Welding process and welding device of vacuum furnace

A welding device and welding process technology, applied in welding equipment, auxiliary devices, manufacturing tools, etc., can solve the problems of unstable welding quality, uneven heat distribution, low work efficiency, etc., and achieve enhanced welding effect, uniform heat distribution, even heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

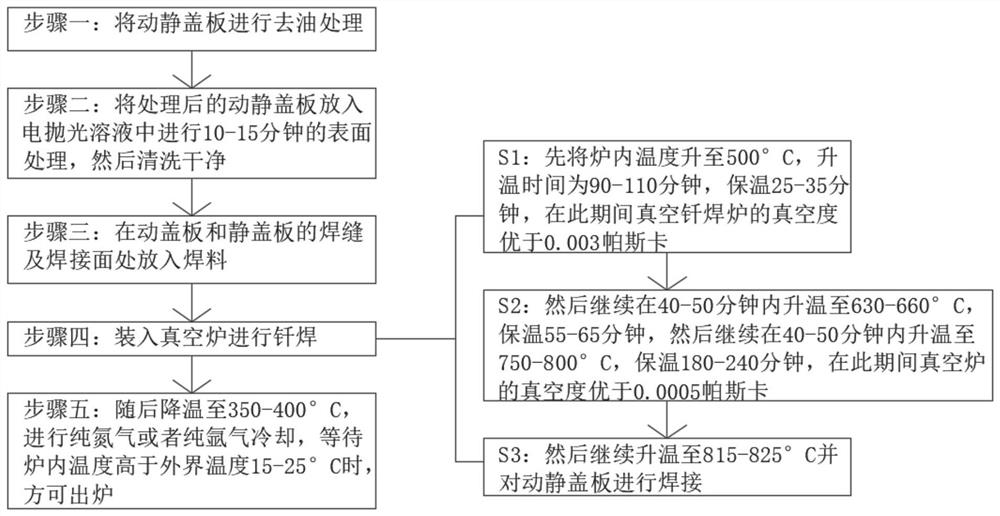

[0037] see figure 1 As shown, the present invention is a welding process of a vacuum furnace, comprising:

[0038] Step 1: Degrease the static and dynamic cover plate;

[0039] Step 2: Put the treated dynamic and static cover plate into the electropolishing solution for 10-15 minutes of surface treatment, and then clean it;

[0040] Wherein, the raw material weight ratio of the electropolishing solution is: sulfuric acid 25-35 phosphoric acid 15-25 water 45-55;

[0041] Step 3: Put solder on the welding seam and welding surface of the moving cover plate and the static cover plate;

[0042] Step 4: Load into a vacuum furnace for brazing;

[0043] Wherein, the heating steps inside the vacuum furnace are as follows:

[0044] S1: first raise the temperature in the furnace to 500°C, the heating time is 90-110 minutes, and the temperature is kept for 25-35 minutes, during which the vacuum degree of the vacuum brazing furnace is better than 0.003 Pascal;

[0045] S2: then continue...

Embodiment 2

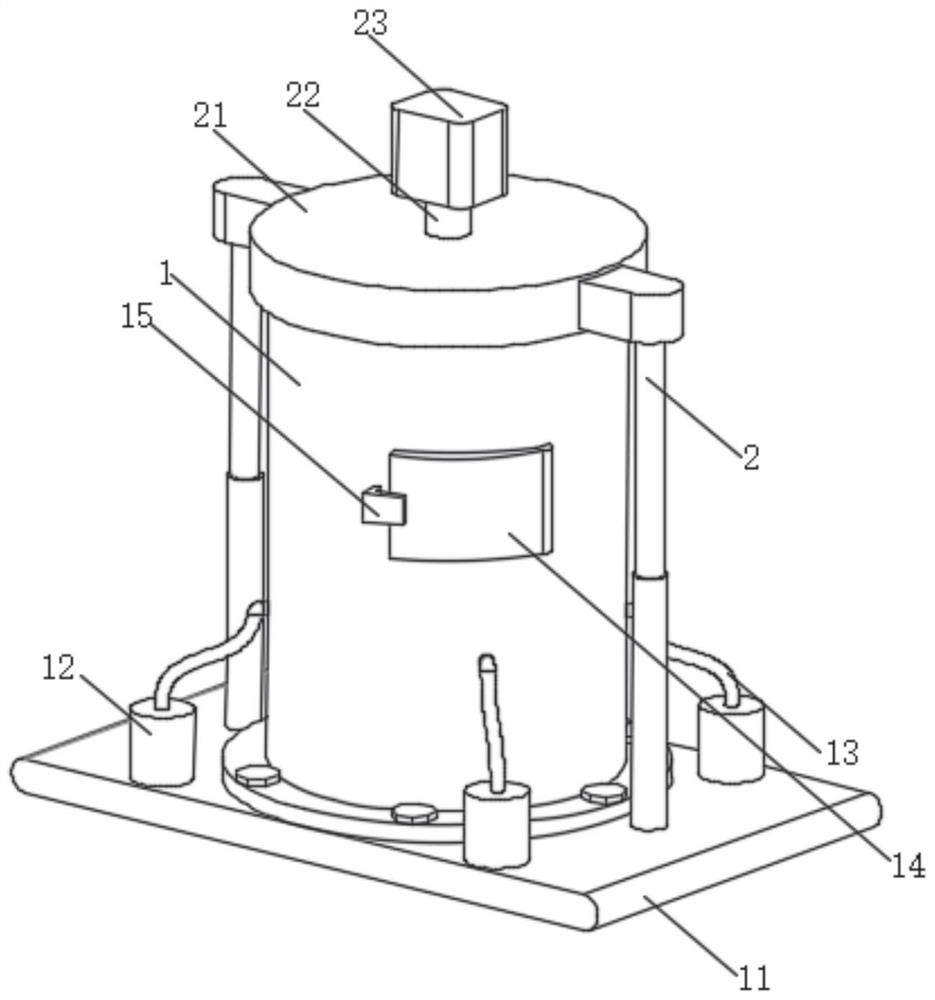

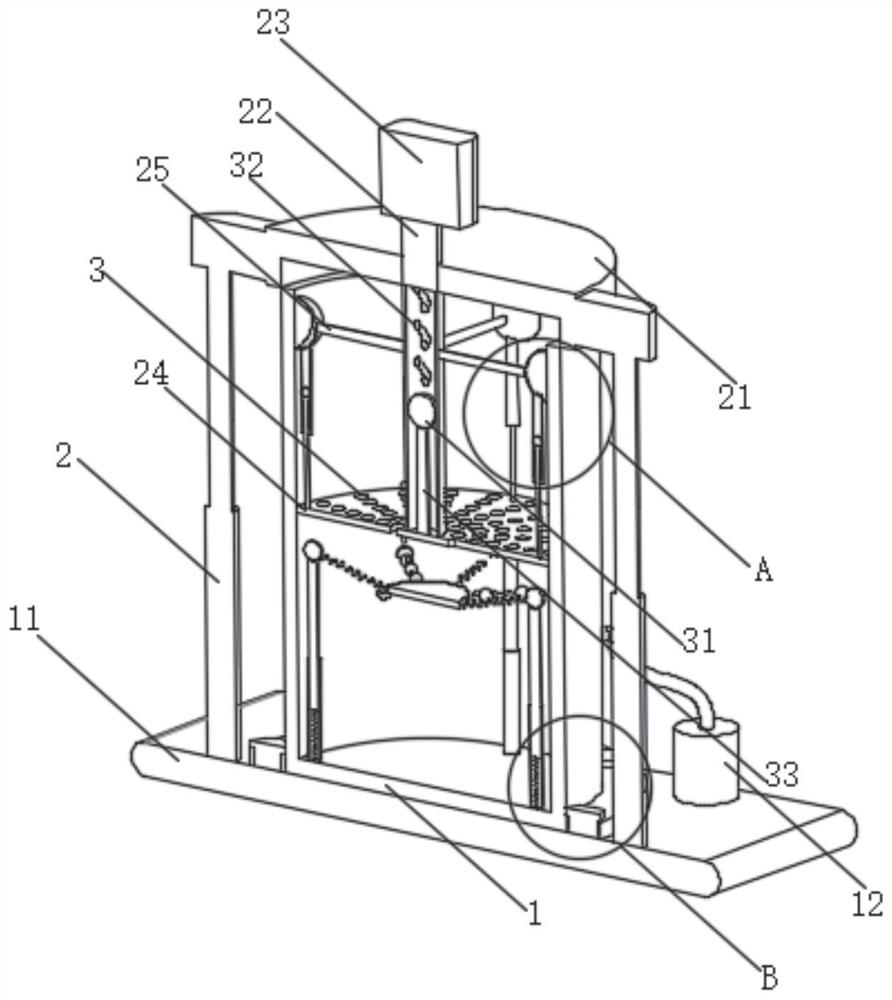

[0049] see Figure 2-Figure 7 As shown, the present invention is a welding device of a vacuum furnace, including a furnace body 1, the purpose of this setting is to facilitate welding, and the bottom of the furnace body 1 is fixedly connected with a bottom plate 11, and the purpose of this setting is to facilitate the welding of the furnace body 1. For support, the top opening of the furnace body 1 is set, and the purpose of this setting is to facilitate the limiting of the furnace body 1. The four sides of the bottom plate 11 are respectively fixed and connected with a suction cylinder 12. The purpose of this setting is to facilitate the suction, the suction cylinder The top of 12 is communicated with a suction hose 13. The purpose of this setting is to facilitate the transportation of gas. The end of the suction hose 13 away from the suction cylinder 12 is communicated with the lower side wall of the furnace body 1. The purpose of this setting is In order to facilitate the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com