Camshaft fixture cramp and its automatically printing method

A tooling fixture and camshaft technology, which is applied to printing devices, printing, typewriters, etc., can solve the problem that the camshaft cannot be used for error proofing, marking and scanning, etc., and achieves the effect of various varieties and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

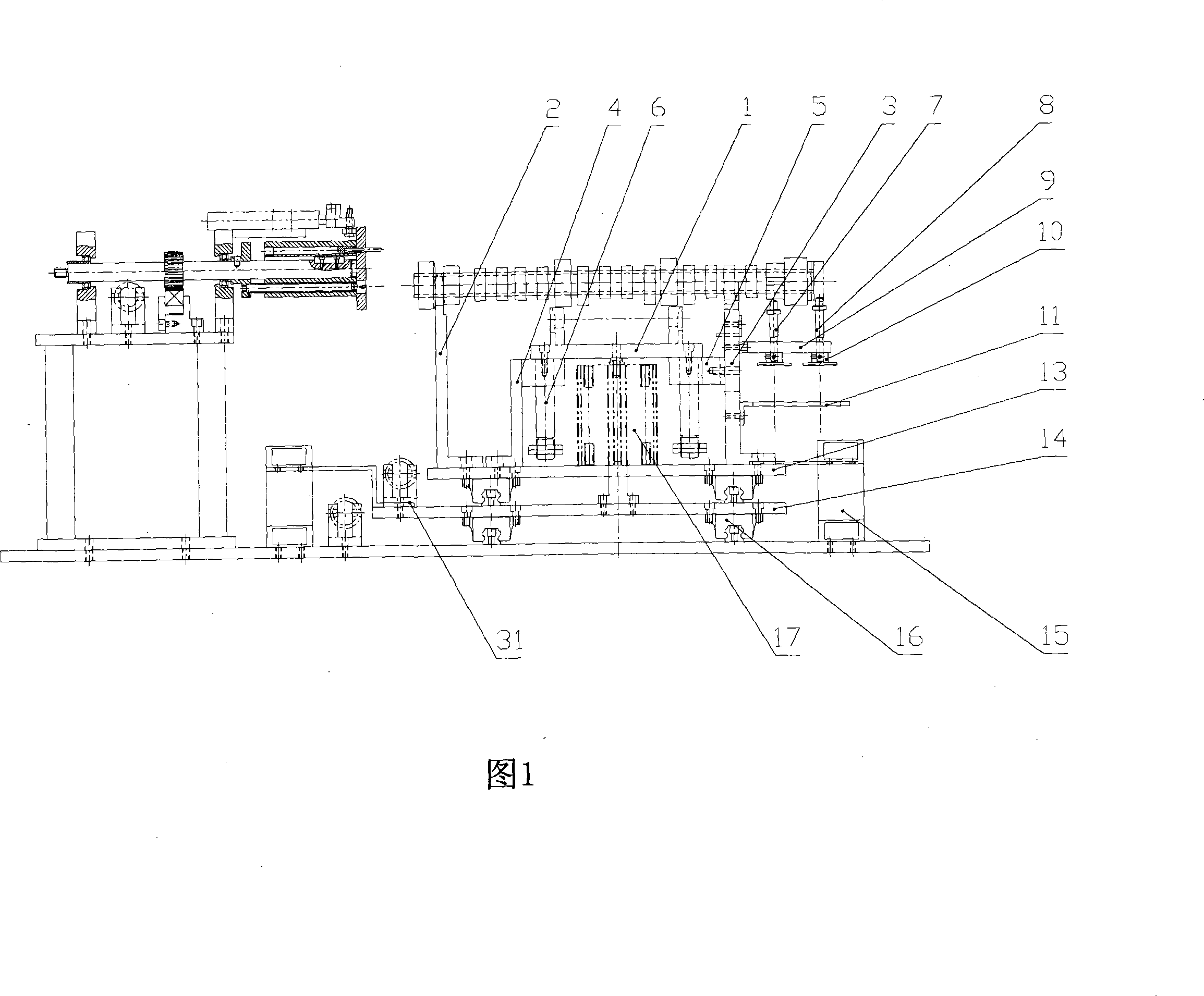

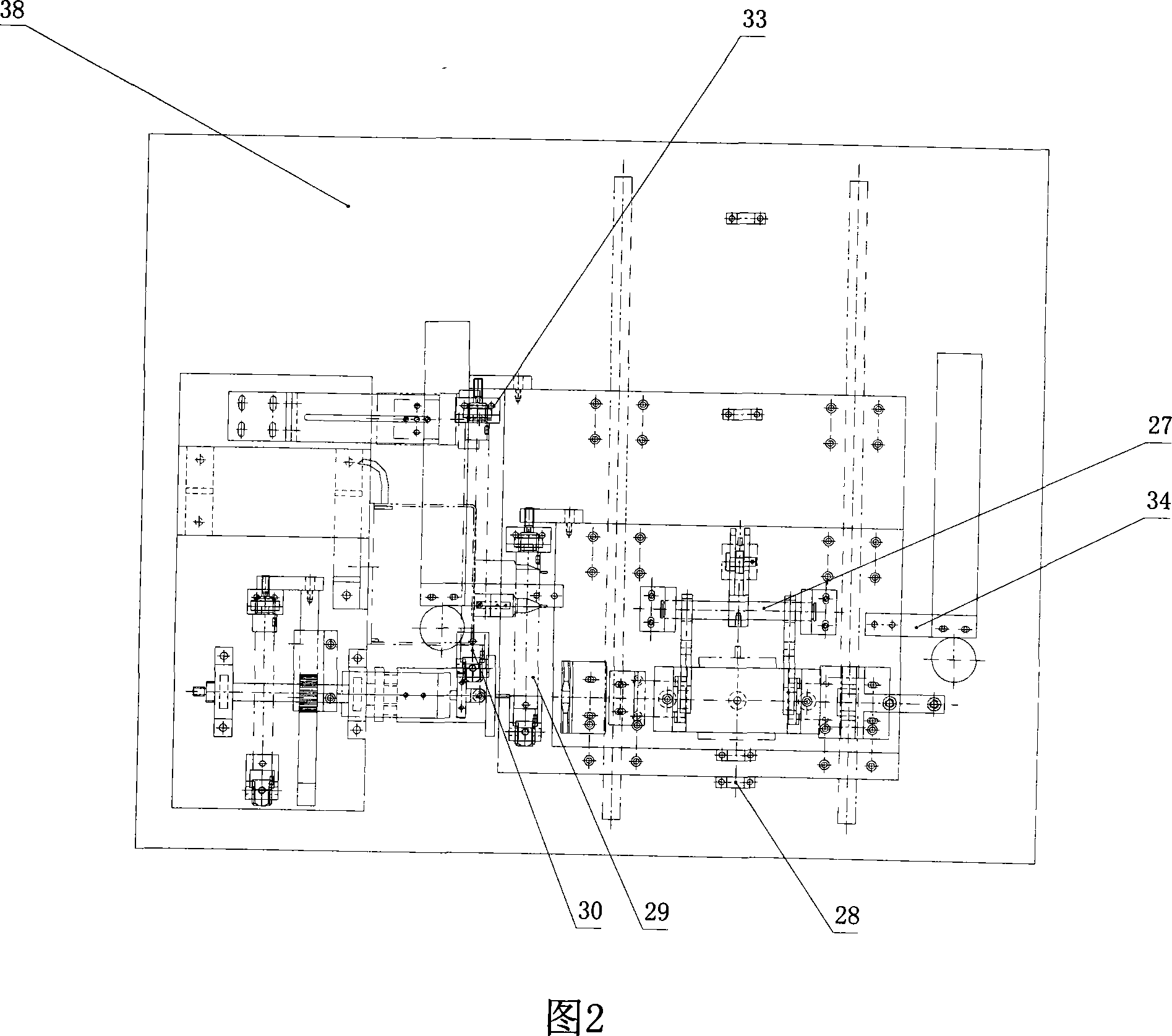

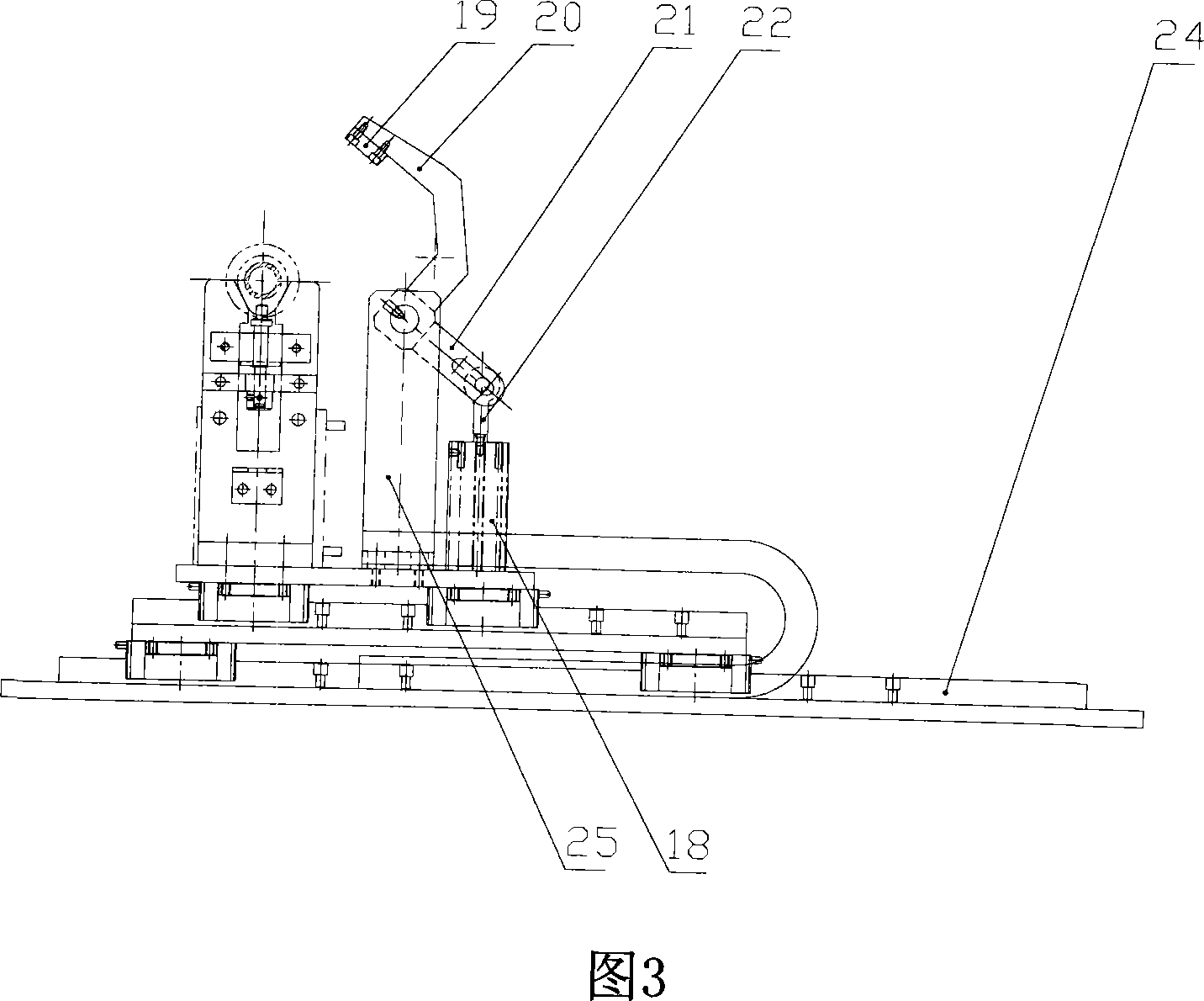

[0104] Referring to accompanying drawings 1, 2, 3, 4, and 5, the present invention can perform error-proofing, marking, and scanning for different camshafts. The relative positions of the 2 process holes on the end face of the camshaft and the cam are random, so when the cam is used for positioning, the positions of the 2 holes in the printing section are not fixed, and the steel needle printer must avoid the two holes when printing, otherwise the steel will be damaged. Needle printers, that's the key.

[0105] The device of the present invention is mainly composed of the hardware part of the camshaft marking system, including: tooling fixture, air supply device, pneumatic component box, electrical box, profile protection net and PANEL box parts. The tooling fixture is composed of a camshaft lifting mechanism, a thimble It consists of a pushing mechanism, a positioning mechanism, a camshaft rotating mechanism, a camshaft clamping mechanism, a printing position pushing mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com