Control system and working method of computer panel saw

A computer panel saw and control system technology, which is applied to work accessories, manufacturing tools, wood processing appliances, etc., and can solve problems such as no disclosure of system components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

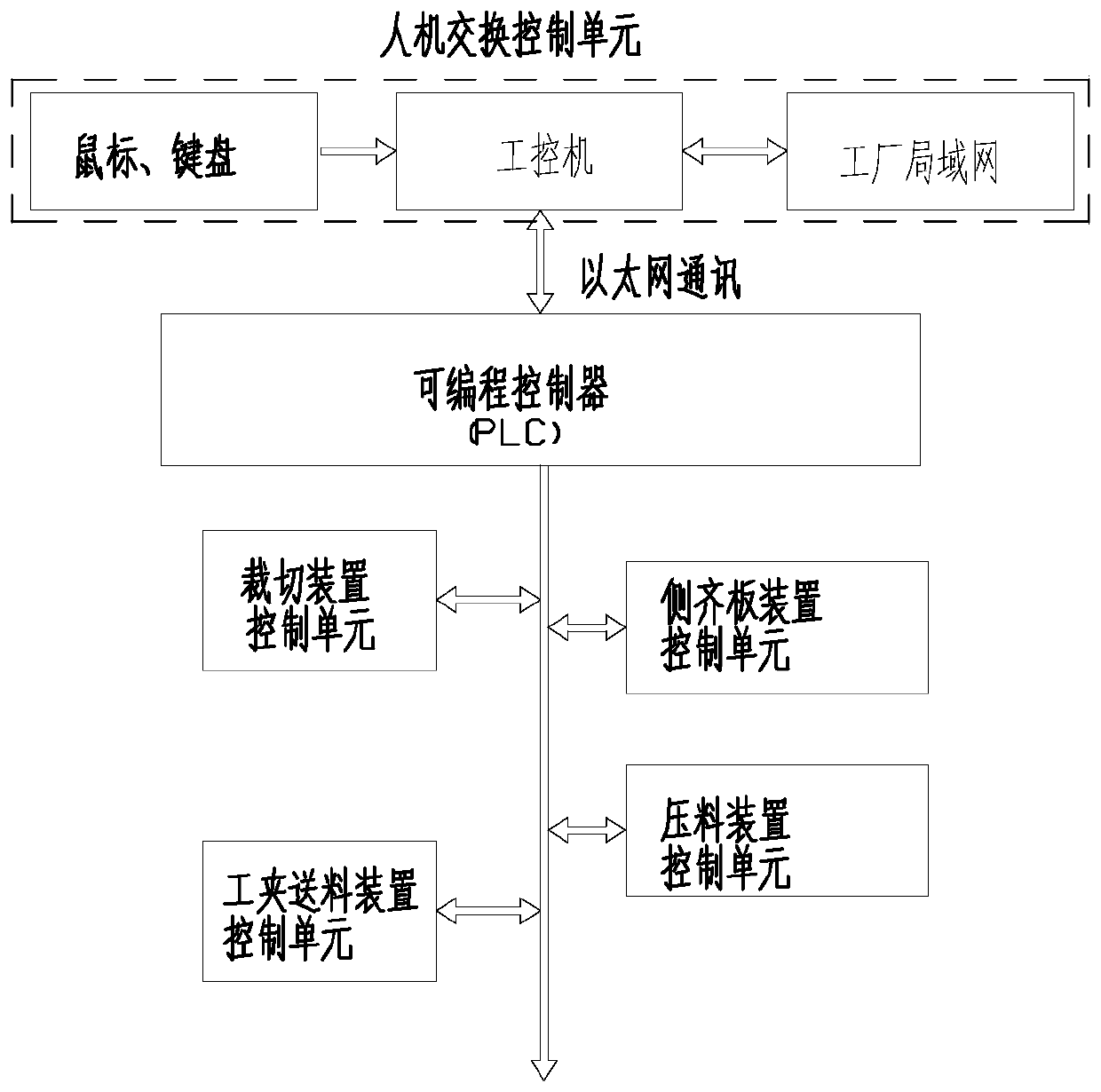

[0108] Such as figure 1 As shown, a control system of a computerized panel saw includes a man-machine exchange control unit, a programmable controller (PLC) connected to the man-machine exchange control unit through Ethernet for two-way control, and a data bus connected to the programmable controller , Two-way control in parallel connected to the data bus clamp feeding device control unit, side alignment device control unit, pressing device control unit, cutting device control unit.

[0109] The human-machine exchange control unit includes an industrial computer, a mouse and a keyboard connected to the industrial computer for one-way control, and a factory LAN connected to the industrial computer for two-way control; the mouse and keyboard one-way control the industrial computer. The industrial computer is connected with the programmable controller bidirectionally through Ethernet.

[0110] Programmable logic controller (PLC) refers to the program control system of computer n...

Embodiment 2

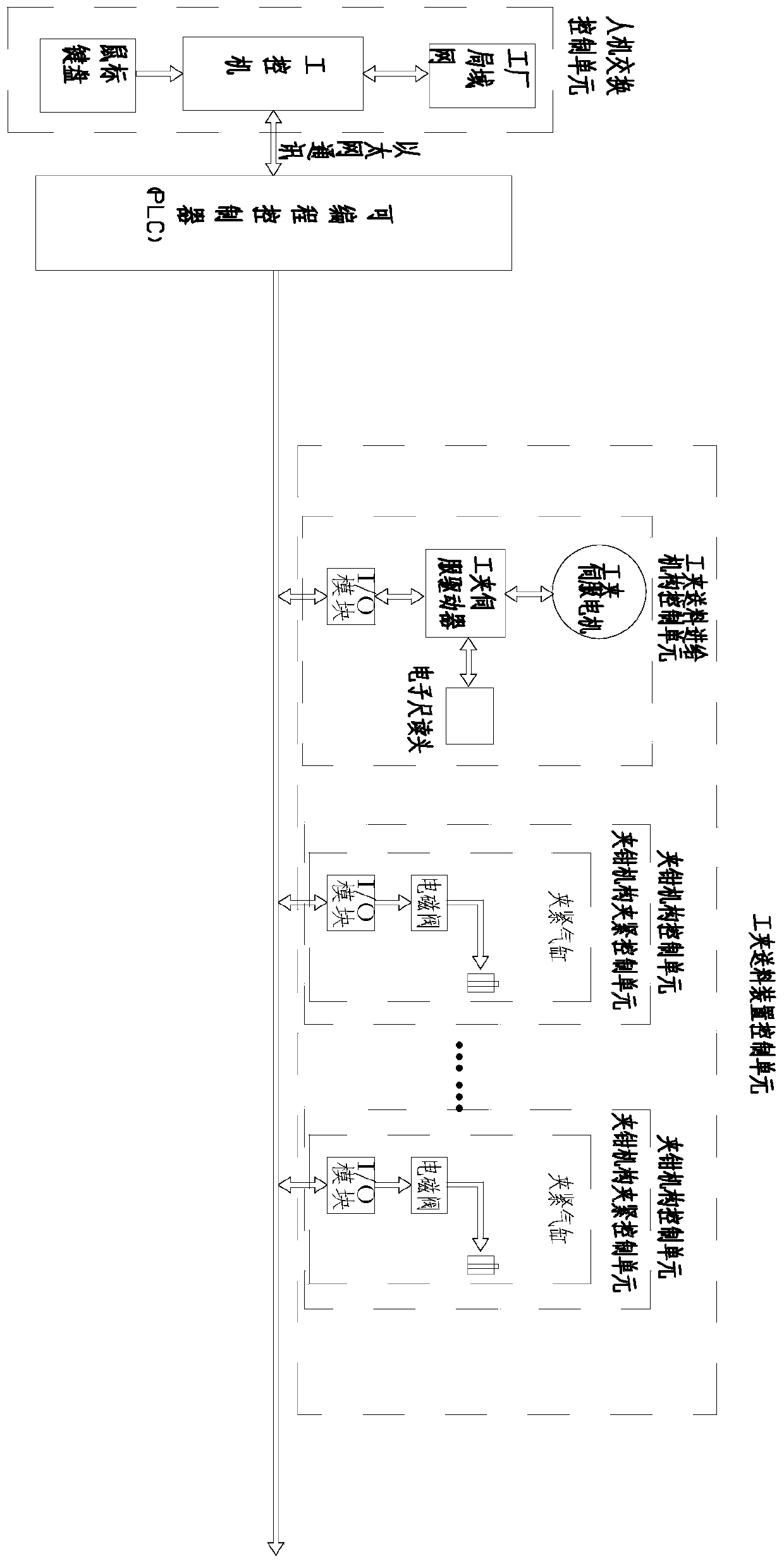

[0137] Such as Figure 4 As shown, the difference from Embodiment 1 is that the computerized panel saw also includes a feeding device control unit, a pushing device control unit, and a front aligning device control unit

[0138] Such as Figure 5 As shown, the feeding device control unit includes a feeding device feeding control unit and a feeding device feeding control unit.

[0139] The feeding control unit of the feeding device includes an I / O module connected in parallel with the bidirectional control of the data bus, a thermal relay connected in series with the one-way control of the I / O module, a contactor connected in series with the one-way control of the thermal relay, and a contactor connected in series with the one-way control of the I / O module. One-way control of the feed motor connected in series; I / O module one-way control of the thermal relay, one-way control of the thermal relay contactor, one-way control of the contactor feed motor.

[0140]The feeding contr...

Embodiment 3

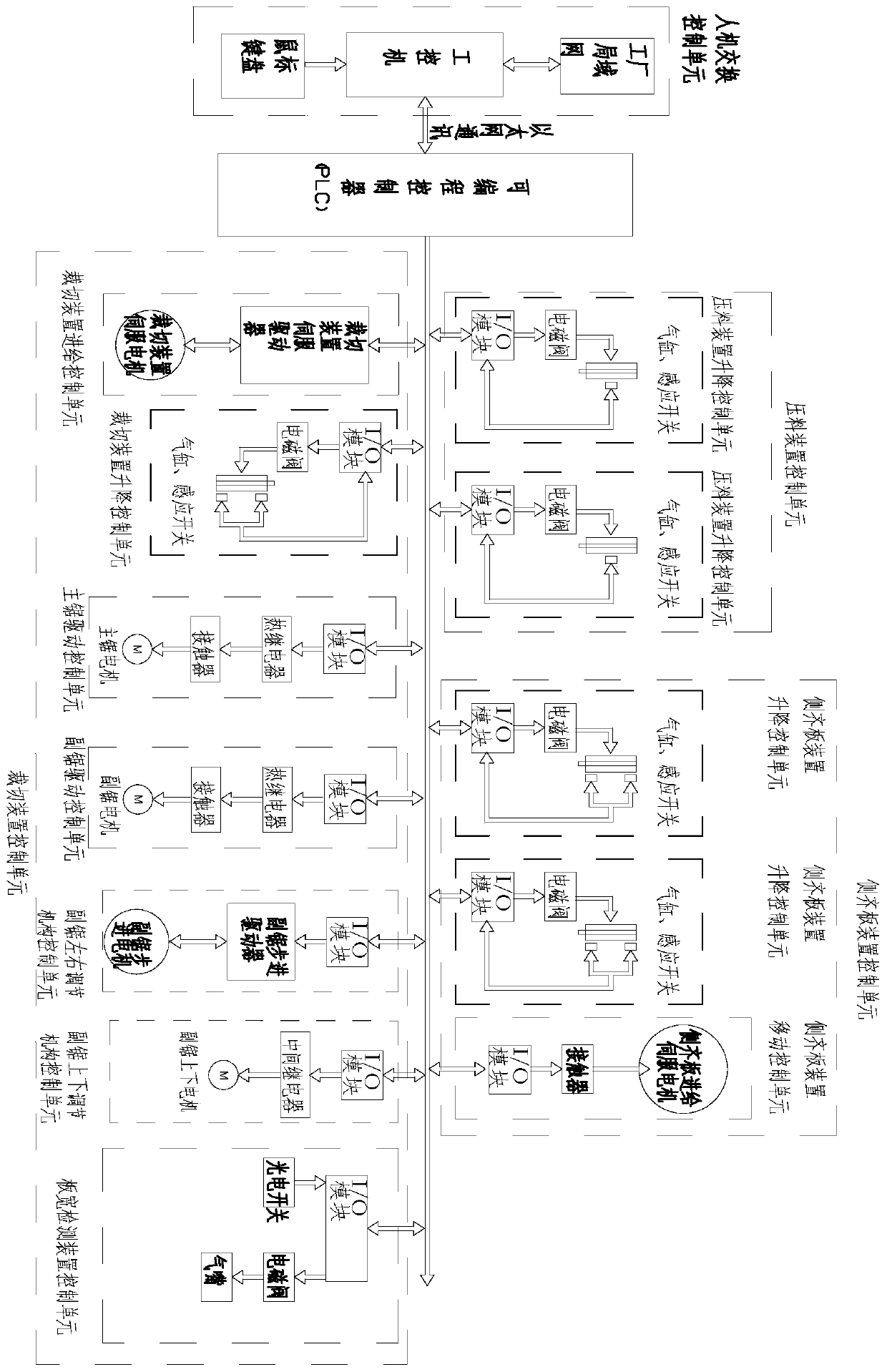

[0147] Such as Figure 6 As shown, the difference from Embodiment 2 is that the feeding device control unit includes a feeding device feeding control unit and a feeding device feeding control unit.

[0148] The feeding control unit of the feeding device includes an I / O module connected in parallel with the bidirectional control of the data bus, a thermal relay connected in series with the one-way control of the I / O module, a contactor connected in series with the one-way control of the thermal relay, and a contactor connected in series with the one-way control of the I / O module. One-way control of the feed motor connected in series; I / O module one-way control of the thermal relay, one-way control of the thermal relay contactor, one-way control of the contactor feed motor.

[0149] The feeding control unit of the feeding device includes an I / O module connected in parallel with the bidirectional control of the data bus, a thermal relay connected in series with the unidirectional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com