Work clamp matched with universal miller and used for milling seam faces of glass molds

A technology of glass molds and universal milling machines, applied in the field of tooling and fixtures, can solve problems such as poor finish of milling surfaces, waste of equipment resources, and difficulty in quality assurance, and achieve the effects of simple overall structure, guaranteed processing quality, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

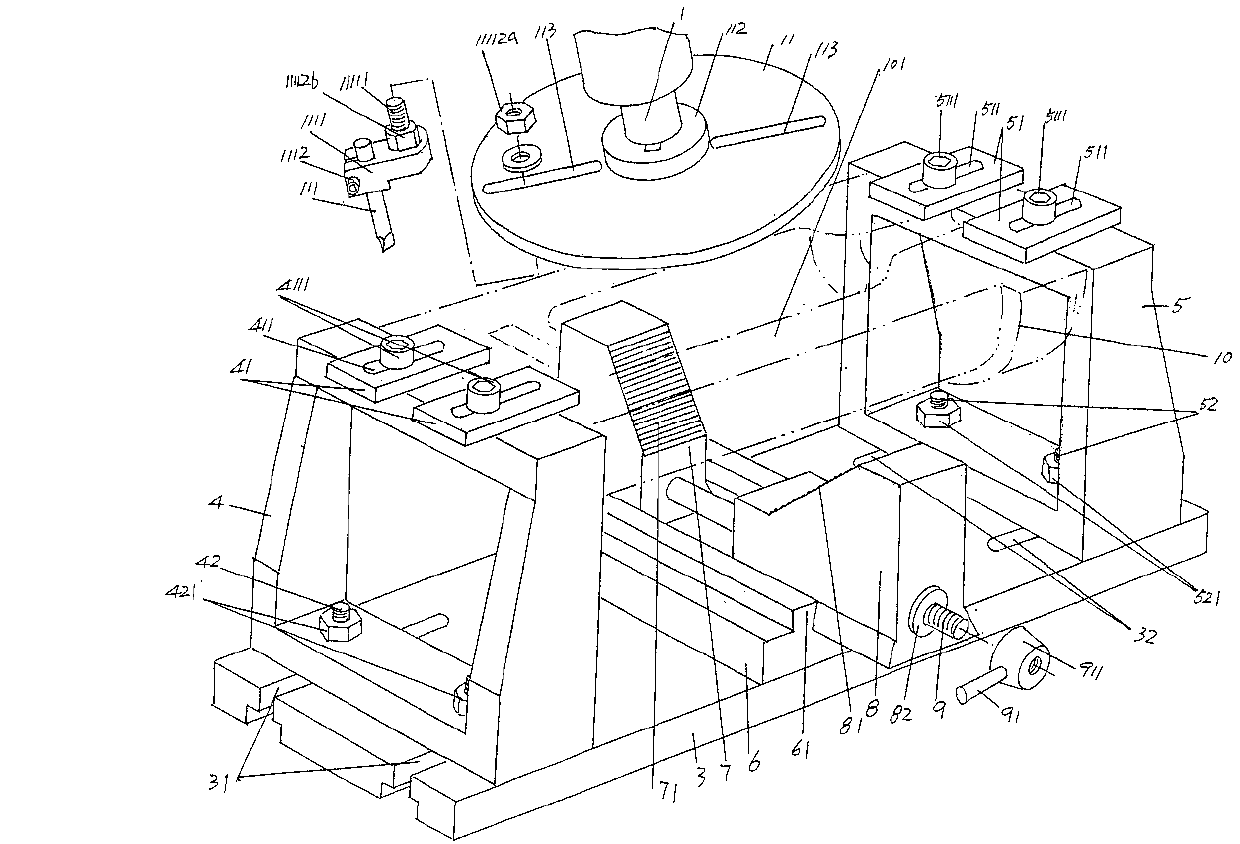

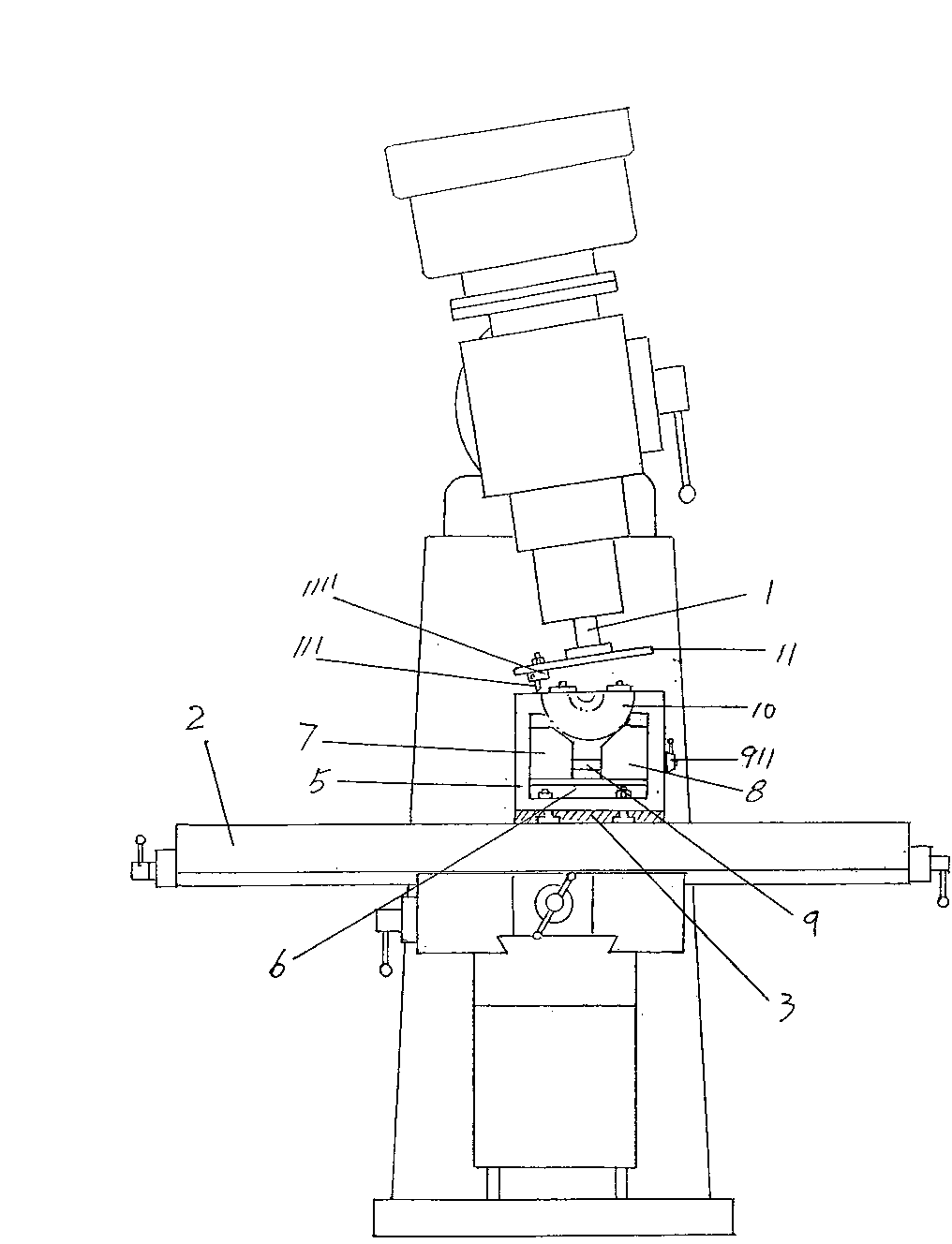

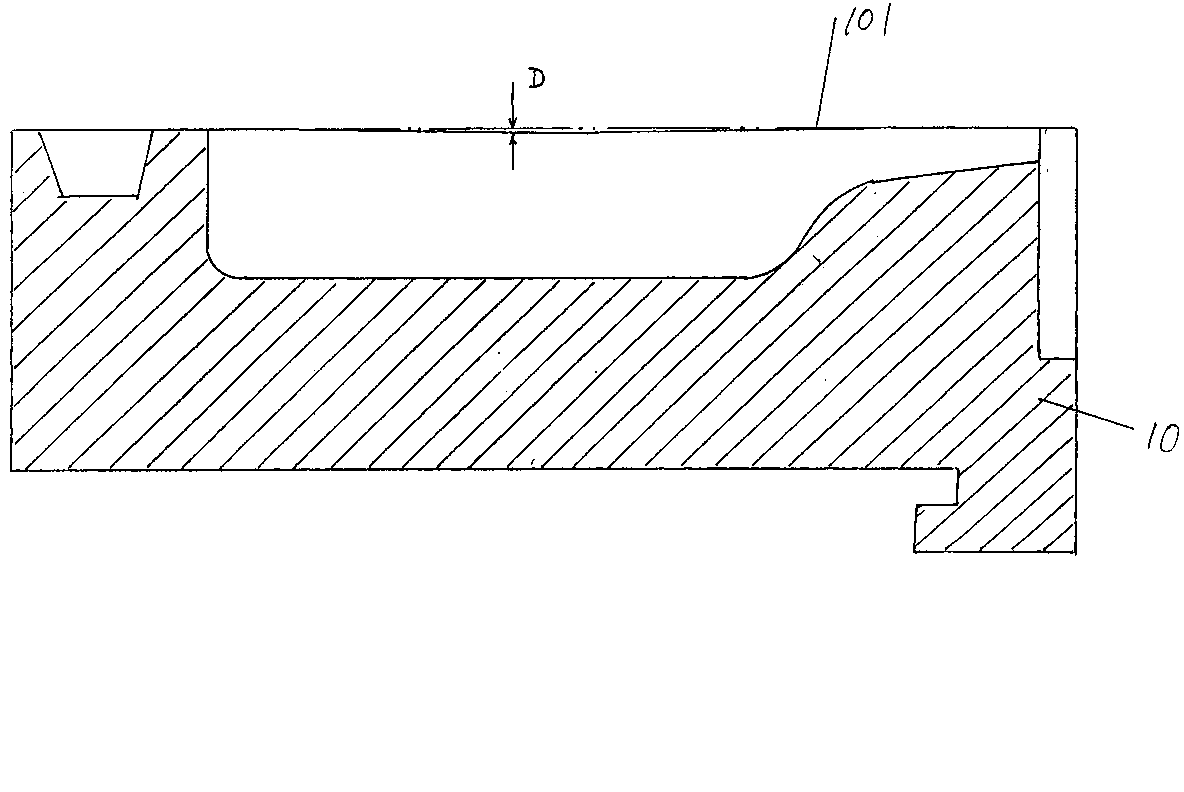

[0020] See figure 1 with figure 2 , the milling machine spindle 1 and the milling machine working platform 2 belonging to the structural system of the universal milling machine are given. According to the common technical knowledge in the industry, the angle of the milling machine spindle 1 of the universal milling machine can be adjusted arbitrarily, so as the inclination angle of the milling machine spindle 1 The change of the inclination angle of the milling cutter fixed disk 2 driven by the milling machine spindle 1 and fixed therewith. Depend on figure 1 As shown, a milling cutter fixing seat 112 is formed at the central position of the disc-shaped milling cutter fixing disk 11, and the milling cutter fixing seat 112 is fixed with the flat key on the milling machine main shaft 1, and is set on the milling cutter fixing disk 11. There is a pair of milling cutter position adjustment grooves 113 distributed on the same straight line, one of the milling cutter position adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com