Flexible plate surface drilling device and drilling method

A drilling device and plate technology, applied in fixed drilling machines, wood processing appliances, manufacturing tools, etc., can solve problems such as low drilling efficiency of plates, improve perforation efficiency, improve compaction effect, and prevent excessive deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

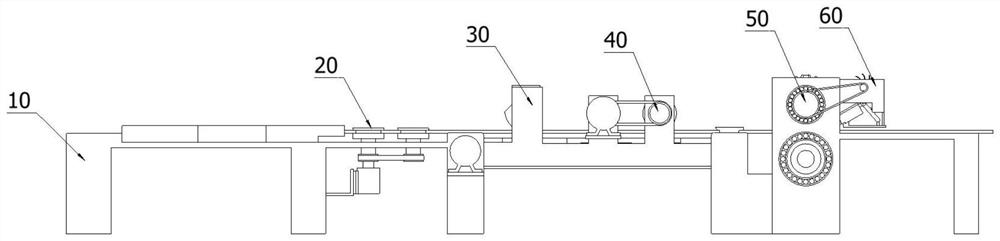

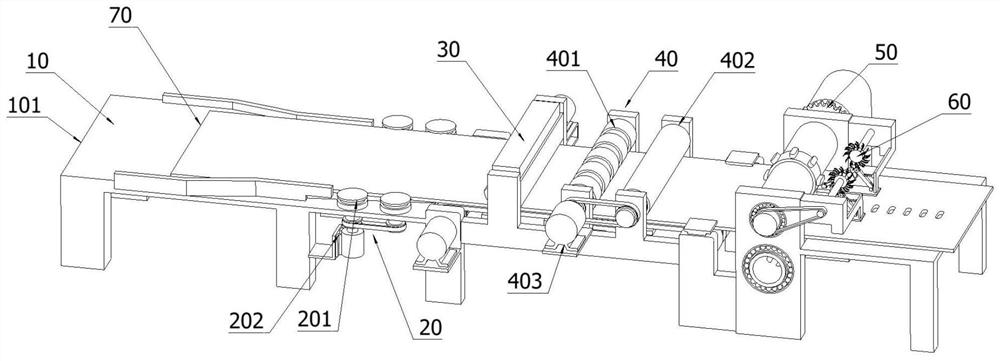

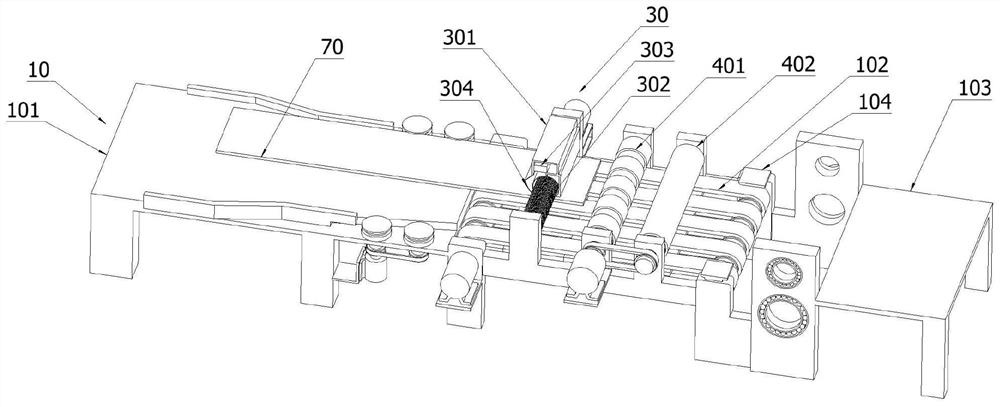

[0047] like figure 1 , 2 As shown in , 3, this embodiment discloses a surface drilling device for a flexible plate 70, including: a body 10, a conveying device 20, a cleaning device 30, a leveling device 40, and a punching device 50. The body 10 is arranged on a plane, The body 10 includes: a first conveying path 101, a second conveying path 102, a third conveying path 103, and a limit plate 104. The first conveying path 101 is located on the left side of the body 10, and the surface of the first conveying path 101 is set to be flat. The surface of the first conveying path 101 is provided with guide plate, and the guide plate is contracted shape, and the width of the constricted opening of guide plate is greater than the width of plate 70; The conveyer road 101 is fixedly connected, and the middle of the second conveyer road 102 is provided with a conveyer belt, and the conveyer belt is movably connected with the second conveyer passage 102, and the conveyer belt is driven to...

Embodiment 2

[0054] Same as Embodiment 1, also includes such as Image 6 , 7 As shown, the stabilizing device 60, the stabilizing device 60 is arranged on the top of the third conveying path 103, the stabilizing device 60 is movably connected with the third conveying path 103, the stabilizing device 60 is positioned at the right side of the punching device 50, and the stabilizing device 60 comprises: a conveyor belt 601, driving rod 602, stabilizing plate 603, slide block 604, swing bar 605, back-moving spring 606, fixed housing 607, conveyor belt 601 is arranged on the outside of the third delivery path 103, and one end of conveyor belt 601 is connected with first rotating shaft 501; The rod 602 is arranged inside the third conveying path 103, the driving rod 602 is movably connected with the third conveying path 103, one end of the driving rod 602 is connected with the other end of the conveyor belt 601, and the driving rod 602 is driven to rotate by the conveyor belt 601; the fixed shel...

Embodiment 3

[0056] like Figure 8 As shown, finally a drilling method for a flexible plate 70 surface drilling device is provided, comprising the following steps:

[0057] Conveying the plate 70, placing the plate 70 on the first conveying path 101 of the machine body 10, moving the plate 70 to the second conveying path 102 through an external pushing mechanism, and conveying the conveying device 20 when the plate 70 passes through the first conveying path 101 The wheel 201 will be in contact with the two sides of the plate 70 to guide the position and maintain stable transportation;

[0058] To clean the surface, when the plate 70 moves to the second conveying path 102, the cleaning brush 302 of the cleaning device 30 is rotated by an external driving device, and the surface of the plate 70 is rolled, and the plate 70 is brushed when rolling. Partial impurity removal on the surface does not affect the operation of the leveling device 40, and the removed impurities flow into the interior...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com