Flow field characteristic experiment device of combustion chamber of hydrogen-burning gas turbine

A technology of gas turbines and experimental devices, which is applied in the direction of measuring devices, aerodynamic tests, and machine/structural component tests, etc., can solve the problems of inability to obtain test results, long research cycle, poor followability, etc., and achieve convenient recording and processing , reducing debugging time, flexible and convenient debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

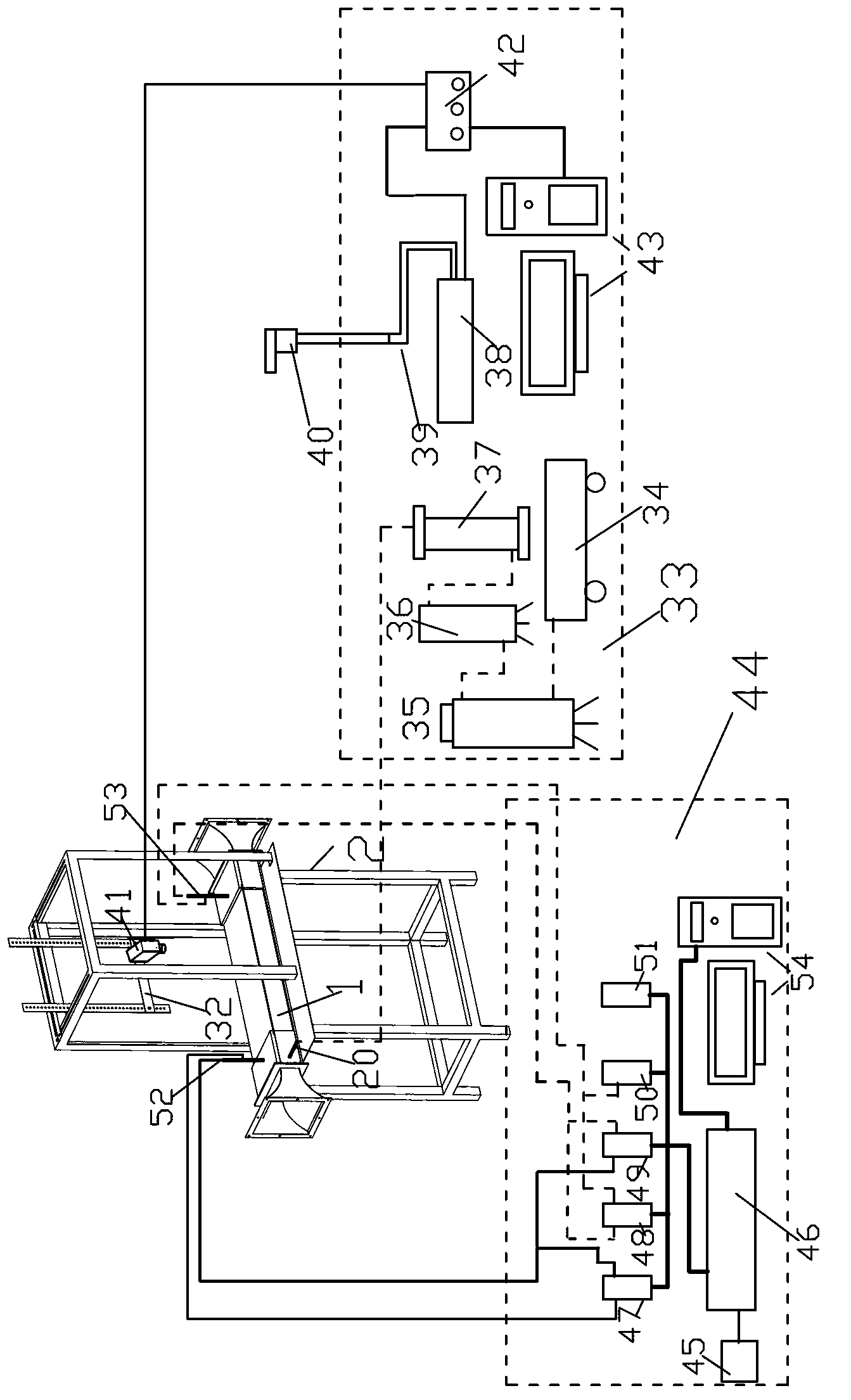

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Such as Figure 1-10 As shown, an experimental device for flow field characteristics of a hydrogen-fired gas turbine combustor, including three pairs of blunt bodies arranged in a combustor test piece 1, a PIV test bench 2, a PIV test system 33, and a differential pressure and ambient temperature test system 44;

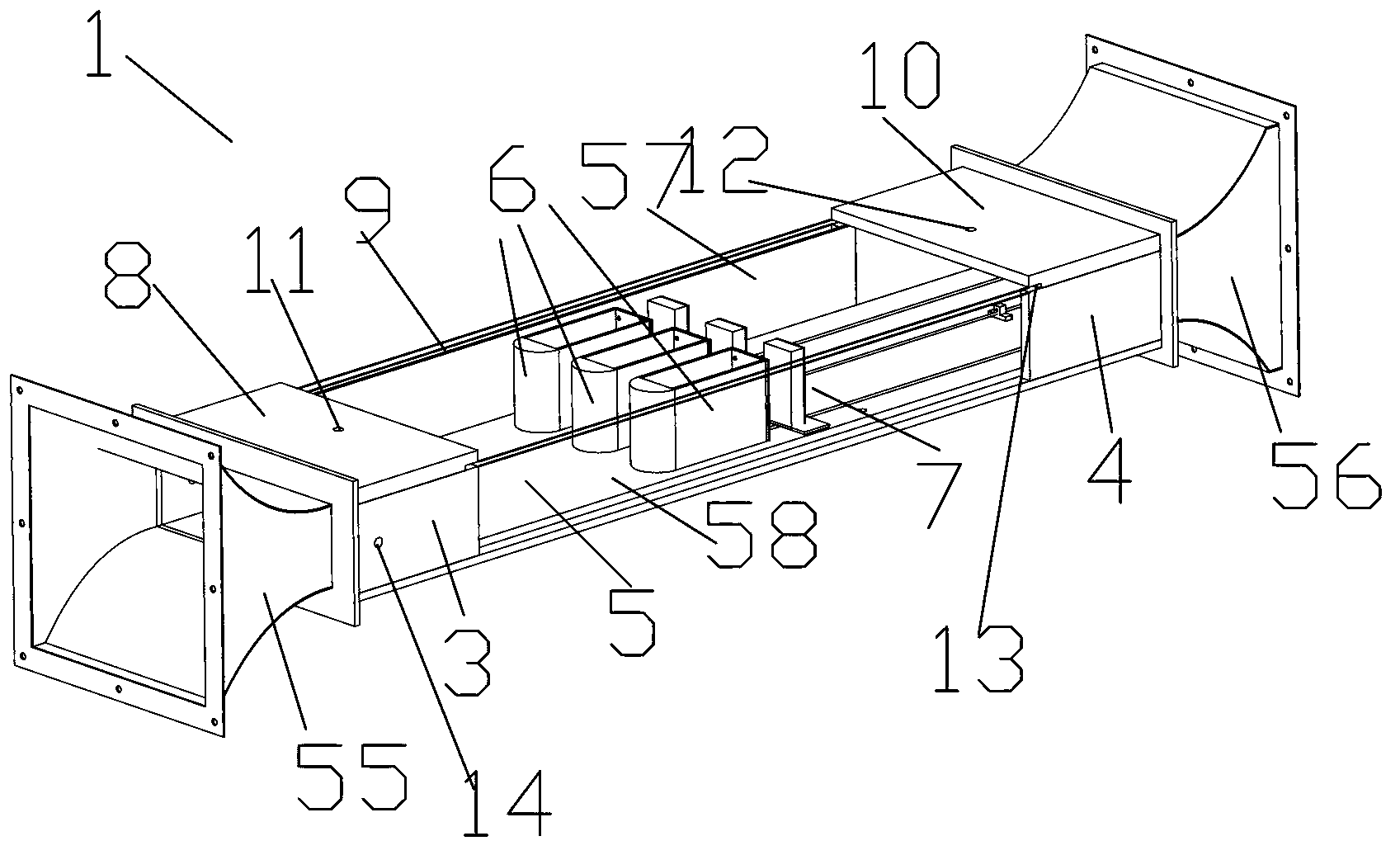

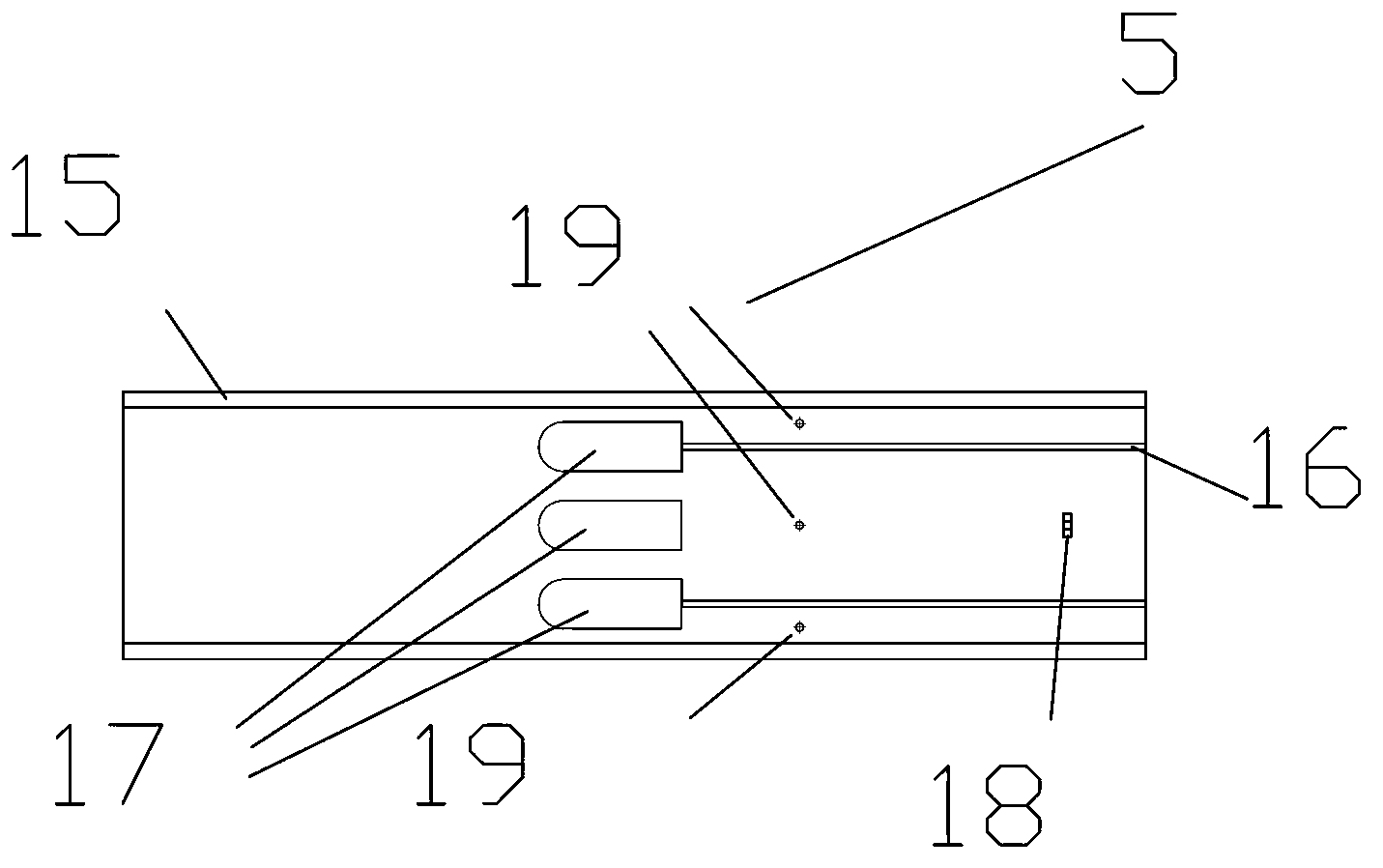

[0039] The three pairs of blunt body arrangement combustion chamber test piece 1 includes a front side plate 3, a rear side plate 4, a bottom plate 5, a front blunt body 6, a rear blunt body and its auxiliary mechanism 7, a front top plate 8, matte glass, Top glass plate 57, side glass plate 58, rear top plate 10, air intake flange 55 and exhaust flange 56; the bottom plate 5 is provided with bottom plate glass slot 15, rear blunt body moving channel 16, front Blunt body sockets 17 and air holes 19, and screw supports 18 are arranged; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com