Continuous tube cluster perforation intelligent ignition device and process

A technology of ignition device and oil pipe, which is applied in wellbore/well components, production fluid, earthwork drilling and other directions, can solve the problems of inability to meet field operation requirements, low operation time efficiency, complicated operation, etc., to improve the efficiency of perforating operation, The effect of improving the passing capacity and improving the conveying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

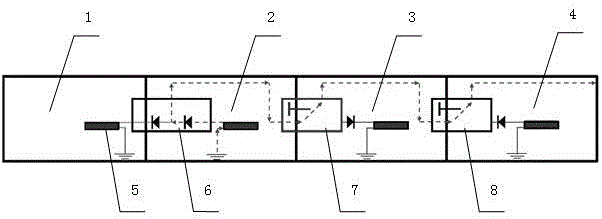

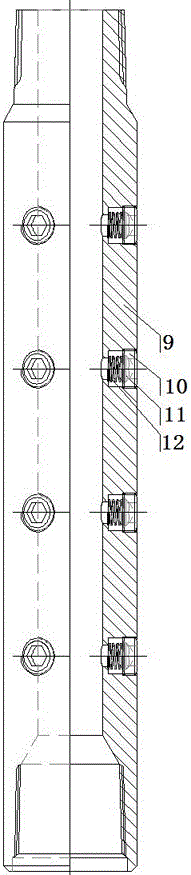

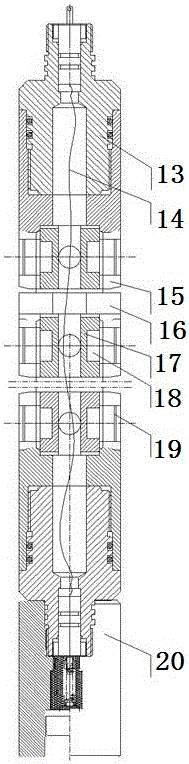

[0027] An intelligent ignition device for coiled tubing cluster perforation, comprising sequentially connected coiled tubing 21, an automatic liquid inlet valve 22, an electronic detonator 23, a single-core flexible connection device 24 for perforation, and a clustered perforation string 25. The automatic liquid inlet valve 22 includes a body 9 on which a plurality of one-way valves for automatic liquid inlet are arranged; the perforating single-core flexible connection device 24 includes an upper joint assembly 13, an H card and a lower joint assembly 20, the upper joint assembly 13 and the lower joint assembly 20 are connected by an H card, the ends of the upper joint assembly 13 and the lower joint assembly 20 are provided with pins, and the two pins are connected by wires 14; the sub-shower The perforation string 25 includes a plurality of perforating guns connected in sequence, and the positive ignition diode 7 and the negative ignition diode 8 are connected alternately in...

Embodiment 2

[0041] This embodiment describes the present invention in conjunction with the accompanying drawings.

[0042] Such as figure 1 , the schematic diagram of the ultra-high temperature and ultra-high pressure cluster perforation principle: after all the pipe strings are assembled, they are lowered into the predetermined position in the well. The first perforating gun 1 is ignited with the positive ignition function of the straight-through ignition diode 6, and the large resistance detonator 5 and the perforating gun are ignited. After the operation was completed, the second cluster position was mentioned above, and the second perforating gun 2 was ignited with the negative ignition function of the straight-through ignition diode 6 . After the ignition is completed, the liquid in the well conducts the forward ignition diode 7, and positively ignites the third perforating gun 3 on the ground. After the ignition is completed, the liquid in the well conducts the negative ignition d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com