Work clamp of stator pressing plate

A tooling fixture and pressure plate technology, applied in the field of tooling fixtures, can solve the problem of low assembly accuracy and achieve the effect of improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

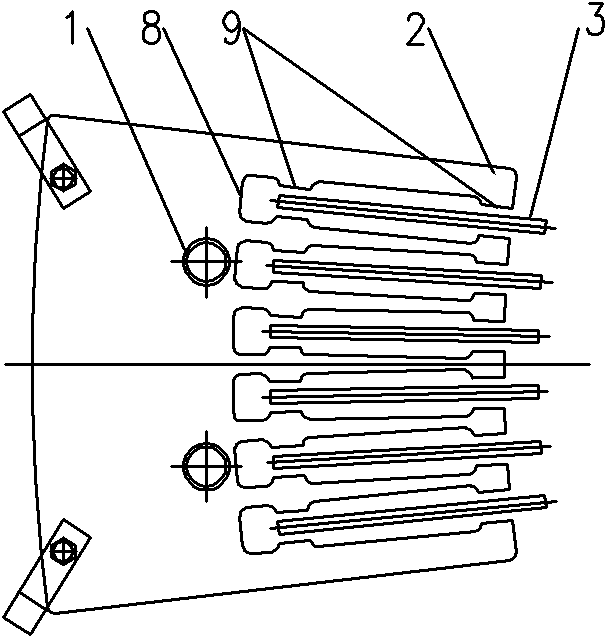

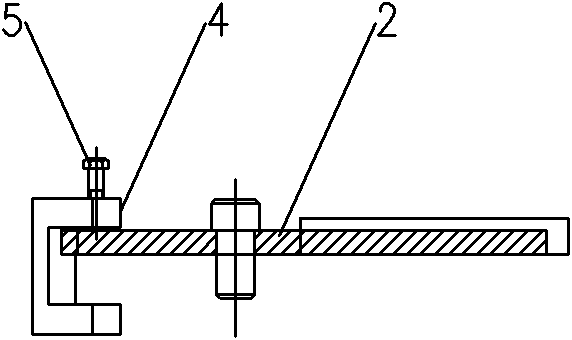

[0018] Such as figure 1 , figure 2 Among them, a tooling fixture for a stator pressure plate, the clamp body 2 is provided with two C-shaped clamps at one end, two positioning pins 1 at the middle, and a plurality of opening slots arranged in an arc at the other end, and positioning pins are provided in the opening slots. Partition 3. The bottom end of the open slot is provided with a positioning arc line 8, and the two sides of the open slot are provided with four positioning constrictions 9, two respectively at the two sides of the open slot.

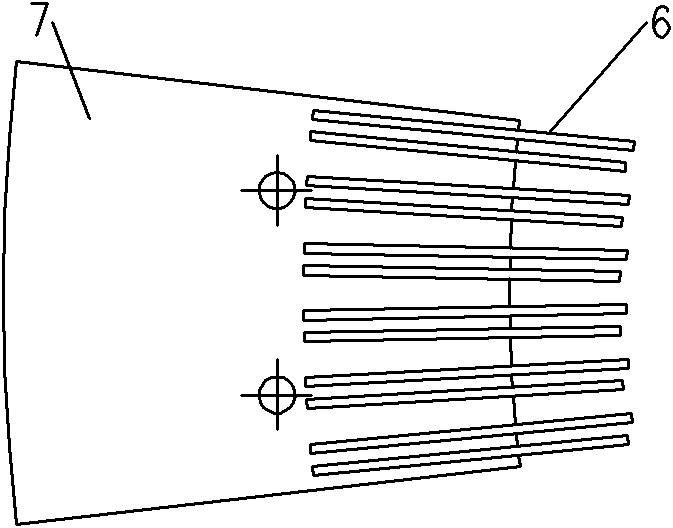

[0019] A row of deep opening slots are milled on the clamp body 2 by machining. The opening slots are processed into a certain angle according to the product requirements. On the arc, the relative position of the rack 6 is positioned by using two spaced positioning necks 9 and the positioning partition 3 in the groove. The thickness of the positioning partition 3 is processed according to the thickness of the rack 6 and the groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com