Vertical type of double disc surface grinding machine

a technology of double discs and grinding machines, which is applied in the direction of grinding work supports, metal-working equipment, manufacturing tools, etc., can solve the problems of affecting the accuracy of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

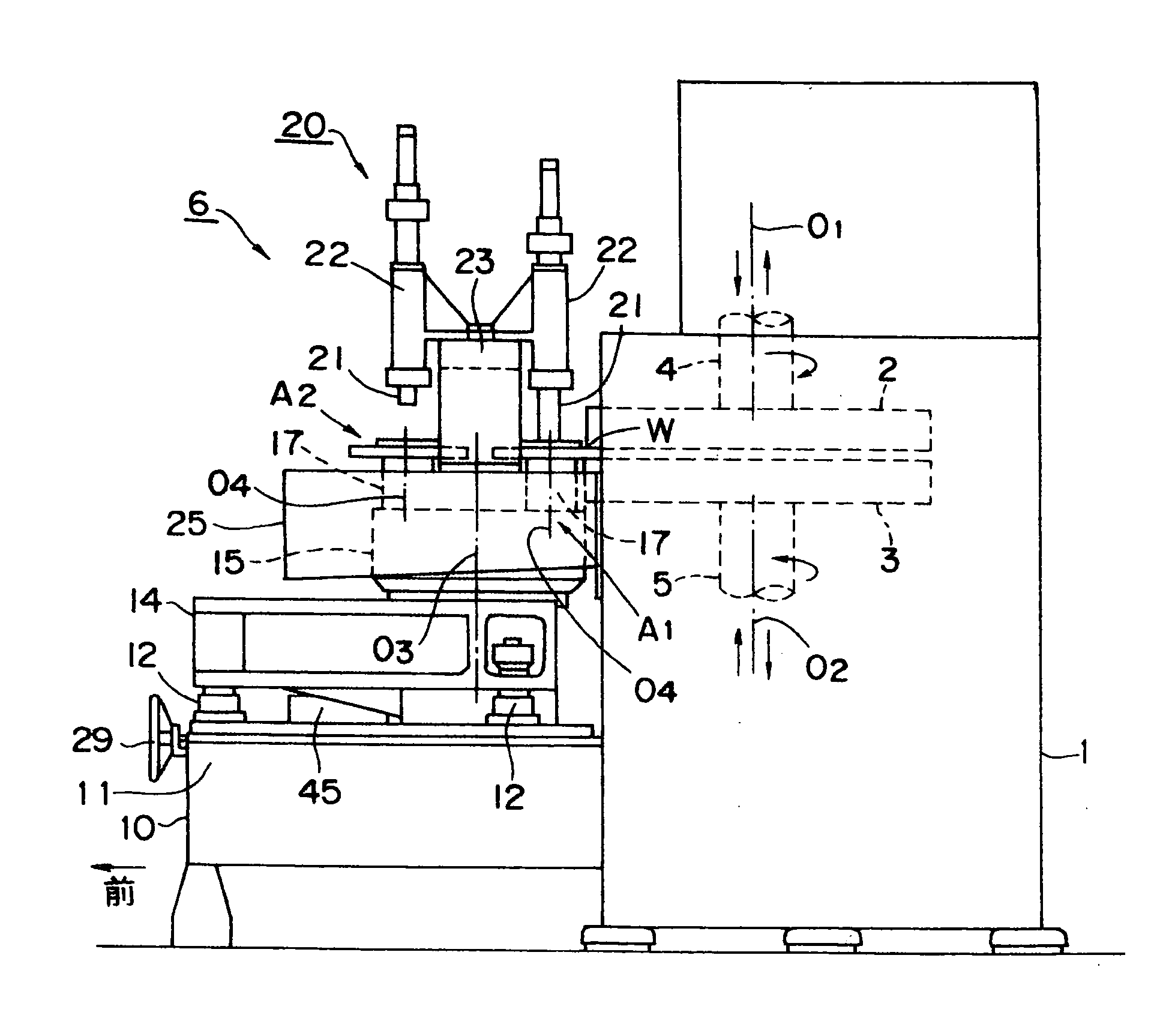

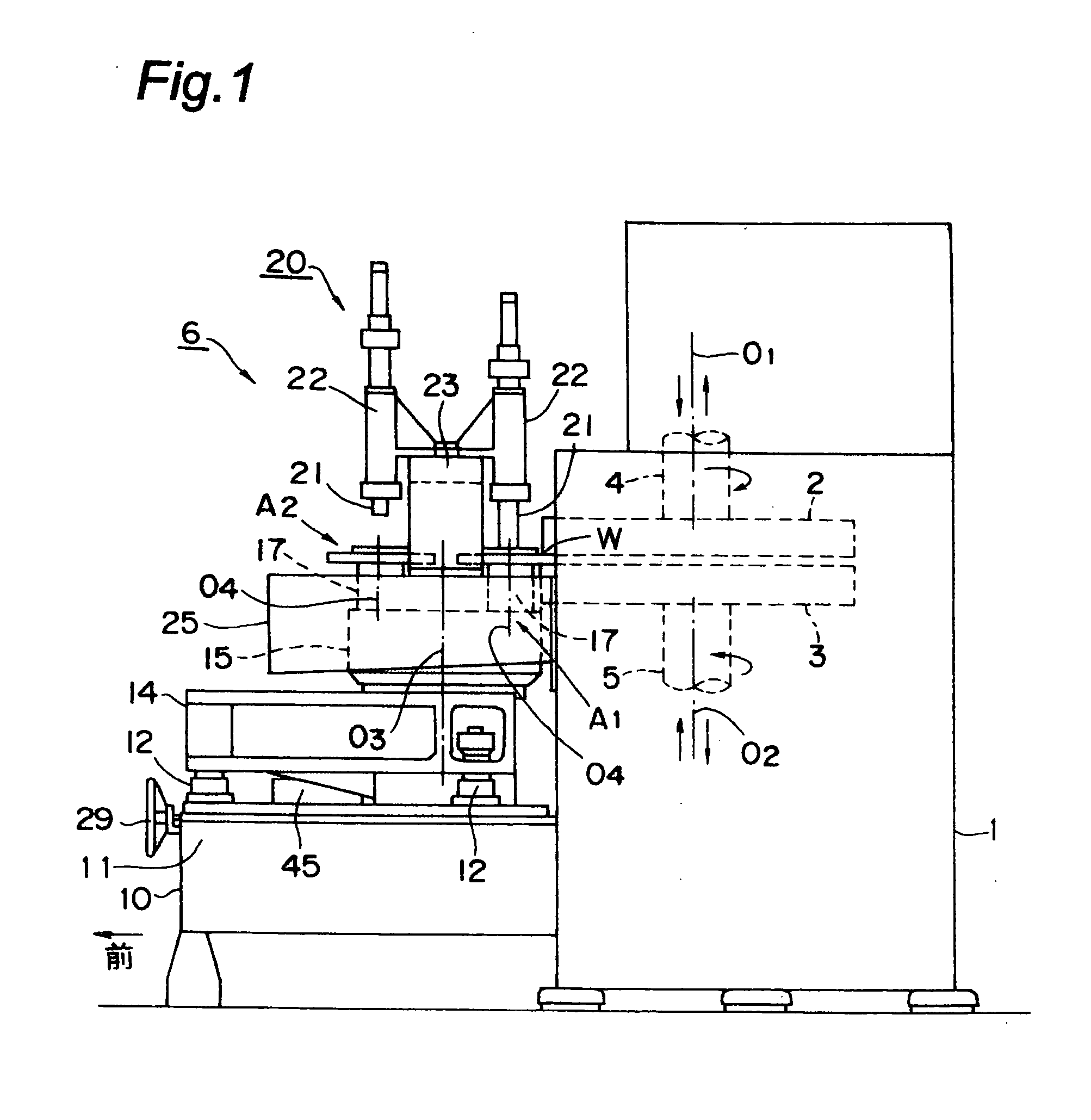

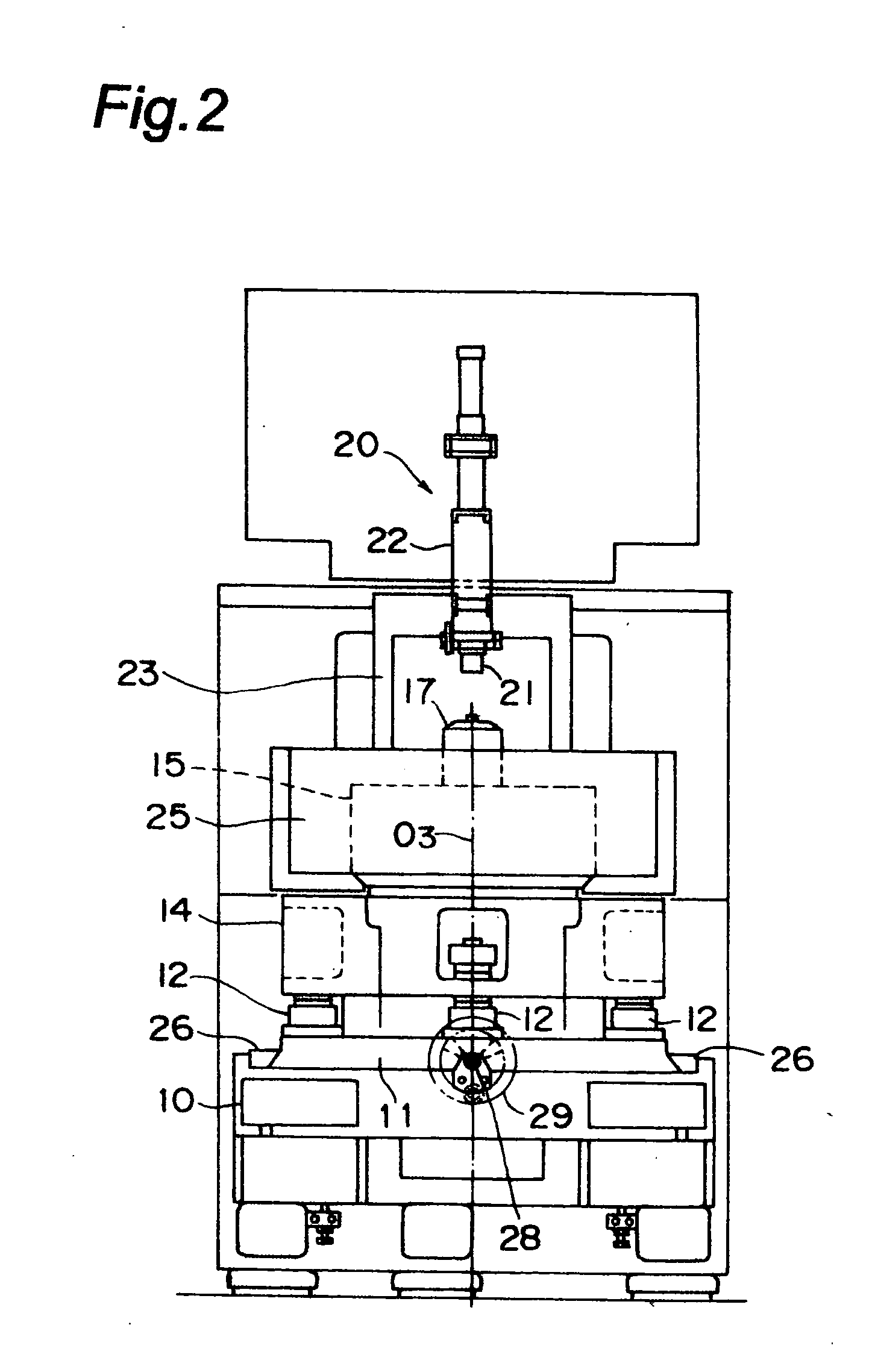

[0019]FIG. 1 is the side view of the vertical type of double disc surface grinding machine to which the invention of this application is applied. A pair of grinding wheels 2&3 opposing each other in vertical direction and a not-shown power transmitting mechanism are housed in a body case 1, and a work supplying device 6 is installed adjacent to the body case 1. For convenience of explanation, description will be made on a condition that a side where the work supplying device 6 is installed is assumed as a front side.

[0020] A lower grinding wheel 3 is secured to the top end of a vertical lower grinding wheel spindle 5, an upper grinding wheel 2 is secured to the bottom end of an upper grinding wheel spindle 4 disposed on a spindle axis 01 concentric with a lower grinding wheel spindle axis 02. The both grinding wheel spindles 4&5 are so designed as movable in the vertical direction by elevating mechanisms respectively and are connected to the power transmitting mechanism so as to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com