Spark-erosion perforating machine guide device

A guide device and piercing machine technology, applied in the direction of accessory devices, electric processing equipment, metal processing equipment, etc., can solve the problems of affecting the normal operation of the guide, poor chip punching effect, upward recoil, etc., to improve the perforation efficiency and save energy. Time, the effect of increasing water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

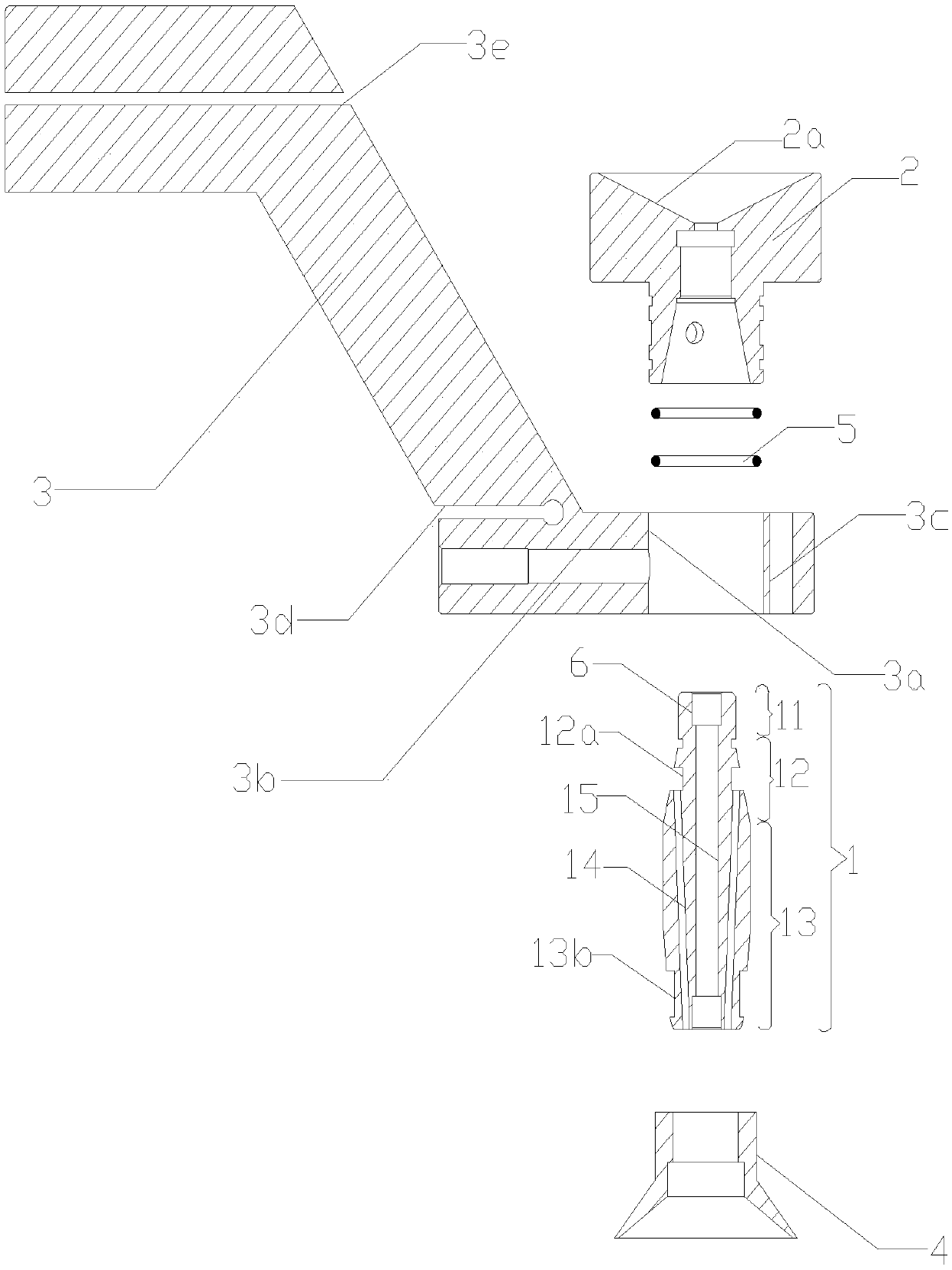

[0026] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be practiced. The directional terms mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "inside", "outside", "side", etc., are for reference only The directions of the appended drawings, therefore, the directional terms used are for explaining and understanding the present invention, but not for limiting the present invention.

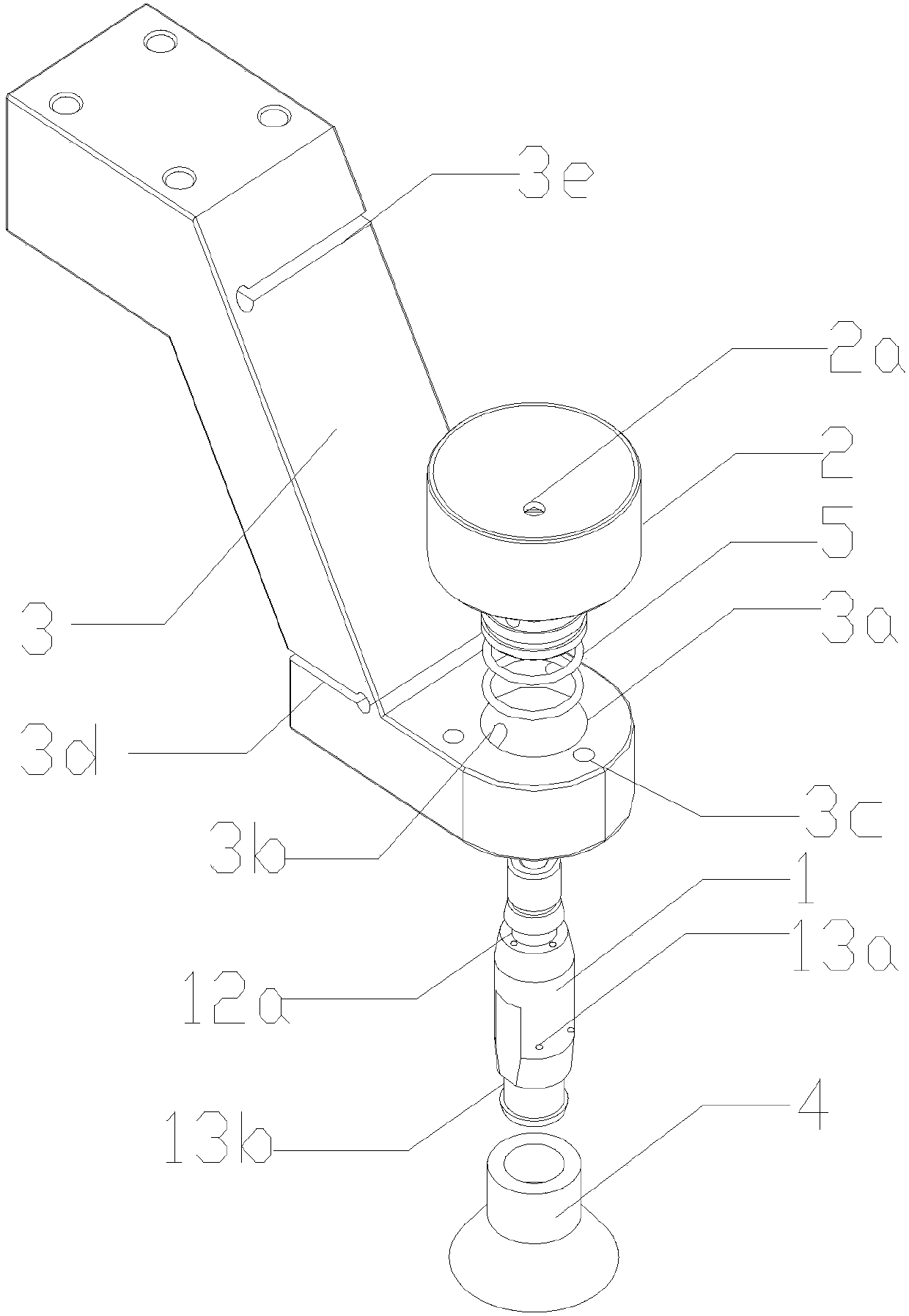

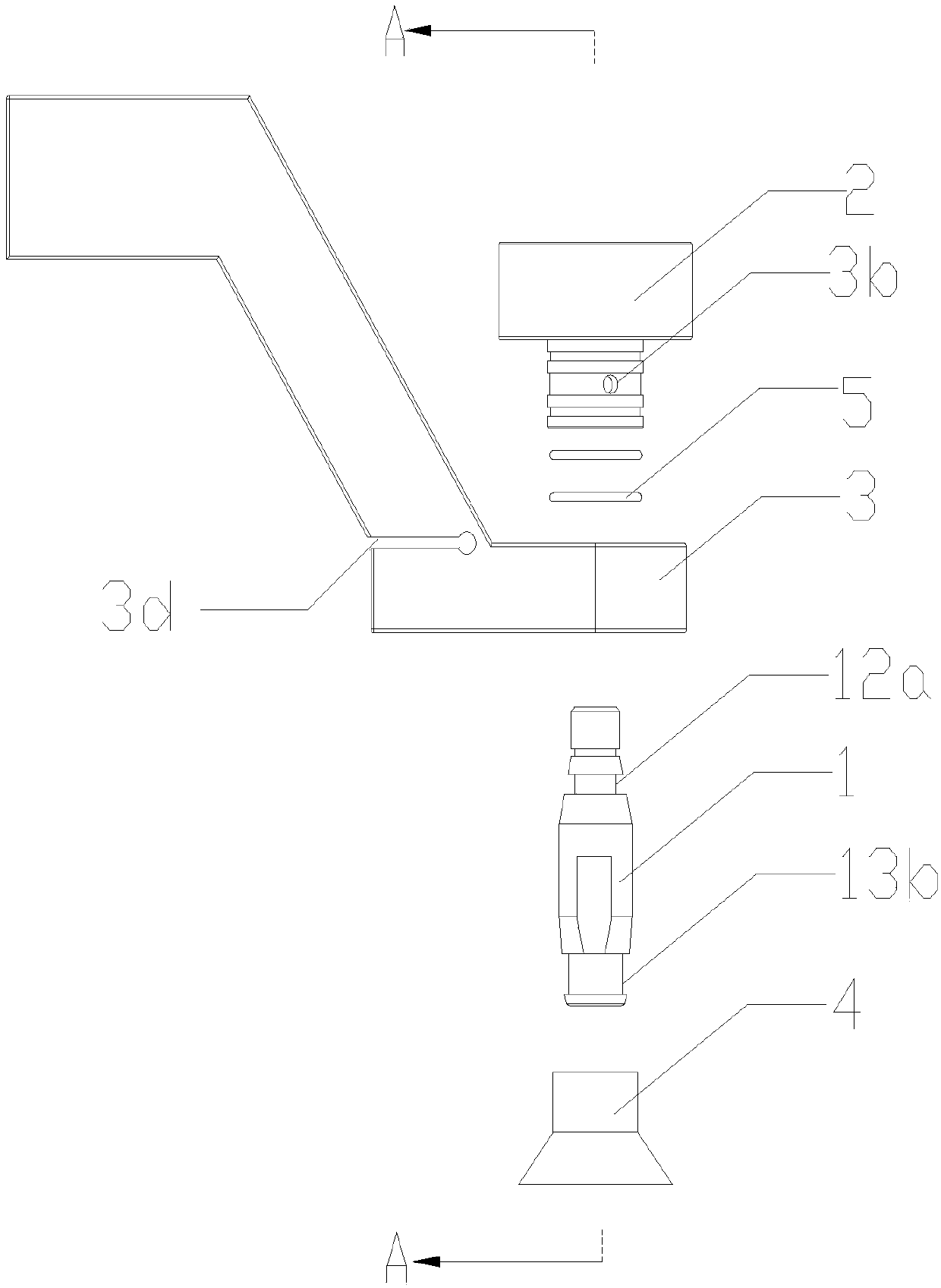

[0027] combined with figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 As shown, the present embodiment is a guide device for an electric spark piercer, including a guide 1, a guide seat 2 and a guide bracket 3, the outer wall of the upper section 11 of the guide is provided with locking screws, and the inside of the guide seat 2 is provided with a locking screw. Tighten the threads that match the thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com