Modification method of lithium ion battery cathode material

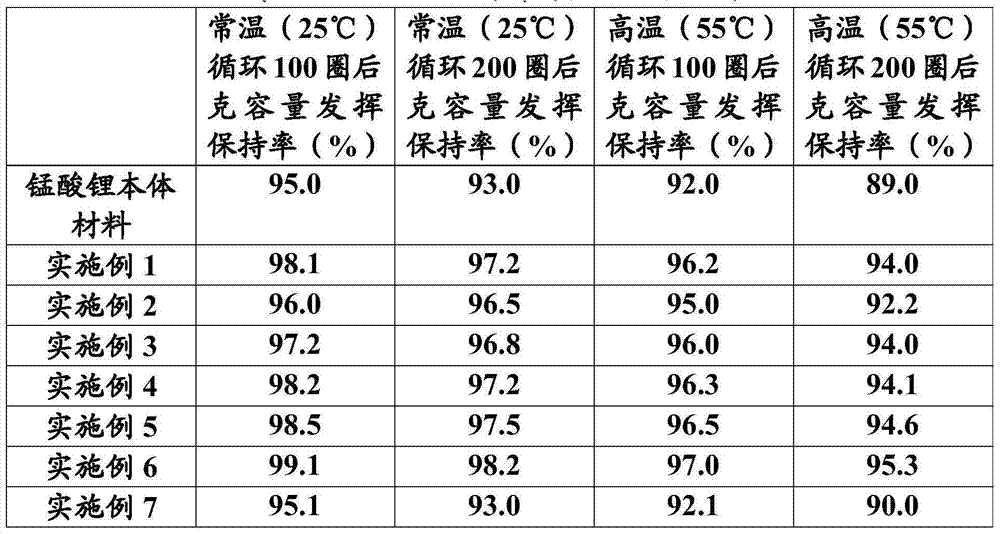

A cathode material and lithium ion technology, which is applied in the field of cathode material preparation of lithium ion batteries, can solve the problems of poor high temperature performance and cycle instability, and achieve the effects of good consistency, good coating uniformity and improved high temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

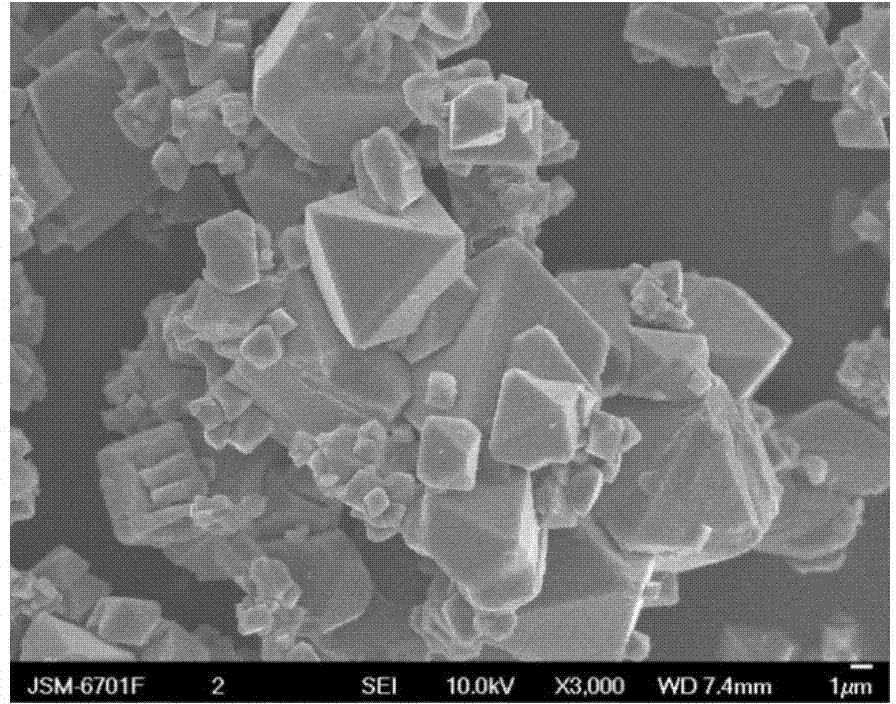

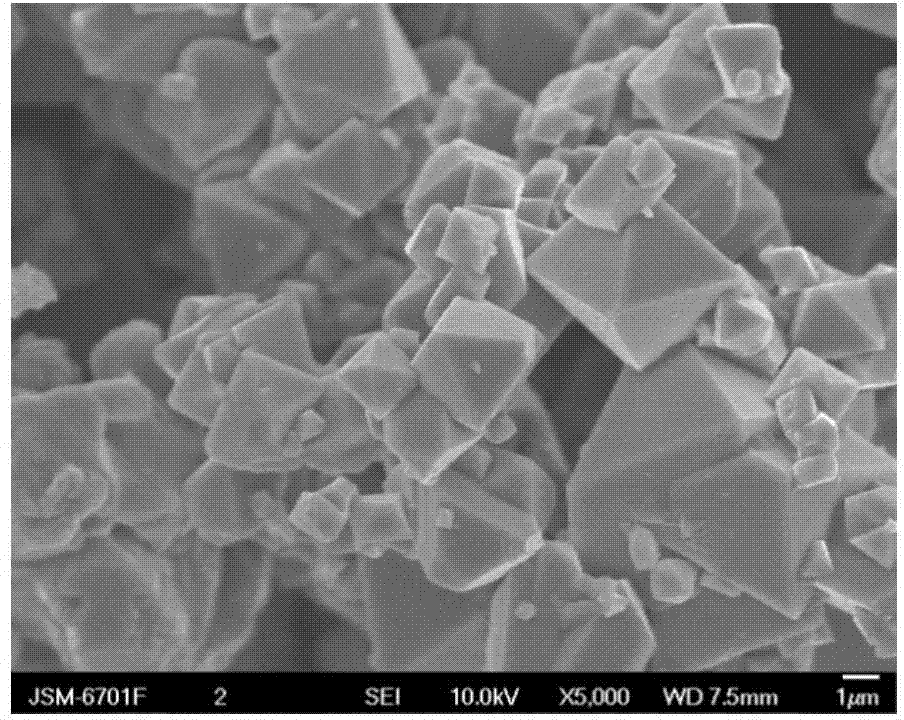

[0026] Titanium oxide-coated lithium manganate material: put the prepared lithium manganate body material into a vacuum chamber, and evacuate to a vacuum degree of 3×10 -4 Pa, heated to 100°C, bombarded metal titanium (purity 99.9%) with high-speed particles, firstly introduced argon gas into the vacuum chamber with a flow rate of 50 sccm, and then injected oxygen at a flow rate of 5 sccm, the whole process lasted for 5 minutes, and obtained nano-titanium oxide Coated lithium manganese oxide material (such as figure 2 shown). The thickness of the cladding material is 1-3nm.

Embodiment 2

[0028] The whole process of feeding oxygen lasts for 10 minutes, so as to control the thickness of the cladding material to be 8-10 nm, and the others are the same as in Example 1.

Embodiment 3

[0030] Zinc oxide-coated lithium manganate material: put the prepared lithium manganate body material into a vacuum chamber, and evacuate to a vacuum degree of 2×10 -4 Pa, heated to 150°C, and bombarded metal zinc (purity 99.9%) with high-speed particles, argon gas was introduced into the vacuum chamber at a flow rate of 50 sccm, and then oxygen was injected at a flow rate of 5 sccm. The whole process lasted for 3 minutes, and the thickness of the cladding layer was controlled. The thickness is 3-5nm, and the lithium manganese oxide material coated with nano-zinc oxide is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com