Perforating charge body powder metallurgy billet and cold extrusion forming process method

A technology of powder metallurgy and perforating bullets, which is applied in the fields of mining fluids, earthwork drilling, wellbore/well components, etc. It can solve the problems of limited selection of projectile materials, increased salvage operation costs, and unstable perforation penetration. Achieve low cost, improve perforating operation efficiency, and fine fragments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below with examples.

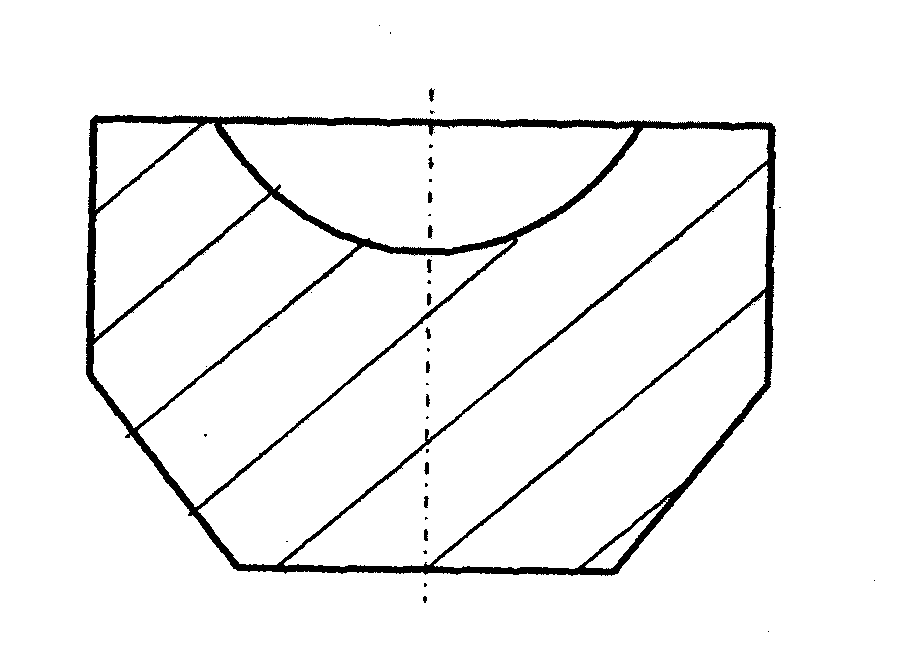

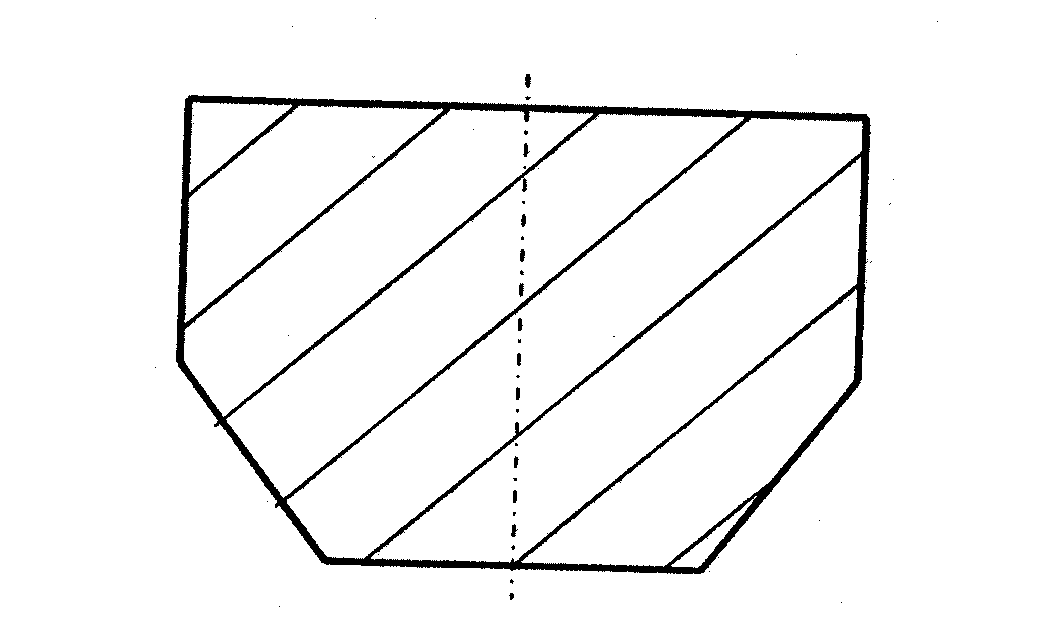

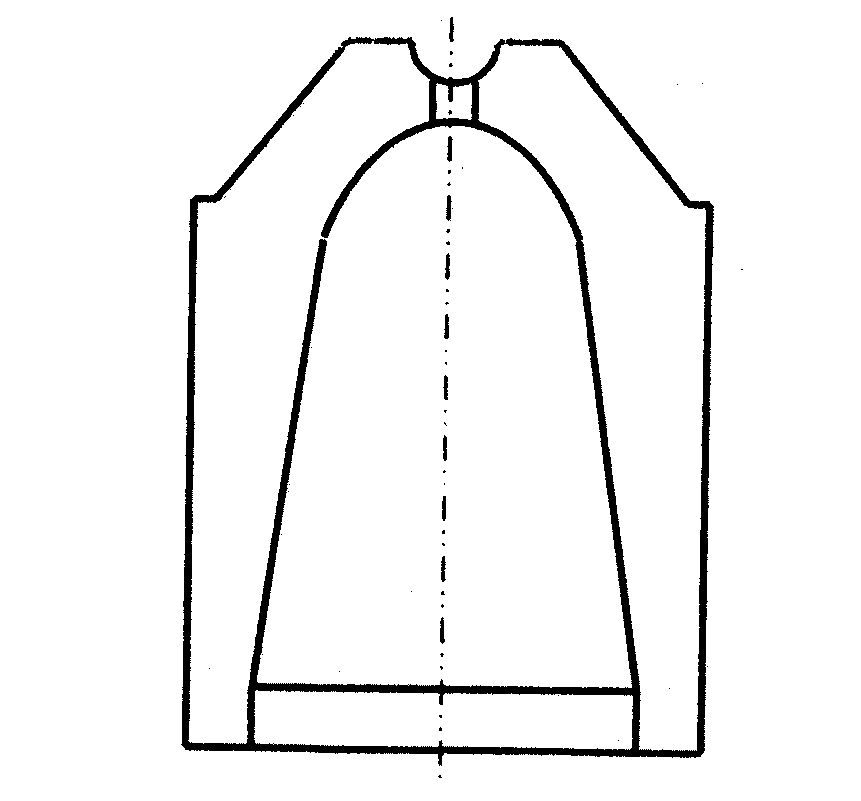

[0010] Weigh 6 kg of copper powder, 6 kg of nickel powder, 5 kg of graphite powder, 6 kg of molybdenum powder, 7 kg of binder, and 970 kg of iron powder. 0.6%, 0.5%, 0.6%, 0.7% and 97%. The particle size of iron powder is less than 200 mesh, and the particle size of copper powder, nickel powder, graphite powder, molybdenum powder and binder is less than 300 mesh. When processing, put the prepared powder into the mixer and mix at 60 rpm for 1 hour to prepare a mixed powder; weigh the mixed powder according to the weight of the projectile, press it into a mold, and sinter it to make a projectile blank. , the pressing pressure is 600-800MPa, and the blank pressing density is 7.1-7.2g / cm 3 , the sintering temperature is 1000-1100 ℃, and the temperature is kept for 1-2 hours; the sintered projectile blank is subjected to cold extrusion deformation to increase the density, and the final shape of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com