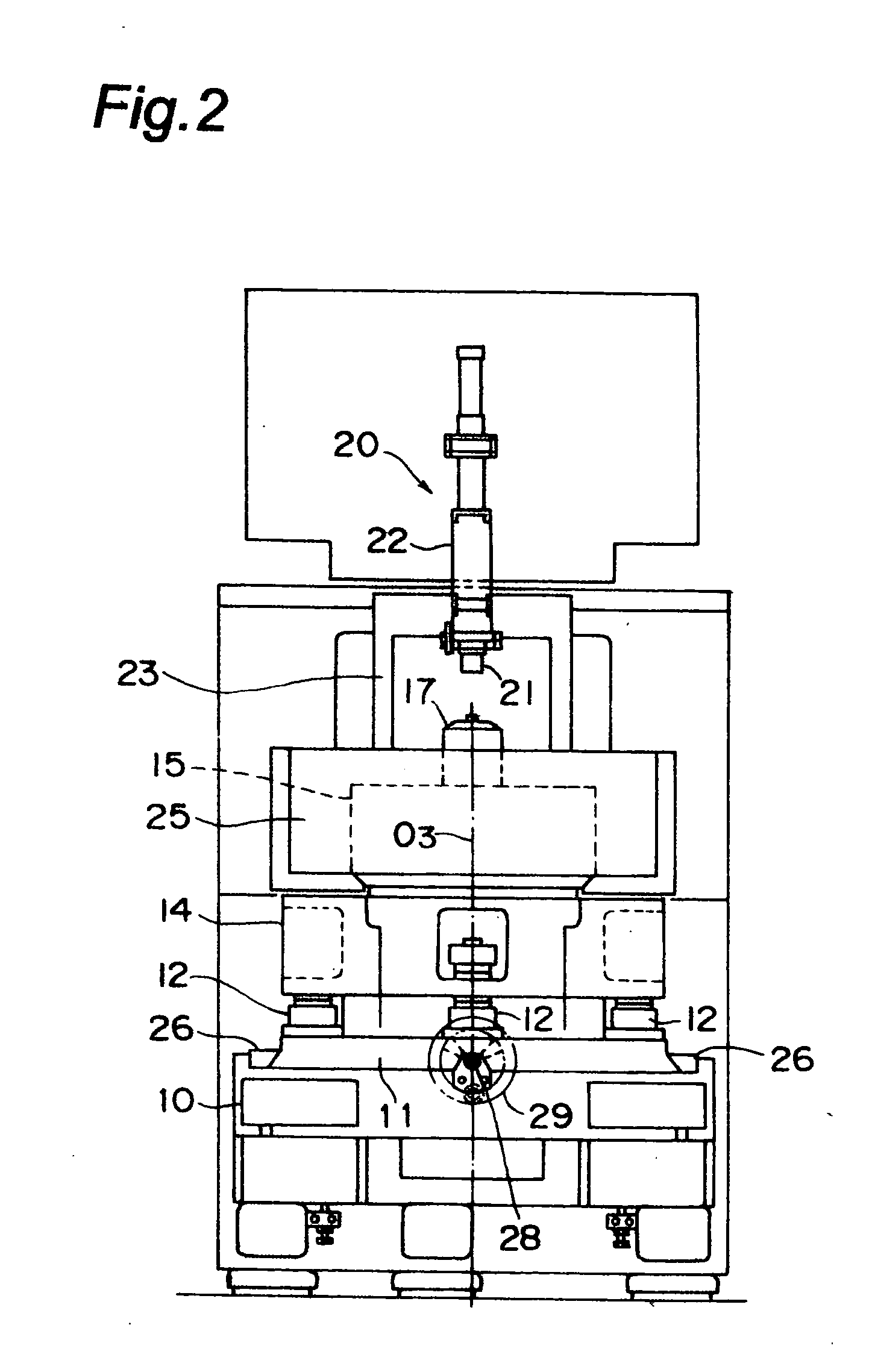

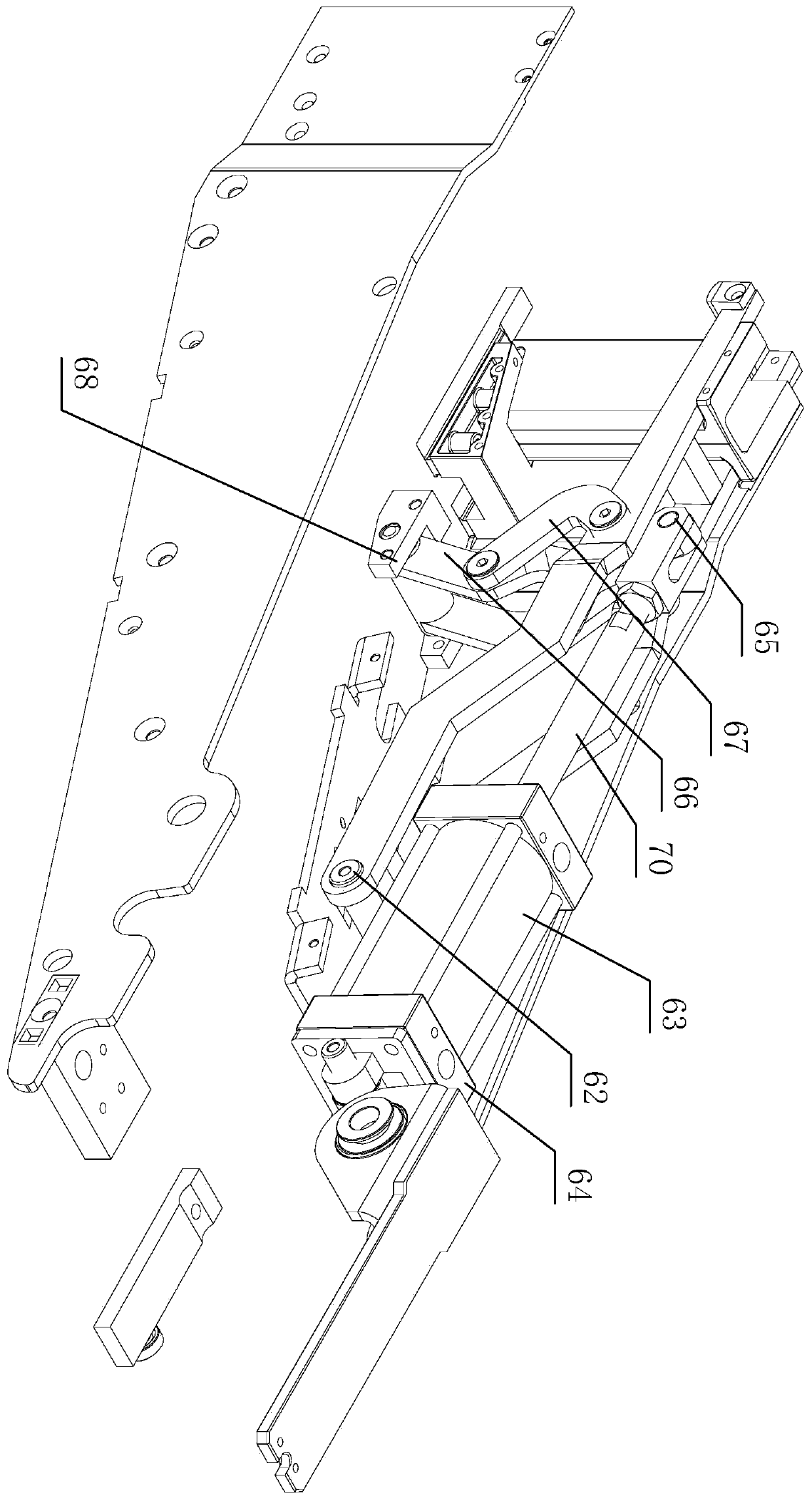

Vertical type of double disc surface grinding machine

In a vertical type of double disc surface grinding machine, an object of this invention is to enable simple adjustment of a parallelism between a grinding surface of a lower grinding wheel and a work end face clamped by a clamping jig of a rotary table, even when a grinding wheel spindle axis is disordered. The vertical type of double disc surface grinding machine is equipped with a pair of grinding wheels 2 &3 opposing each other in vertical direction and fixed to a pair of vertical grinding wheels 4 &5 and a rotary table 15 holding a work W and supplying it to a grinding position A1 located between the grinding wheels 2 &3, and provided on the rotary table 15 with a work clamping jig 17 including a rotary shaft 63 which clamps the work W at a specified position and makes it spin itself. The table 15 and a bed 14 supporting its drive mechanism are supported by plural supporting legs 12 adjustable in their heights, so that front-to-back and right-to-left inclination angles can be adjusted in relation to horizontal level, and the supporting legs 12 are installed on a slide bed 11 slidable in horizontal direction.

Owner:DAISHO SEIKI CORP

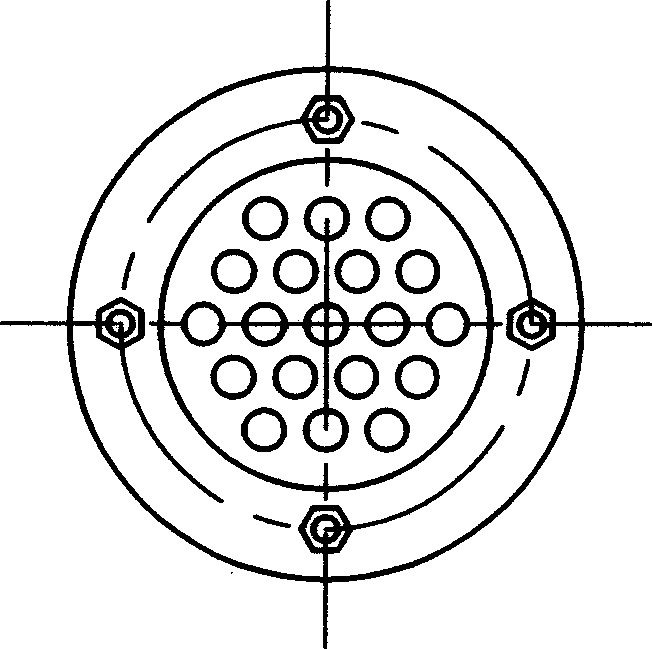

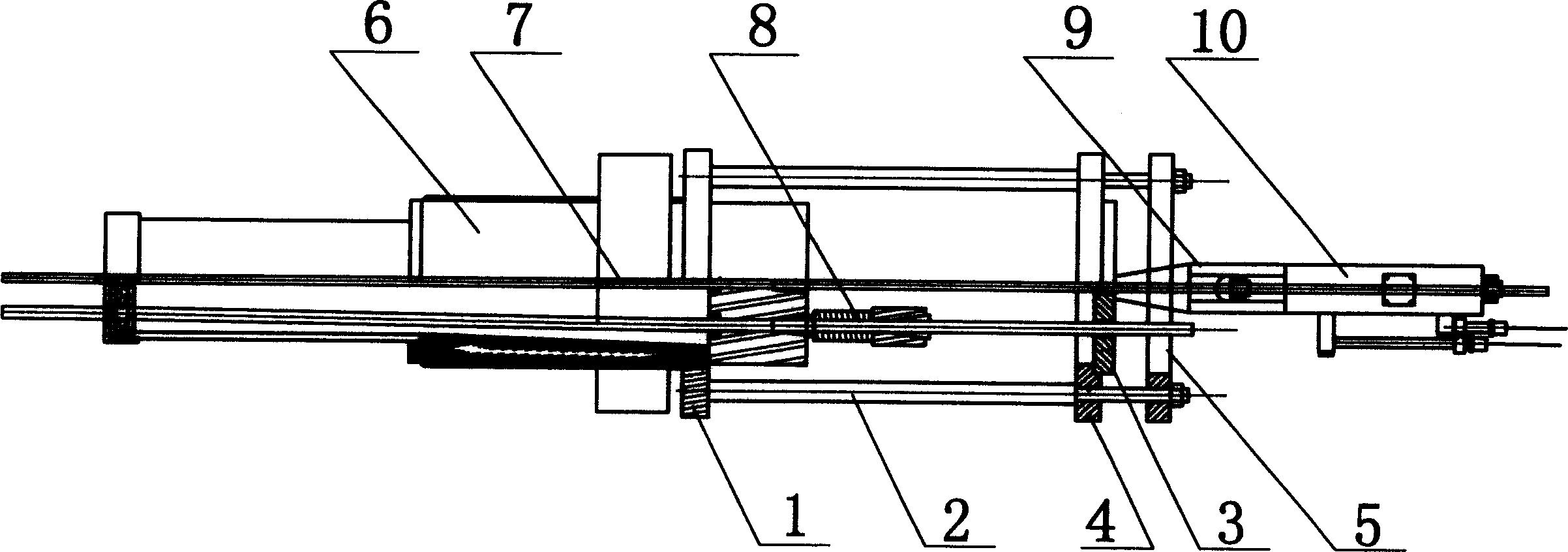

Single stay tensing construction method and apparatus for parallel twisted steel stay system

InactiveCN1458347AAvoid scratchesAvoid problems such as hidden dangers of anchoring and clamping qualityBulkheads/pilesPull forceEngineering

Owner:LIUZHOU OVM MASCH CO LTD

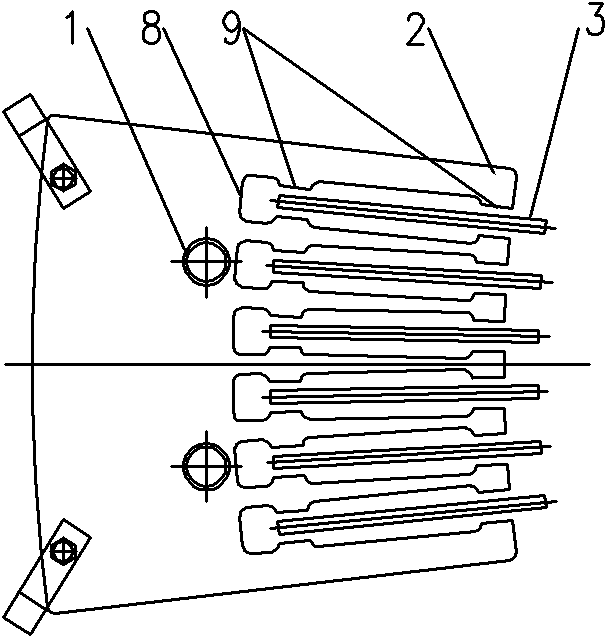

Work clamp of stator pressing plate

InactiveCN101862931AGuaranteed assemblyImprove labor productivityWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringC shaped

The invention discloses a work clamp of a stator pressing plate, wherein one end of a clamp body is provided with a C-shaped clamp, the middle part of the clamp body is provided with at least one positioning pin, the other end of the clamp body is provided with a plurality of opening grooves which are arranged in a circular arc, and a positioning separator is arranged in each opening groove; and the bottom of each opening groove is provided with a positioning circular arc line, and two sides of each opening groove are provided with a plurality of positioning reduced necks. The invention can ensure that the assembly between racks and the pressing plate and the after-welding precision reach the requirement of a blueprint, even if all rack end parts are positioned in the same positioning circular arc, and the size error is + / -0.5 mm, and the deviation of rack angles is controlled to be within + / -0.05 degrees. In the invention, the stator pressing plate is welded so that the labor production ratio is at least increased by over one time.

Owner:YICHANG JIANGXIA MARINE MACHINERY

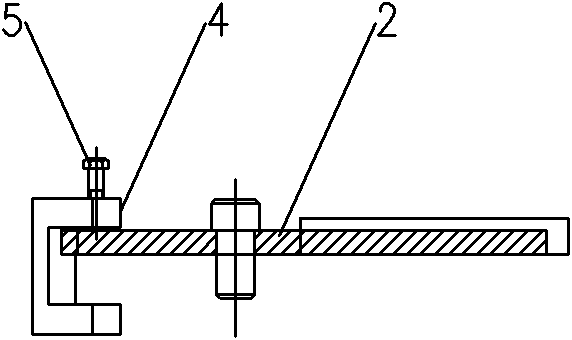

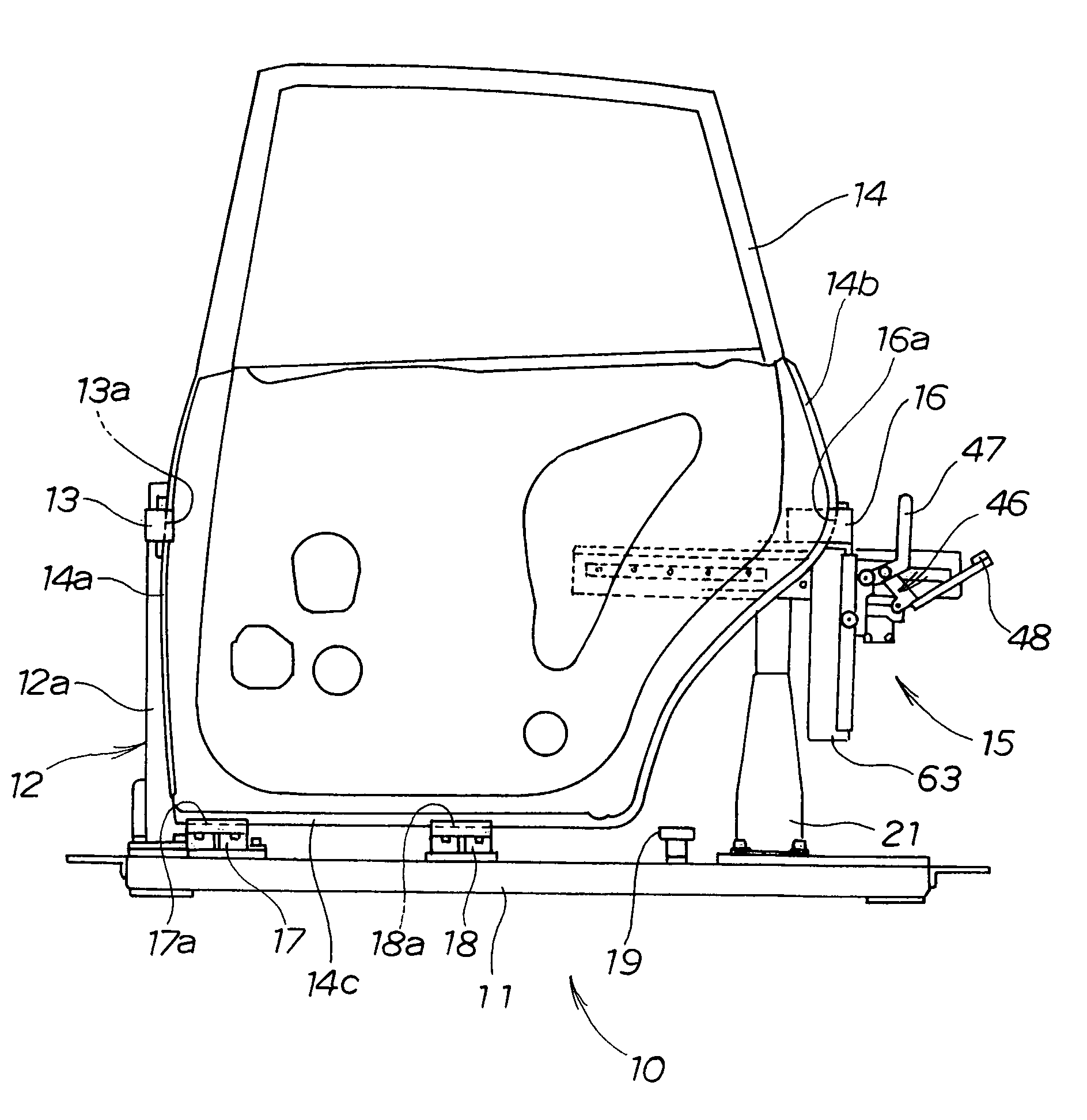

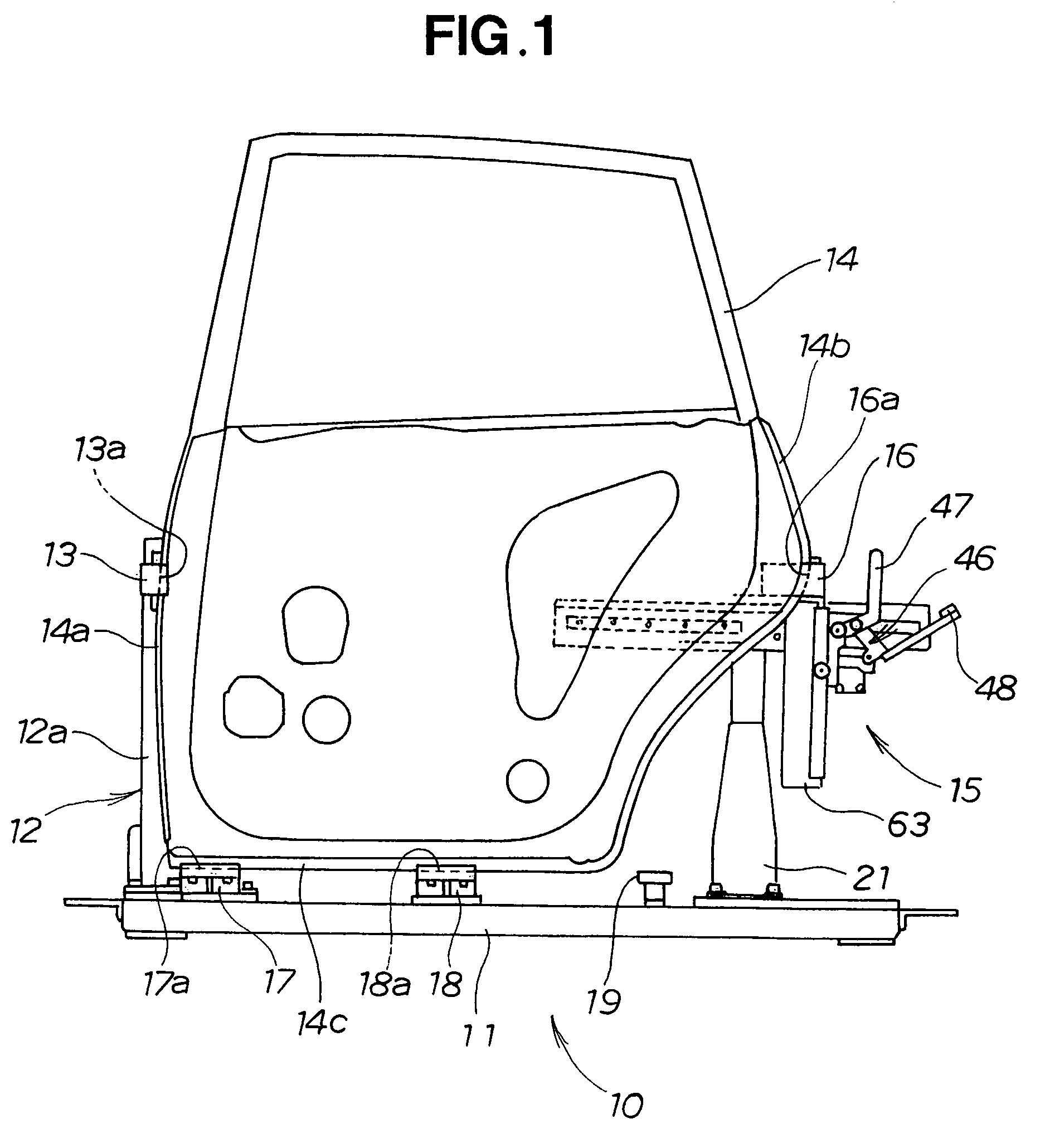

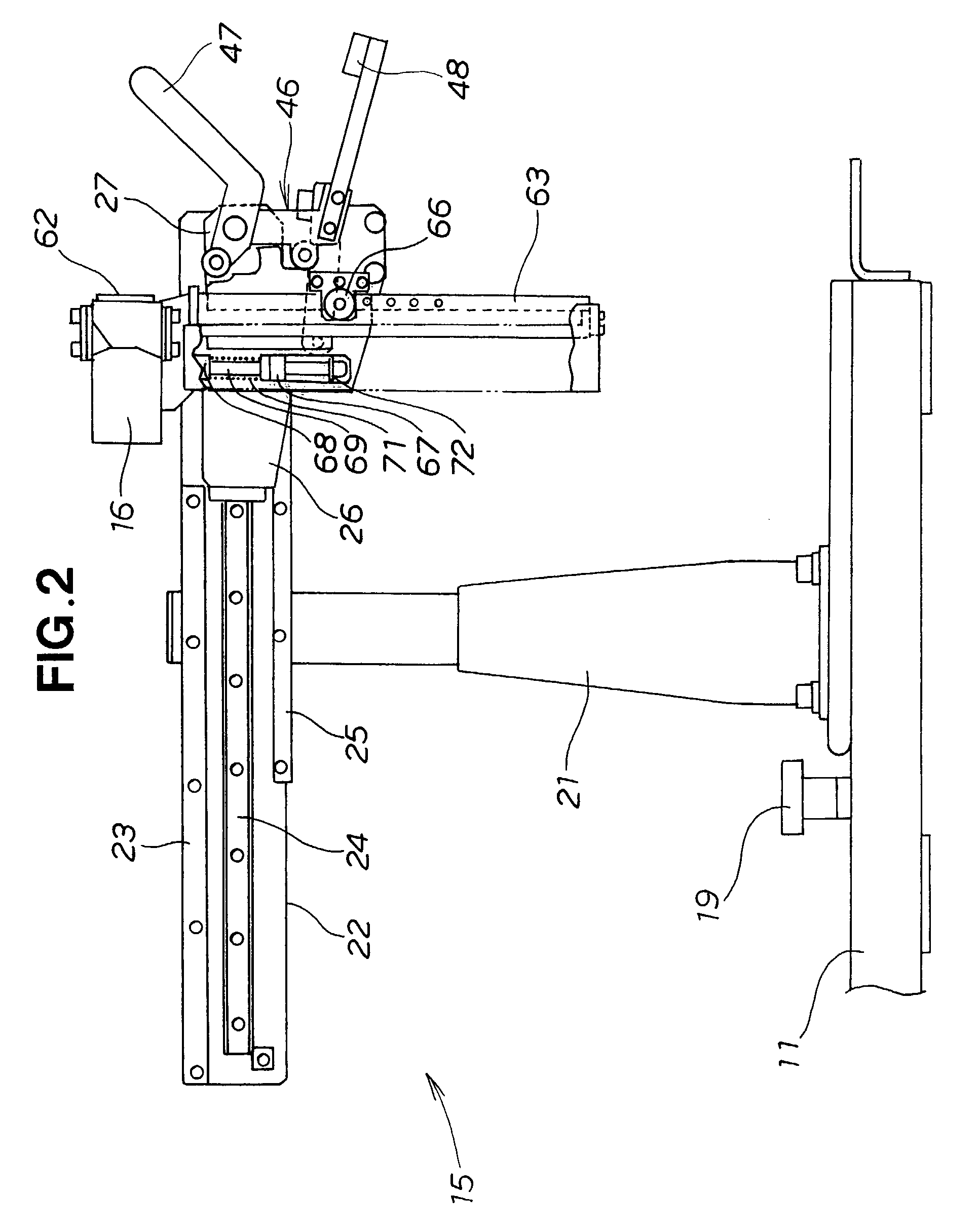

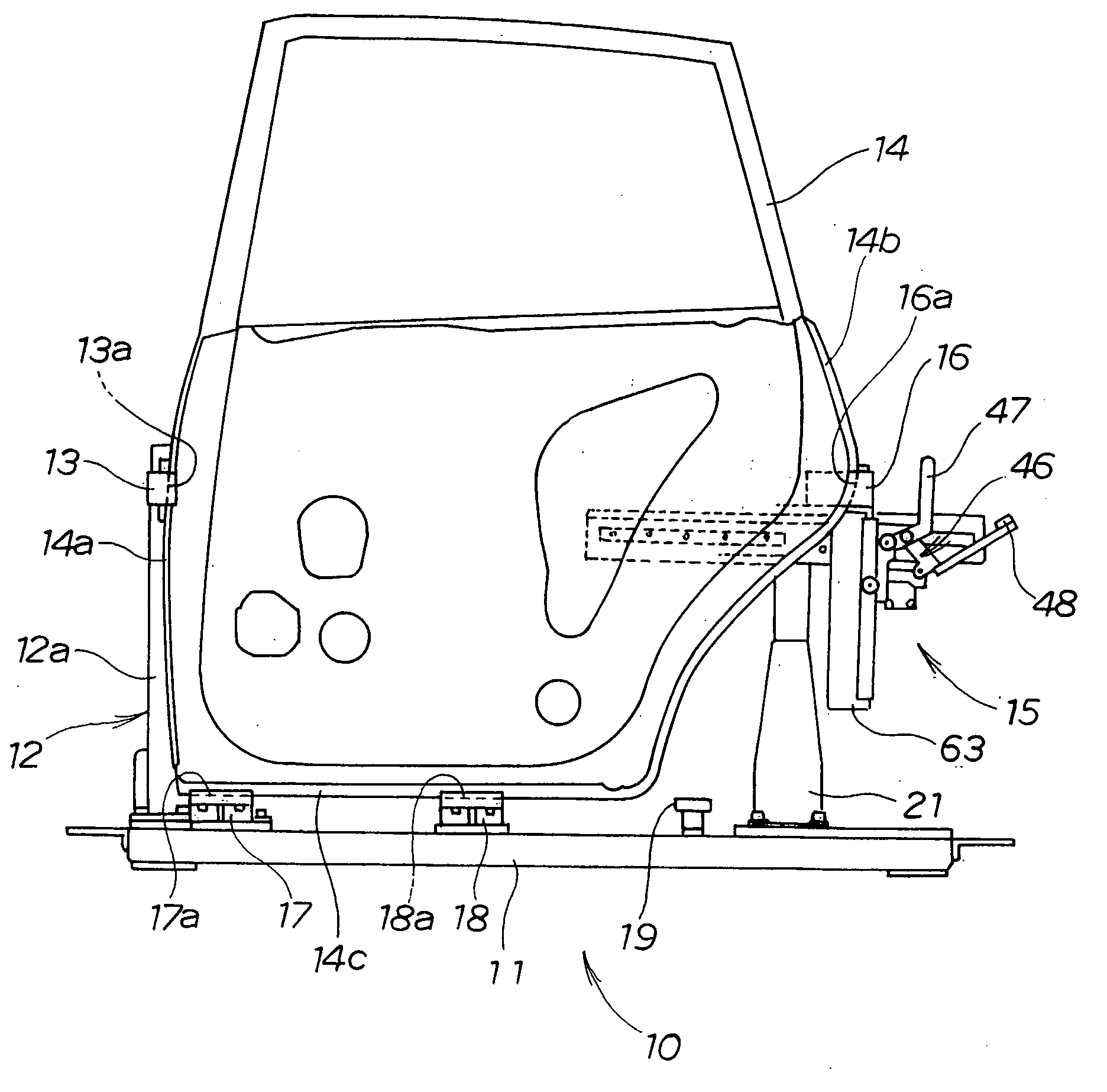

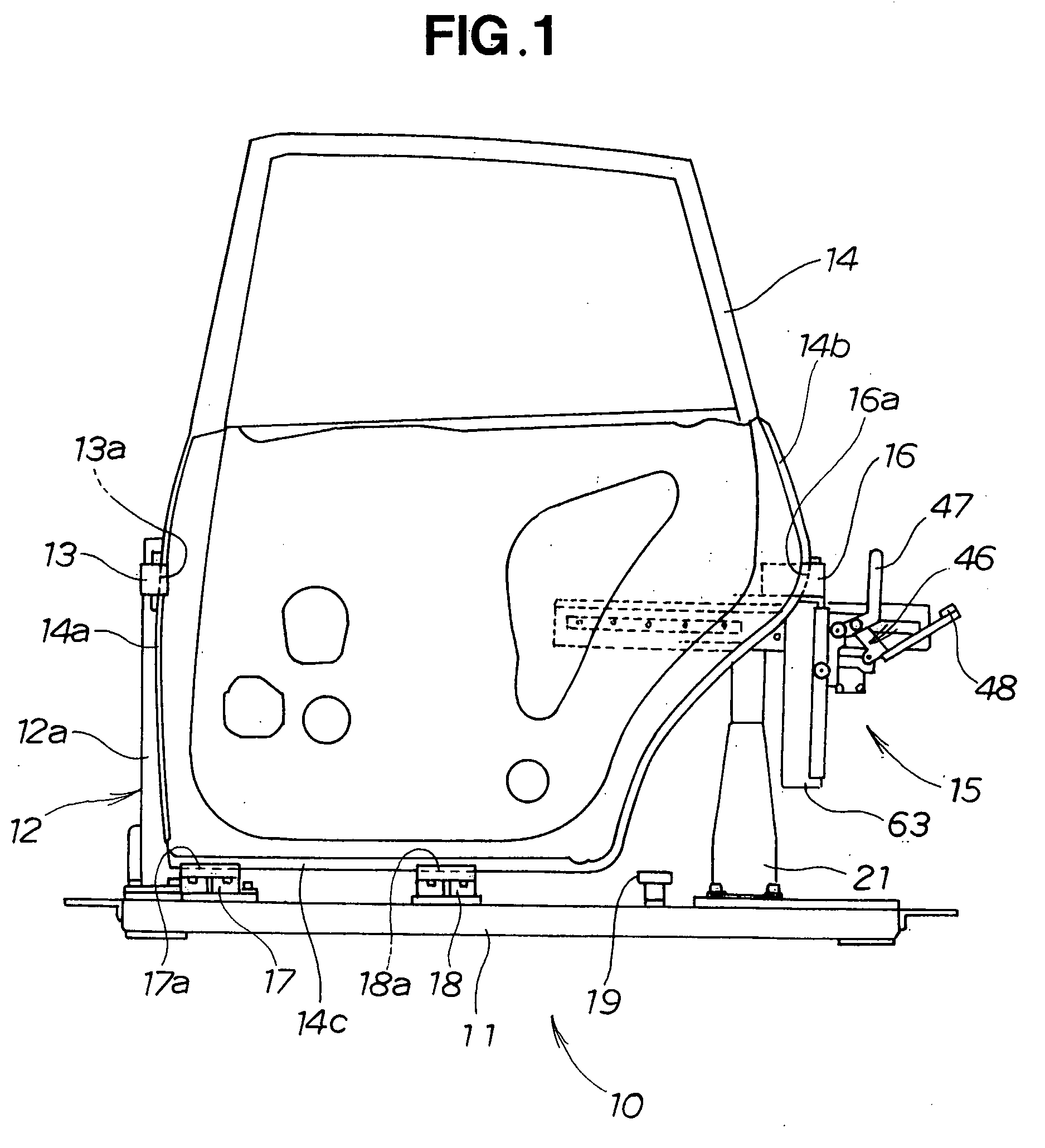

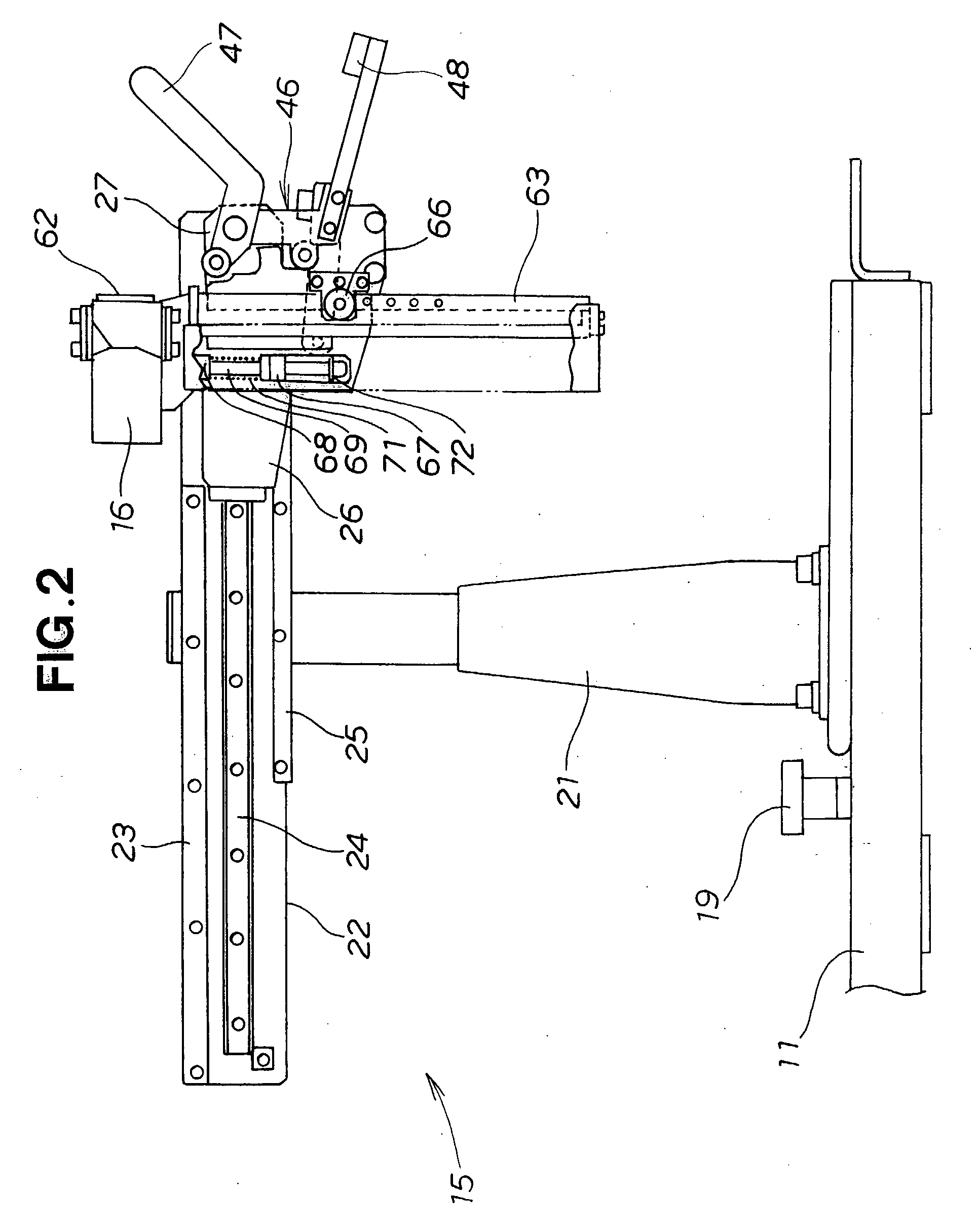

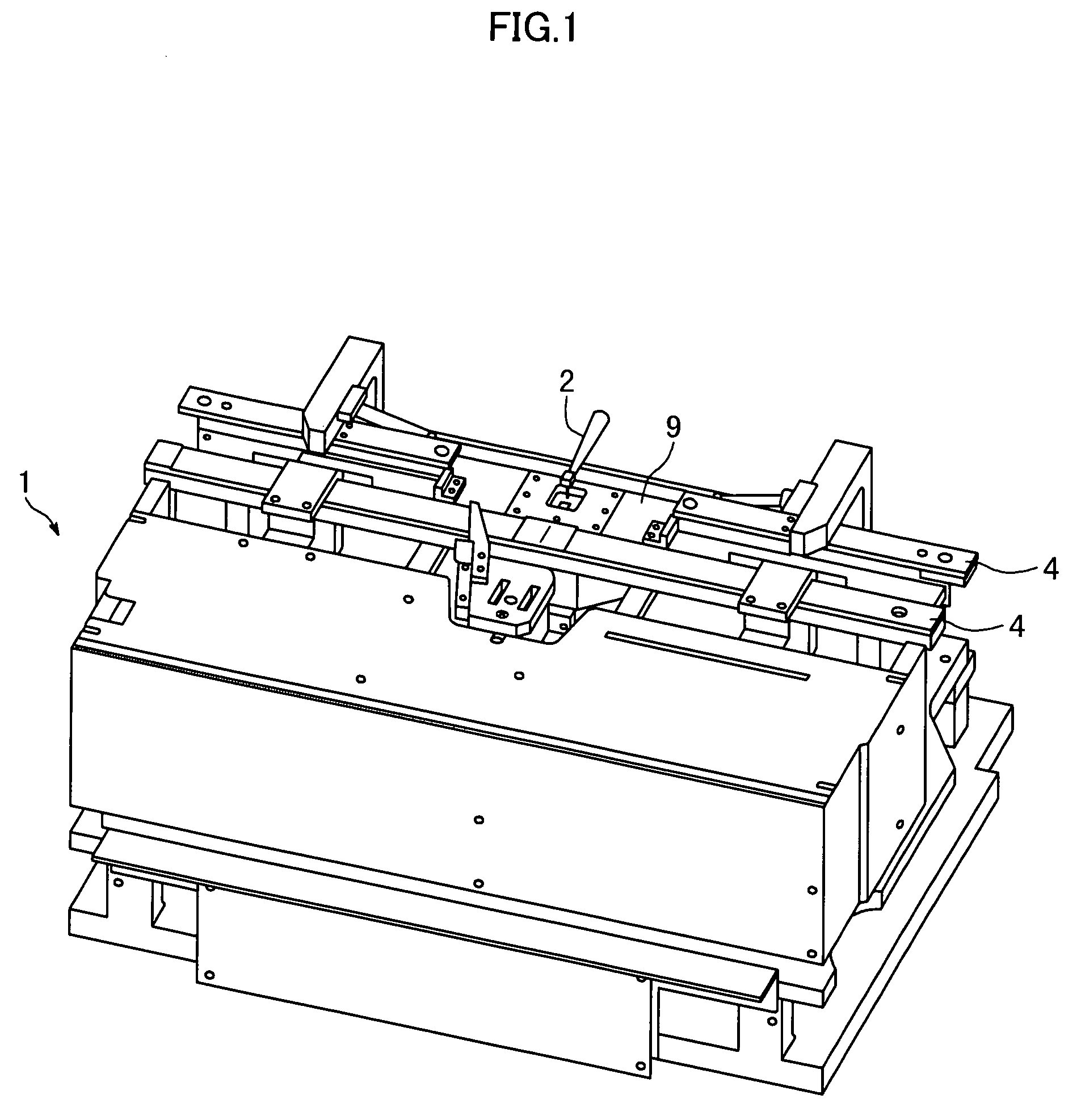

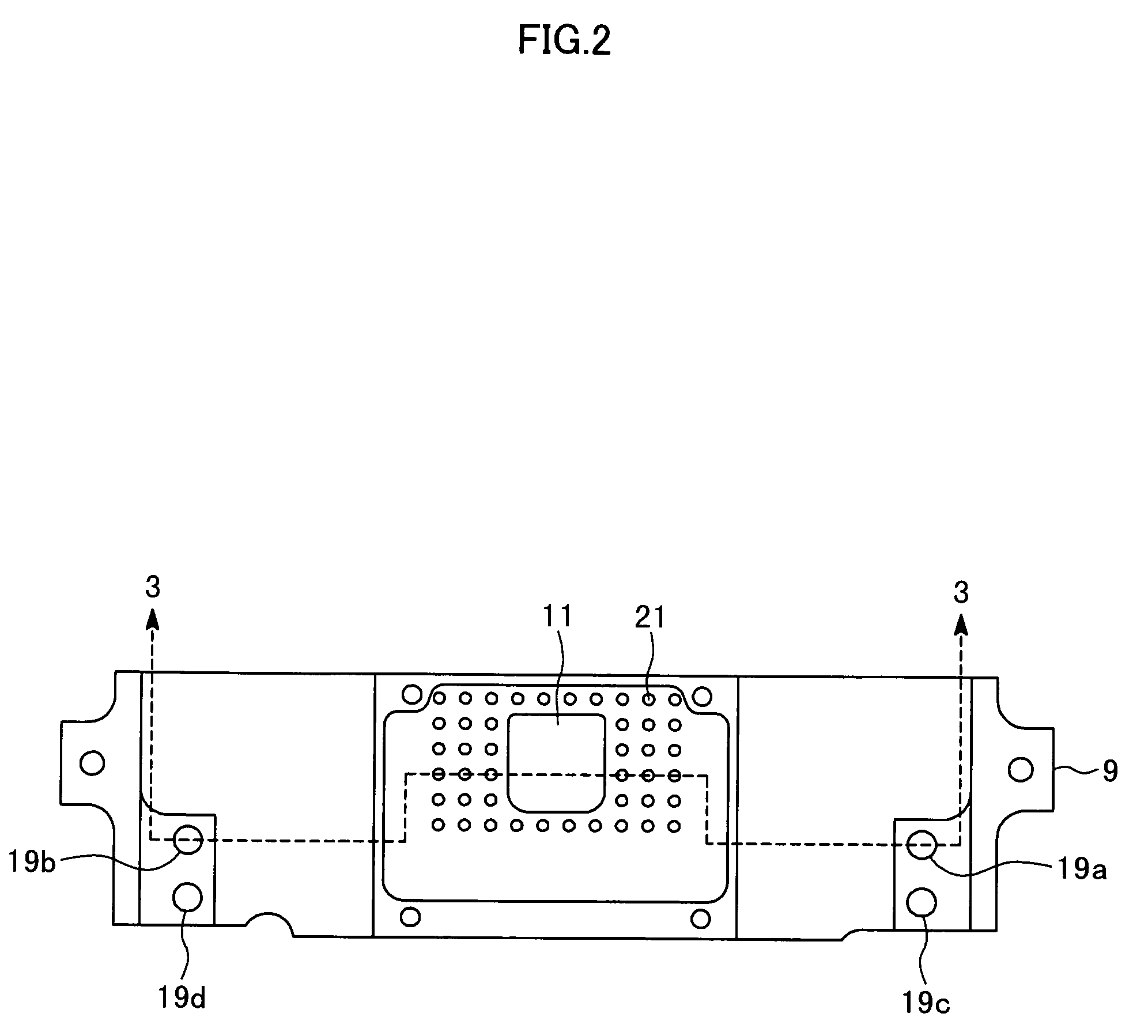

Work carrier and work clamping method using the same

A work carrier includes a movable clamp unit (15) having resiliently connected first and second sliders (26, 27) mounted on a guide rail (24), a lock lever (37) mounted on the second slider and normally urged in a direction to move a toothed portion (41) into meshing engagement with a rack (25), an operating lever (46) pivotally mounted on the second slider, and a cam mechanism (43, 38, 44, 45) operable in response to pivotal movement of the operating lever in one direction such that the second slider is locked in position against movement relative to the guide rail via meshing engagement between the toothed portion and the rack and, subsequently, the first slider and clamp member carried thereon are forcibly displaced away from the second slider while the second slider remains locked on the guide rail.

Owner:HONDA MOTOR CO LTD

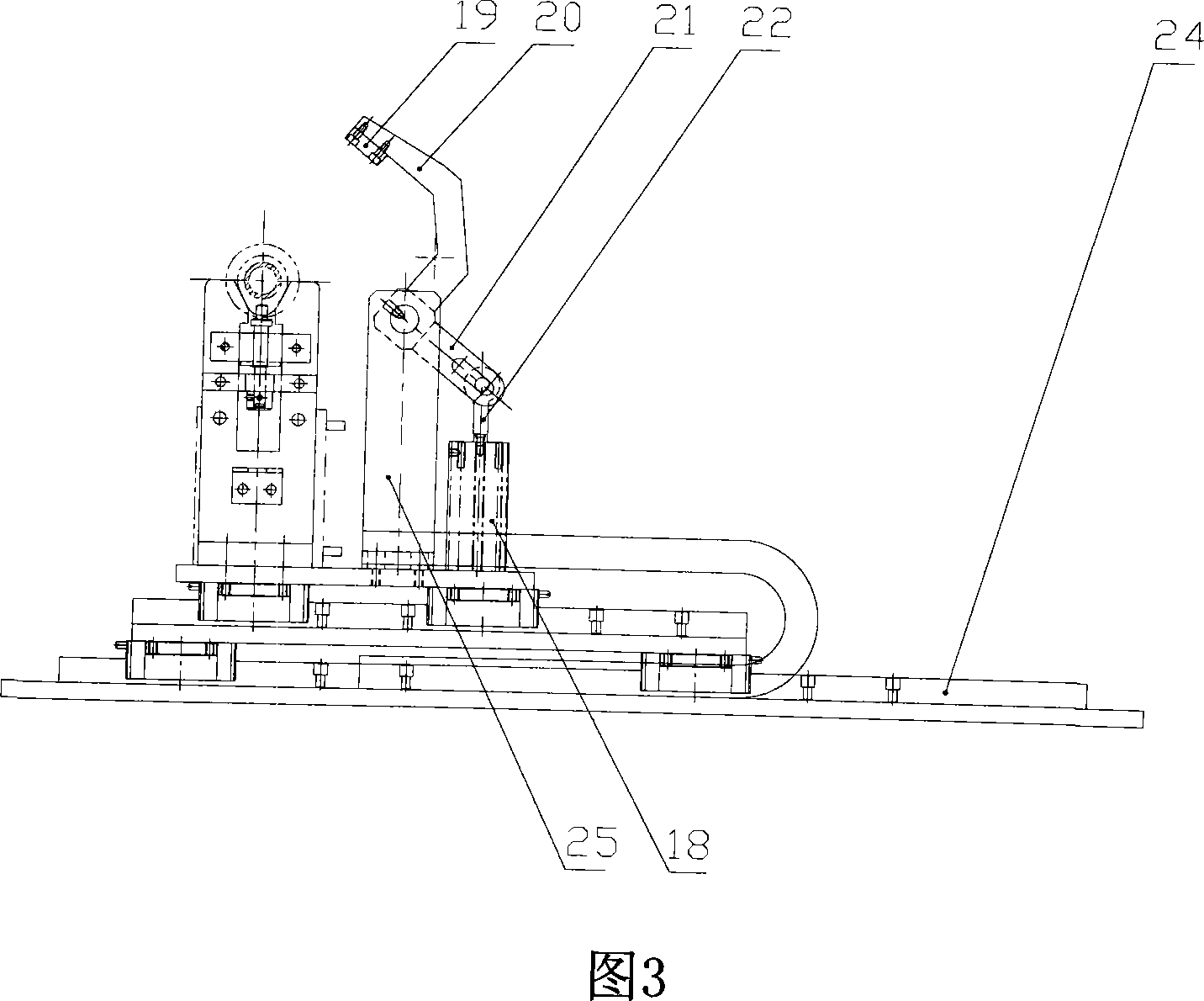

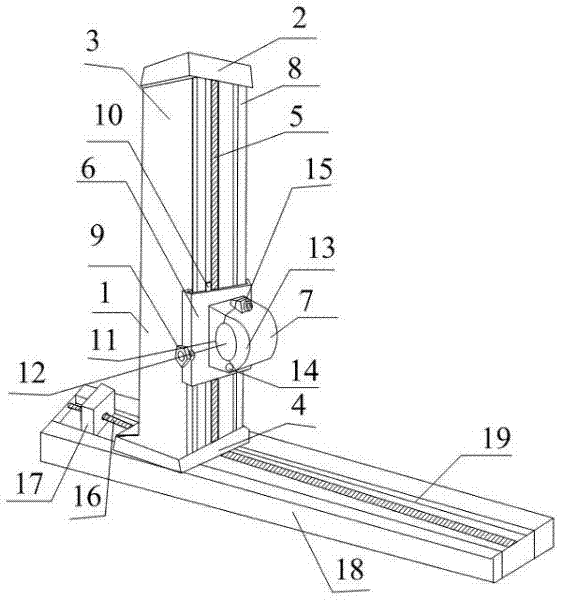

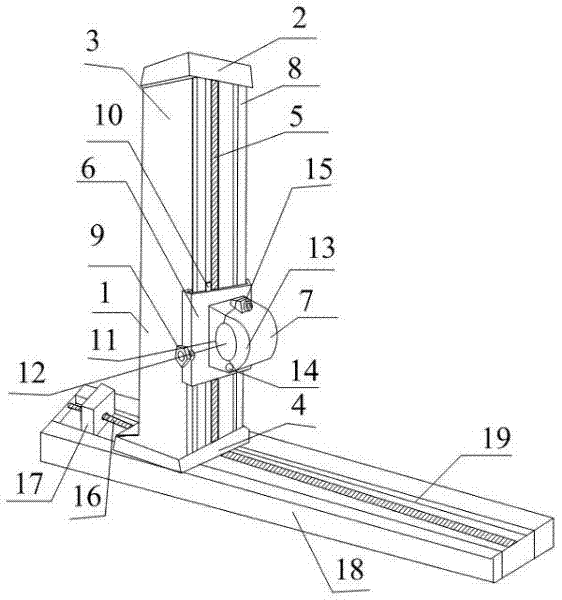

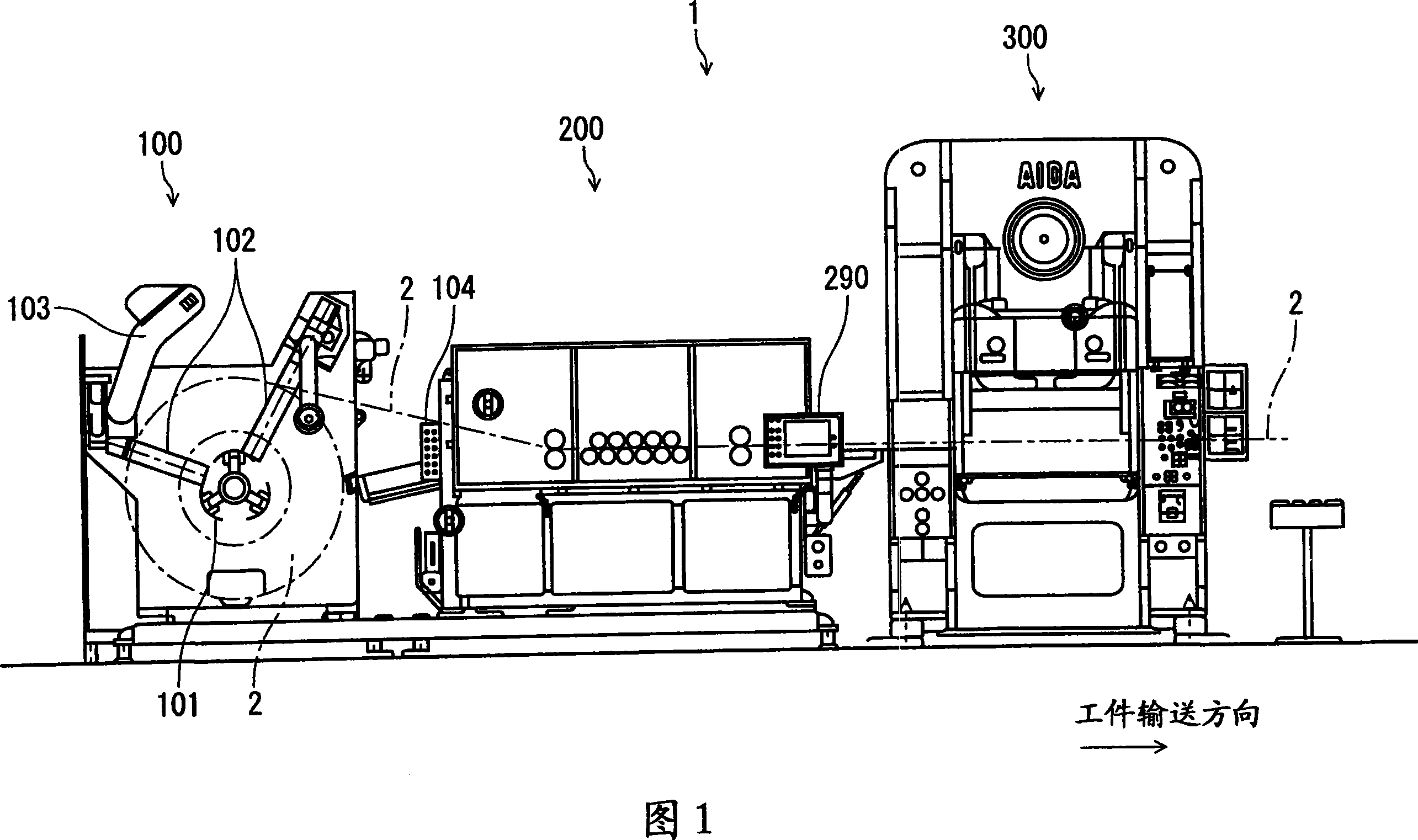

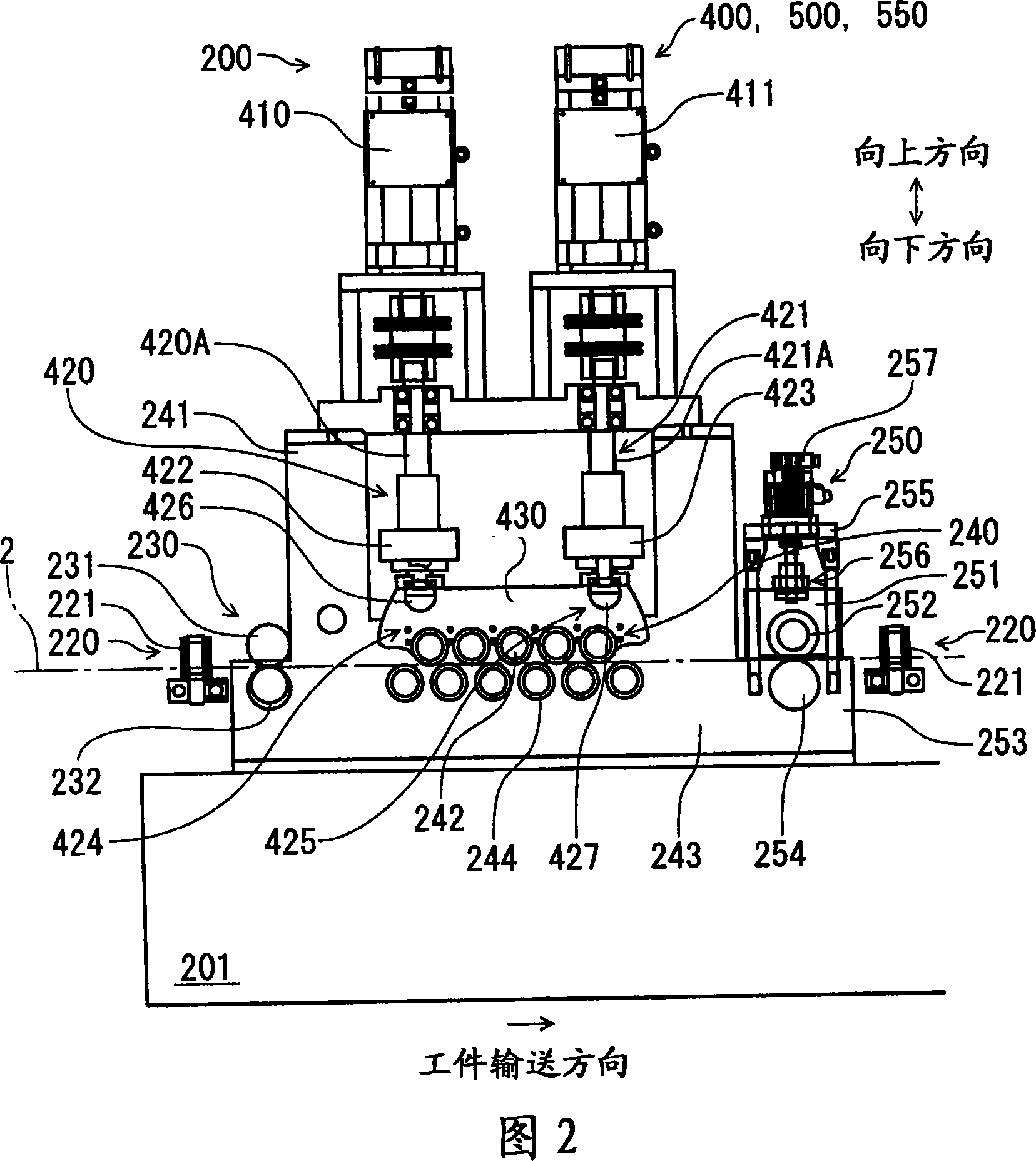

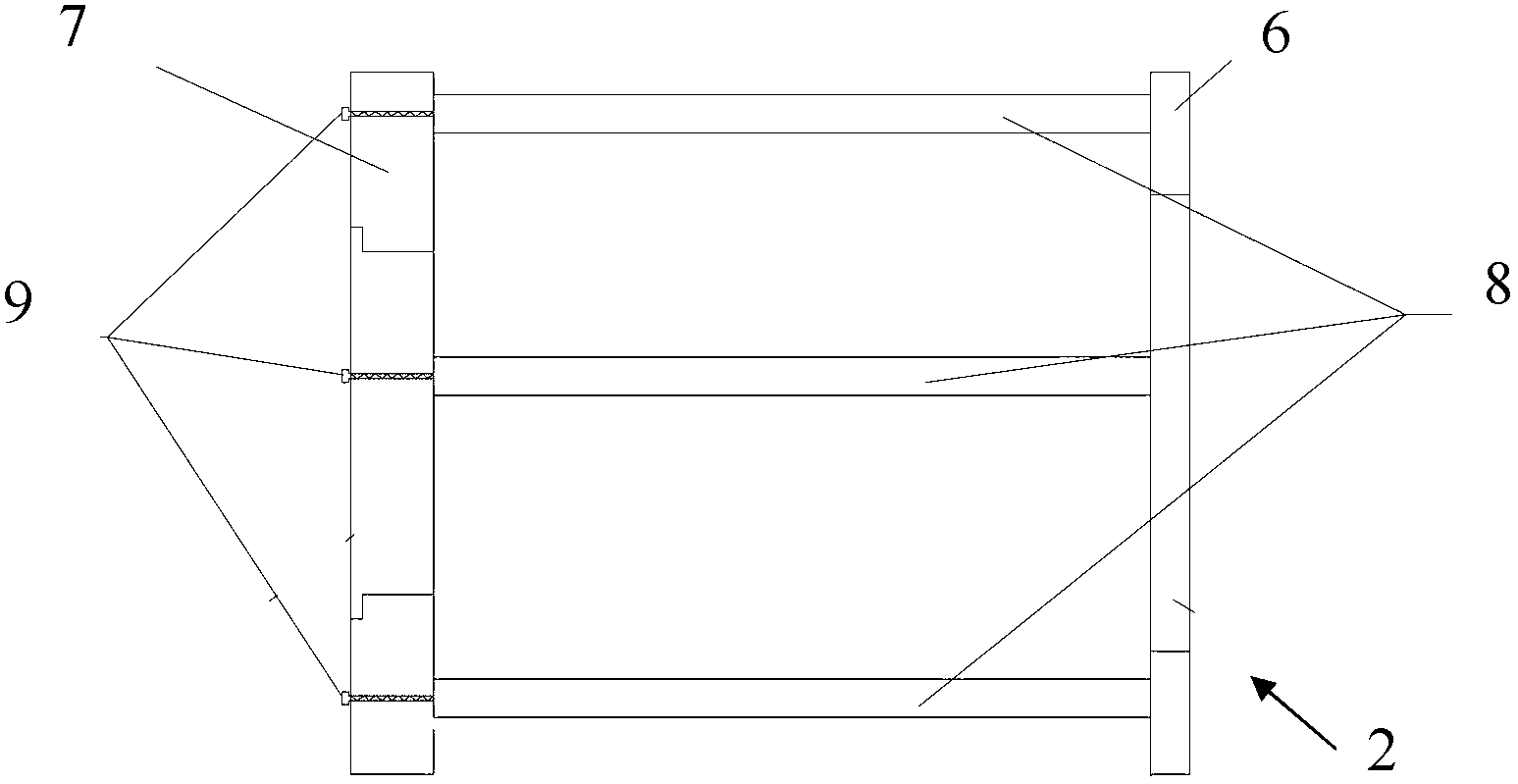

Workpiece two-dimensional conveying device

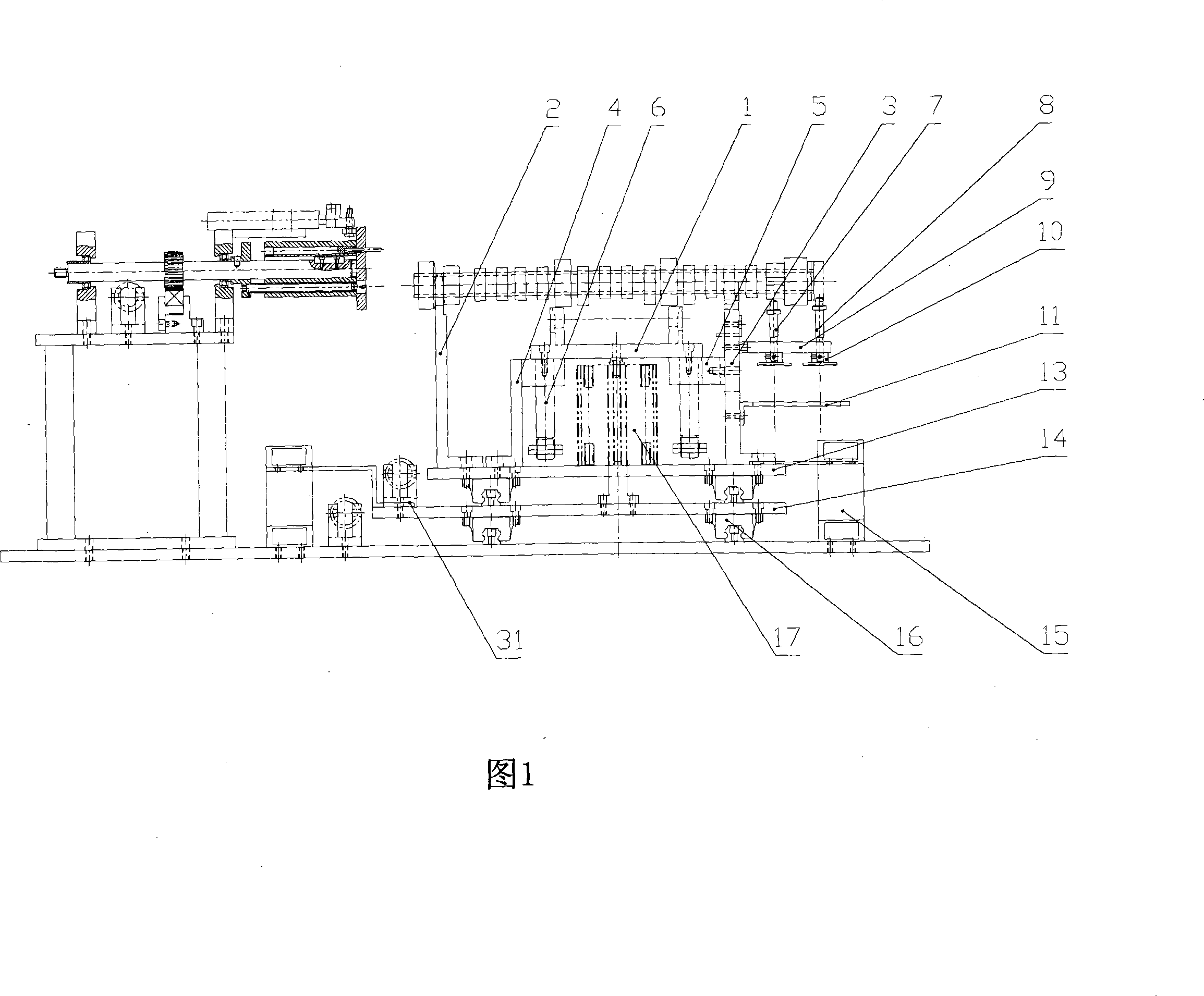

InactiveCN102294616ASimple structureEasy to processMetal working apparatusEngineeringParallel arrangement

The device of the present invention discloses a workpiece two-dimensional conveying device, which includes a vertical lifting mechanism and a horizontal moving mechanism; the vertical lifting mechanism includes a main body frame (1), the top of the main frame is provided with a top plate (2), and two sides are provided with two two opposite side plates (3), and a lifting screw (5) is arranged vertically between the two side plates, and a lifting platform (6) is arranged on the lifting screw, and a work clamp is arranged on the lifting platform holding mechanism (7); the horizontal moving mechanism includes a horizontal guide rail (18), a guide groove (19) arranged along the horizontal guide rail, a lead screw assembly (16) installed in the guide groove, and a transmission mechanism connected with the lead screw assembly block (17); the bottom of the main body frame (1) is installed on the horizontal guide rail (18), and is arranged in parallel with the transmission block (17). The device of the invention has the advantages of simple structure, convenient processing and easy popularization and application.

Owner:CHENGDU KESHENG PETROLEUM TECH +1

Two arm-brace stretching method of arc bridge tie bar cable

The invention discloses a two arm-brace stretching method of an arc bridge tie bar cable, comprising the following steps of: sequentially installing a working anchor, a working anchor arm brace, a rear tool anchor, a tool anchor arm brace, a hydraulic jack and a front tool anchor, enabling the working anchor and the rear tool anchor in a loosening state, clamping a prestressing steel strand by using the front tool anchor and stretching an oil cylinder by using the hydraulic jack to feed oil and pushing the front working anchor for stretching the prestressing steel strand; stopping the stretching of the oil cylinder by using the hydraulic jack to feed oil when the hydraulic jack reaches the maximum stroke, clamping the prestressing steel strand by using the rear tool anchor to enable the front tool anchor to be in a loosening state and stretching the oil cylinder by using the hydraulic jack; carrying out next round of stretching operation after stretching the oil cylinder by using the hydraulic jack to return oil in place; and clamping the prestressing steel strand by using the working anchor when the prestressing steel strand reaches the requirement. In the stretching process, a working clamping piece of the working anchor is not forced, thus the invention solves the problems that the work clamping piece of the working anchor is repeatedly forced and teeth are blocked in the stretching process of a long steel strand cable in the prior art and prolongs the service life of the working anchor.

Owner:中铁大桥(郑州)缆索有限公司

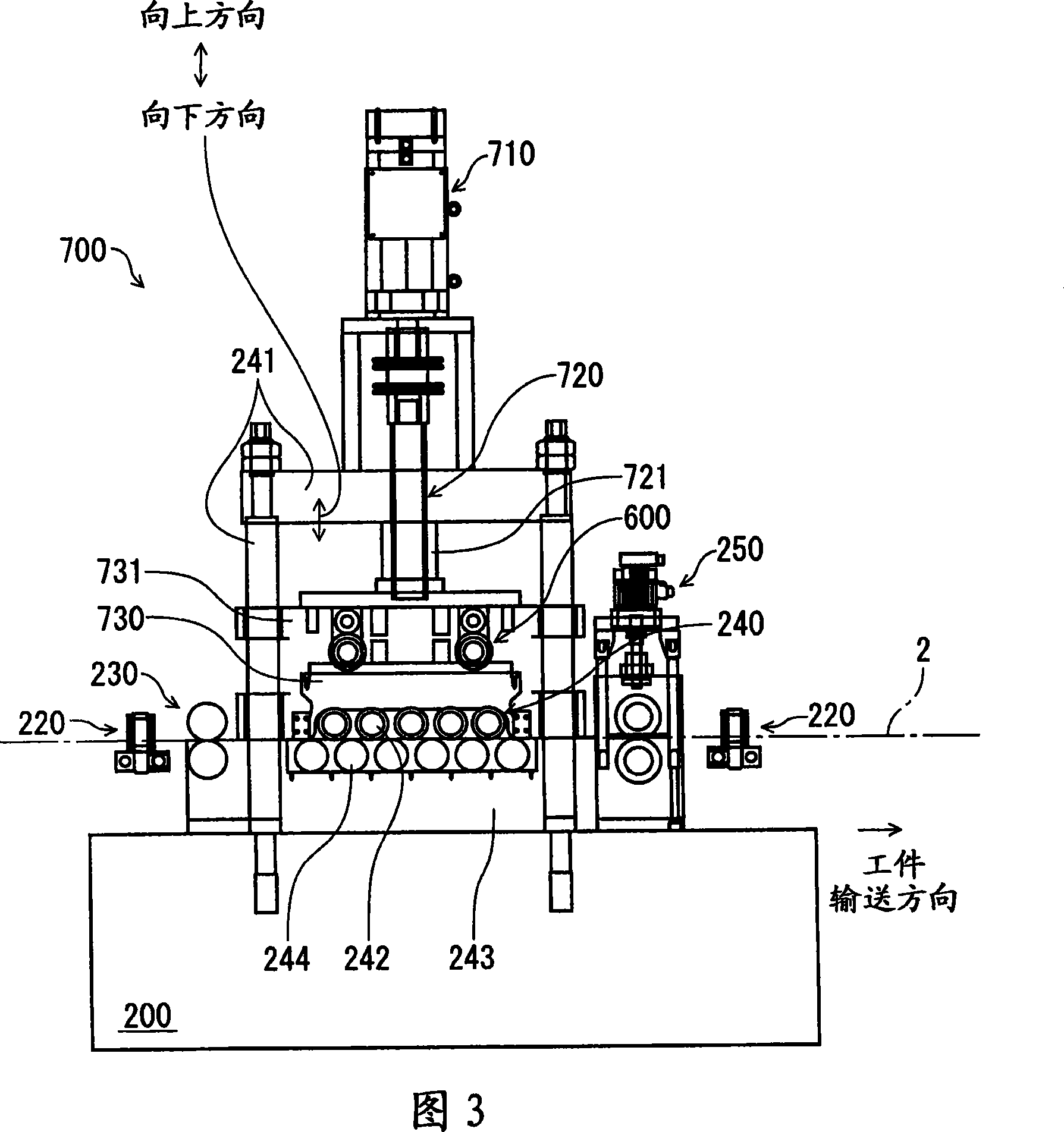

Releasing mechanism and leveling apparatus

A release mechanism for use in a leveling apparatus that performs a leveling process on a work object that has been wound in a coil configuration as a result of the work object being passed between a front side work roll in contact with the front side surface of the work object and a back side work roll that is in contact with the back side surface of the work, wherein the releasing mechanism switches between a work clamp state that allows performance of the leveling process and a release state that releases the work object from the clamp state by displacing a work roll support member that supports one of the work rolls relative to the another support member to change a distance between the work rolls by utilizing rotational movement of an electric motor.

Owner:AIDA ENG LTD

Work carrier and work clamping method using the same

A work carrier includes a movable clamp unit (15) having resiliently connected first and second sliders (26, 27) mounted on a guide rail (24), a lock lever (37) mounted on the second slider and normally urged in a direction to move a toothed portion (41) into meshing engagement with a rack (25), an operating lever (46) pivotally mounted on the second slider, and a cam mechanism (43, 38, 44, 45) operable in response to pivotal movement of the operating lever in one direction such that the second slider is locked in position against movement relative to the guide rail via meshing engagement between the toothed portion and the rack and, subsequently, the first slider and clamp member carried thereon are forcibly displaced away from the second slider while the second slider remains locked on the guide rail.

Owner:HONDA MOTOR CO LTD

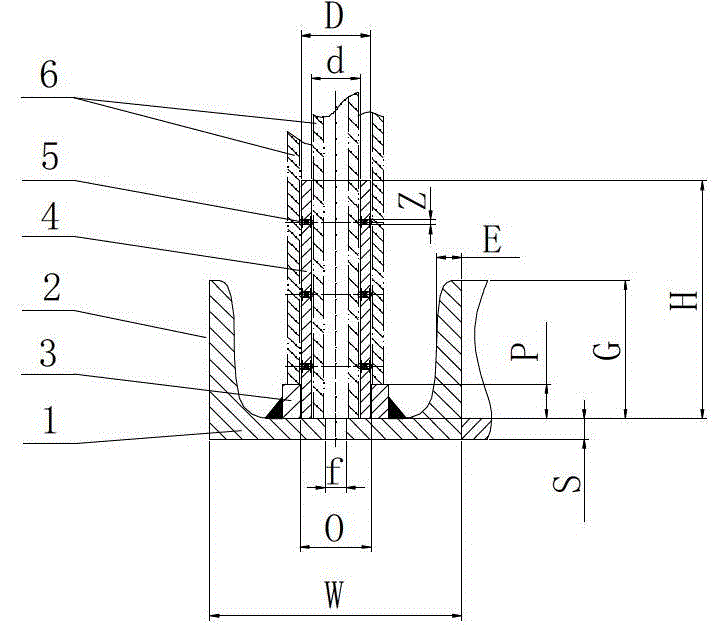

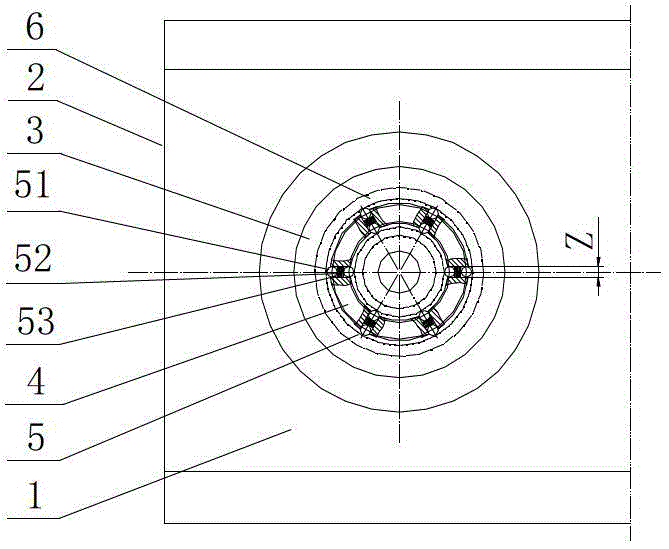

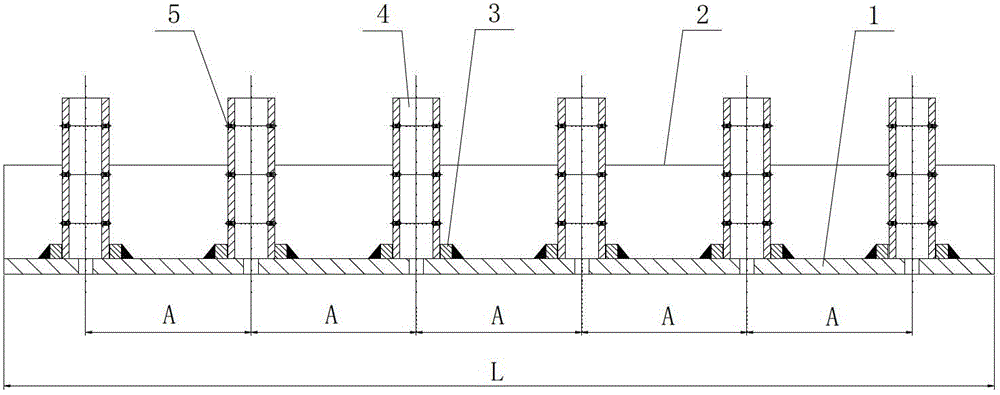

Multifunctional upright column base for scaffold and manufacturing process thereof

ActiveCN102720346AReduce the amount of processingSimple processOther manufacturing equipments/toolsScaffold accessoriesMarine engineeringSynchronous control

The invention discloses a multifunctional upright column base for a scaffold and a manufacturing process thereof. The invention adopts the technical scheme as follows: the multifunctional upright column base comprises a horizontal bed which is formed by perpendicularly connecting a plurality of U-shaped steel plates, and a plurality of anchoring rod stands and anchoring rods matched with the anchoring rod stands, which are arranged on the U-shaped steel plates, wherein locking devices are arranged in layers and columns inside the cylindrical walls of the anchoring rods; and a product is manufactured under the synchronous control of discharge equipment, sand-blast equipment, grinding equipment, auxiliary equipment, marking equipment, drilling equipment, milling equipment, turning equipment, working clamp equipment, welding equipment, sleeve-pressing equipment and stacking equipment. The multifunctional upright column base overcomes the problems in the prior art that the construction efficiency and construction safety are poor because standard members are unavailable for the horizontal bed and the base during scaffold construction; and is suitable for building construction, advertising and decoration and building repair and maintenance.

Owner:湖南省第三工程有限公司

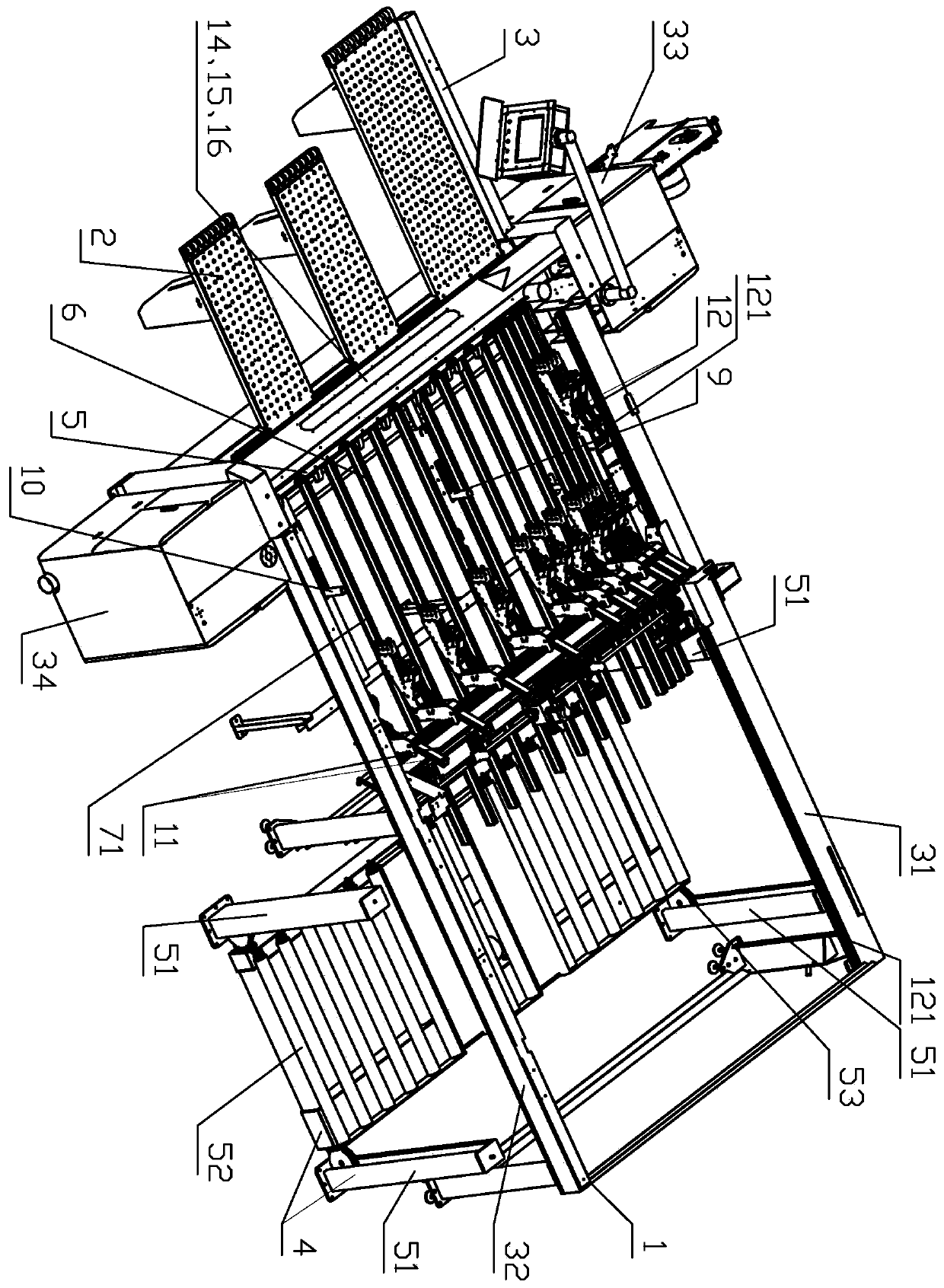

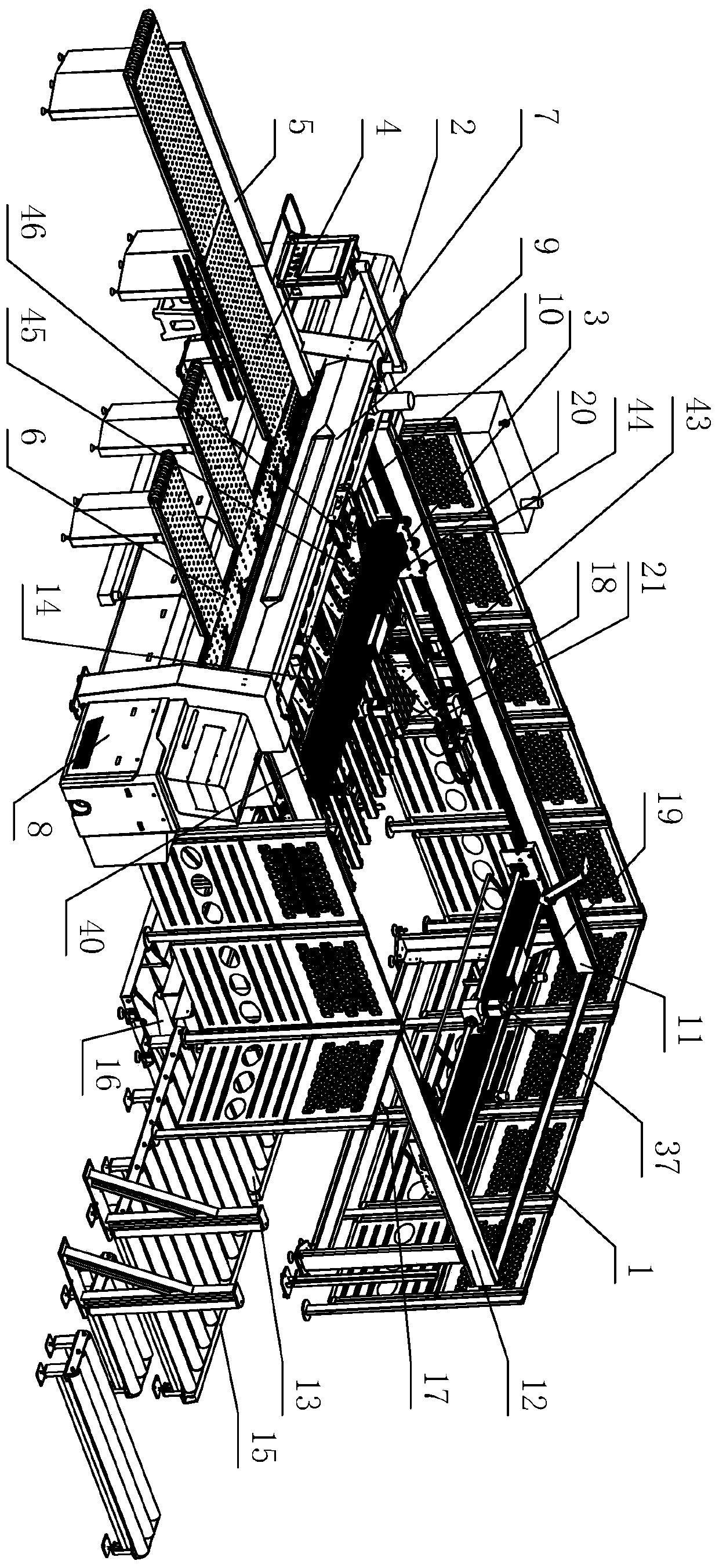

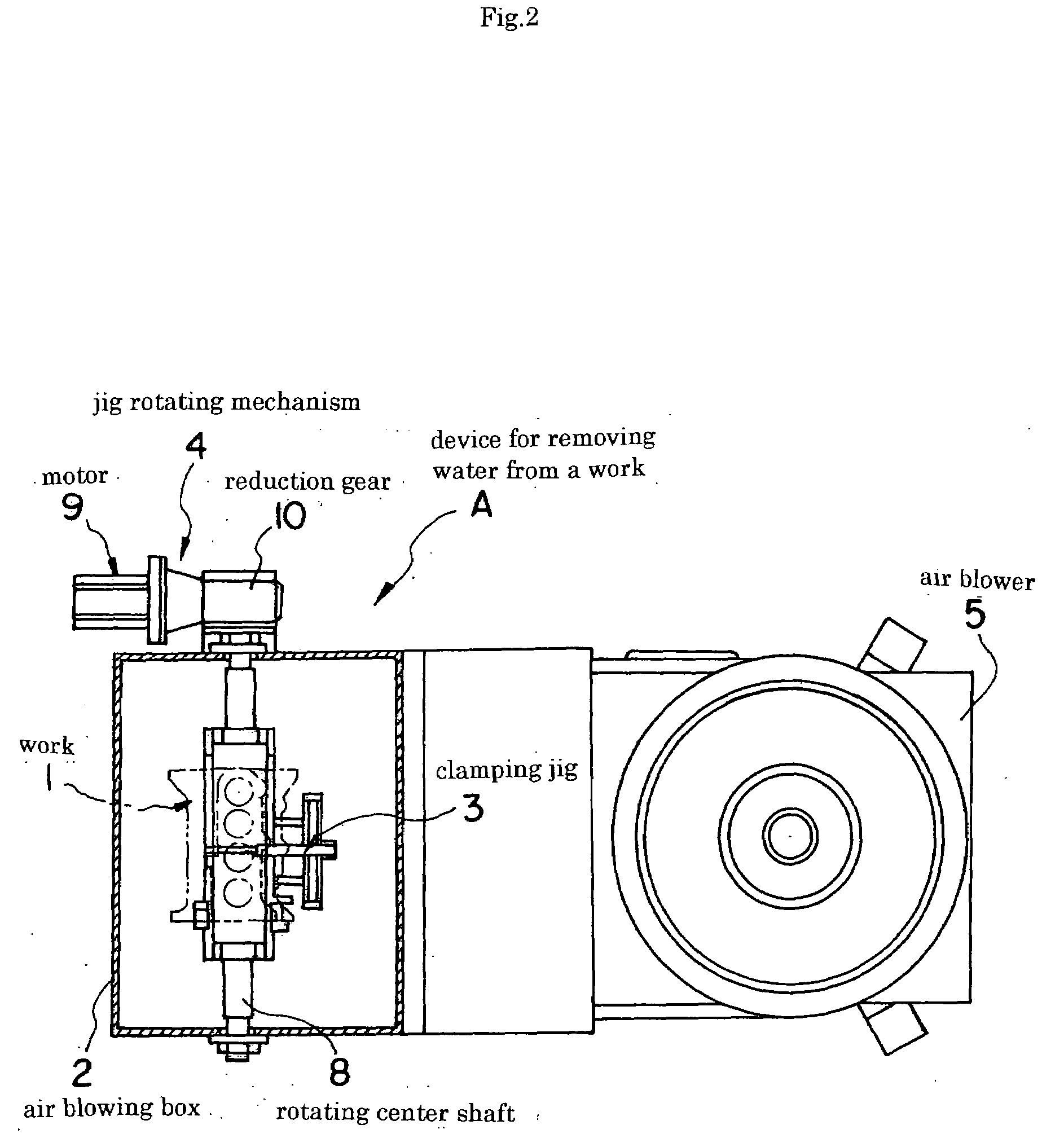

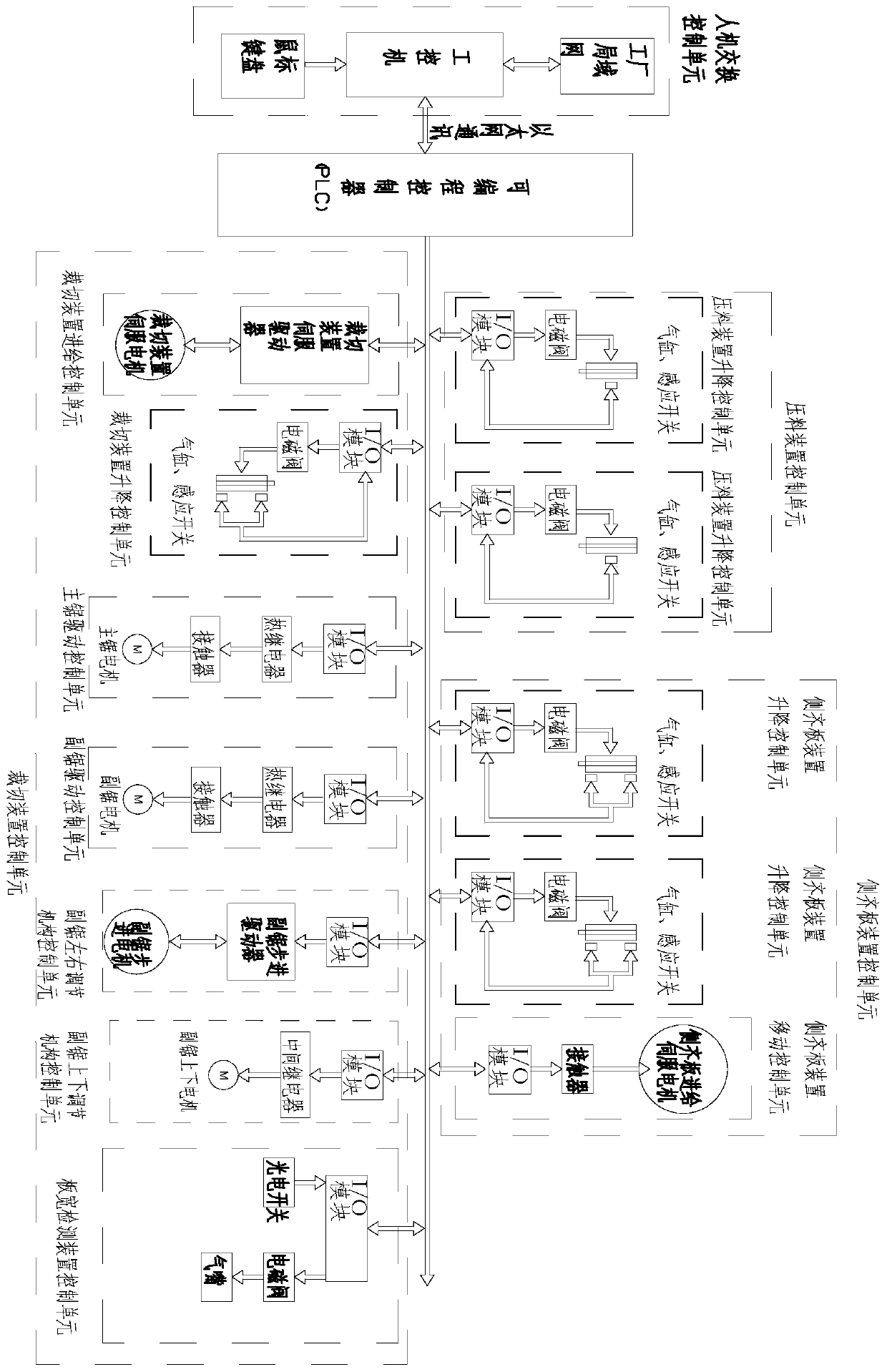

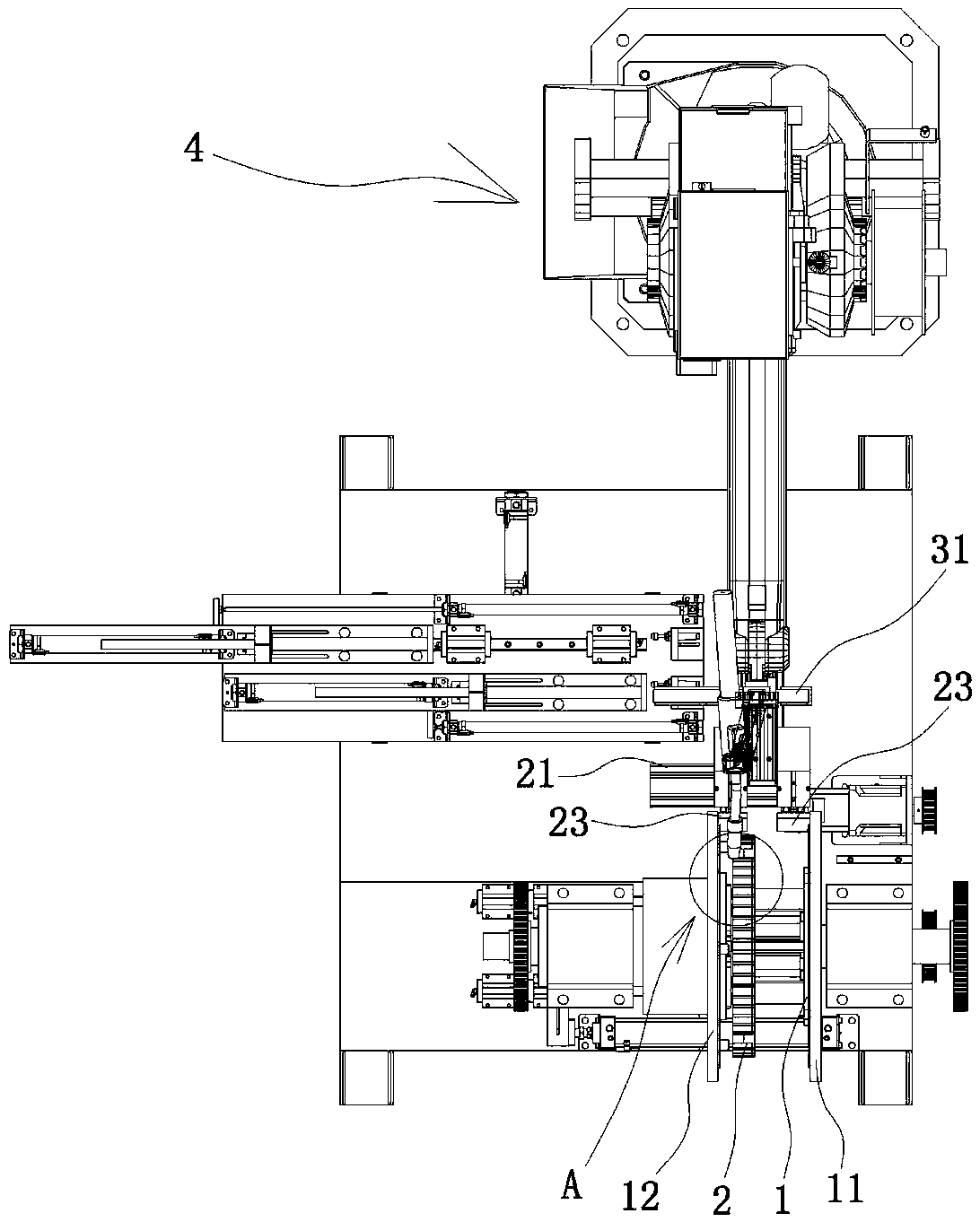

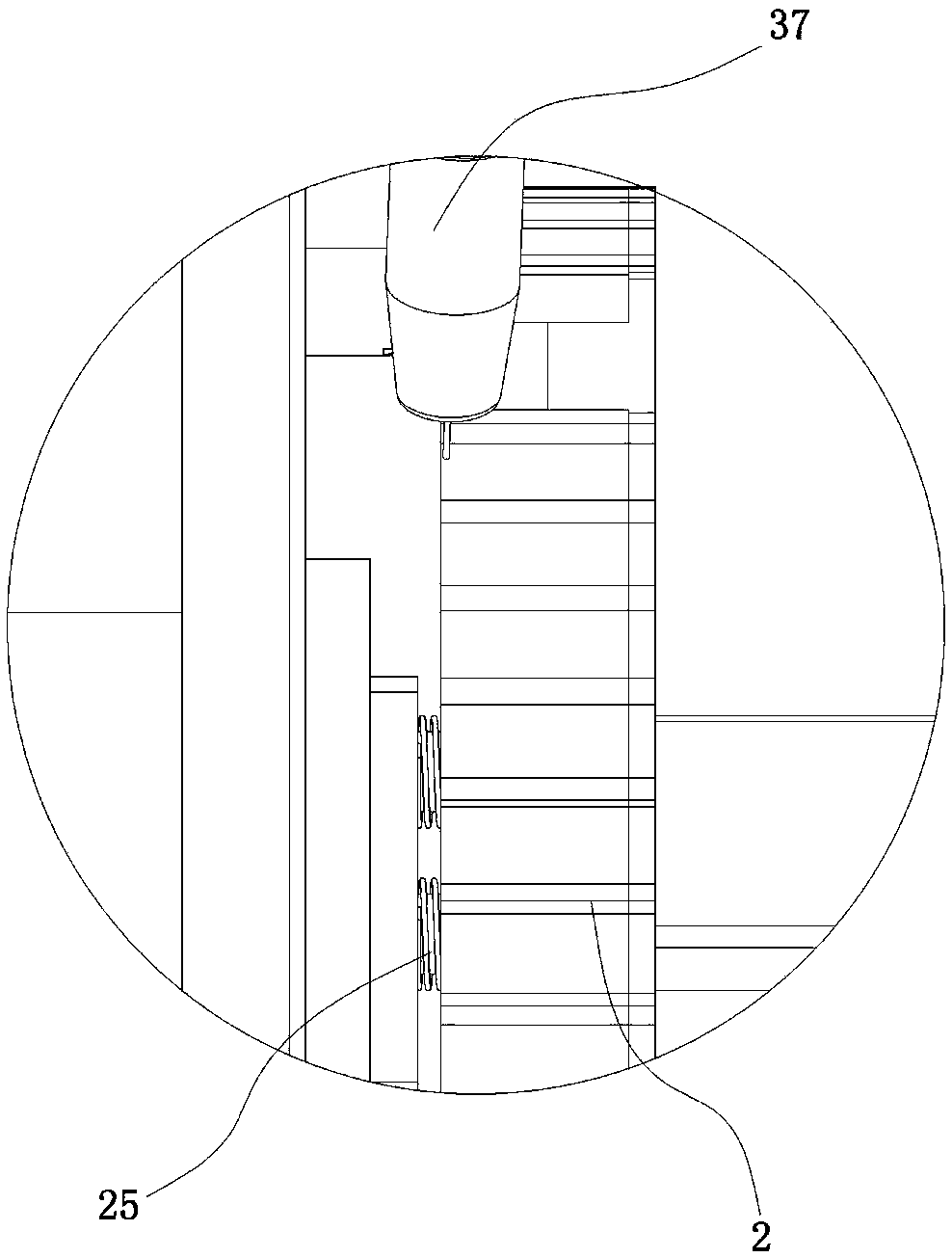

Computer panel saw, control system and processing method

ActiveCN111546425AEasy to installSports reliableFeeding devicesCircular sawsControl systemControl engineering

The invention discloses a computer panel saw. The computer panel saw includes a main work clamp feeding device and an auxiliary work clamp feeding device; the auxiliary work clamp feeding device includes an auxiliary work clamp mounting seat, an auxiliary work clamp driving mechanism, an auxiliary work clamp guiding mechanism, and an auxiliary clamp mechanism; a control system includes a main workclamp feeding device control unit and an auxiliary work clamp feeding device control unit; the auxiliary work clamp feeding device control unit includes an auxiliary work clamp feeding mechanism control unit and an auxiliary clamp mechanism control unit; both a main clamp mechanism control unit and the auxiliary clamp mechanism control unit include a clamp mechanism flip control unit and a clampmechanism clamping control unit; and a working method includes the feeding method of front loading and placing a panel, so that one of the feeding methods of the asynchronous feeding method of the main work clamp feeding device and the auxiliary work clamp feeding device, or the synchronous feeding method of the main work clamp feeding device and the auxiliary work clamp feeding device, or the independent feeding method of the main work clamp feeding device, or the independent feeding method of auxiliary work clamp feeding device is used. The advantage is that the sawing of two kinds of boardsof different lengths can be completed by one sawing.

Owner:NANXING MACHINERY CO LTD

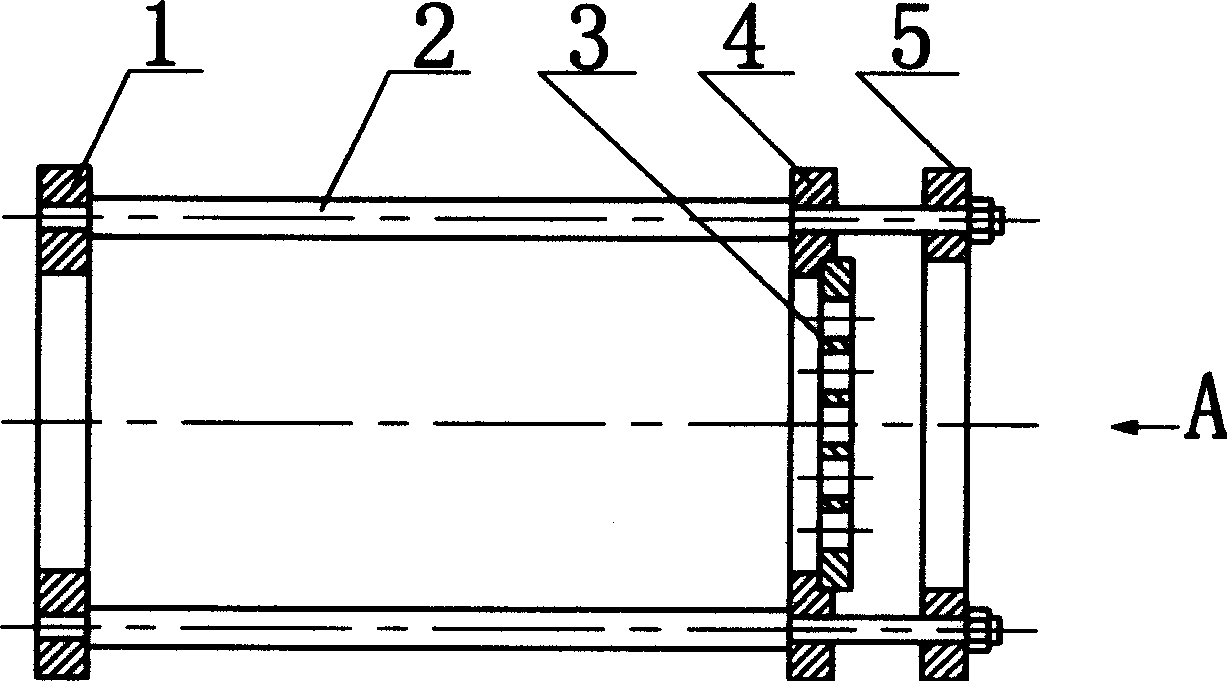

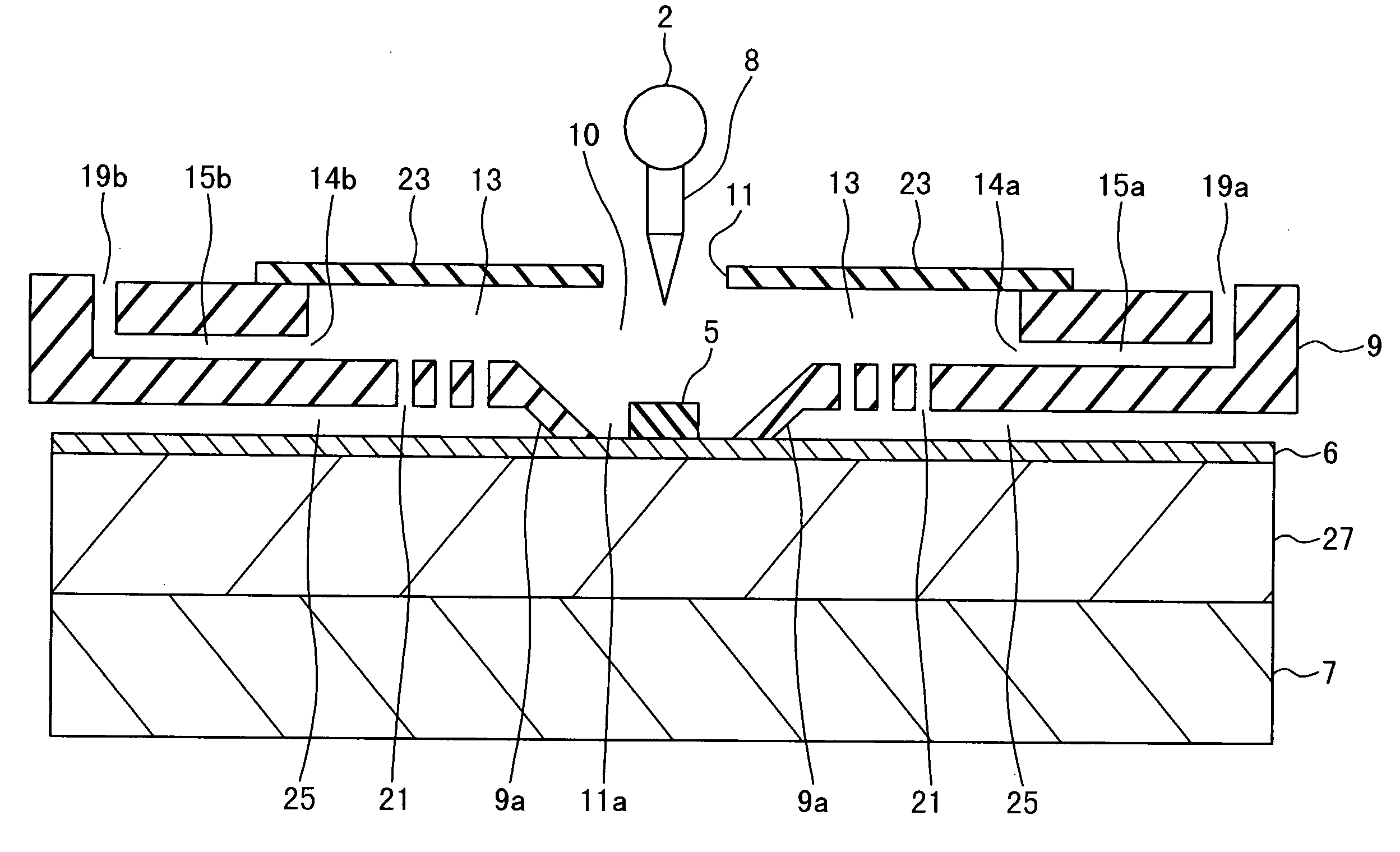

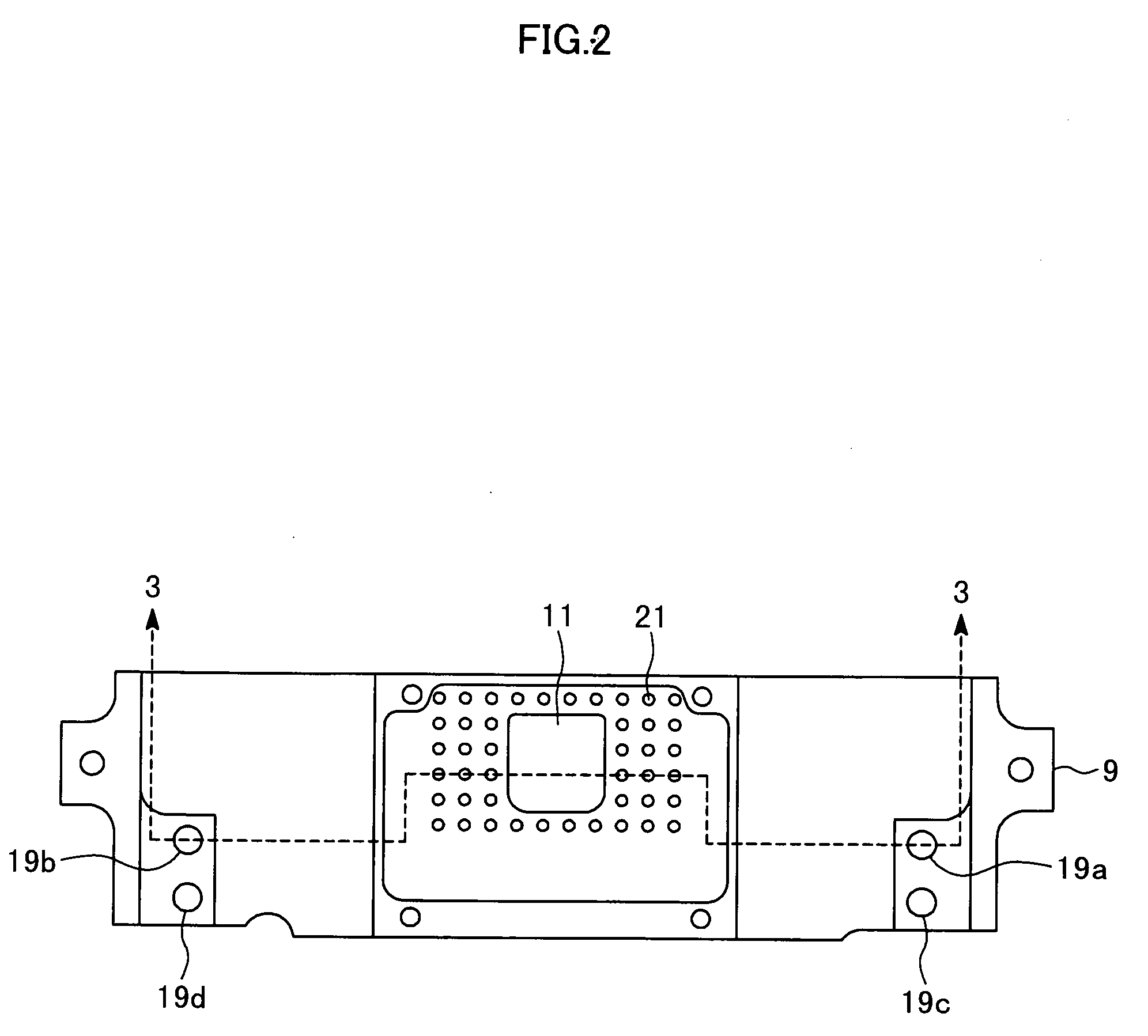

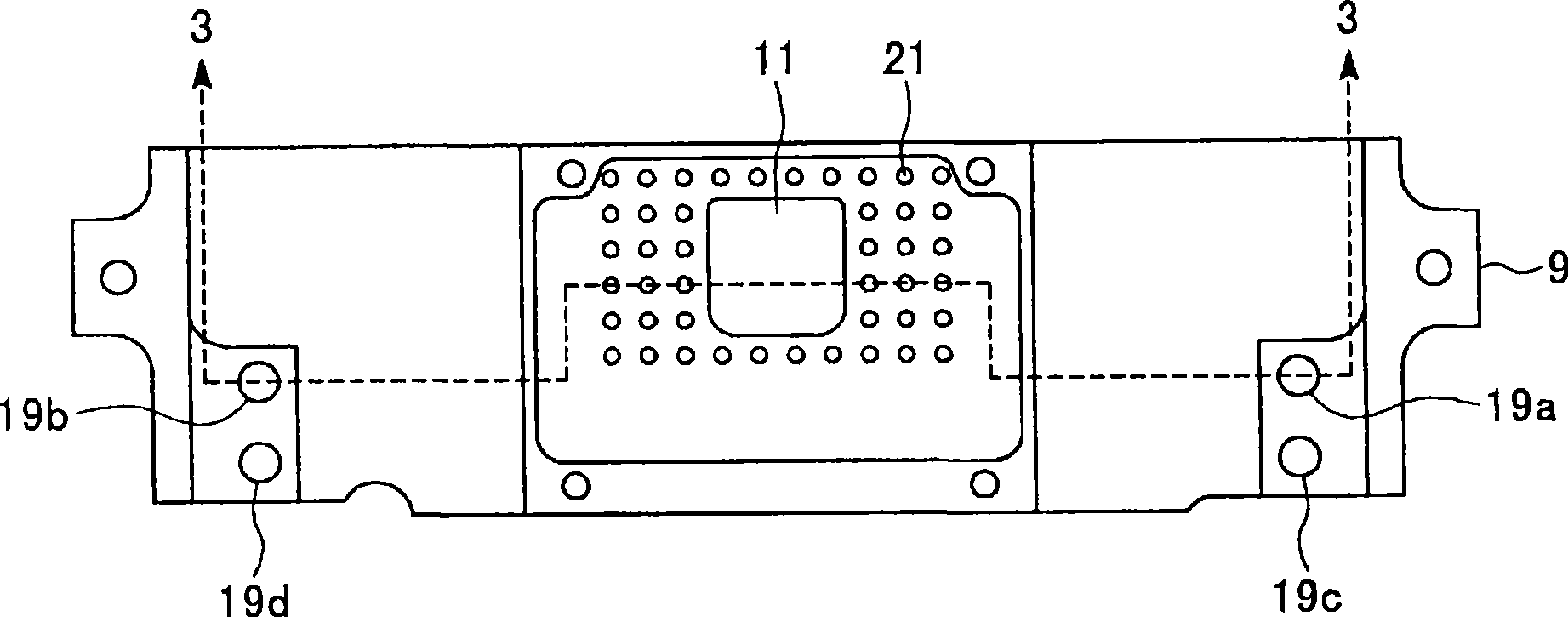

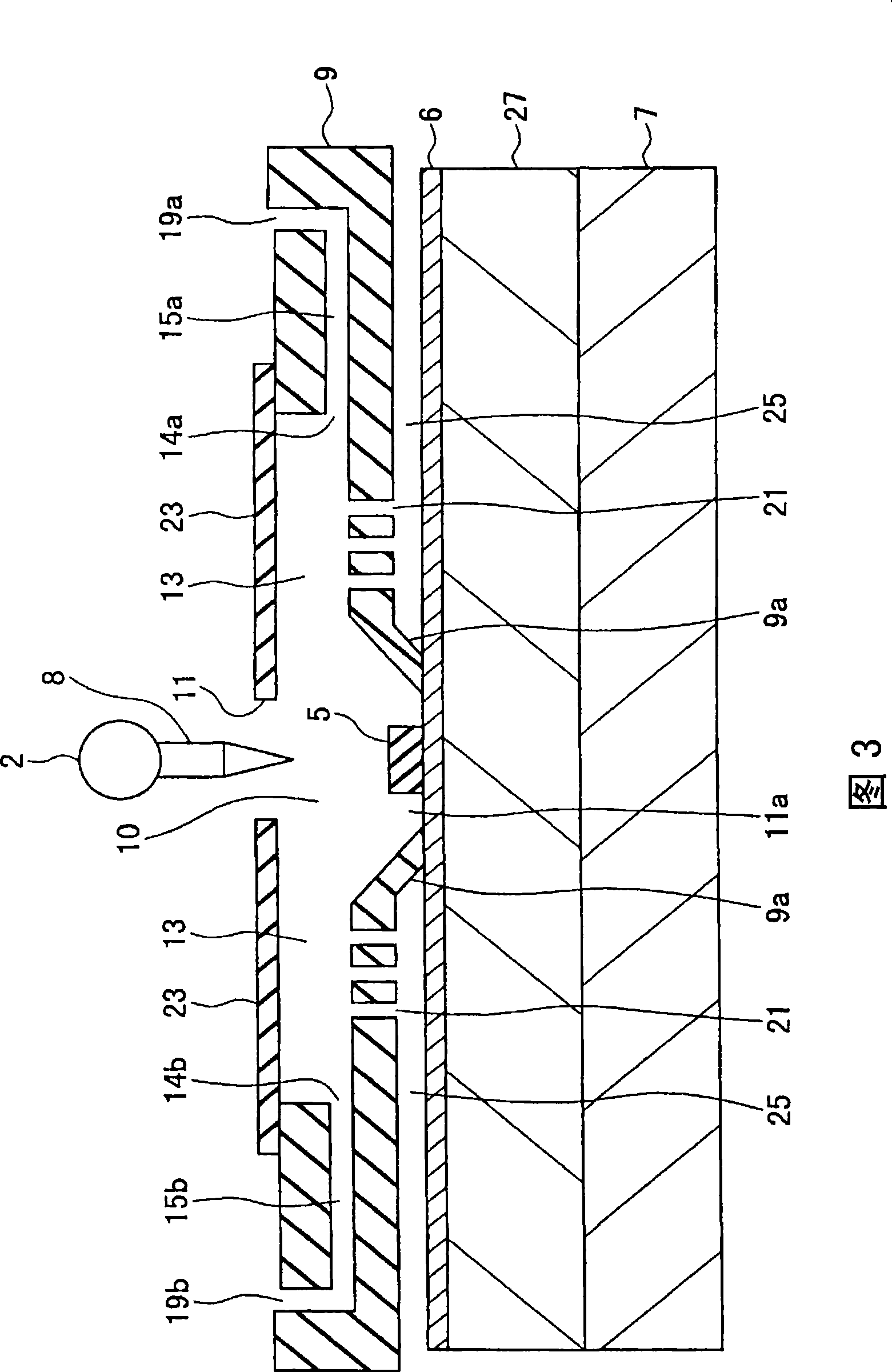

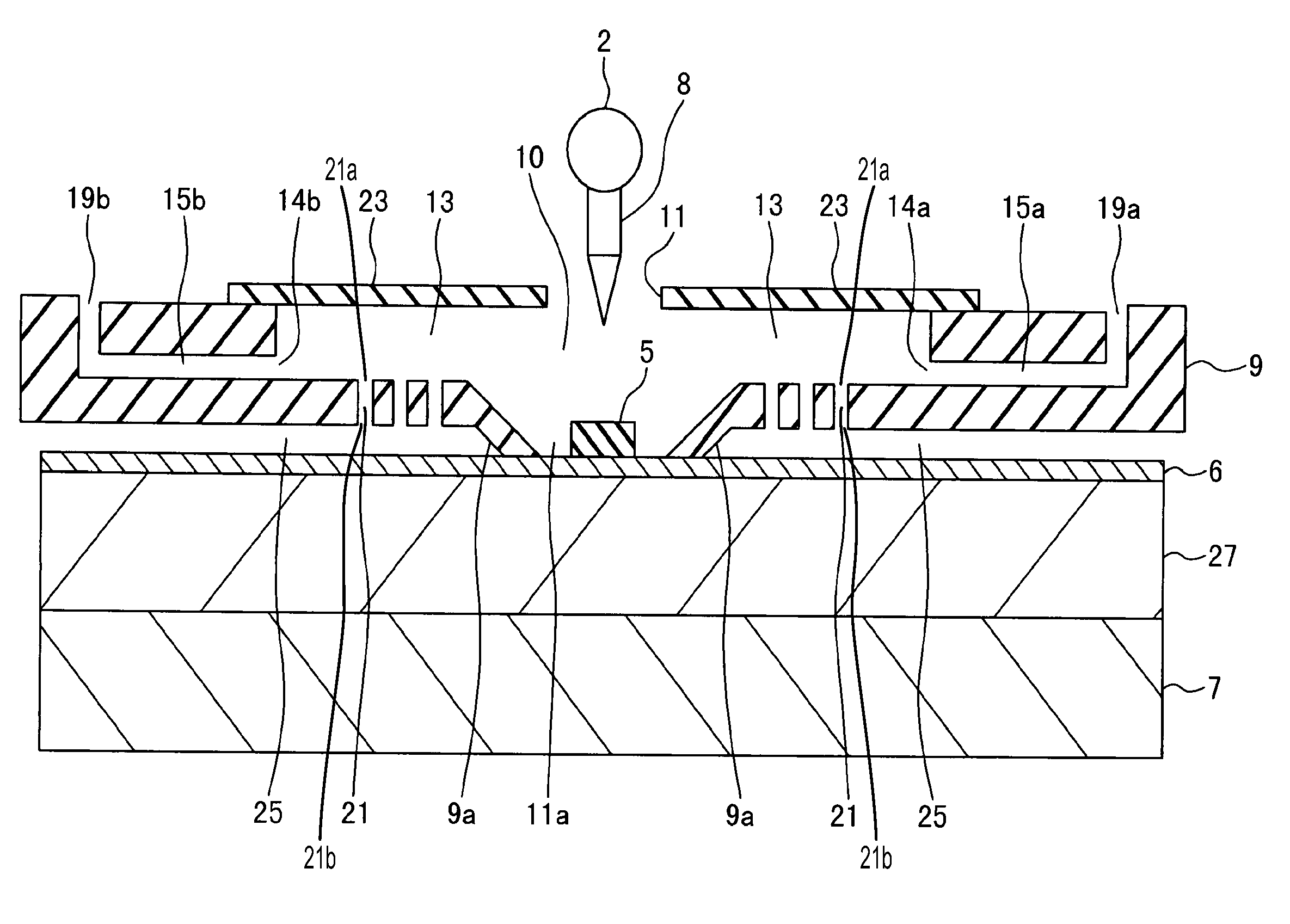

Work Clamp and Wire Bonding Apparatus

ActiveUS20090134201A1Prevent oxidationReduce usageSolid-state devicesWelding/cutting auxillary devicesLead bondingEngineering

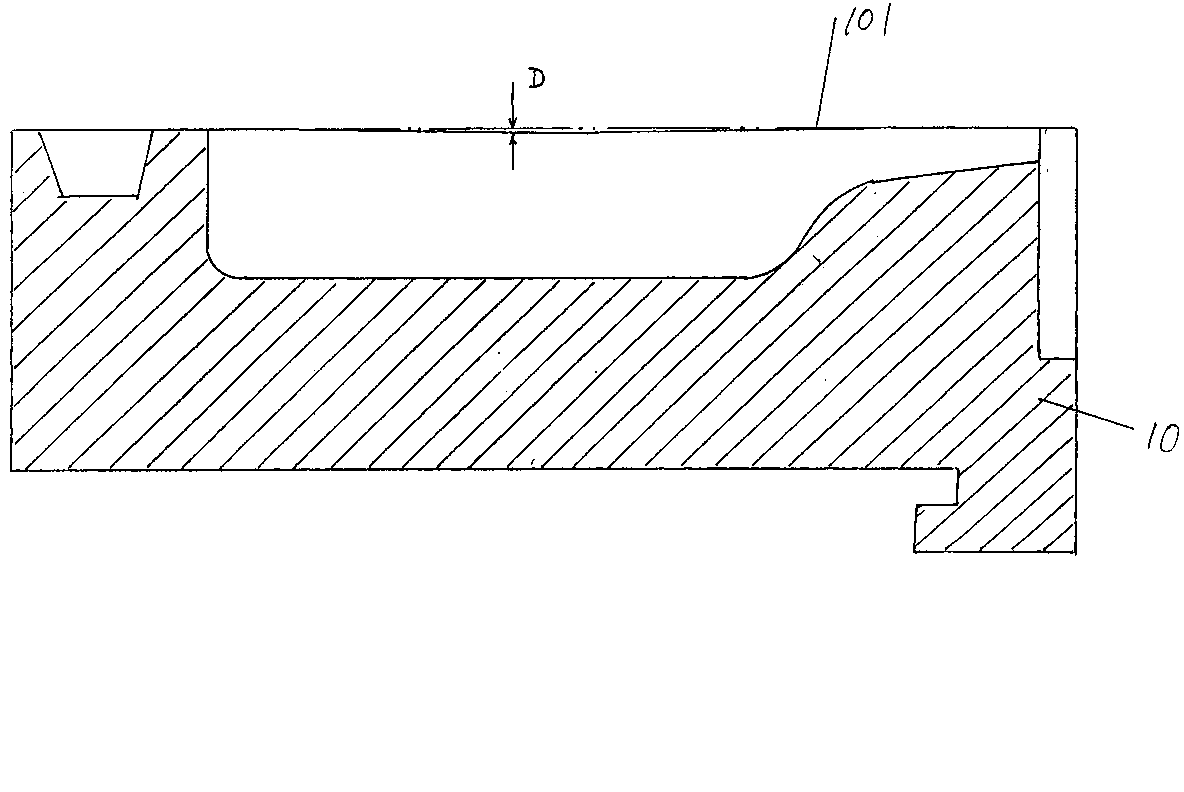

A work clamp and a wire bonding apparatus that can sufficiently restrain oxidation of a bonding area even while reducing a use amount of antioxidant gas are provided. The work clamp according to the present invention includes an interior hollow portion 10 providing an atmosphere of the antioxidant gas, a lower opening portion 11a provided below the interior hollow portion, for containing the bonding area in the interior hollow portion, an upper opening portion 11 provided above the interior hollow portion, for exposing the bonding area, a cavity 13 covering the interior hollow portion and having an area larger than an opening area of the upper opening portion, gas introduction ports 14a, 14b provided at the cavity, for introducing the antioxidant gas into the cavity, and holes 21 connected to below the cavity, for blowing the antioxidant gas introduced from the gas introduction port to a portion other than the bonding area of the work.

Owner:KAIJOO KK

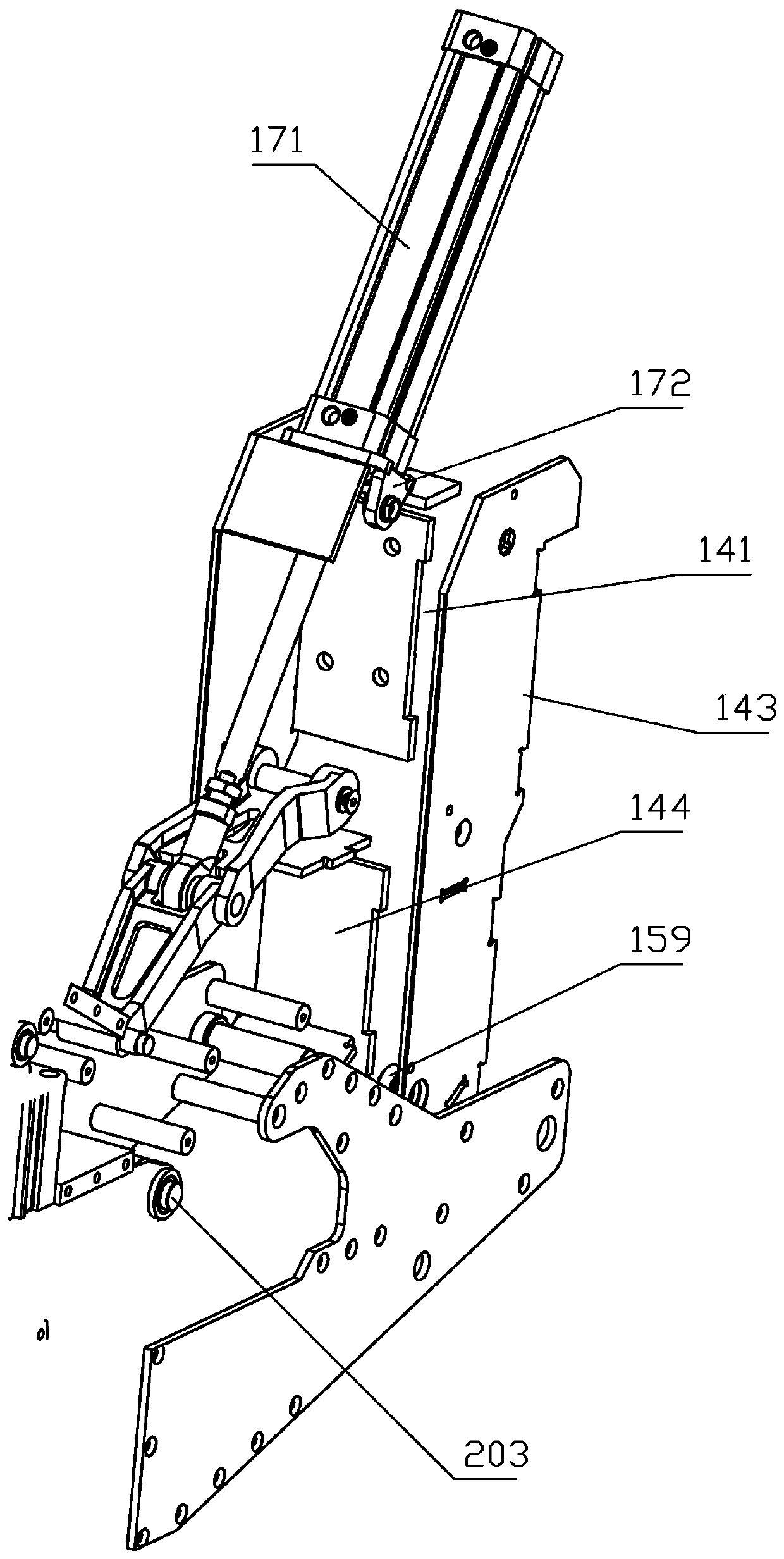

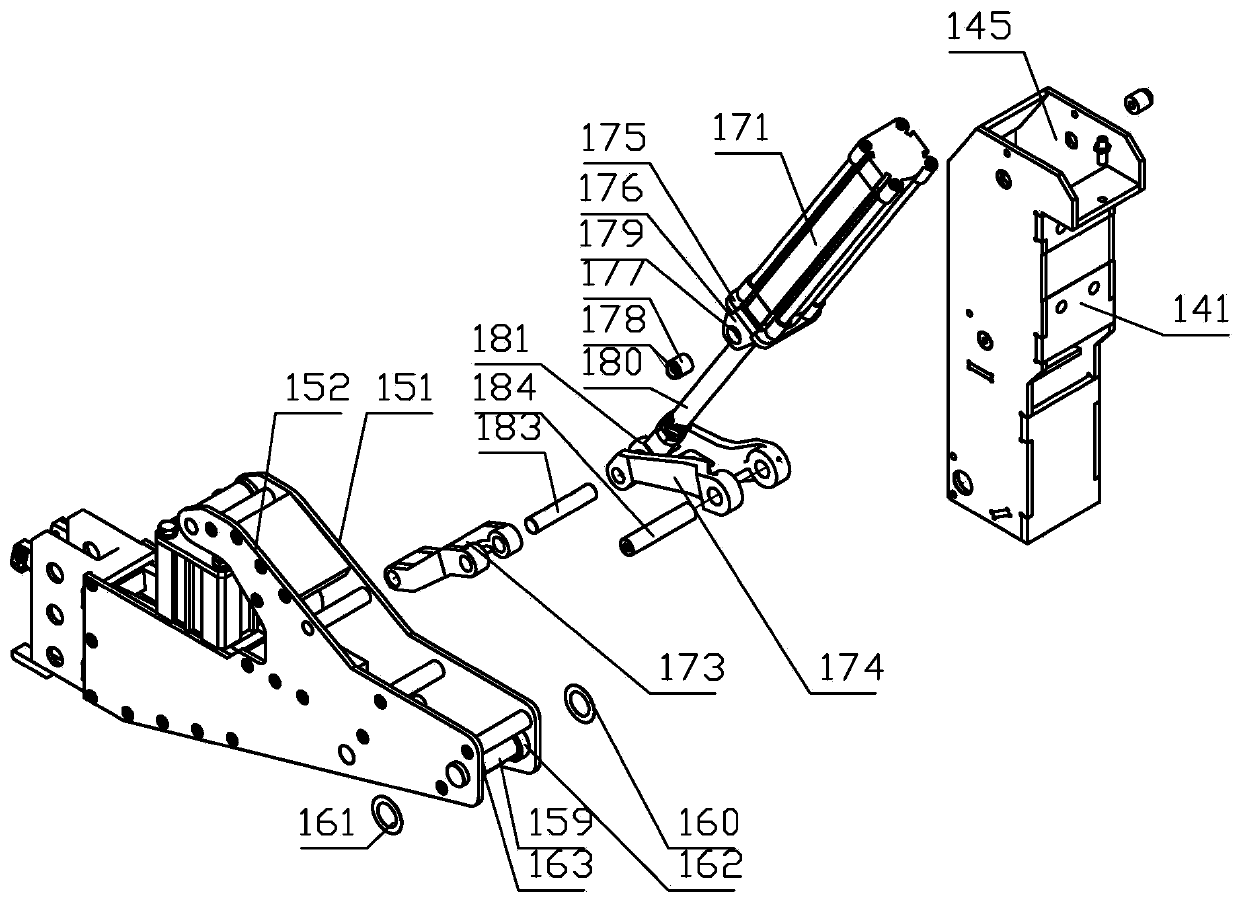

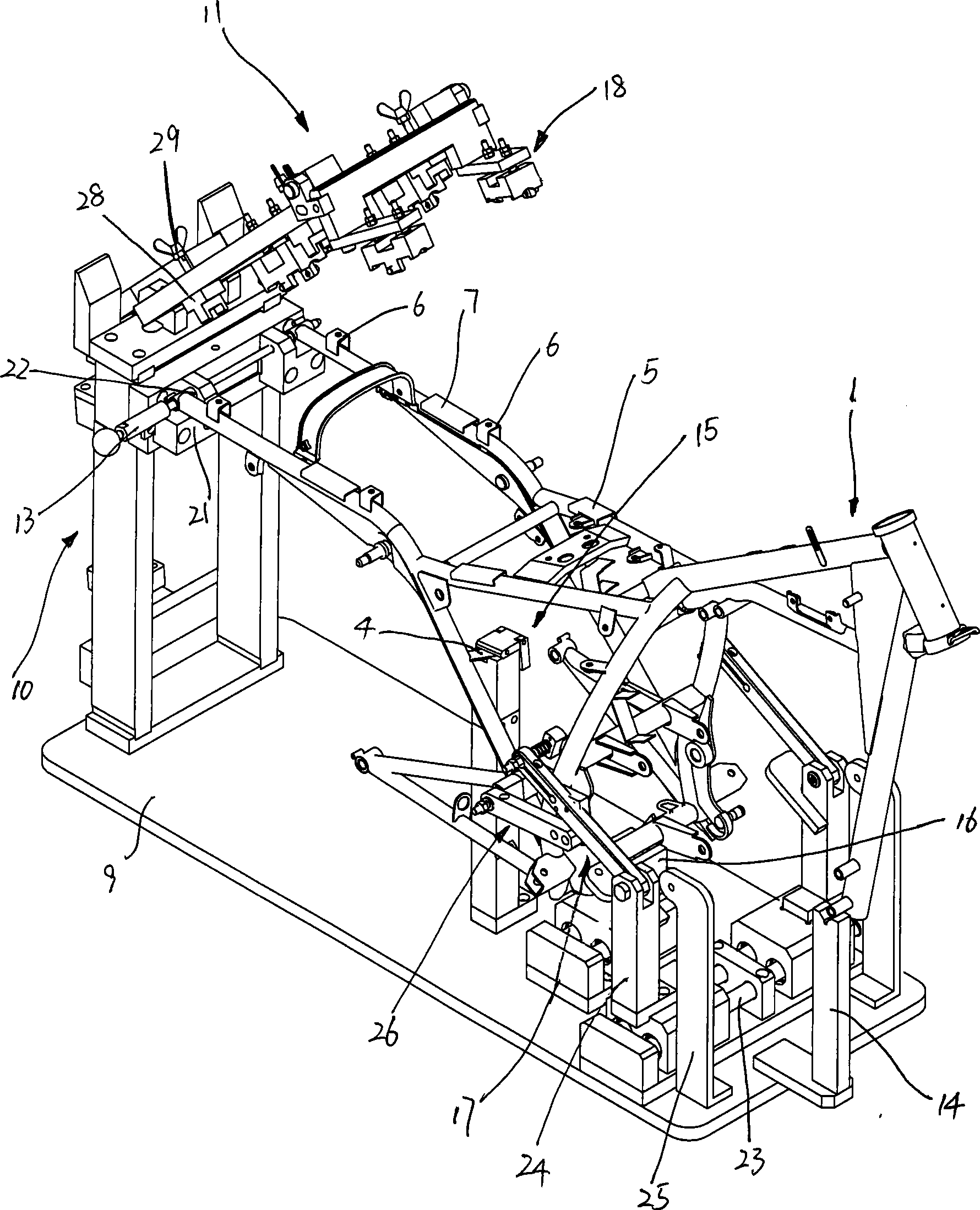

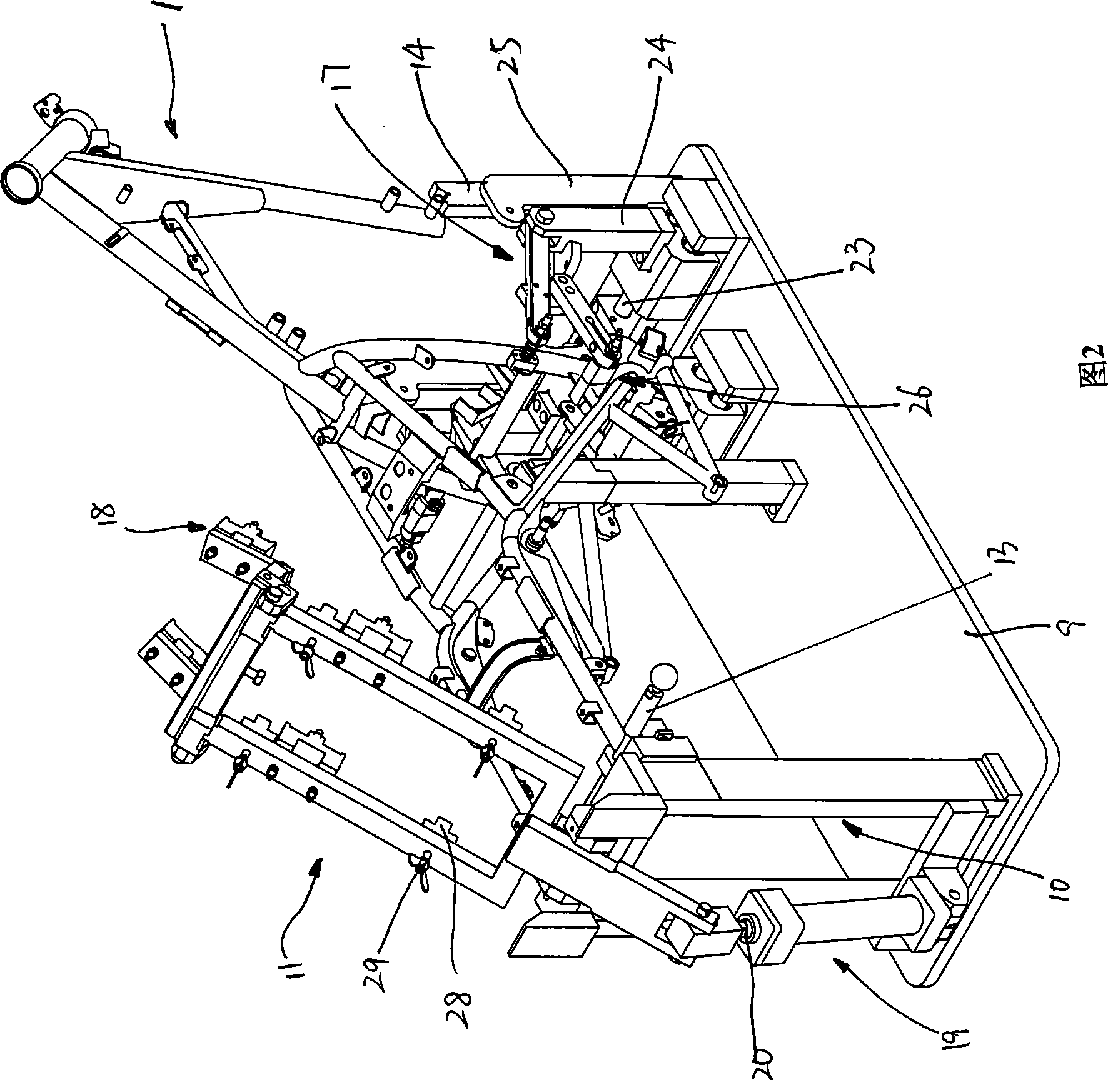

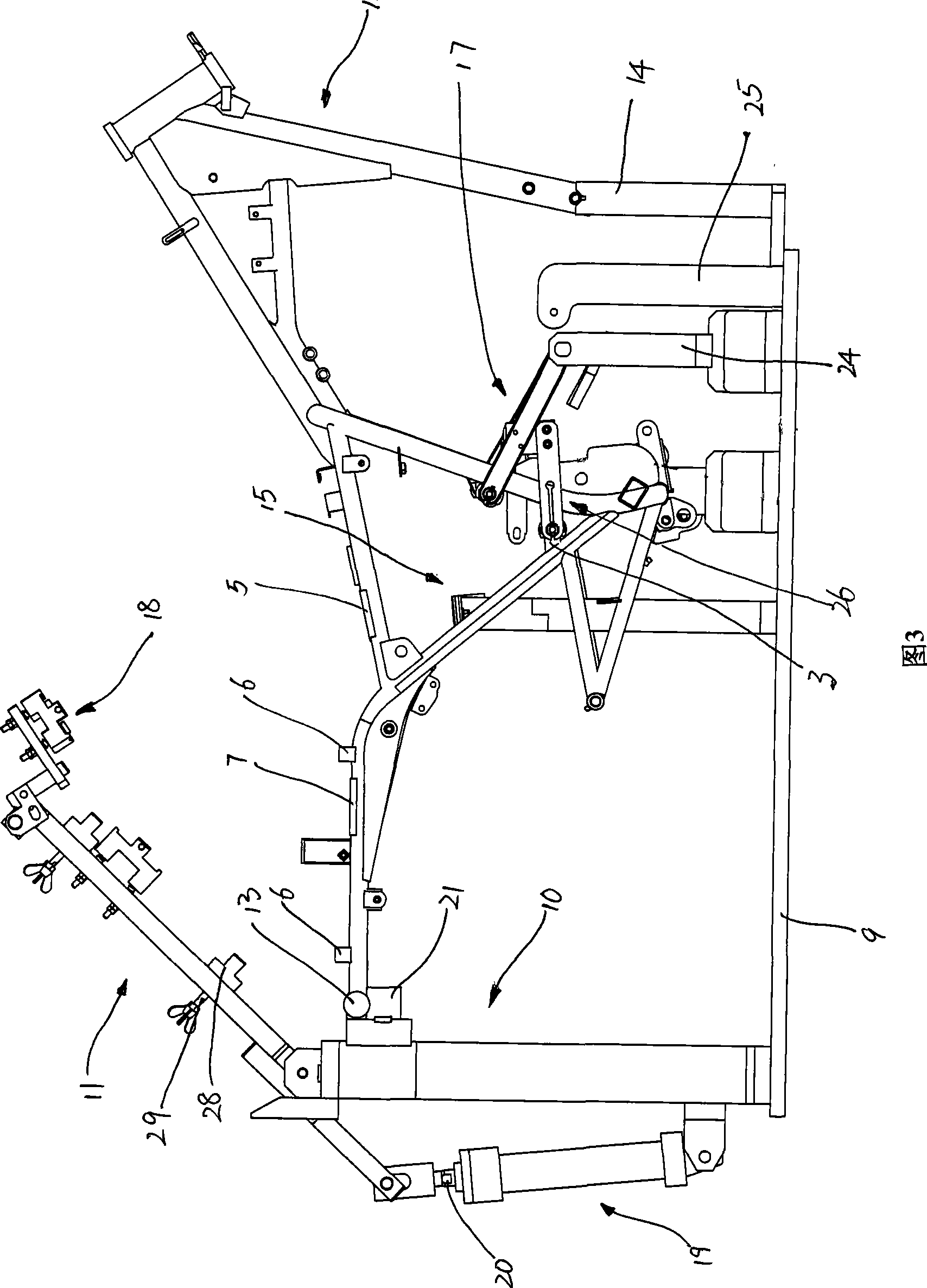

Welding clamp for vehicle frame parts and components

InactiveCN101376199ARapid positioningPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameSpare part

The invention relates to a welding fixture of chassis spare parts, which comprises a stander, a rear support frame and a front support frame which are used for fixing a chassis body, as well as a support block used for supporting the middle part of the chassis body. The upper part of the rear support frame can be rotationally connected with a spare part fixing platform; the lower part of the spare part fixing platform is connected with a plurality of work clamps used for clamping parts to be welded; and a first workseat, a pair of second workseats, and a third workseat which are used for clamping workpieces to be welded are also arranged on the stander. The welding fixture can rapidly and accurately position the chassis body, thereby providing a reliable basis for correct welding positions of other welding parts thereof; the workpieces to be welded are respectively positioned and clamped, so as to complete the welding at one time, thereby greatly improving work efficiency; and each workpiece to be welded is positioned very conveniently, so that the complex preparatory labor is saved during the previous period of welding, furthermore, the welding fixture has the advantages of reasonable structure, improved efficiency, saving labor, saving time and the like.

Owner:庄添财

Automatic tool anchor plate

InactiveCN104499653ASave installation timeEasy to useBuilding reinforcementsMechanical engineeringWork clamp

Owner:柳州市桥厦科技发展有限公司

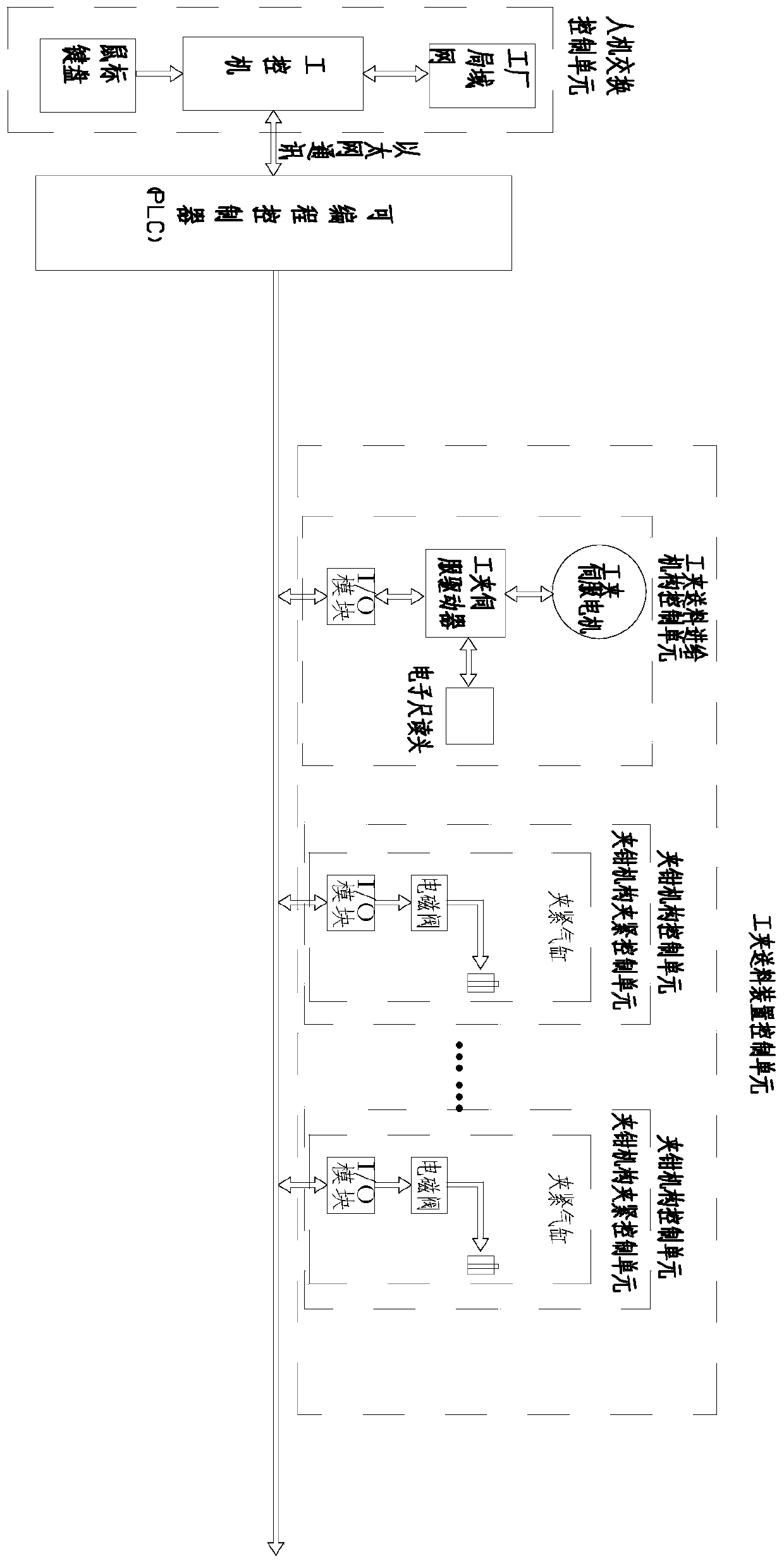

Control system and working method of computer panel saw

ActiveCN111496945AReduce manufacturing costImprove efficiencyMulti-purpose machinesWorking accessoriesControl systemControl engineering

The invention discloses a control system and a working method of a computer panel saw. The control system of the computer panel saw comprises a main work clamp feeding device control unit and an auxiliary work clamp feeding device control unit, wherein the main clamp feeding device control unit comprises a first main clamp mechanism control unit and a second main clamp mechanism control unit, theauxiliary work clamp feeding device control unit comprises an auxiliary clamp mechanism control unit, the first main clamp mechanism control unit comprises an overturning control unit and a clamping control unit, and the second main clamp mechanism control unit and the auxiliary clamp mechanism control unit each comprise a clamping control unit and a moving and overturning control unit; and the working method comprises the step of using one of the feeding modes of asynchronous feeding of a main work clamp feeding device and an auxiliary work clamp feeding device or synchronous feeding of the main work clamp feeding device and the auxiliary work clamp feeding device or independent feeding of the main work clamp feeding device or independent feeding of the auxiliary work clamp feeding device. The system has the advantages that two plates with different lengths can be sawed at the same time, so that the efficiency can be doubled.

Owner:NANXING MACHINERY CO LTD

Lateral welding clamp for laser welding

ActiveCN107097005AImprove accuracyCompact structureLaser beam welding apparatusEngineeringAutomation

The invention discloses a lateral welding clamp for laser welding. The lateral welding clamp for laser welding comprises a base, a chuck, a chuck rotation driving part, an installation seat, a work clamp, a connection support, a telescopic rod assembly and an abutting piece used for tightly abutting against a workpiece. The chuck rotation driving part is installed on the base and connected with the chuck. The installation seat is clamped into the chuck. The workpiece clamp is installed on the installation seat. One side of the connection support is in rotating fit with the installation seat. The telescopic rod assembly is installed on the other side of the connection support. The abutting pin is rotationally installed on the telescopic rod assembly and faces the workpiece clamp. The lateral welding clamp for laser welding has the advantages of being high in automation degree, completing welding of all the lateral faces in a one-off manner after clamping, achieving accurate alignment and being high in production efficiency.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

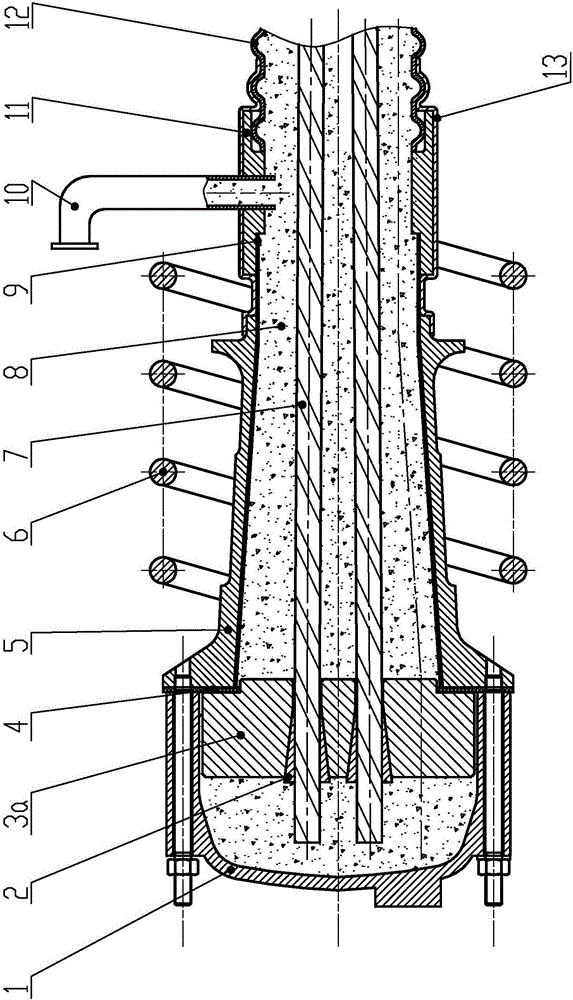

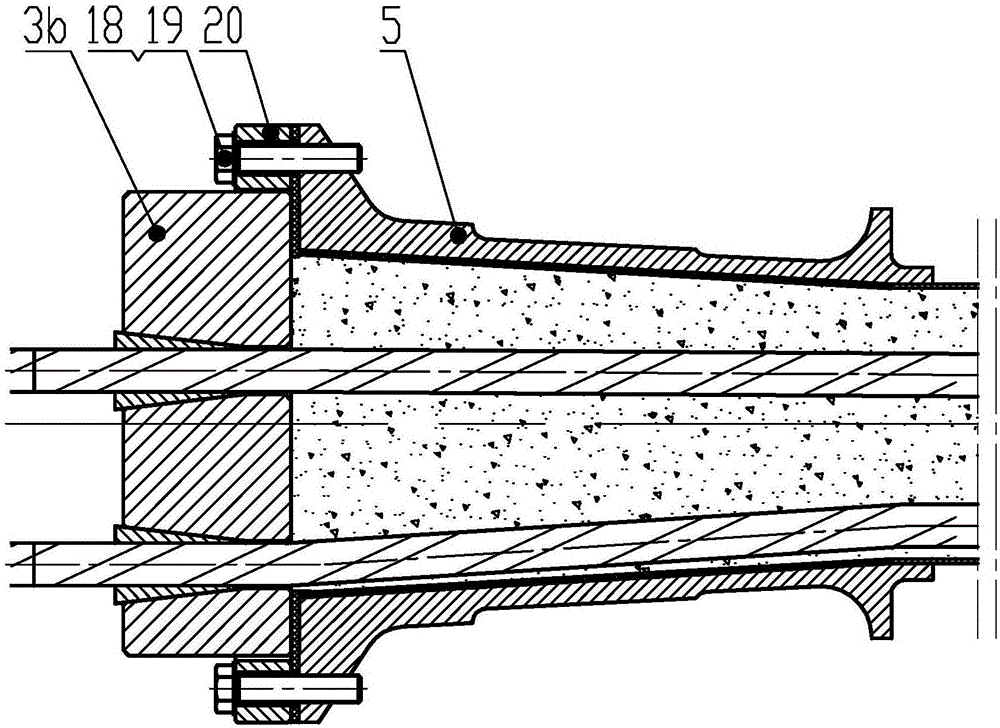

Electrical isolation prestressed anchorage system and construction and installation method thereof

ActiveCN106835985AImprove anti-corrosion performanceRealize non-destructive testingBridge erection/assemblyBuilding reinforcementsPre stressEngineering

An electrical isolation prestressed anchorage system comprises a work anchor plate, an anchor backing plate, a work clamping piece, a prestressed tendon, a slurry body, a structure rib and concrete which are installed sequentially, and further comprises insulating parts including an insulating anchor cover, a crush-resistance insulating pad, an insulating neck bush, an insulating connector, an insulating corrugated pipe and the like; the insulating anchor cover is fixed to the anchor backing plate through a fastening part, so that the work anchor plate is completed covered; the work anchor plate is matched with the anchor backing plate, and the crush-resistance insulating pad is arranged between the end surface of the anchor backing plate and the end surface of the insulating neck bush; the crush-resistance insulating pad is of an annular structure, the insulating neck bush is installed in the anchor backing plate, the outer diameter of the insulating neck bush is matched with the inner diameter of the anchor backing plate, and the insulating neck bush is connected with the insulating corrugated pipe through the insulating connector; and the middle portion of the cylindrical surface of the insulating connector is provided with an assembling hole for being connected with a grout pipe for pouring of insulating slurry. The electrical isolation prestressed anchorage system is connected with an electrical isolation performance detector, and then an electrical isolation anchorage system capable of conducting detection can be formed. The electrical isolation prestressed anchorage system is reasonable in structure, quite convenient and quick in installation and construction and capable of achieving nondestructive testing of engineering.

Owner:LIUZHOU OVM MASCH CO LTD

Whole-bundle disanchoring device and disanchoring method adopting same

ActiveCN102704691AShorten the demolition periodImprove work efficiencyBuilding material handlingPre stressEngineering

The invention discloses a whole-bundle disanchoring device and a disanchoring method adopting the same. The whole-bundle disanchoring device comprises a top-front working pile and a top-rear disanchoring device, wherein the top-front working pile is pipe-shaped and is arranged at the outer part of one end of a large prestressed member; the top-rear disanchoring device is formed by a first ring, a second ring and a plurality of cylinders; the first ring and the second ring are arranged in parallel; the plurality of cylinders are arranged between the first ring and the second ring at a distance; one end of each cylinder is fixed on the first ring, and the other end of each cylinder is connected on the second ring by a bolt. The whole-bundle disanchoring device and the disanchoring method disclosed by the invention has the beneficial effects that the top-front working pile and the top-rear disanchoring device are respectively arranged at the outer parts of a temporary anchor and a first working anchor in the disanchoring process of a prestressed steel-stranded bundle and is used for assisting a hollow jack and the working anchor to finish the assembly and disassembly of a working clamping piece together and eliminating the stress, so that works such the construction process of whole disanchoring operation of the prestressed steel-stranded bundle are finished. The whole-bundle disanchoring device disclosed by the invention has the advantages of simple design, simpleness and convenience for operation and the like.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

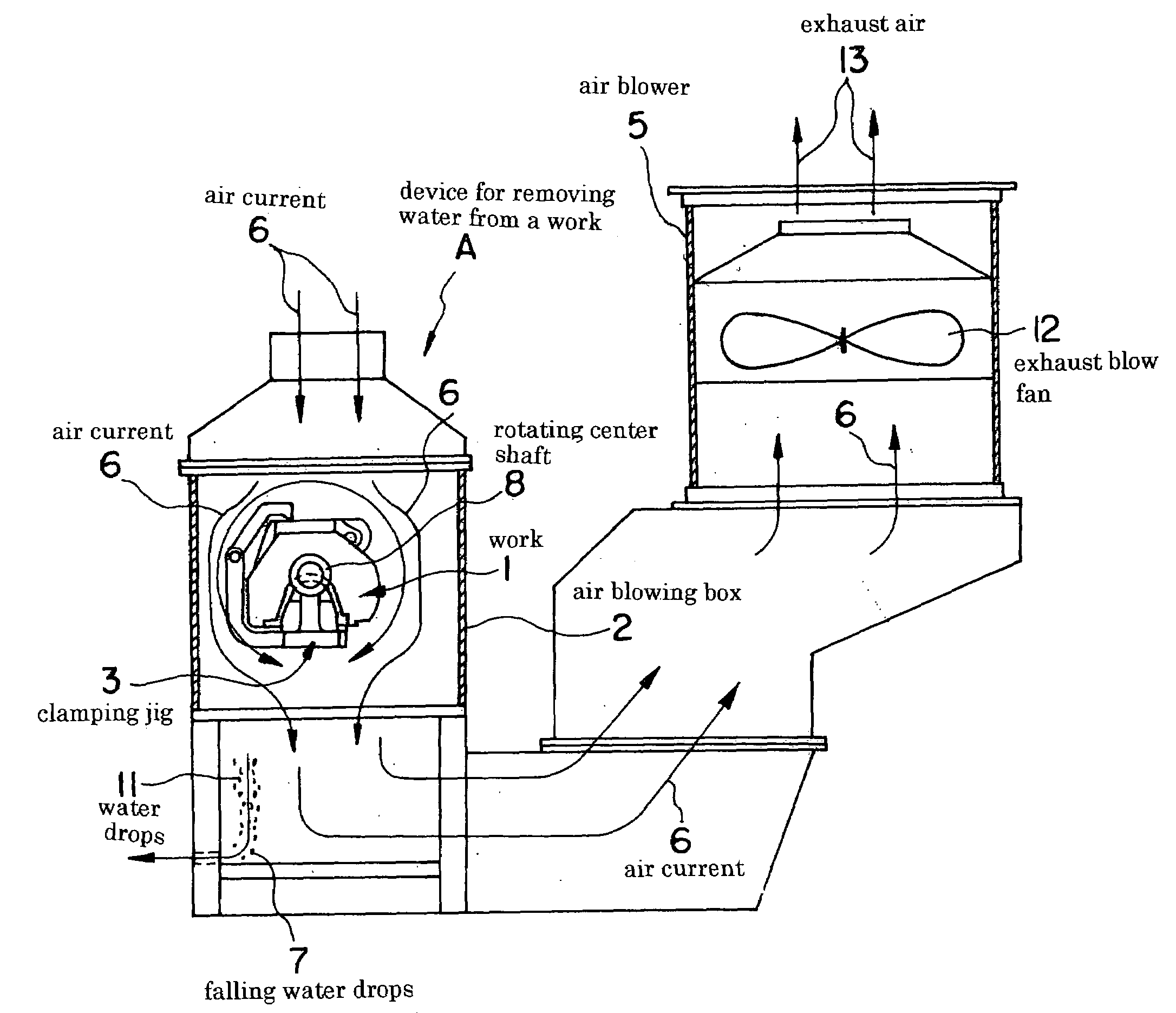

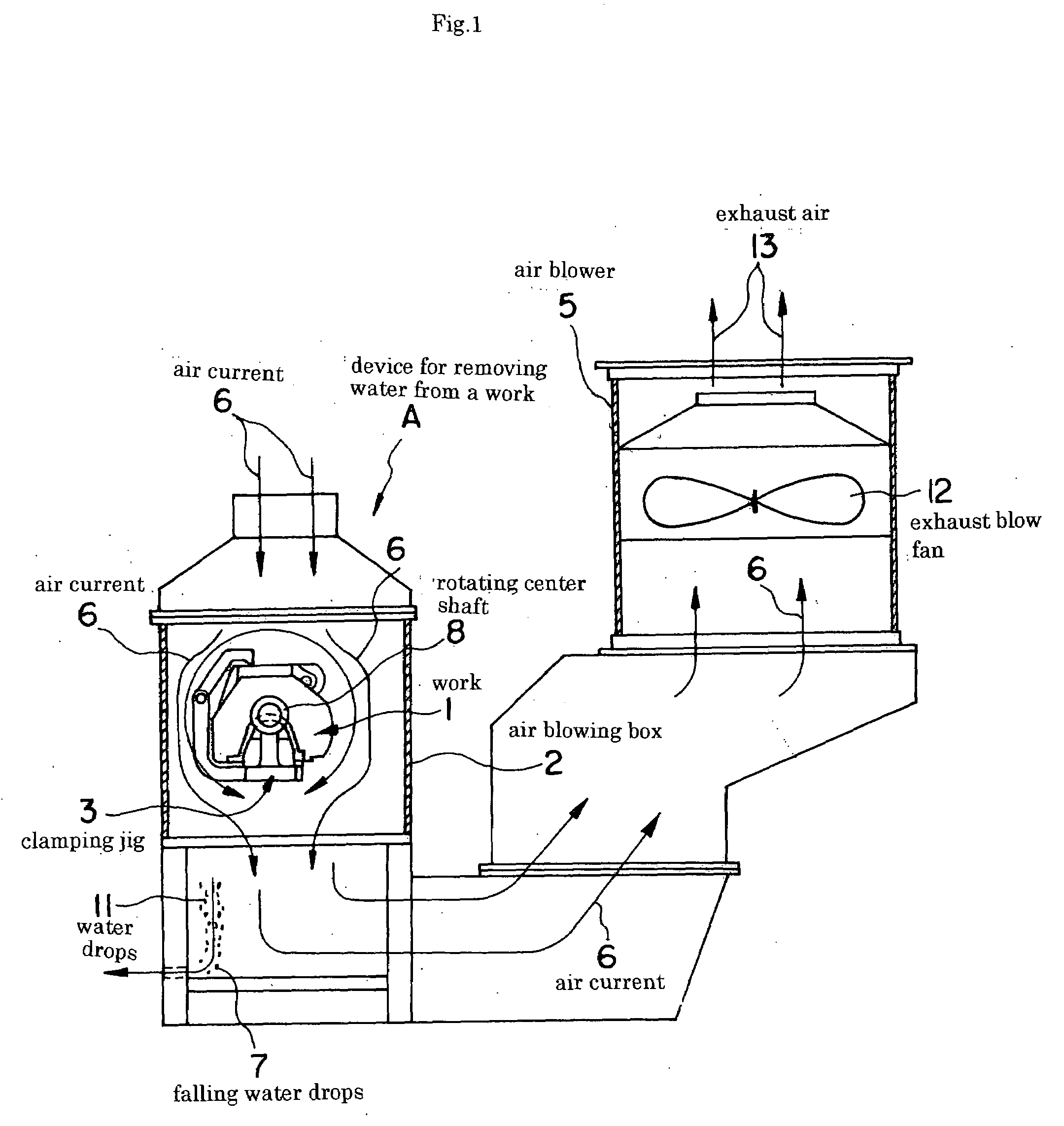

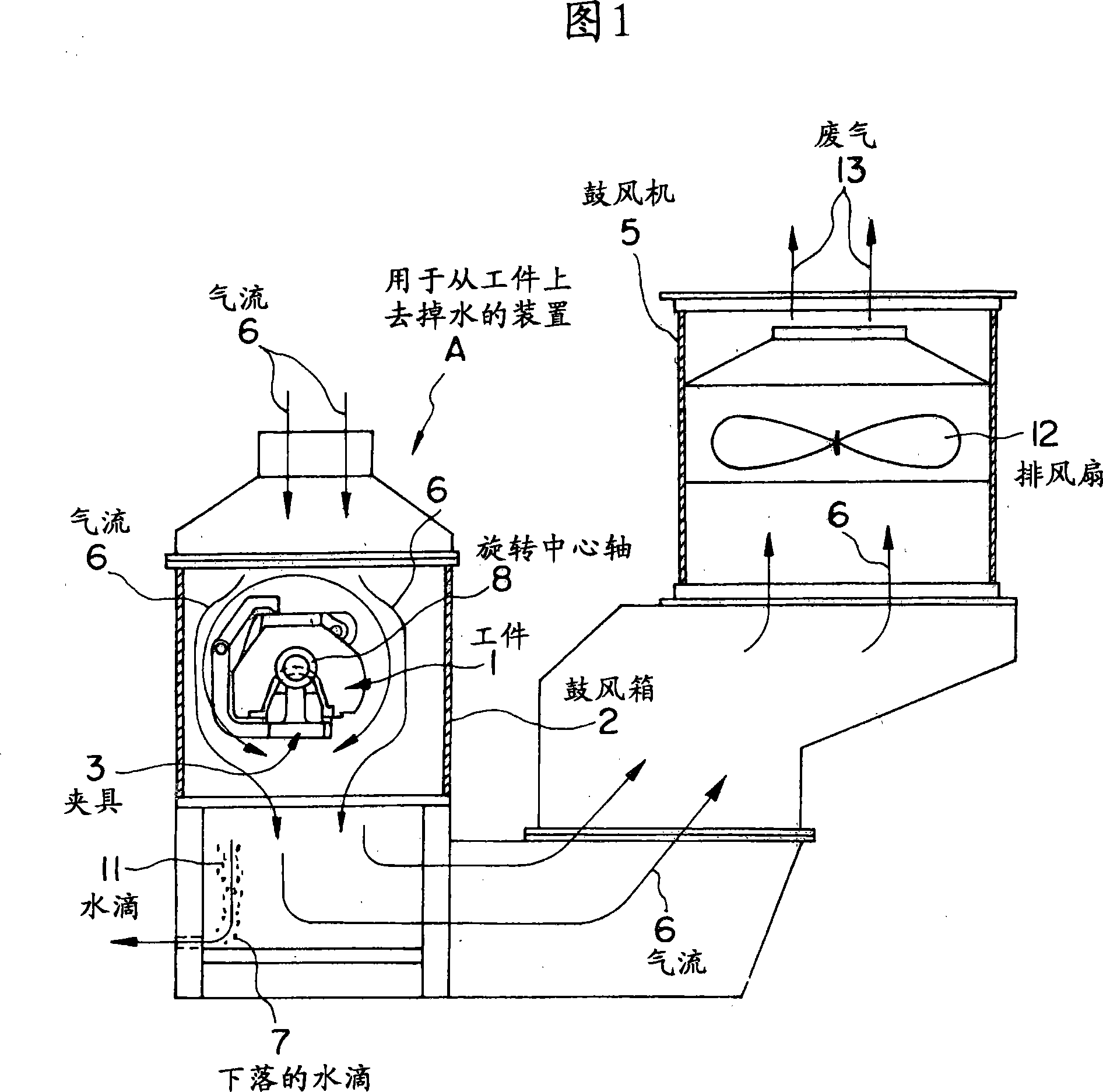

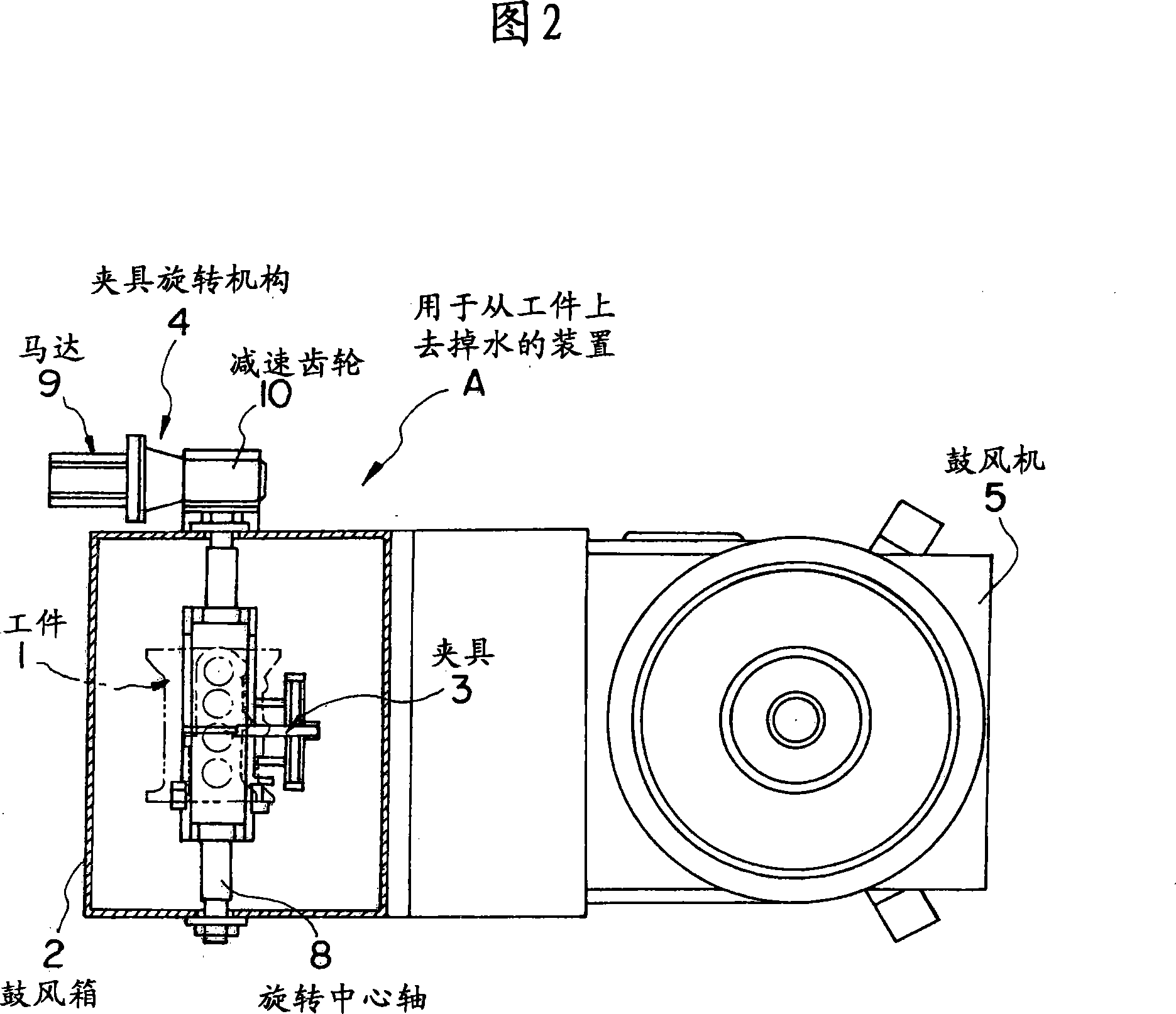

Device for removing water from a work

InactiveUS20080078098A1Agriculture tools and machinesDrying solid materials without heatAir blowerIndustrial engineering

Owner:SHIGAYAMASHITA

Control system and working method of computer panel saw

PendingCN111452149AReduce manufacturing costVersatilityMulti-purpose machinesWorking accessoriesProgrammable logic controllerControl system

The invention relates to a control system and working method of a computer panel saw. The computer panel saw comprises a programmable logic controller (PLC), a data bus, a work clamp feeding device control unit, a pressing device control unit and a cutting device control unit. The data bus is connected with the PLC. The work clamp feeding device control unit, the pressing device control unit and the cutting device control unit are connected in parallel with the data bus in a bidirectional control mode. The work clamp feeding device control unit comprises a work clamp feeding mechanism controlunit and a plurality of clamp mechanism control units. The pressing device control unit comprises two pressing device lifting control units. The cutting device control unit comprises a cutting devicefeeding control unit, a cutting device lifting control unit, a main saw drive control unit, an auxiliary saw drive control unit, and a board width detection device control unit. The computer panel sawhas the advantages of high safety, fault tolerance, high efficiency, stability, high precision and simple control structure.

Owner:NANXING MACHINERY CO LTD

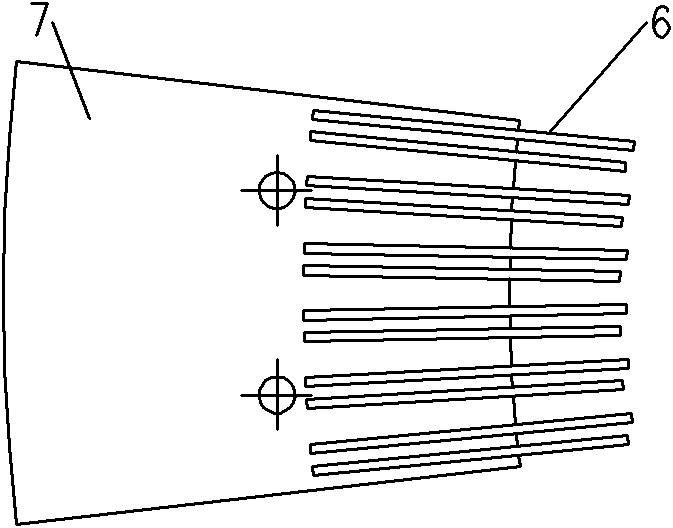

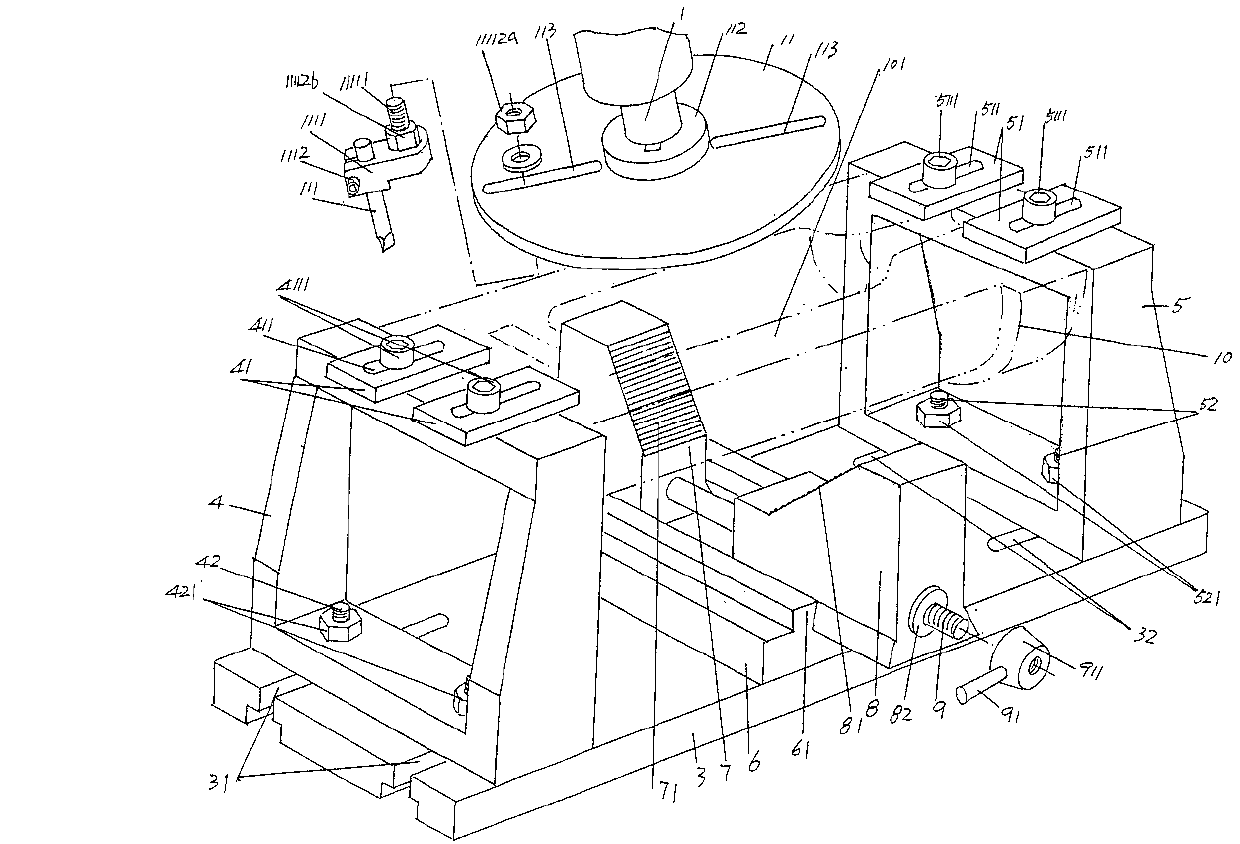

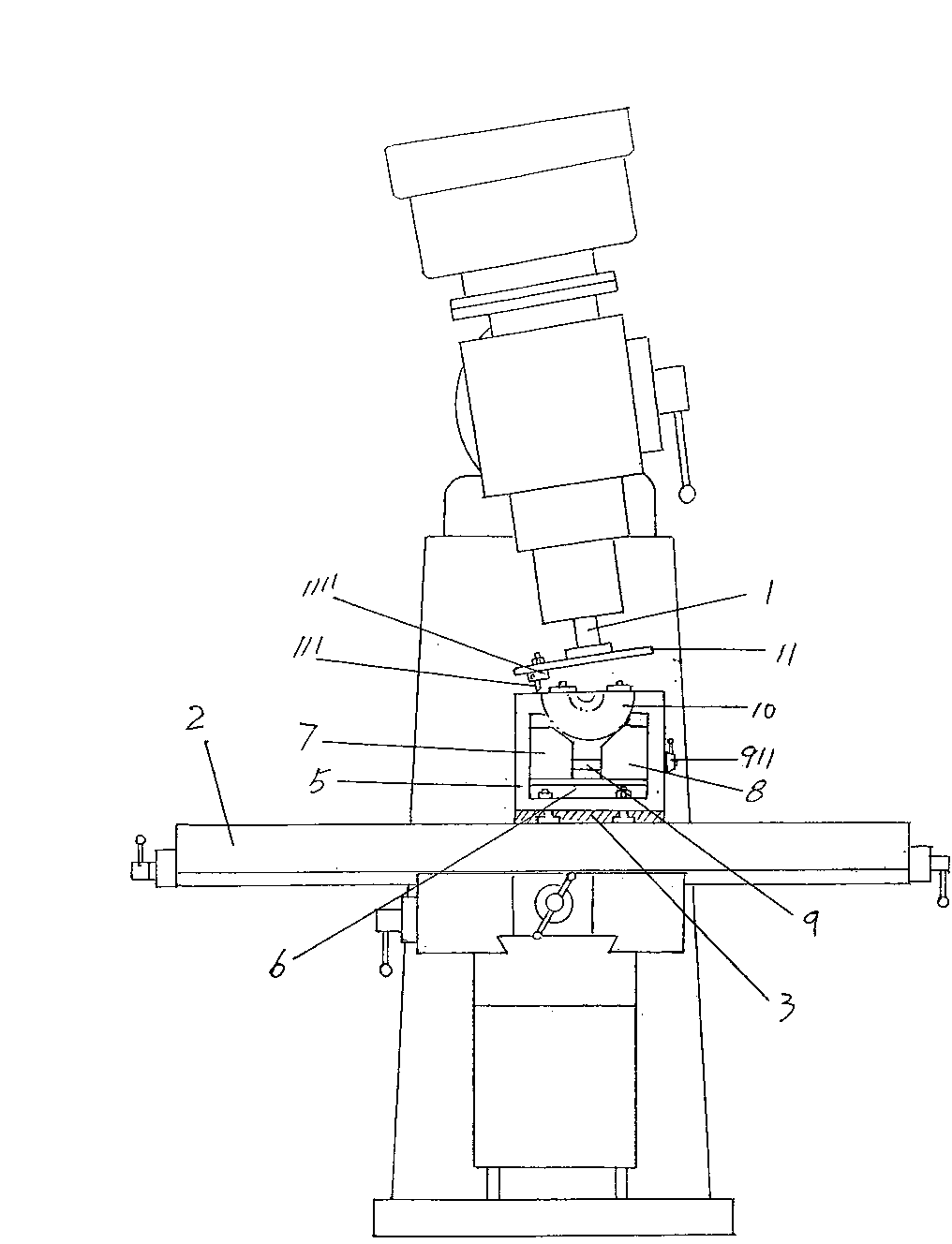

Work clamp matched with universal miller and used for milling seam faces of glass molds

InactiveCN103273344AMeet the requirements of processing concave arc surfaceReliable positioning and clampingMilling cuttersPositioning apparatusBaseboardMilling cutter

The invention discloses a work clamp matched with a universal miller and used for milling seam faces of glass molds. The universal miller comprises a miller main shaft and a miller working platform. The work clamp comprises a baseboard, a first adjustment support, a second adjustment support, a guide rail seat, a fixed mold clamping seat, a movable mold clamping seat and a screw, wherein the baseboard is arranged on the miller working platform, the first adjustment support and the second adjustment support are arranged at the two ends of the baseboard, at least one first adjustment pressing plate and one second adjustment pressing plate are arranged on the top portion of the first adjustment support and on the top of the second adjustment support, the guide rail seat is fixedly arranged on the middle portion of the baseboard, a pair of guide rails are formed on the guide rail seat, the fixed mold clamping seat corresponds to the movable mold clamping seat, a screw sliding sleeve is configured on the movable mold clamping seat, one end of the screw is connected with the fixed mold clamping seat, the other end of the screw is matched with the screw sliding sleeve, and a screw manipulation handle is fixedly arranged on the end portion, extending out of the screw sliding sleeve, of the screw. The work clamp matched with the universal miller and used for milling the seam faces of the glass molds is convenient to manufacture, to use and to maintain, cheap, capable of meeting the requirement of machining concave arc surfaces on the seam faces of the glass molds, high in machining efficiency, not heavy in working strength, and is suitable for molds of different standards. Further, by means of the work clamp, the glass molds do not loose when the glass molds are milled with milling cutters.

Owner:ORI MOLD TECH SUZHOU

Releasing mechanism and leveling apparatus

ActiveUS8250894B2Improve responseReduce noiseMetal-working feeding devicesPositioning devicesWork rollEngineering

A release mechanism for use in a leveling apparatus that performs a leveling process on a work object that has been wound in a coil configuration as a result of the work object being passed between a front side work roll in contact with the front side surface of the work object and a back side work roll that is in contact with the back side surface of the work, wherein the releasing mechanism switches between a work clamp state that allows performance of the leveling process and a release state that releases the work object from the clamp state by displacing a work roll support member that supports one of the work rolls relative to the another support member to change a distance between the work rolls by utilizing rotational movement of an electric motor.

Owner:AIDA ENG LTD

Work clamp and wire bonding device

ActiveCN101427359APrevent oxidationCurb usageSolid-state devicesWelding/cutting auxillary devicesMechanical engineeringWire bonding

A work clamp, and wire bonding apparatus, that even when the amount of antioxidant gas used is reduced, can satisfactorily inhibit the oxidation of bonding area. The work clamp is characterized by including interior hollow (10) providing an atmosphere of antioxidant gas; inferior aperture (11a) disposed under the interior hollow and provided to insert the bonding area in the interior hollow; superior aperture (11) disposed above the interior hollow and provided to expose the bonding area; cavity (13) covering the interior hollow and provided with an area larger than the opening area of the superior aperture; gas introduction ports (14a,14b) provided in the cavity and adapted to introduce the antioxidant gas in the cavity; and hole (21) connected to an inferior zone of the cavity and provided for blowing of the antioxidant gas introduced from the gas introduction ports to portions other than the bonding area of the work.

Owner:KAIJOO KK

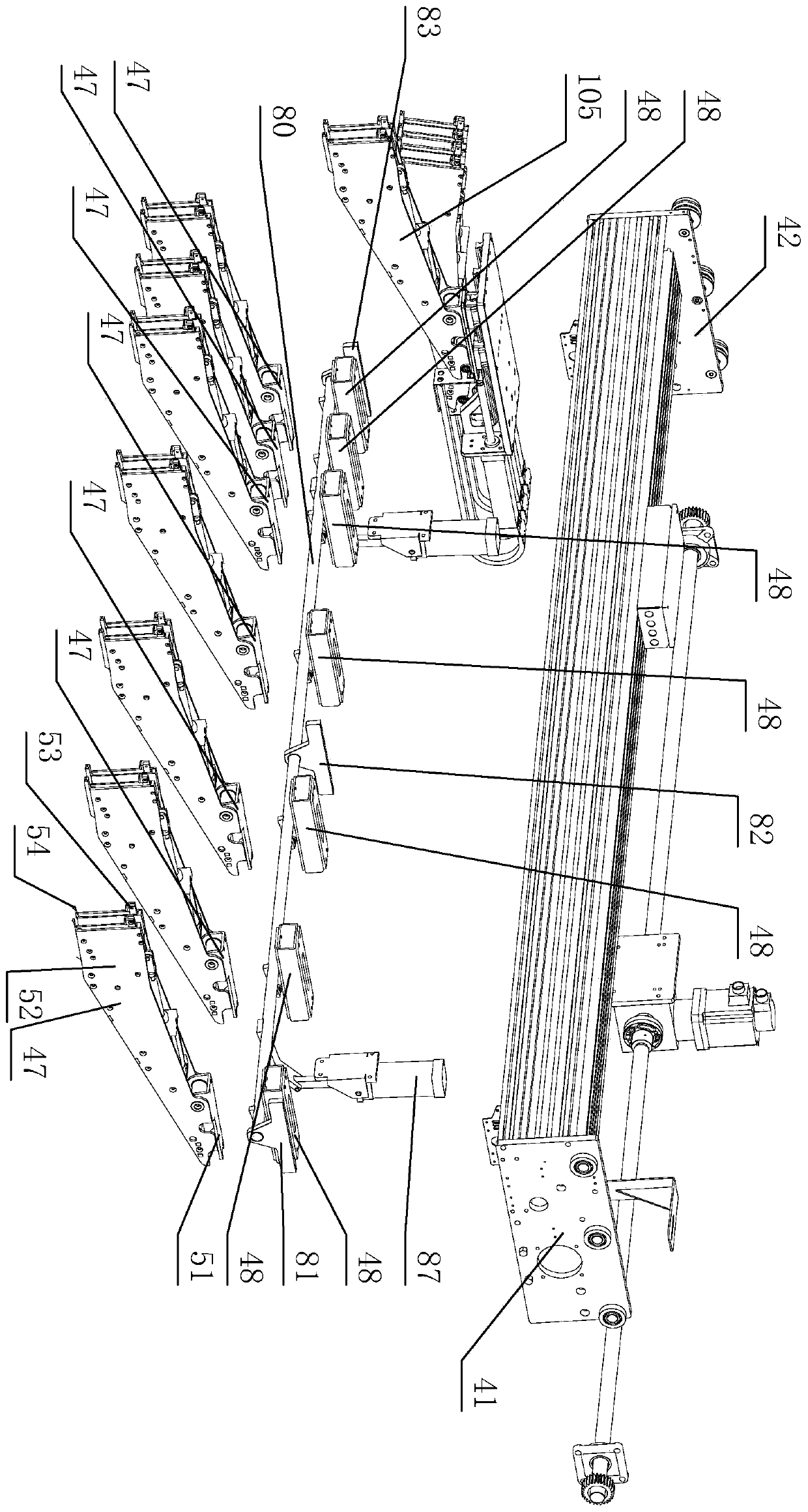

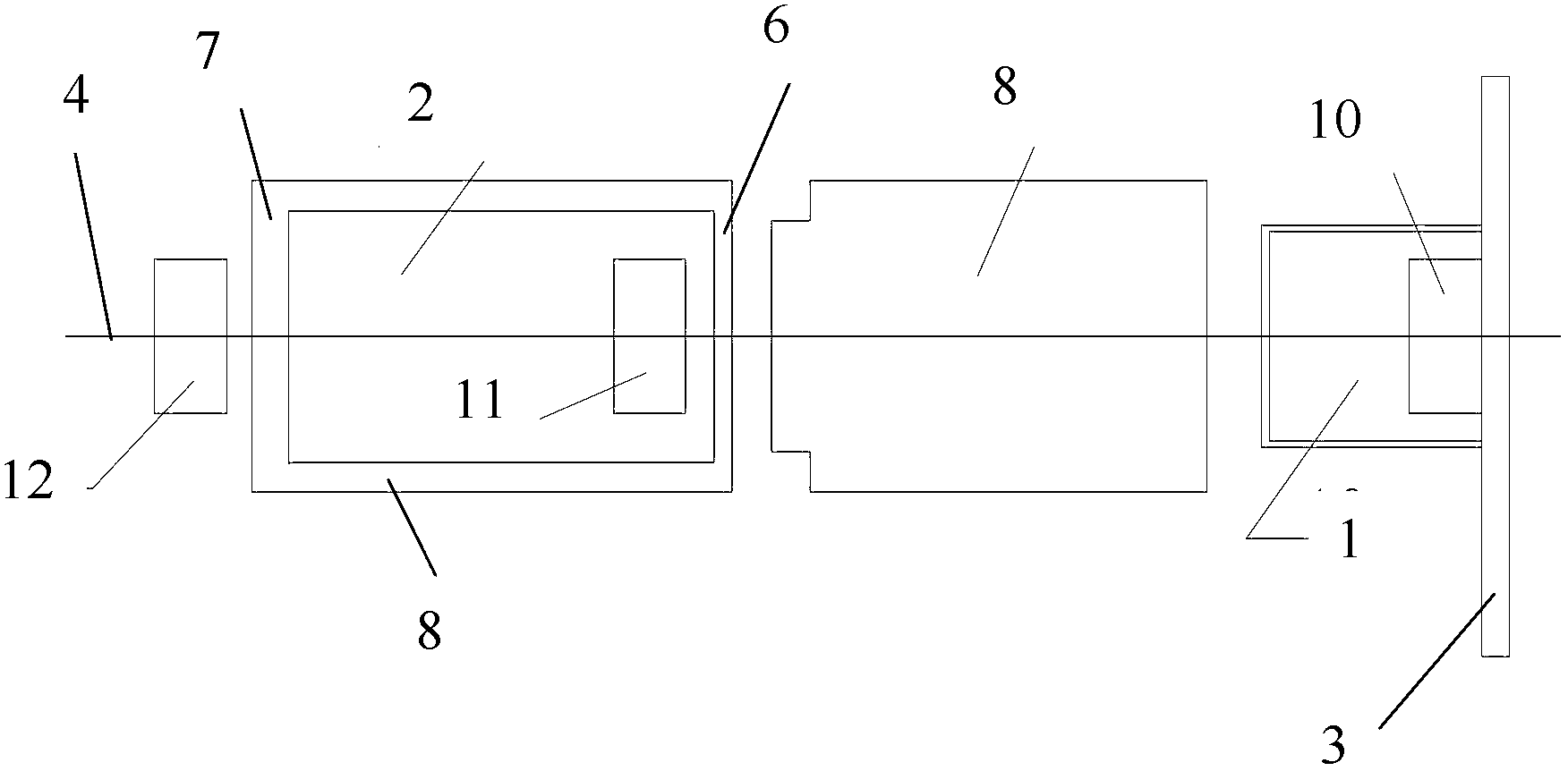

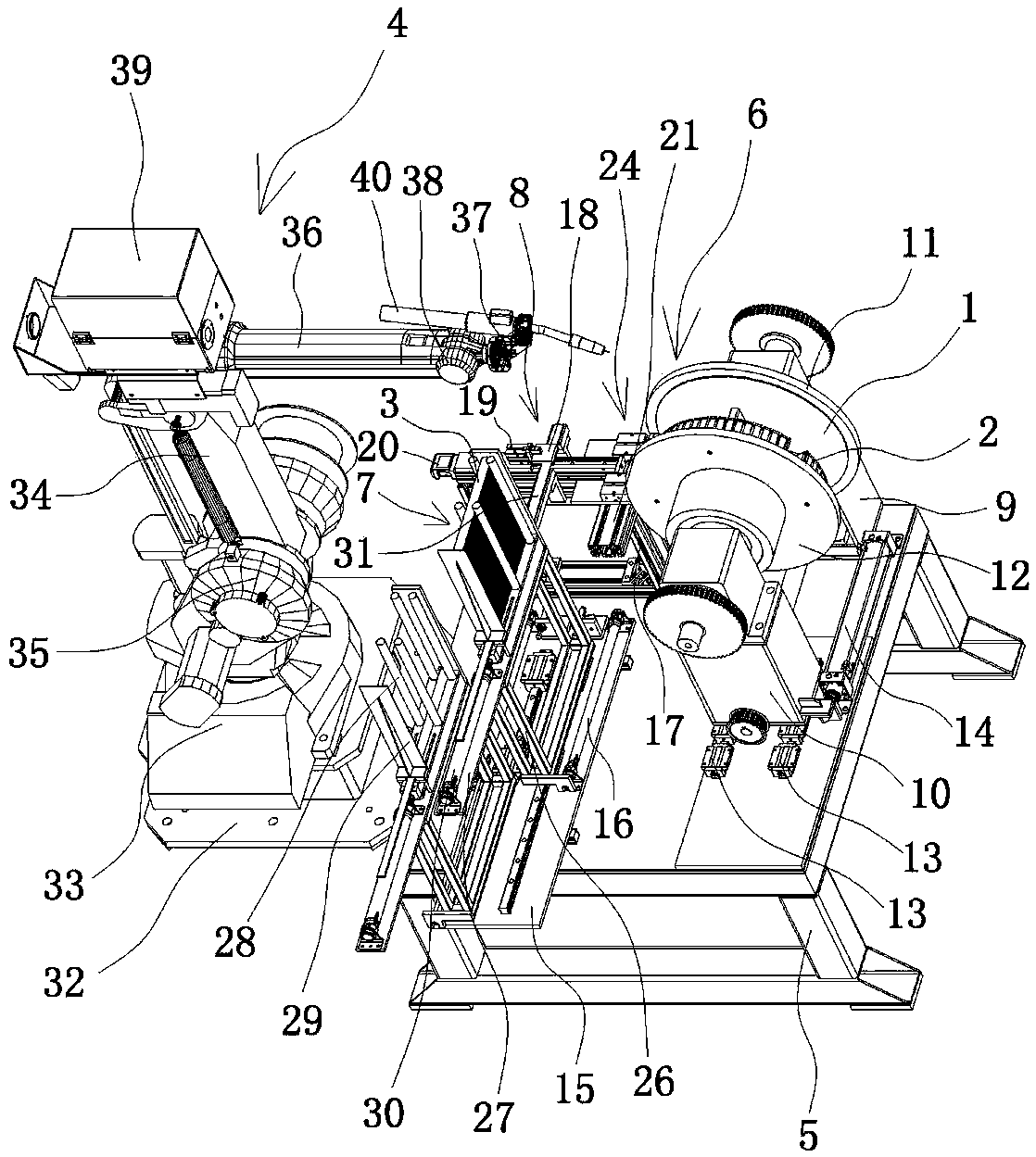

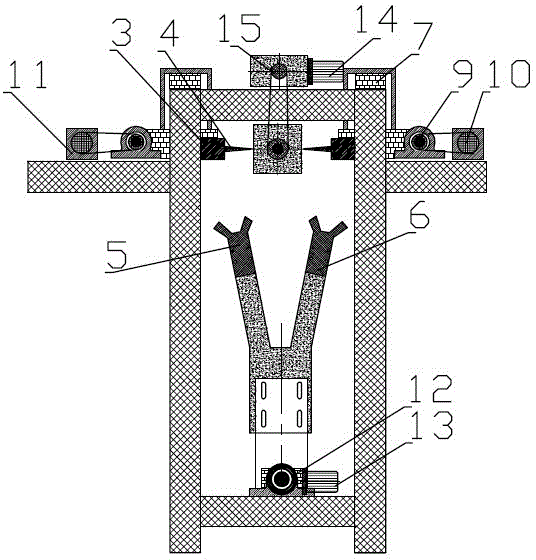

Automatic welding equipment for impeller of multi-blade fan

ActiveCN105364353AIncrease productivityImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesImpellerAutomatic test equipment

The invention provides automatic welding equipment for an impeller of a multi-blade fan and belongs to the technical field of machines, aiming at solving the problems of the prior art that impellers of the existing multi-blades fan are low in production efficiency and poor in welding quality. The equipment comprises a welding robot, a rack and a work clamp, a storage device and a clamping and delivery device, wherein the work clamp comprises a stand column I and a stand column II which are fixedly connected to the rack; a chuck I and a chuck II are arranged between the stand column I and the stand column II; the rack is provided with a slide rail for the stand column II to move left and right and is also provided with a cylinder I capable of pushing the stand column II to move on the slide rail; the storage device is fixedly connected with the rack by a bottom plate; the bottom plate is provided with a slide rail for the storage device to move left and right and is also provided with a cylinder II capable of pushing the storage device to move on the slide rail; the clamping and delivery device comprises a support fixedly connected to the rack; the support is provided with a clamping jaw, a clamping cylinder and a cylinder III; and the opening and closing of the clamping jaw are controlled by the clamping cylinder. The automatic welding equipment has the advantages of being high in production efficiency, good in welding quality and the like.

Owner:ZHEJIANG XINGYI VENTILATOR ELECTRICAL APPLIANCE

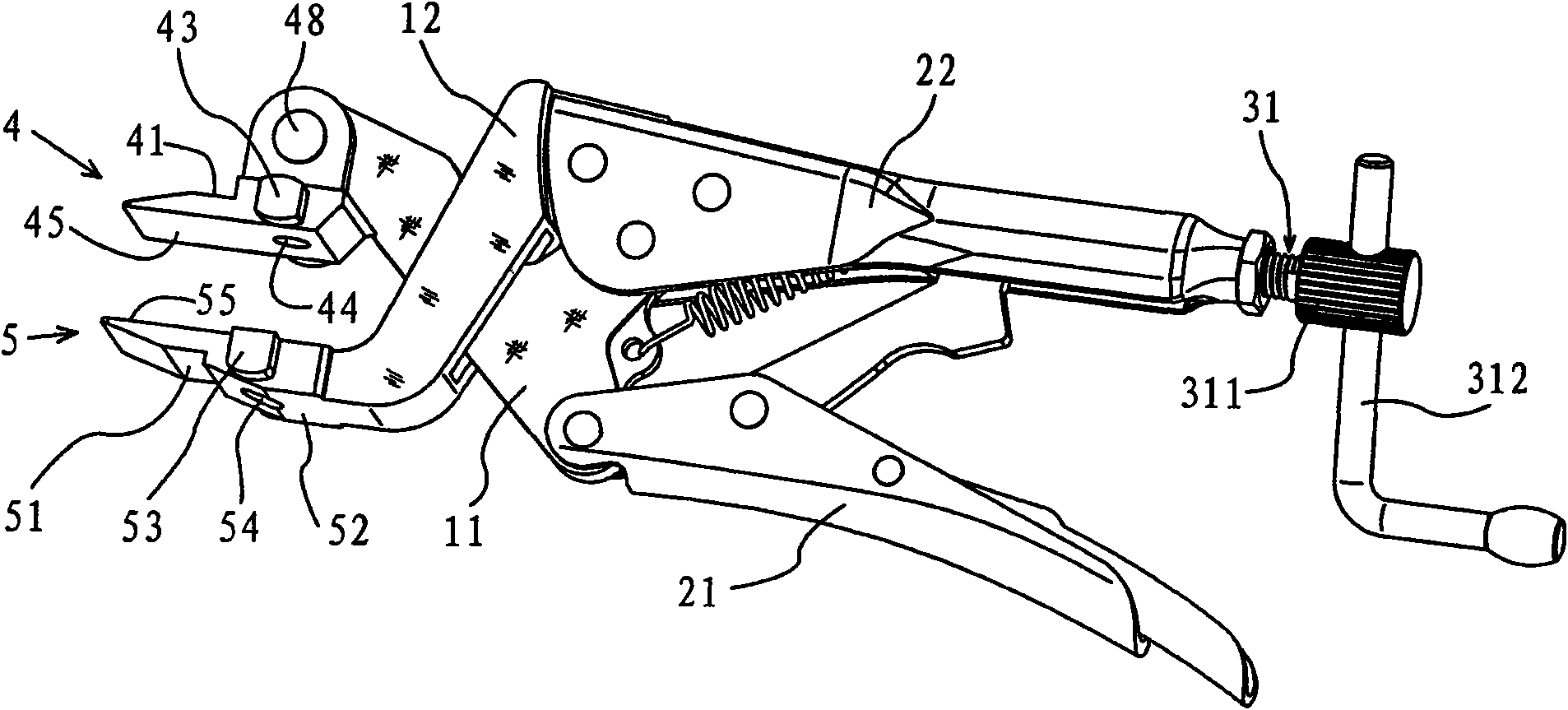

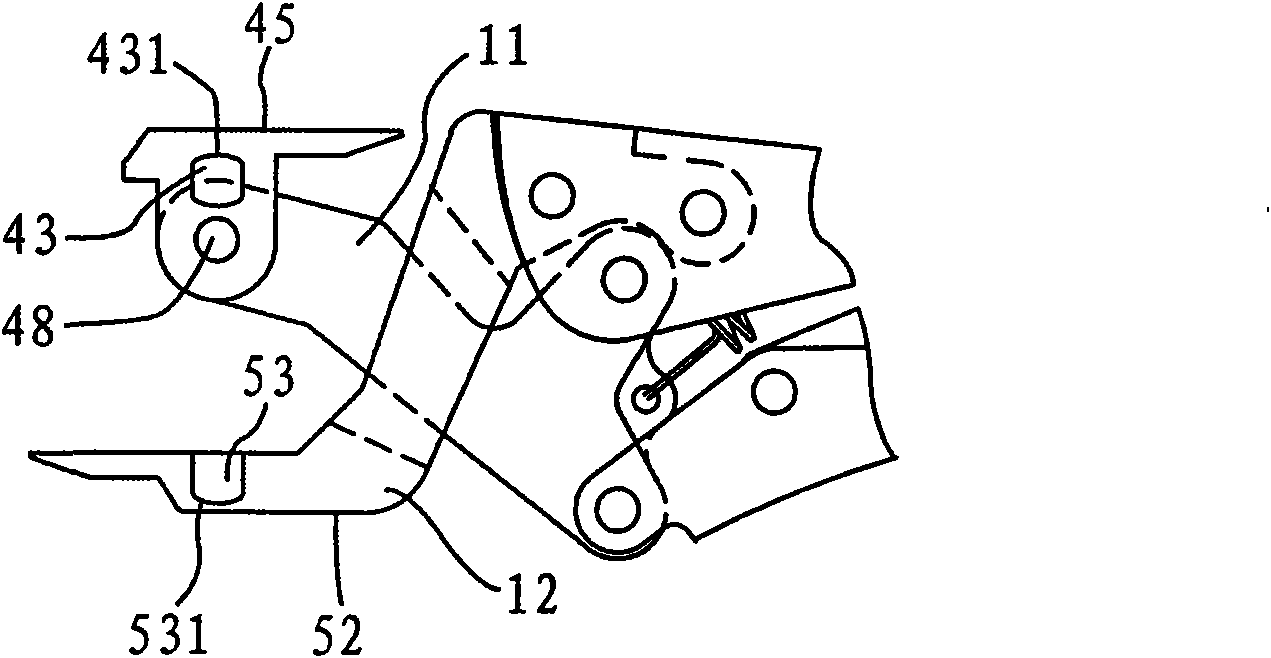

Spreading clamp

The invention relates to a spreading clamp which comprises a movable arm, a fixed arm, a movable handle, a fixed handle and a regulating mechanism, wherein the movable arm and the fixed arm are partially or totally crossly arranged from the process that the clamp is fully opened to the process that the clamp is closed, the movable arm and the fixed arm are provided with corresponding working clampopenings, the regulating mechanism is used for regulating the opening and closing size of the movable arm and the fixed arm, local or total corresponding working clamp openings of the movable arm andthe fixed arm together form a wedged clamp opening, the clamp opening surface of which is inserted into a narrower target clearance. The design of the wedged clamp opening solves the problem that thenarrower clearance can not be spread by adopting the relevant spreading clamp of a lock wrench body in the prior art, and improves the adaptability. One side of the fixed arm and one side of the movable arm, of which the working clamp openings correspond to each other, are provided with corresponding column bulges naturally extending along the side direction. The spreading clamp can be used for repairing workpieces of damaged or extruded and distorted circular or rectangular steel tubes, and the like.

Owner:VALTRA (SHANGHAI) MASCH CO LTD

Work clamp and wire bonding apparatus

InactiveUS7975899B2Avoid bondingPrevent oxidationSolid-state devicesWelding/cutting auxillary devicesEngineeringMechanical engineering

A work clamp and a wire bonding apparatus that can sufficiently restrain oxidation of a bonding area even while reducing an amount of antioxidant gas that is used are provided. The work clamp includes an interior hollow portion 10 providing an atmosphere of the antioxidant gas, a lower opening portion 11a provided below the interior hollow portion, for containing the bonding area in the interior hollow portion, an upper opening portion 11 provided above the interior hollow portion, for exposing the bonding area, a cavity 13 covering the interior hollow portion and having an area larger than an opening area of the upper opening portion, gas introduction ports 14a, 14b provided at the cavity, for introducing the antioxidant gas into the cavity, and holes 21 connected to below the cavity, for blowing the antioxidant gas introduced from the gas introduction port to a portion other than the bonding area of the work.

Owner:KAIJOO KK

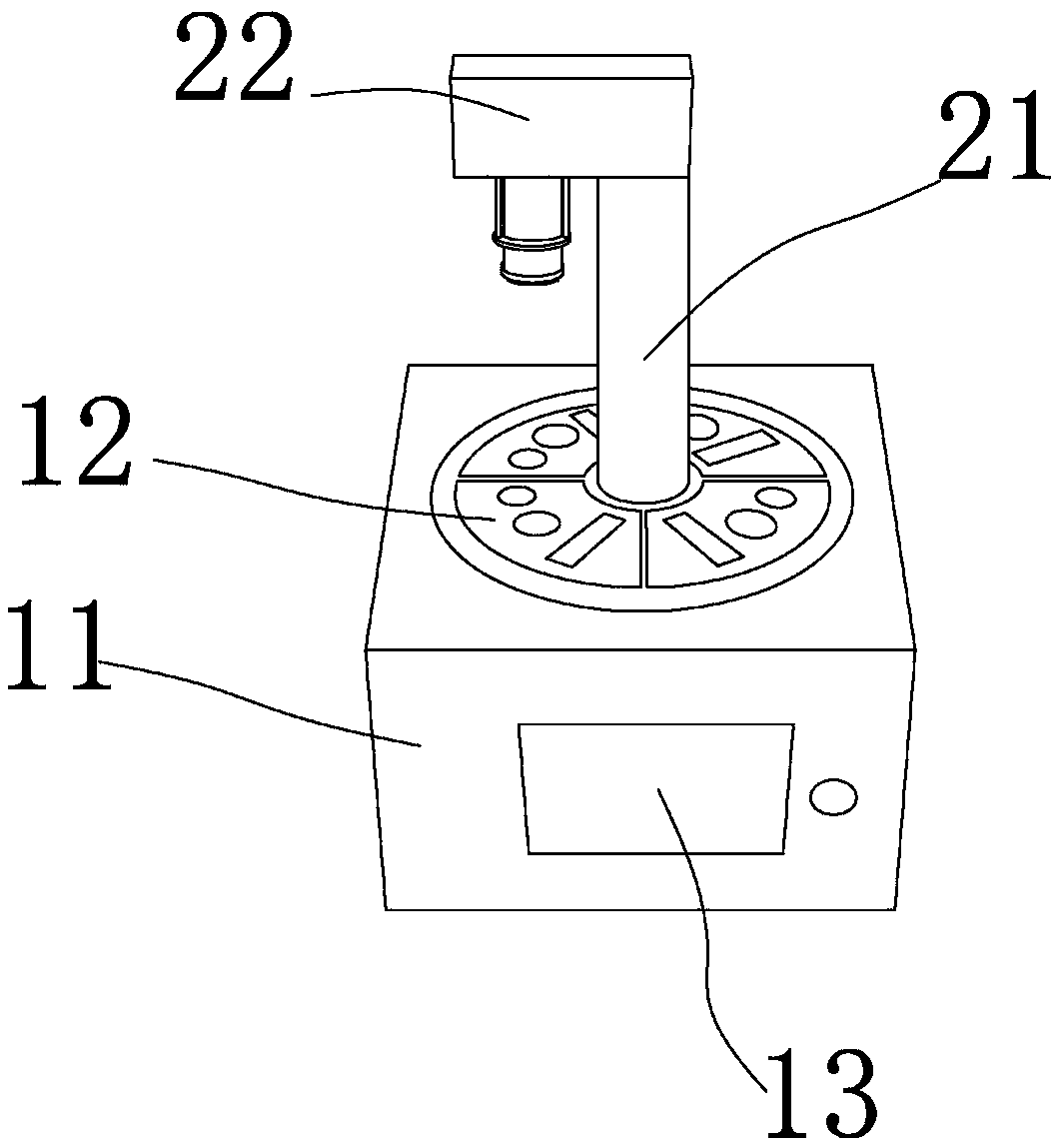

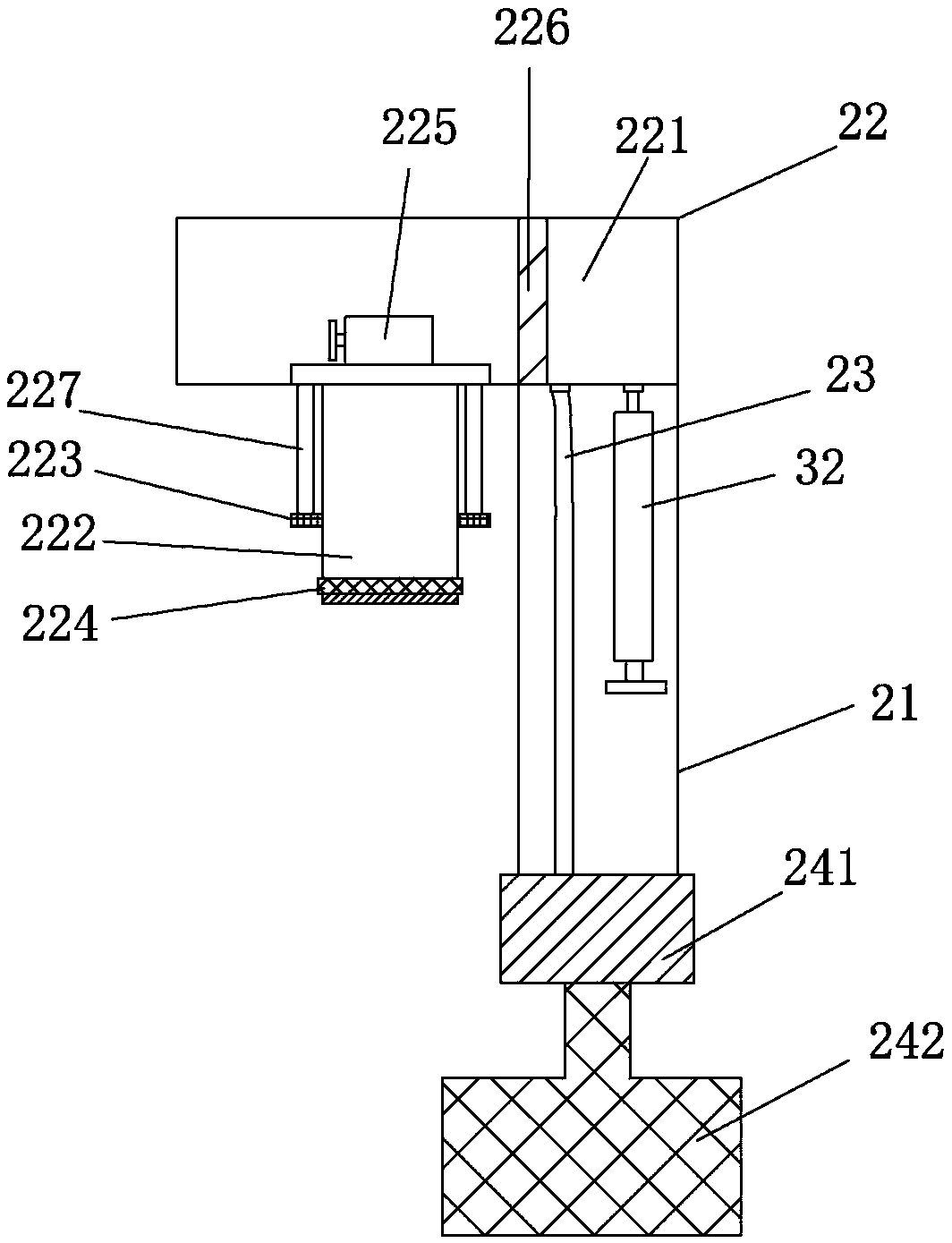

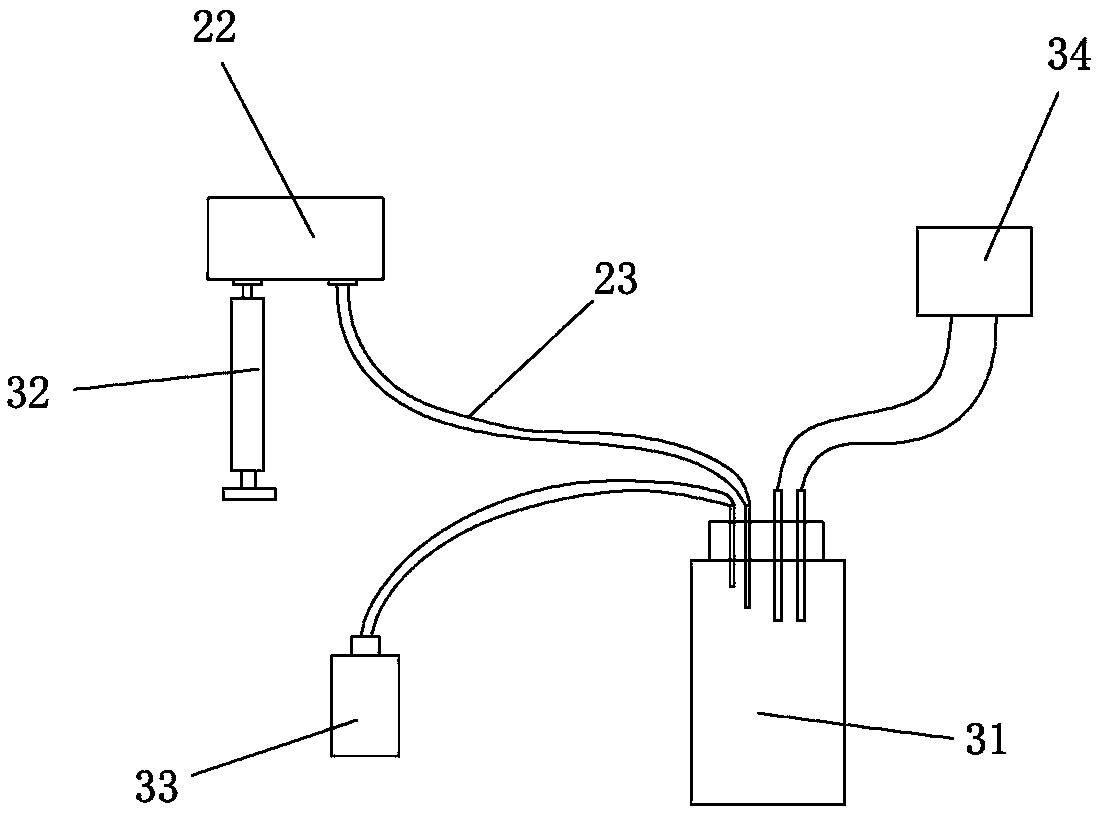

Membrane type monolayer cell sheet manufacturing machine and sheet manufacturing method thereof

PendingCN107643201AImprove throughputShort timePreparing sample for investigationStainingCollection system

The invention provides a membrane type monolayer cell sheet manufacturing machine. The membrane type monolayer cell sheet manufacturing machine comprises a carrying platform, a mechanical arm, a pneumatic waste liquid collection system and a control system, wherein a fixed disc is embedded into the upper part of the carrying platform and is provided with a working clamp groove; the mechanical armis fixedly arranged at the dead center of the upper part of the carrying platform, and can do circumference and lifting movement along a center shaft; the mechanical arm comprises a membrane cylinderloading device, a vertical support part and a liquid drain pipe; the membrane cylinder loading device is used for automatically loading a membrane cylinder, draining liquid, transferring a sample, andunloading the membrane cylinder; one end of the liquid drain pipe is connected to a liquid drain circular hole in the membrane cylinder loading device, and the other end of the liquid drain pipe is connected with a waste liquid collecting bottle. The sheet manufacturing method comprises the following steps of sucking cells onto a membrane by negative pressure, enabling the mechanical arm to transfer the cells onto a slide, treating the cell sheet by a special immobilizing solution, and performing pathological staining. The membrane type monolayer cell sheet manufacturing machine has the advantages that the labor operation amount is reduced, the sample flux is large, the manufacturing is standard, the cells are uniformly distributed, the stability and reliability are realized, and the large-scale popularization and application effects are realized.

Owner:MOTIC XIAMEN MEDICAL DIAGNOSTICS SYST

Device for removing water from a work-piece

InactiveCN101158537ADeposition is complete or sufficientDrying solid materials without heatDrying machines with non-progressive movementsAir blowerIndustrial engineering

The problem (object) is to provide a device for removing water from a machined piece (work) which realizes a technique for completely (sufficiently) removing water beads deposited on a work. [Means to Solve the Problem (Means to Attain the Object)] The water removing device comprises an air blowing box 2 for holding a work 1 to be subjected to water removal; a work clamping jig 3 mounted in the air blowing box 2 for clamping the work 1 ; a jig rotating mechanism 4 for rotating the work clamping jig 3 to rotate the clamped work 1 , thereby causing water beads deposited on the work 1 to drop; and an air blower 5 for generating an air current flowing in the same direction as the a falling direction of water drops 11 which have been caused to drop from the work 1.

Owner:SHIGAYAMASHITA

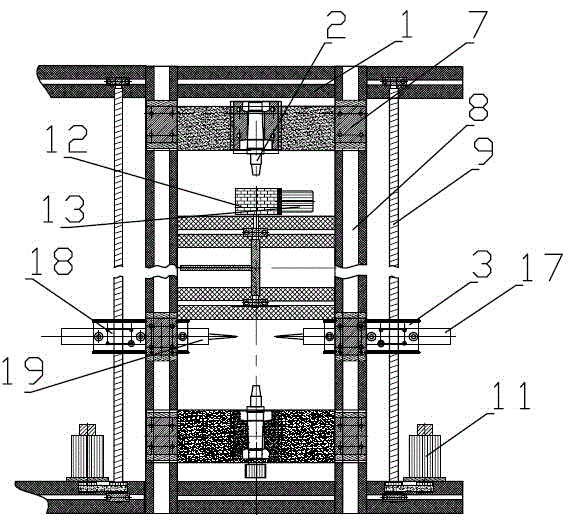

Automatic punch

InactiveCN104475820ARealize punching needsGuaranteed automated productionFeeding apparatusDriving apparatusPunchingWork clamp

Owner:袁瑞军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com