Multi-control-unit multi-beam laser perforation device in oil well

A technology with multiple control units and control units, applied in optics, installation, optical components, etc., can solve the problems of low perforation efficiency, influence, laser influence, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

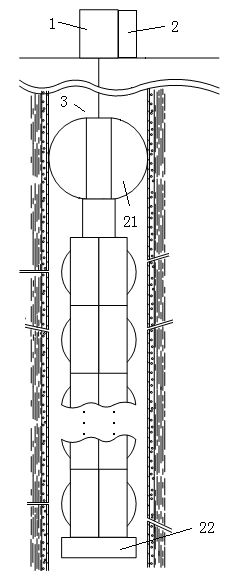

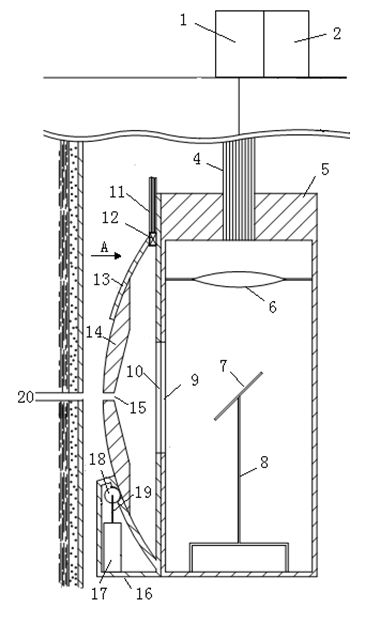

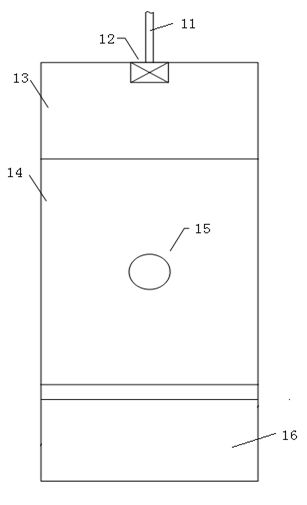

[0056] refer to Figure 1 to Figure 3 And as Figure 4 As shown, the device in this embodiment includes a laser source 1, a high-pressure gas source 2, and a downhole laser perforator 3. The laser source 1 and the high-pressure gas source 2 are located on the ground, so that on the one hand, the influence of the complex environment downhole on the instrument is avoided. On the other hand, it eliminates the limitation of the size of the well pipe on the size and volume of the instrument; the laser source 1 is a high-power all-solid-state laser, and the high-energy laser generated by it is transmitted to the downhole laser perforator 3 through an optical fiber; where:

[0057] The downhole laser perforator 3 includes a centralizer 21, a rotary controller 22 and three groups of laser perforation units, wherein the three groups of perforation units are connected in sequence along the longitudinal direction, and the centralizer 21 is installed on the top of the downhole laser perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com