Apparatus and method for promoting interaction of fine particles in coal-fired boiler flue gas

A technology for fine particles and coal-fired boilers, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as increased flue resistance, increased collisions and interactions, and small changes in fluid velocity gradients. The effect of close connection, reasonable overall layout and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

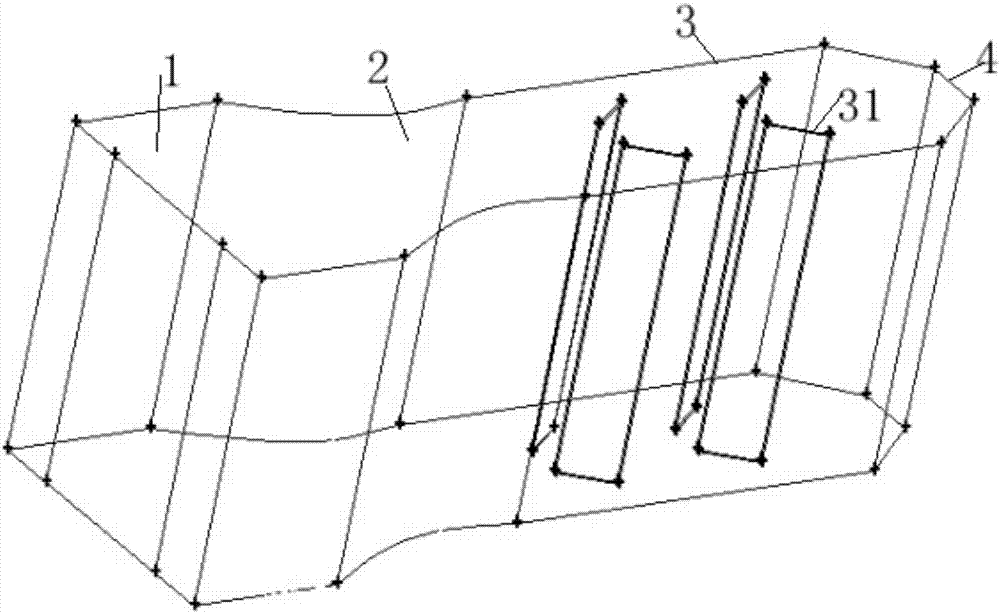

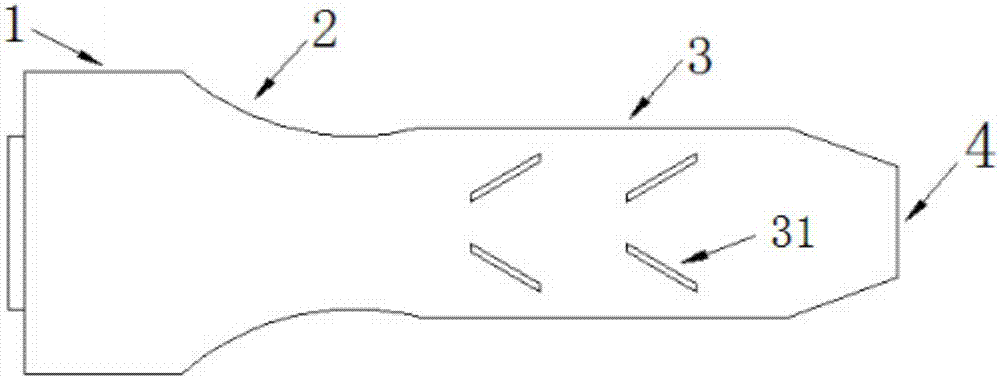

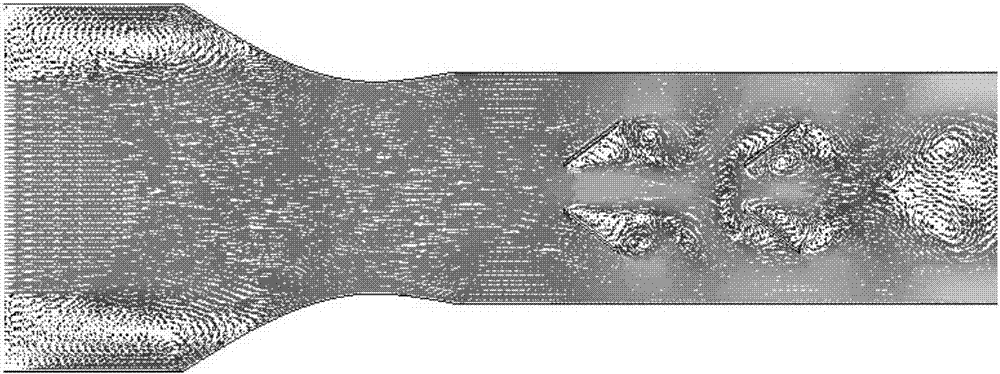

[0036] In this embodiment, the device for promoting the interaction of fine particles in the flue gas of a coal-fired boiler includes a rectangular channel 1, a zoom throat 2, a turbulent agglomeration chamber 3, and a flue gas outlet 4, the rectangular channel 1 is the flue gas inlet, and the zoom throat The port 2 includes a tapered part and a tapered part, the tapered part is connected to the rectangular channel 1, the tapered part is connected to one end of the turbulent flow reunion chamber 3, and the other end of the turbulent flow reunion chamber 3 is provided with a smoke outlet 4, which is connected to the Subsequent dust removal equipment connection; said turbulent flow reunion chamber 3 is provided with a certain number of rectangular fins 31, every two rectangular fins are a group, a total of n groups, and n≥2, each group of two rectangular fins 31 is in the shape of "eight", and the small mouth end of the "eight" shape faces the direction of the incoming flow of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com