Simulation experiment device for aero-engine suction object on-line static monitoring system

A simulation experiment device and aero-engine technology, applied in the direction of engine testing, measuring devices, electrostatic field measurement, etc., can solve the problems of reducing fatigue life, blade damage, blade fracture, etc., and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

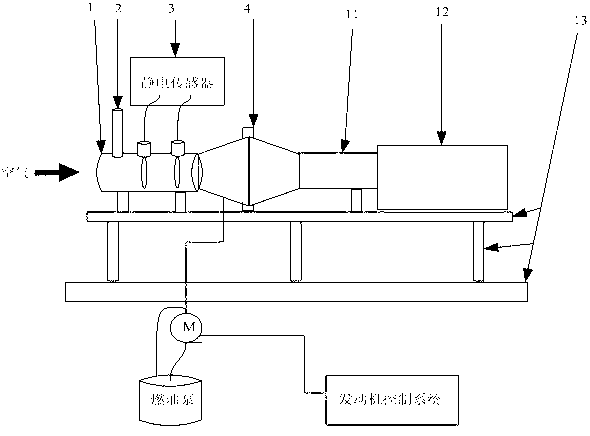

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

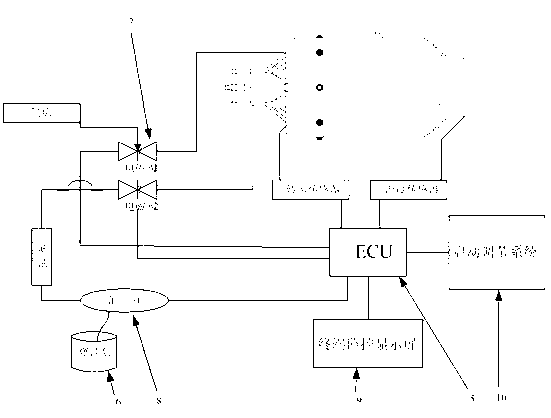

[0021] As shown in the figure: the simulation experiment device of the on-line electrostatic monitoring system for aeroengine inhalation, including the airway extension tube 1, the particle injection device 2, the inlet ring sensor 3, 4, the aviation turbojet engine 4, and the ECU electronic control unit 5. Fuel pump 6, fuel control solenoid valve 7, oil tee 8, terminal monitoring display 9, start adjustment system 10, tail nozzle extension pipe 11, exhaust cooling device 12, installation platform 13.

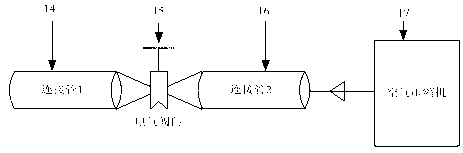

[0022] The air inlet extension pipe 1 is connected to the air intake end of the aviation turbojet engine 4, and the particle injection device 2 communicates with the air inlet extension pipe 1 through the injection port on the air inlet extension pipe 1, and the upper part of the air inlet extension pipe 1 section layout monitoring device; one end of the tail nozzle ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com