Three-level polyaluminium chloride coagulation treatment method for electro-polishing wastewater

A technology of polyaluminum chloride and electrolytic polishing, which is applied in metallurgical wastewater treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve problems such as difficult to achieve satisfactory TP treatment effect, endanger the health of surrounding residents, and affect industrial and agricultural production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

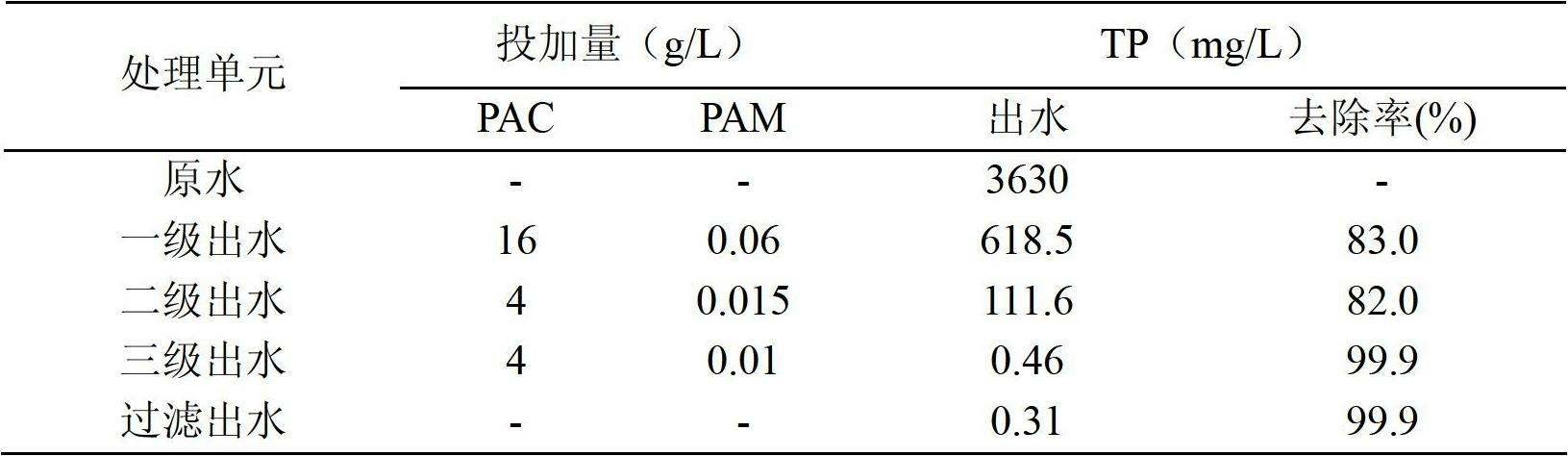

[0014] Embodiment 1, the effect of three-stage PAC coagulation on the removal of total phosphorus in wastewater

[0015] The stainless steel electropolishing wastewater from a medical machinery factory in Shandong was placed in five identical Erlenmeyer flasks, and the pH was adjusted to 7.0 during the coagulation reaction at all levels, and then the dosages of the first, second and third levels of PAC were respectively 16, 4 and 4g / L, and the corresponding coagulant PAM dosages are 0.06, 0.02 and 0.01g / L respectively. The results show that the concentration of total phosphorus in the effluent after the three-stage PAC coagulation can be reduced to below 1.0 mg / L (Table 1), which meets the discharge requirements.

[0016]

[0017] Table 1

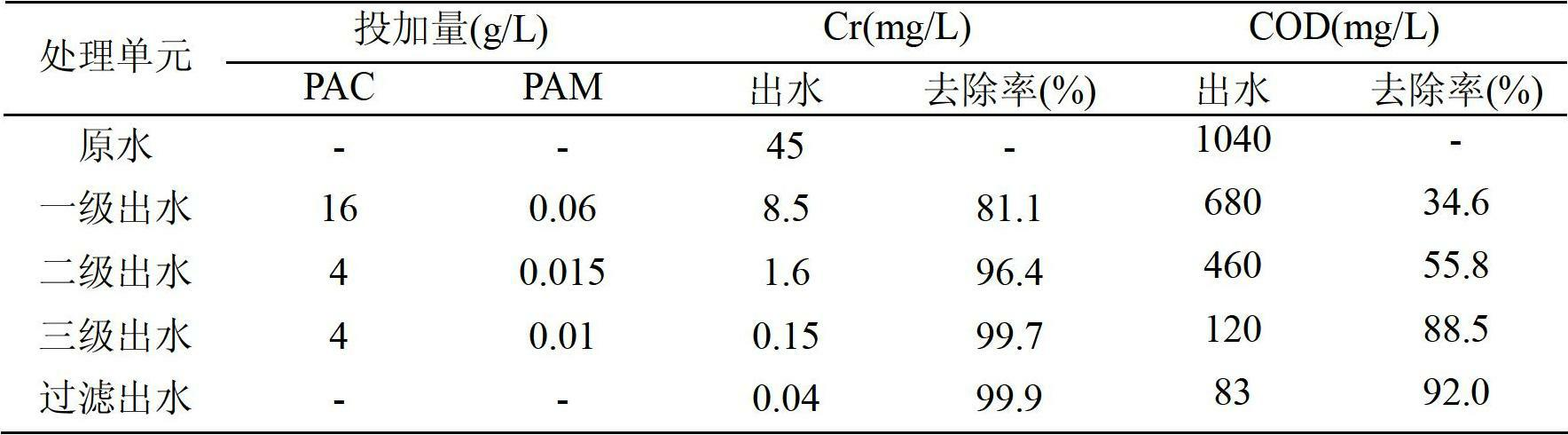

Embodiment 2

[0018] Embodiment 2, waste water source and other experimental conditions are all the same as example 1, carry out the process operation of small scale (reactor effective volume 5L), meanwhile, pH all is adjusted to 7.0 during coagulation reaction at all levels, then one, two and three The dosage of grade PAC is 16, 4 and 4g / L respectively, and the corresponding dosage of coagulant PAM is 0.06, 0.02 and 0.01g / L respectively. The results show that the concentration of Cr and COD in the effluent after the three-stage PAC coagulation can be reduced to below 0.15mg / L and 120mg / L respectively (Table 2), which meets the discharge requirements.

[0019]

[0020] Table 2

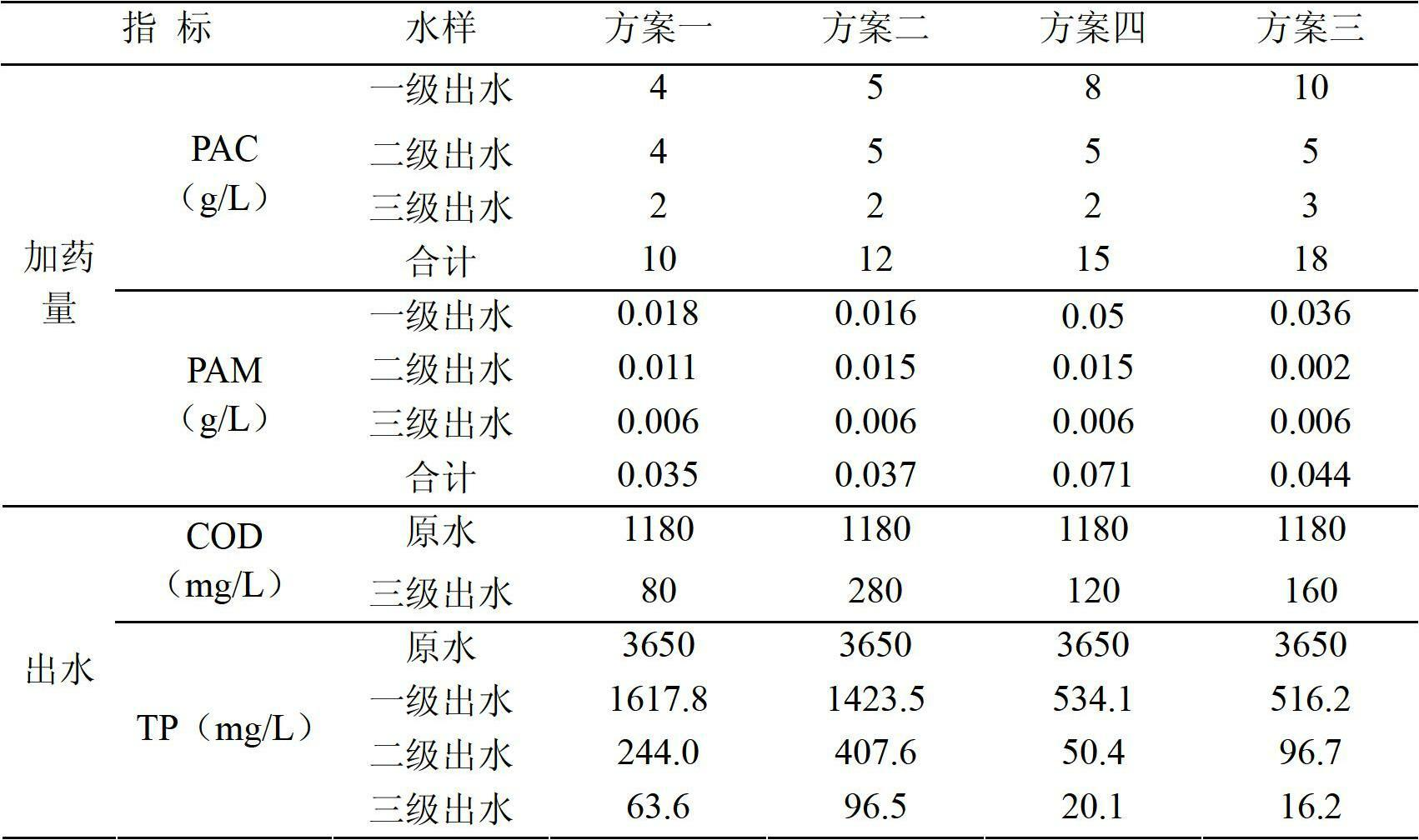

Embodiment 3

[0021] Example 3, Optimization of coagulant dosage in three-stage PAC coagulation process

[0022] The source of wastewater and other experimental conditions are the same as Example 1. In the three-stage PAC coagulation process, when the dosage of PAC increases to 30g / L, it is beneficial to the removal of COD and total phosphorus in wastewater; however, considering the cost of wastewater treatment, the experimental It is determined that the dosage of PAC at each level is 10, 5 and 3g / L respectively (Table 3). After the third-level effluent passes through the membrane, the discharge requirements are met.

[0023]

[0024] table 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com