Electrical isolation prestressed anchorage system and construction and installation method thereof

An installation method and electrical isolation technology, applied in the direction of erecting/assembling bridges, structural elements, bridges, etc., can solve the problems of poor airtightness of anchoring units, inability to detect prestressed anti-corrosion performance, and inability to better achieve electrical isolation performance, etc., to achieve Simple installation and construction, good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

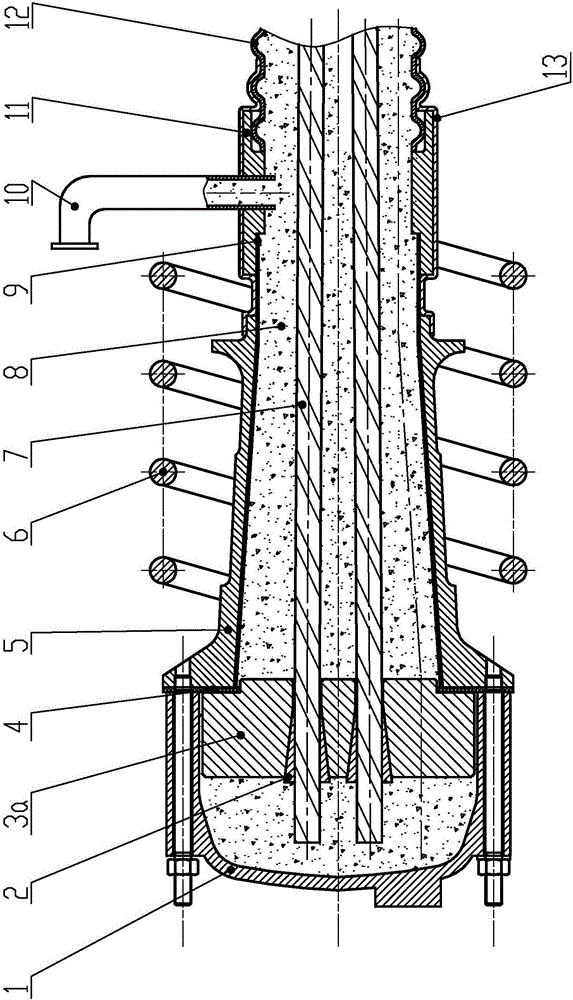

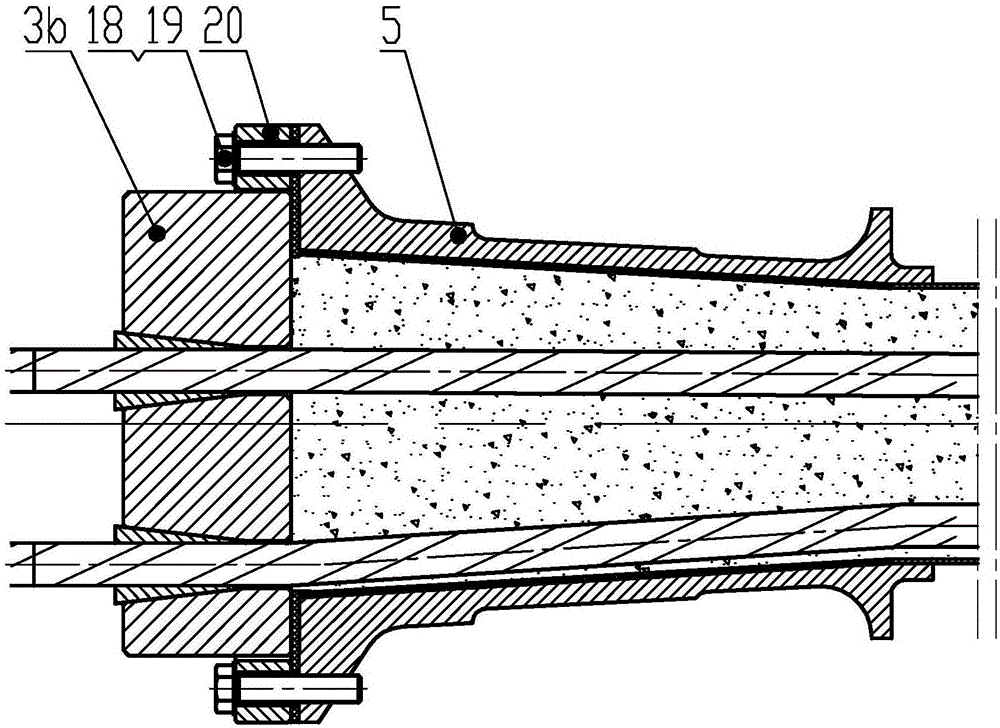

[0051] An electrically isolated prestressed anchorage system,

[0052] Such as figure 1 As shown, the electrical isolation prestressed anchorage system includes a working anchor plate 3, an anchor backing plate 5, a working clip 2, a prestressed tendon 7, a structural tendon 16 and a concrete 17 installed by a conventional method; the working clip 2 is installed on the working The anchor plate 3 is connected to the prestressed tendon 7; the prestressed tendon 7 runs through the working anchor plate 3, the anchor backing plate 5, and the bellows 12, and is fixed by the working clip 2 after being stretched; the spiral rib 6 is installed on the The outer circumferential position of the anchor pad 5 is coaxial with the anchor pad 5;

[0053] The electrically isolated prestressed anchoring system also includes insulating anchor covers 1, pressure-resistant insulating pads 4, insulating inner bushings 9, insulating connectors 11, insulating corrugated pipes 12 and other insulating ...

Embodiment 2

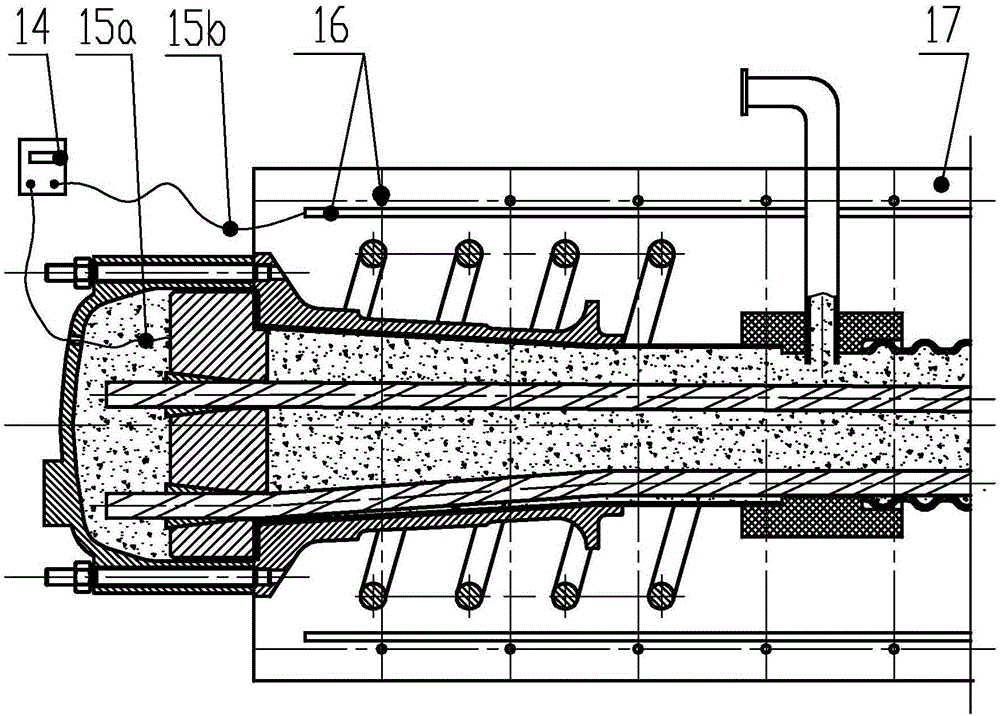

[0063] A detectable electrically isolated prestressed anchorage system:

[0064] The basic structure of this embodiment is the same as that of Embodiment 1, and the difference from Embodiment 1 is that the electrical isolation prestressed anchor system also has an electrical isolation performance detector, and the electrical isolation performance detector includes an electric bridge meter 14, a connection anchor The inner conductor 15a of the system and the outer conductor 15b connected to the structural reinforcement 16 in the concrete, in the assembled state, one end of the inner conductor 15a is connected to the bridge meter 14, and the other end is connected to the working anchor plate or prestressed tendon of the electrically isolated prestressed anchorage system One end of the outer conductor 15b is connected with the bridge table 14, and the other end is connected with the structural rib 16 (see image 3 ).

[0065] As a transformation of Embodiment 1 and Embodiment 2 ...

Embodiment 3

[0074] A method for construction and installation of a detectable electrical isolation prestressed anchorage system, which is the installation method of the electrical isolation prestressed anchorage system described in Embodiment 2, is characterized in that it includes the following steps:

[0075] A. Install the embedded parts: install the spiral rib 6, the anchor plate 5, and the structural rib 16 in sequence; the outer wire 15b needs to be connected to the structural rib 16 during the pre-embedding process;

[0076] B. Install the insulating part: Insert the insulating inner bushing 9 into the anchor backing plate 5 and connect it tightly. One end of the connector 11 is mated and connected, and the insulating heat shrinkable sleeve 13 is installed at this time; the other end of the insulating connector 11 is matched with the insulating bellows. After the installation is completed, the heat shrinkable sleeve 13 is melted so as to completely cover the insulating inner bushing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com