Multifunctional upright column base for scaffold and manufacturing process thereof

A scaffolding and multi-functional technology, applied in other manufacturing equipment/tools, manufacturing tools, scaffolding accessories, etc., can solve problems such as hidden dangers in construction safety, affecting construction efficiency, etc., to reduce transportation costs, shorten construction periods, and reduce The effect of product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

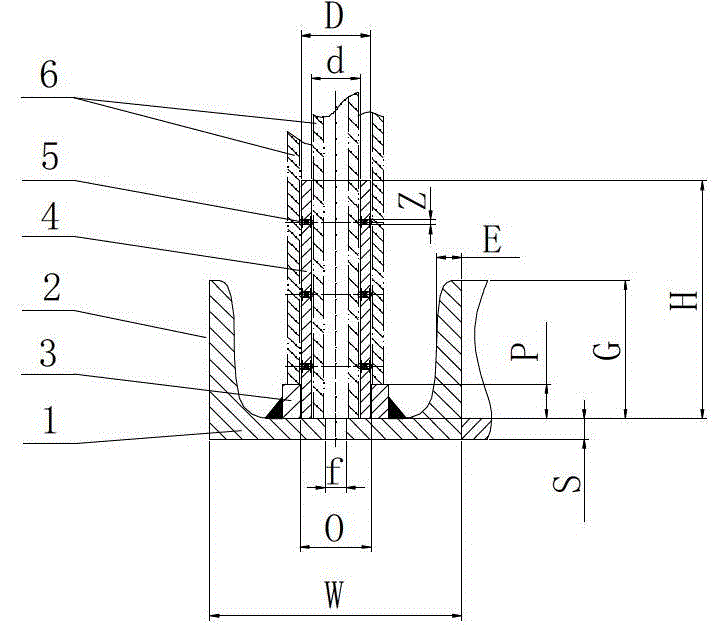

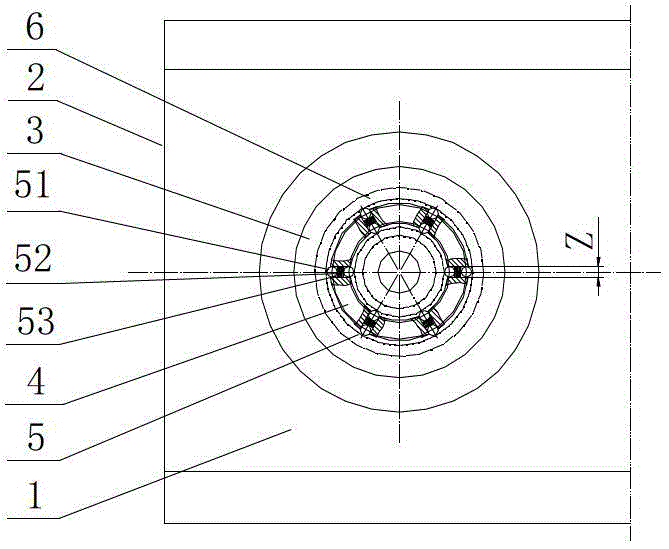

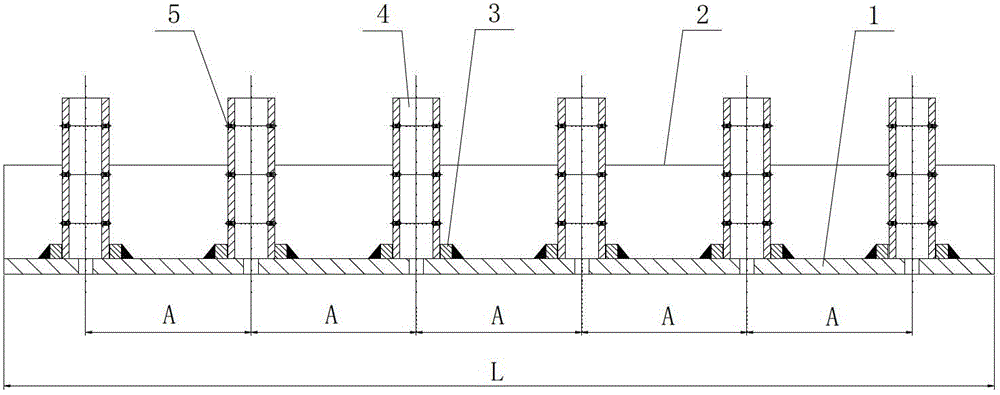

[0042] As shown in the accompanying drawings, a multi-functional scaffold pole base, which includes at least several U-shaped steel plates 1 vertically and horizontally connected to each other to form a horizontal base 2, U-shaped steel plates 1 are provided with more than 3 anchor rod seats 3 and connected with each other. The anchor rod 4 matched with the anchor rod seat 3 has several layers of locking devices 5 arranged in the column wall of the anchor rod 4 .

[0043] Referring to the accompanying drawings, in order to enhance the overall bearing capacity of the base of the scaffold pole against foundation subsidence, the U-shaped steel plate 1 forming the horizontal base 2 is mainly composed of the horizontal direction, and at least 2 pieces are arranged vertically, and the vertical U-shaped steel plates 1 are arranged in parallel, and the U-shaped The distance between the center lines of the steel plates 1 is A×3mm. According to the actual needs of the site, the distance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com