Automatic welding equipment for impeller of multi-blade fan

An automatic welding and fan impeller technology, which is applied in the field of machinery, can solve problems such as uneven product quality, aggravated blade inclination angle, and difficulty in meeting design requirements with manual correction, and achieve good welding quality and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

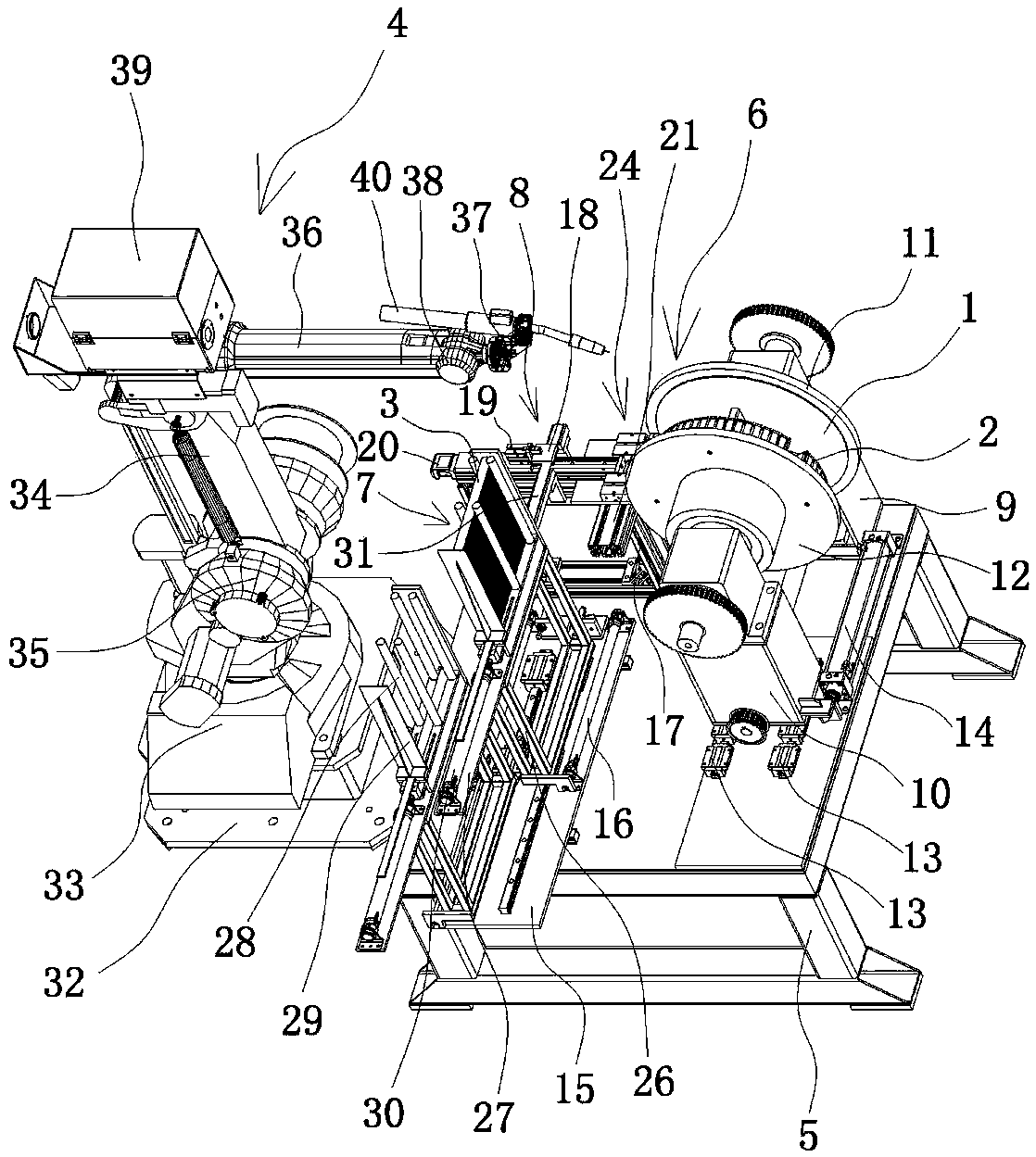

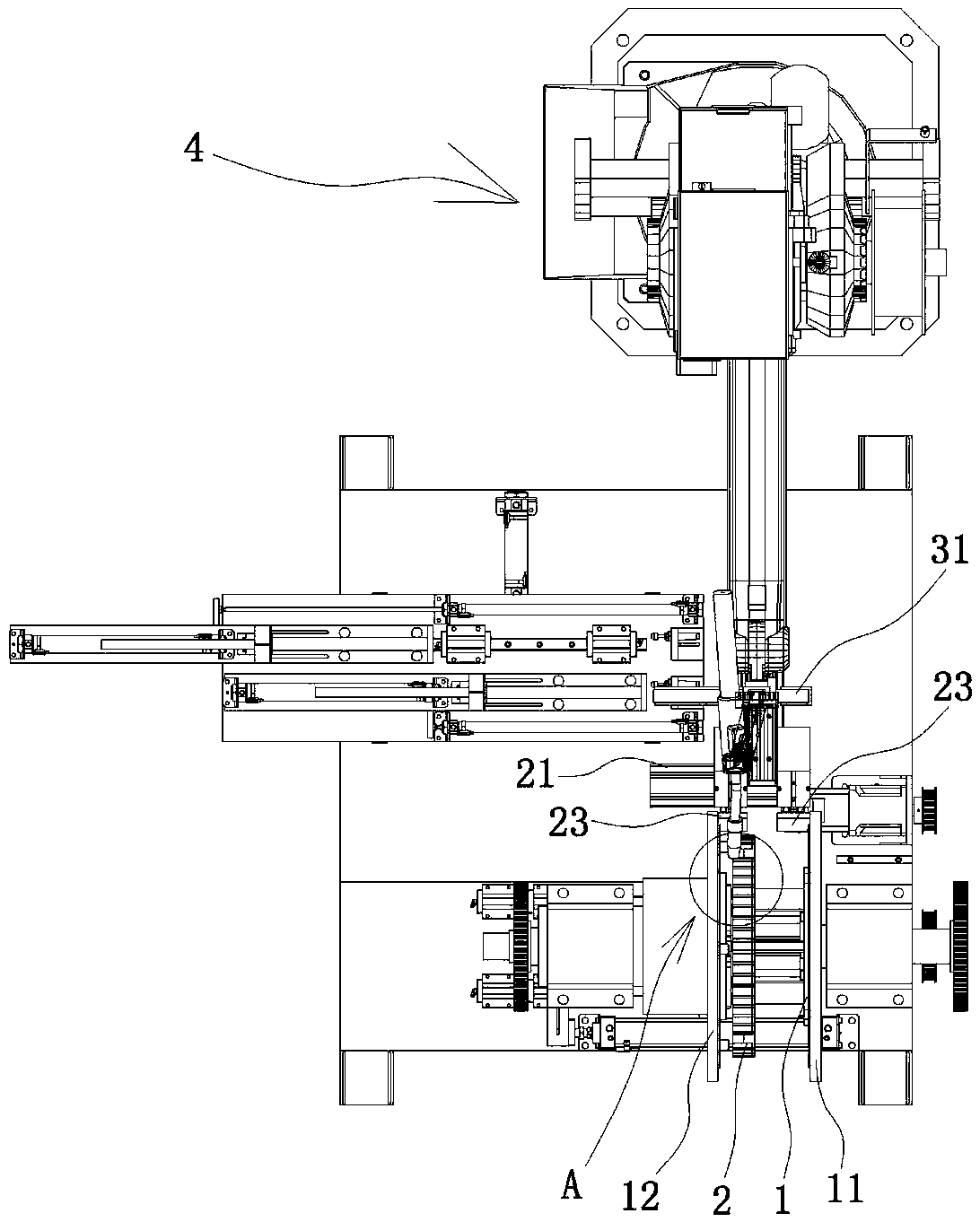

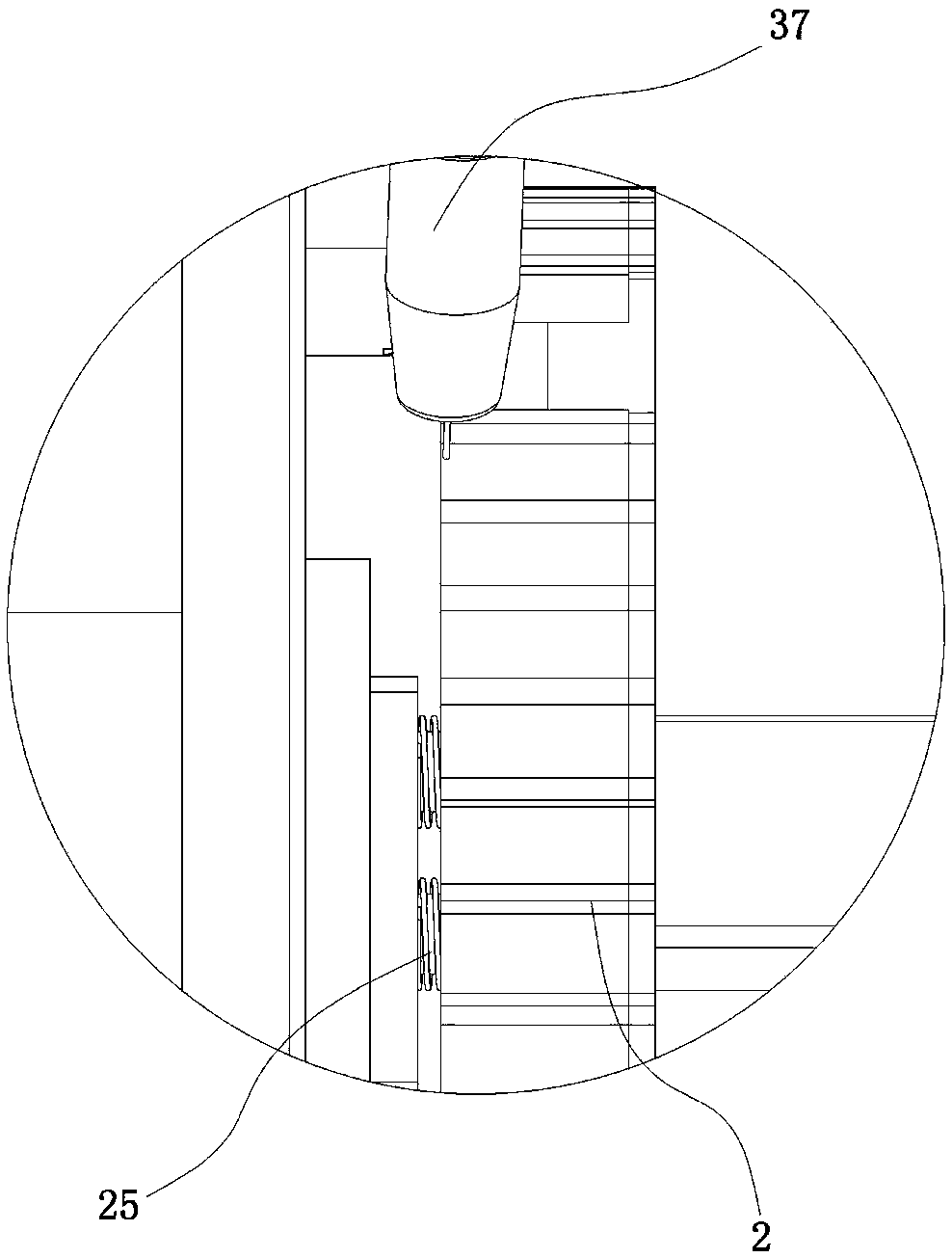

[0017] Such as figure 1 , figure 2 , image 3 As shown, the automatic welding equipment for the multi-wing fan impeller is composed of a wheel disc 1, a wheel cover 2 and a blade 3. The equipment includes a welding robot 4, a frame 5 and a welding robot arranged on the frame 5. The tooling fixture 6, the stocker 7 and the pinch device 8, the tooling fixture 6 includes a column one 9 and a column two 10 fixedly connected to the frame 5, and a chuck one 11 is arranged between the column one 9 and the column two 10 With chuck two 12, the frame 5 is provided with a slide rail 13 for the column two 10 to move left and right, and the frame 5 is also provided with a cylinder one 14 that can promote the column two 10 to move on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com