Spreading clamp

A technology of jaws and movable arms, which is applied in the field of splicing pliers and hand tools, and can solve problems such as the inability to complete narrow gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

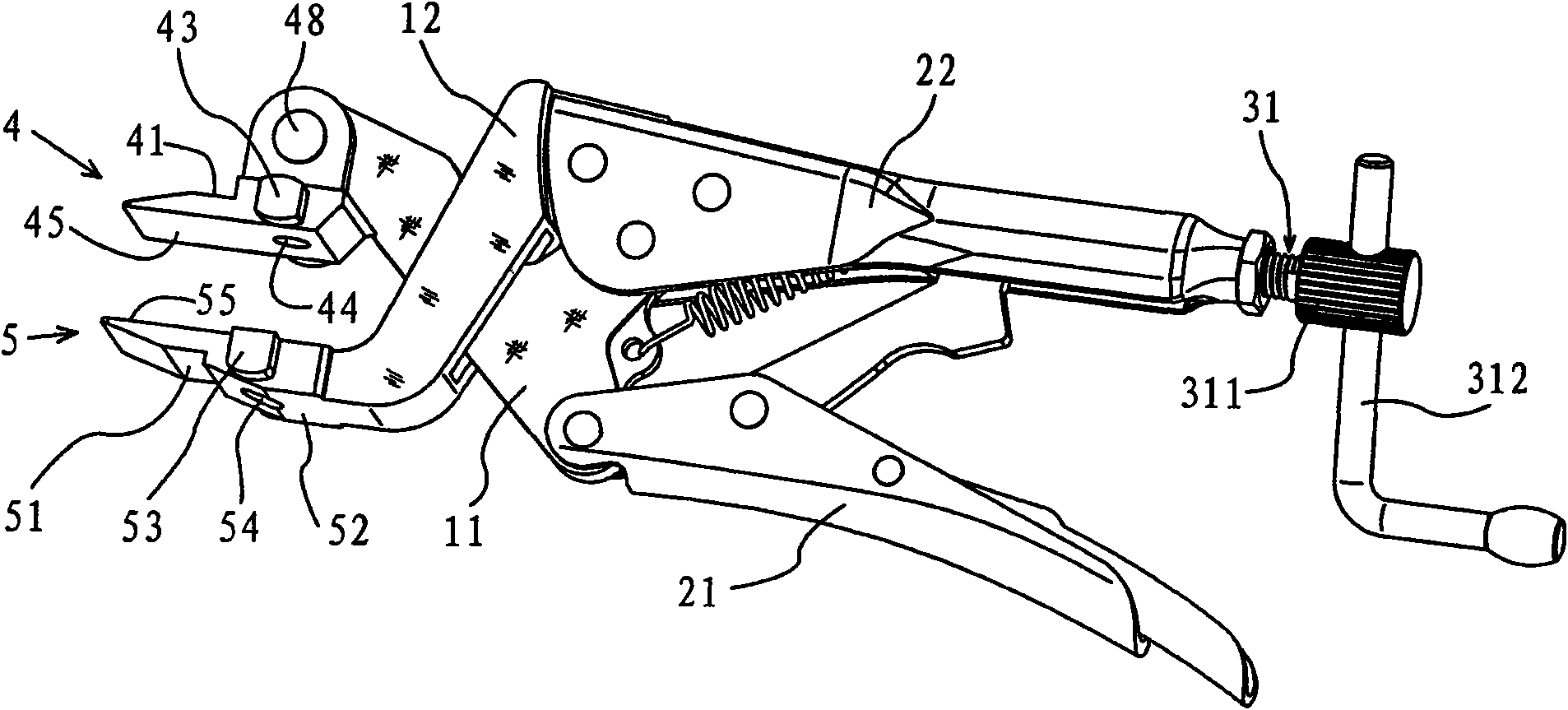

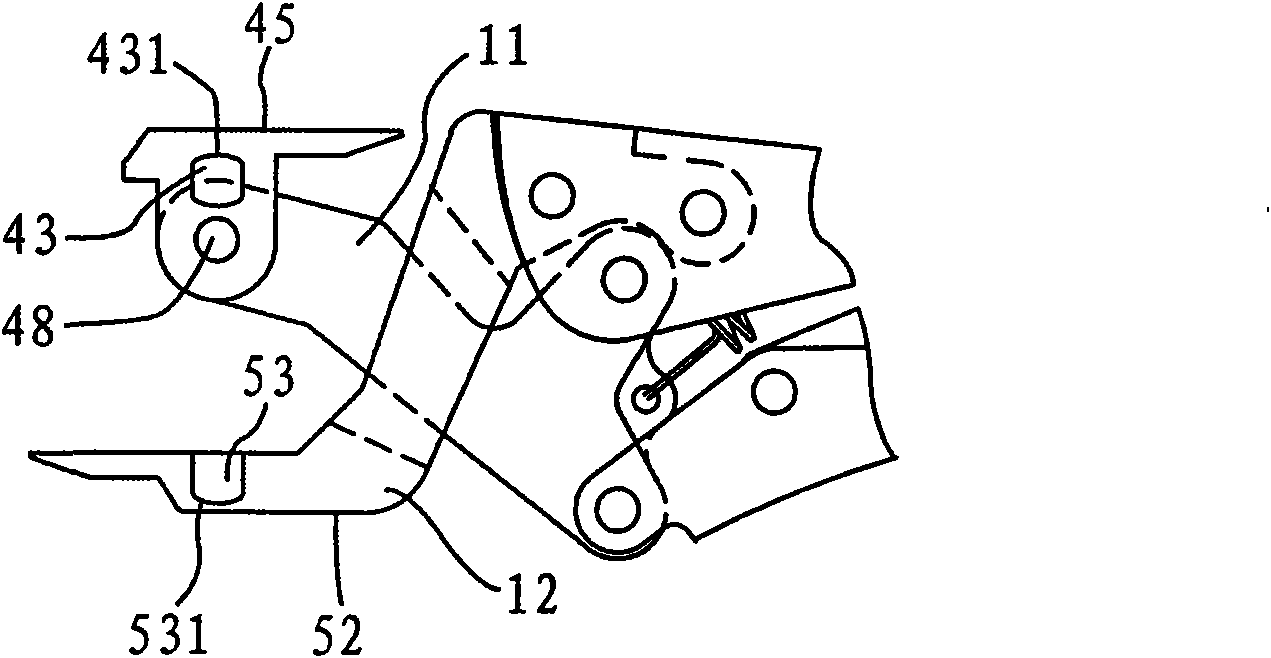

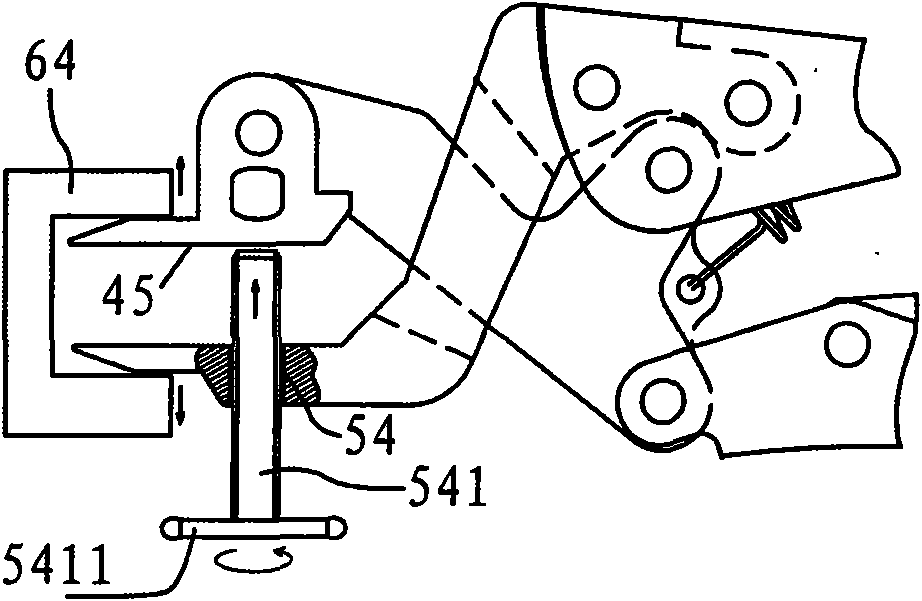

[0032] Such as figure 1 and figure 2 The supporting pliers shown, the clamp body is similar to the common spring type pliers, including the fixed arm 12, the movable arm 11, the fixed handle 22, and the movable handle 21, and a certain adjustment mechanism is formed by springs and other components between them. The adjustment of the adjustment mechanism is used to adjust the opening and closing of the angle between the fixed arm 12 and the movable arm 11. The fixed arm 12 and the movable arm 11 are arranged crosswise. An adjusting tail screw 31 is arranged at the end of the clamp, and a knurl 311 at the end of the tail screw A lever rocker 312 is placed horizontally on the upper side. Shaking the rocker 312 can quickly adjust the relationship between the fixed arm 12 and the movable arm 11, and when the clamp is in a tightened state and cannot continue to manually apply force, the rocker 312 can be used to apply a larger force. force.

[0033]A fixed arm working jaw set 5 a...

Embodiment 2

[0041] Such as Figure 7 Compared with the supporting tongs in the first embodiment, the other supporting tong structure shown is mainly different in the structure of the wedge-shaped jaws. The upper part of the jaw set can form a working jaw surface 42B, which can cooperate with the working jaw surface 52 .

Embodiment 3

[0043] Such as Figure 8 In yet another supporting structure shown, in the working jaw part, the upper and lower jaw structures are basically symmetrically arranged, and have corresponding working jaw surfaces 41, 51 and 42, 52 respectively.

[0044] Such as Figure 9 The support joint structure shown, the support joint 7 is used as the connection accessory of the accessory installation hole in the above embodiment. The support joint has a thread conversion structure, that is, one side of the thread is adapted to the size of the accessory installation hole, and the other side has a different thread. The diameter can be used to switch and connect different accessories, and a larger section of the thread also forms a jaw working surface 71, which can serve as a supporting force surface when bracing.

[0045] The supporting jaw structure of the present invention is not limited to the various types mentioned above, for example, there may be other forms of pushing the working jaw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com