ND steel seamless steel pipe production process

A seamless steel pipe and production process technology, applied in the field of ND steel seamless steel pipe production process, can solve problems such as surface cracks, affect surface quality, and adverse effects on performance, achieve good surface quality, improve surface quality, and resist sulfuric acid dew point The effect of improving the corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

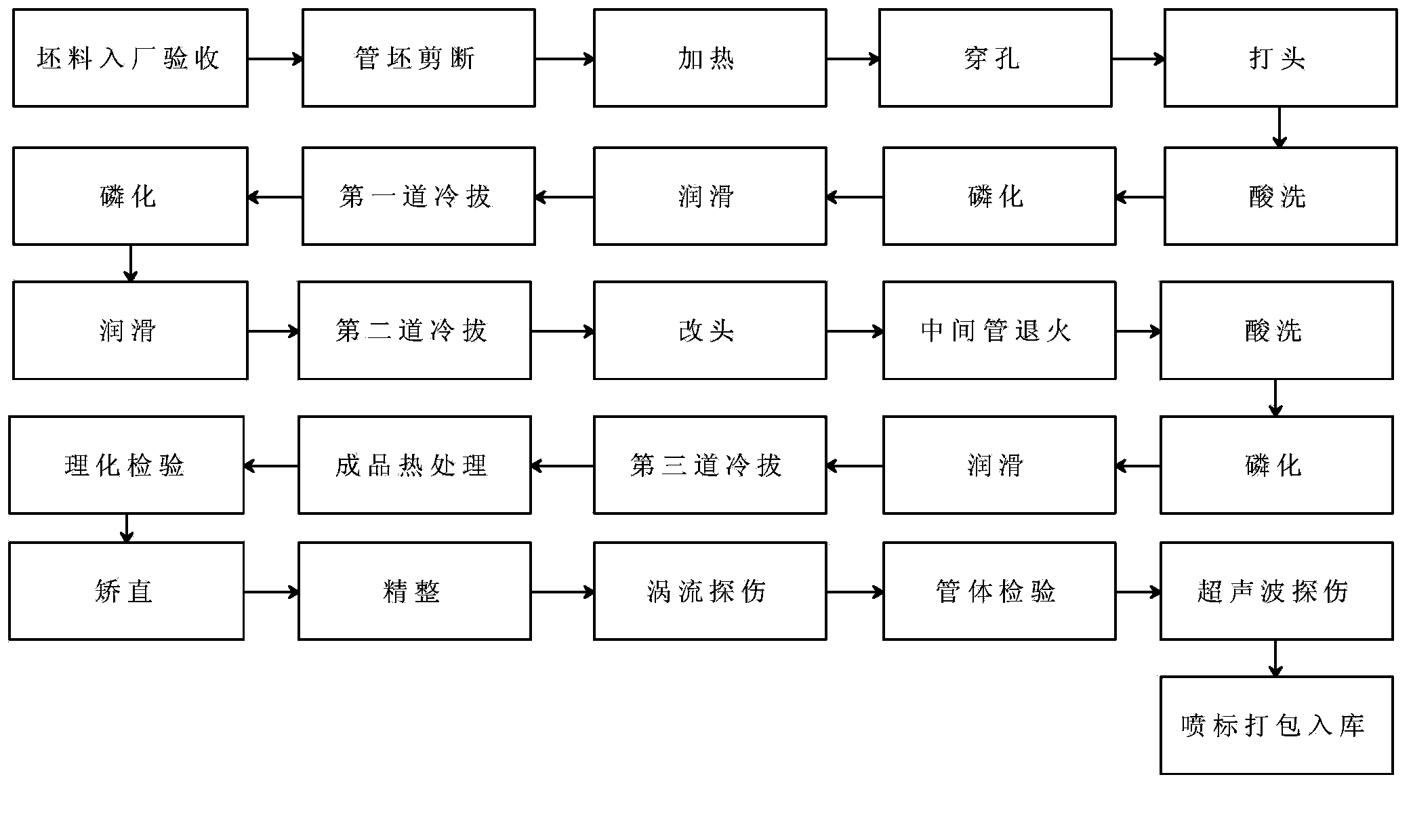

[0037] figure 1 For process flow diagram of the present invention, this ND steel seamless steel pipe production process comprises the following steps:

[0038] (1) Cut the φ70 ND steel billet to the required length;

[0039] (2) Peel the round bar and tube billet, the peeling depth is 0.5mm~1.5mm, to remove the oxide skin on the surface;

[0040] (3) Heat the cut tube blank to 1000~1100°C, and then hold it for 40~80 minutes according to the thickness of the tube blank;

[0041] (4) The piercing is carried out on a DC frequency conversion piercing machine, the piercing temperature is 950~1050°C; the loading current is ≤1500A, and the piercing speed is 500 rpm;

[0042] (5) After the perforation is completed, use the residual heat to start the head;

[0043] (6) pickling, phosphating, and lubricating the steel pipe after step (5);

[0044] 30-35% sulfuric acid is used for pickling, the treatment time is 30-60 minutes, and the treatment temperature is 50-60°C; as a preferred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com