Preparation process of concrete admixture

A technology of concrete admixture and preparation process, which is applied in the field of building materials and can solve the problems of low concrete homogeneity, low strength, and serious water separation in concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

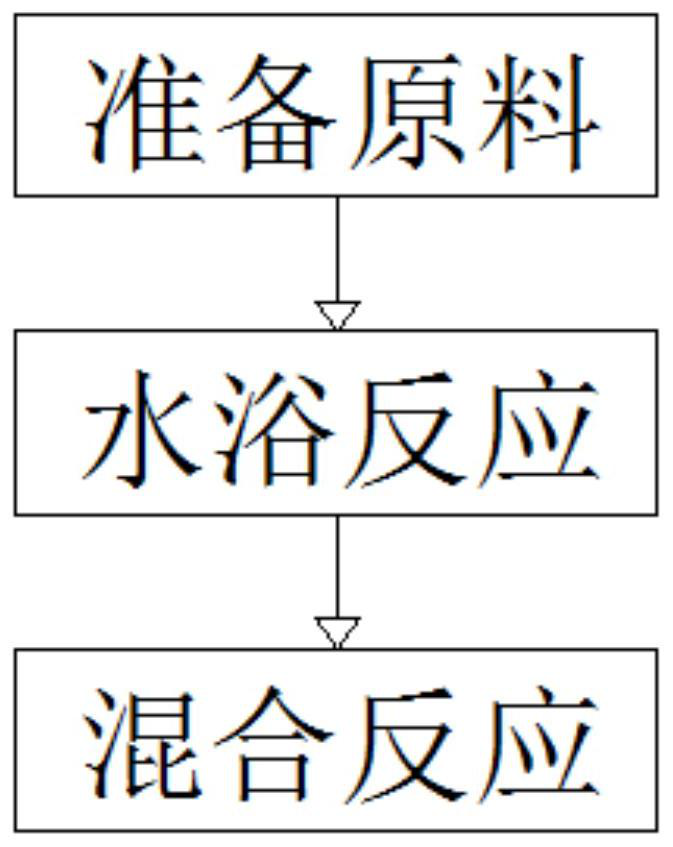

[0033] A preparation process for concrete admixture, comprising the following steps:

[0034] S11. Prepare raw materials: Prepare the following components by weight: 5 parts of superplasticizer, 2 parts of surfactant, 3 parts of ammonium salt, 8 parts of polymerized alcohol amine, 4 parts of allyl polyoxyethylene ether, and 0.1 part of initiator , 0.8 parts of retarder, 0.8 parts of defoamer and 8 parts of sodium tetrapropylene benzene sulfonate;

[0035] S12. Water bath reaction: put polymerized alcohol amine, allyl polyoxyethylene ether, sodium tetrapropylene benzene sulfonate and ammonium salt into the water bath in sequence, then raise the temperature of the water bath to 85°C, and then add the trigger Insulation reaction of the agent for 6 hours to obtain a mixed solution;

[0036] S13. Mixing reaction: inject the mixed solution prepared in S12, superplasticizer, surfactant and retarder into the reactor in sequence, continue stirring for 10 minutes, add defoamer, and sti...

Embodiment 2

[0055] A preparation process for concrete admixture, comprising the following steps:

[0056] S11. Prepare raw materials: Prepare the following components by weight: 5 parts of superplasticizer, 10 parts of surfactant, 3 parts of ammonium salt, 8 parts of polymerized alcohol amine, 5 parts of allyl polyoxyethylene ether, and 0.2 part of initiator , 1 part of retarder, 2 parts of defoamer and 15 parts of sodium tetrapolypropylene benzene sulfonate;

[0057] S12. Water bath reaction: put polymerized alcohol amine, allyl polyoxyethylene ether, sodium tetrapropylene benzene sulfonate and ammonium salt into the water bath in sequence, then raise the temperature of the water bath to 85°C, and then add the trigger Insulation reaction of the agent for 3-6h to obtain a mixed solution;

[0058] S13. Mixing reaction: inject the mixed solution prepared in S12, superplasticizer, surfactant and retarder into the reactor in sequence, continue stirring for 10 minutes, then add defoamer, and ...

Embodiment 3

[0068] A preparation process for concrete admixture, comprising the following steps:

[0069] S11. Prepare raw materials: Prepare the following components by weight: 4 parts of superplasticizer, 6 parts of surfactant, 2 parts of ammonium salt, 4 parts of polymerized alcohol amine, 3 parts of allyl polyoxyethylene ether, and 0.2 part of initiator , 0.9 parts of retarder, 0.08 parts of defoamer and 2-15 parts of sodium tetrapropylene benzene sulfonate;

[0070] S12. Water bath reaction: put polymerized alcohol amine, allyl polyoxyethylene ether, sodium tetrapropylene benzene sulfonate and ammonium salt into the water bath in sequence, then raise the temperature of the water bath to 60°C, and then add the trigger Insulation reaction of the agent for 3 hours to obtain a mixed solution;

[0071] S13. Mixing reaction: inject the mixed solution prepared in S12, superplasticizer, surfactant and retarder into the reactor in sequence, continue stirring for 10 minutes, then add defoamer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com