Computer panel saw, control system and processing method

A computerized panel saw and control unit technology, applied in the general control system, control/regulation system, electrical program control, etc., can solve the problems of not disclosing the system composition, not disclosing the specific composition of the control unit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

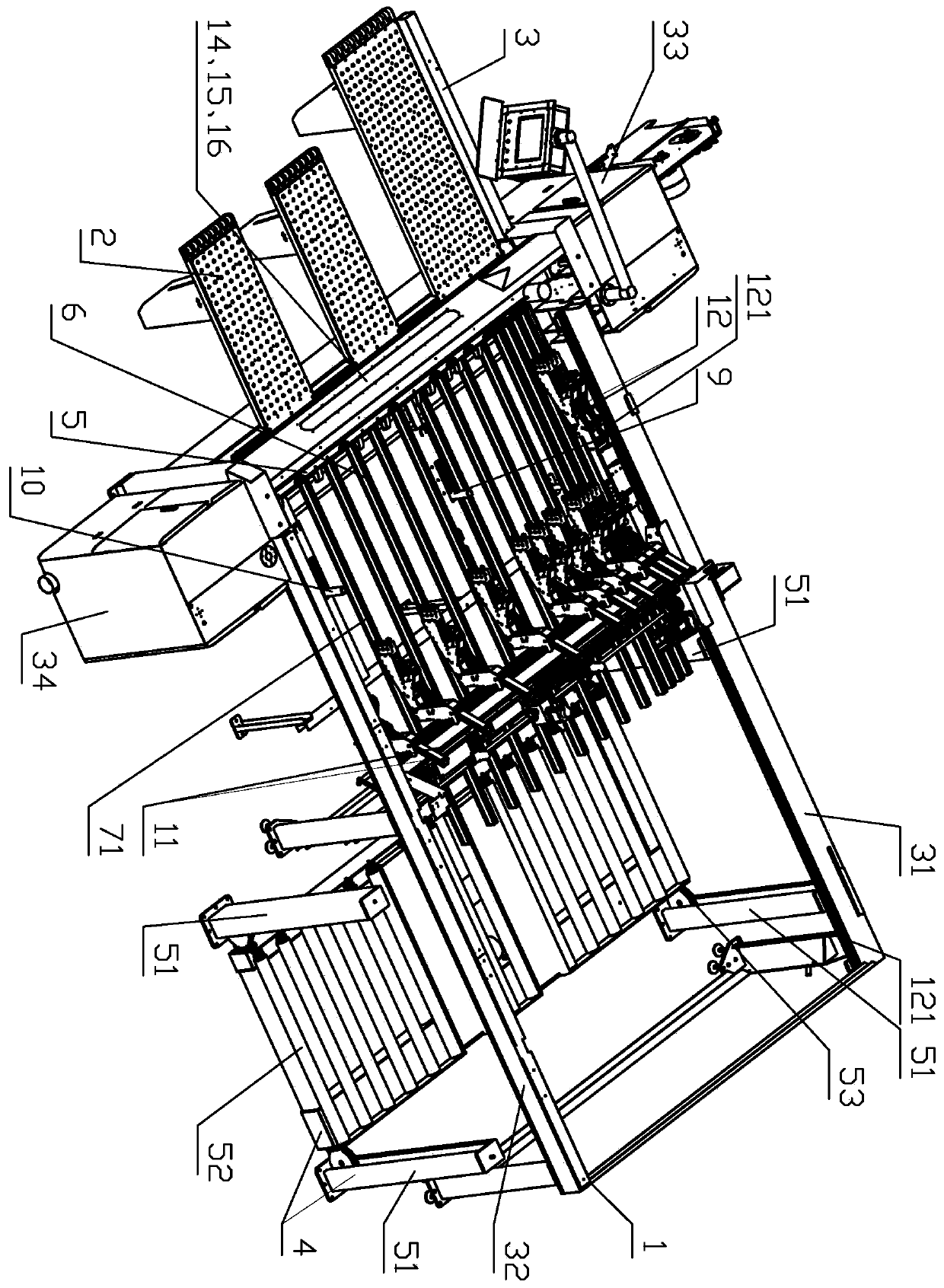

[0199] like figure 1 , figure 2 As shown, a computerized panel saw includes a main frame 1, a discharge device 2 installed on the main frame, a machine body, a feeding unit, and a control system composed of industrial PCs and PLCs. One side of the discharge device 2 is provided with a side positioning backing plate 3 .

[0200] The feeding unit is located at the rear side of the machine body, and the feeding unit includes a feeding device and a feeding device 4 .

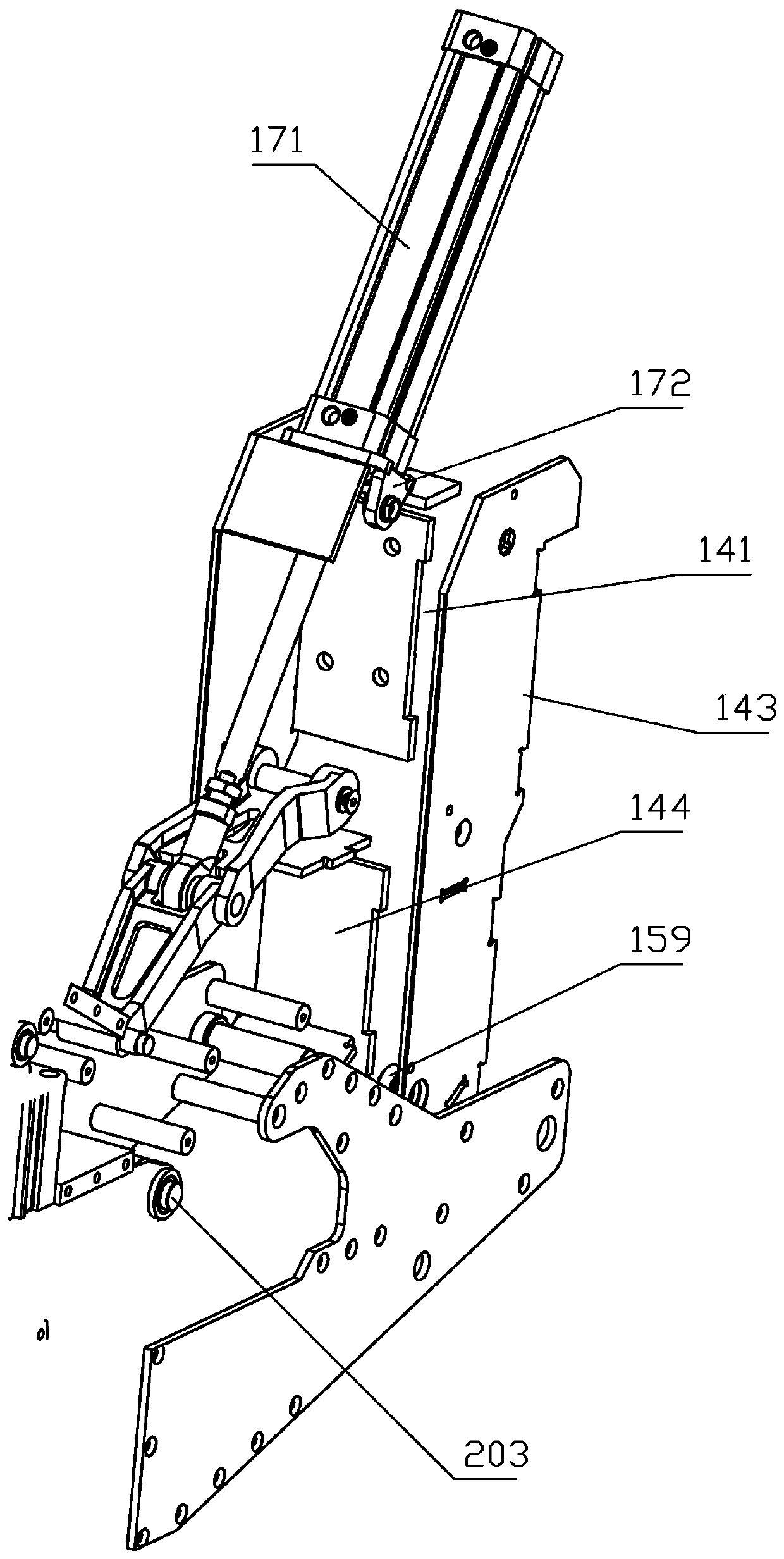

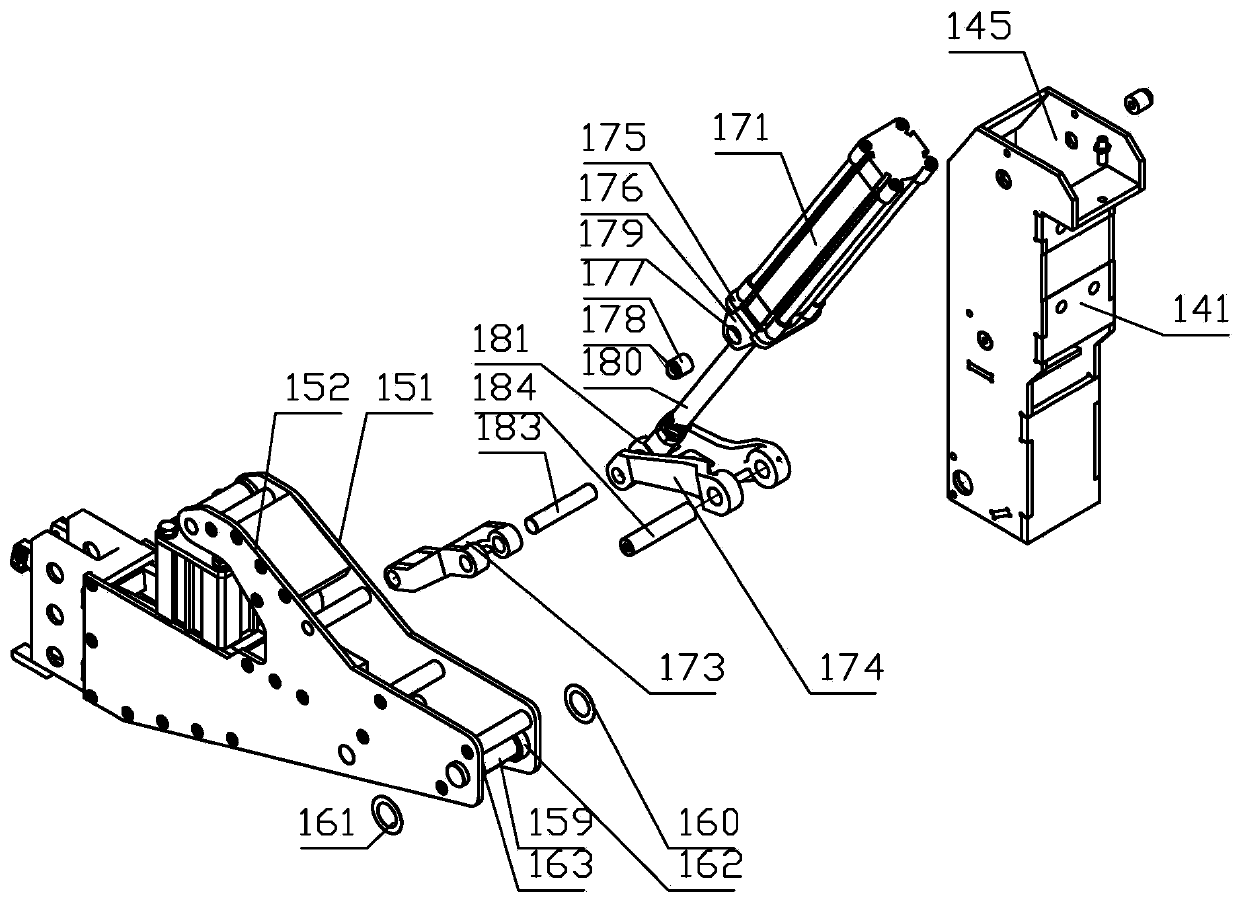

[0201] The main body of the machine includes a workbench 5, a side alignment device 14 for flushing the sheet material with the side positioning backing plate 3, and a pressing device 15 for pressing and positioning the sheet material on the workbench 5 for alignment on the workbench 5. The cutting device 16 for cutting the upper plate. Both the pressing device 15 and the cutting device 16 are installed on the workbench 5 .

[0202] The feeding device includes a feeding frame 6, two sets of pushing devices 7 an...

Embodiment 2

[0267] like Figure 13 As shown, a control system of a computerized panel saw includes a man-machine exchange control unit, a programmable controller (PLC) connected to the man-machine exchange control unit through Ethernet for two-way control, and a data bus connected to the programmable controller , two-way control in parallel connected to the data bus loading device control unit, pushing device control unit, front trimming device control unit, main worker pinch feeding device control unit, auxiliary worker pinch feeding device control unit, synchronization device control unit, Side alignment device control unit, pressing device control unit, cutting device control unit.

[0268]The human-machine exchange control unit includes an industrial computer, a mouse and keyboard connected to the industrial computer for one-way control, a factory LAN connected to the industrial computer for two-way control, and a mouse and keyboard for one-way control of the industrial computer. The...

Embodiment 3

[0315] The working method of the computerized panel saw, including Figure 17 to Figure 22 All steps shown.

[0316] like Figure 17 As shown, first perform the following steps in sequence:

[0317] Start the system initialization; return to the origin; input the processing pattern; whether to execute the loading and board program after starting?

[0318] If not, start the pre-loading and board program, and select the work mode of the main and auxiliary workers;

[0319] If it is, start the loading and board program, and select the working mode of the main and auxiliary workers;

[0320] After selecting the working mode of the main and auxiliary work clamps, do you want to start the leaning operation program? If yes, start the leaning program; after starting the leaning program, it is ready; if not, it is ready;

[0321] When ready, press the saw blade start button and fan start button, and then press the continuous start button;

[0322] After pressing the continuous st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com